Full-automatic corrugated forming press for isolation diaphragm

An isolation diaphragm, fully automatic technology, applied in the field of automatic isolation diaphragm corrugated molding machine, can solve the problems of fragile materials, high cost, and difficulty in meeting the requirements of manipulators, and achieve compact production process, low cost, and easy control and the effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

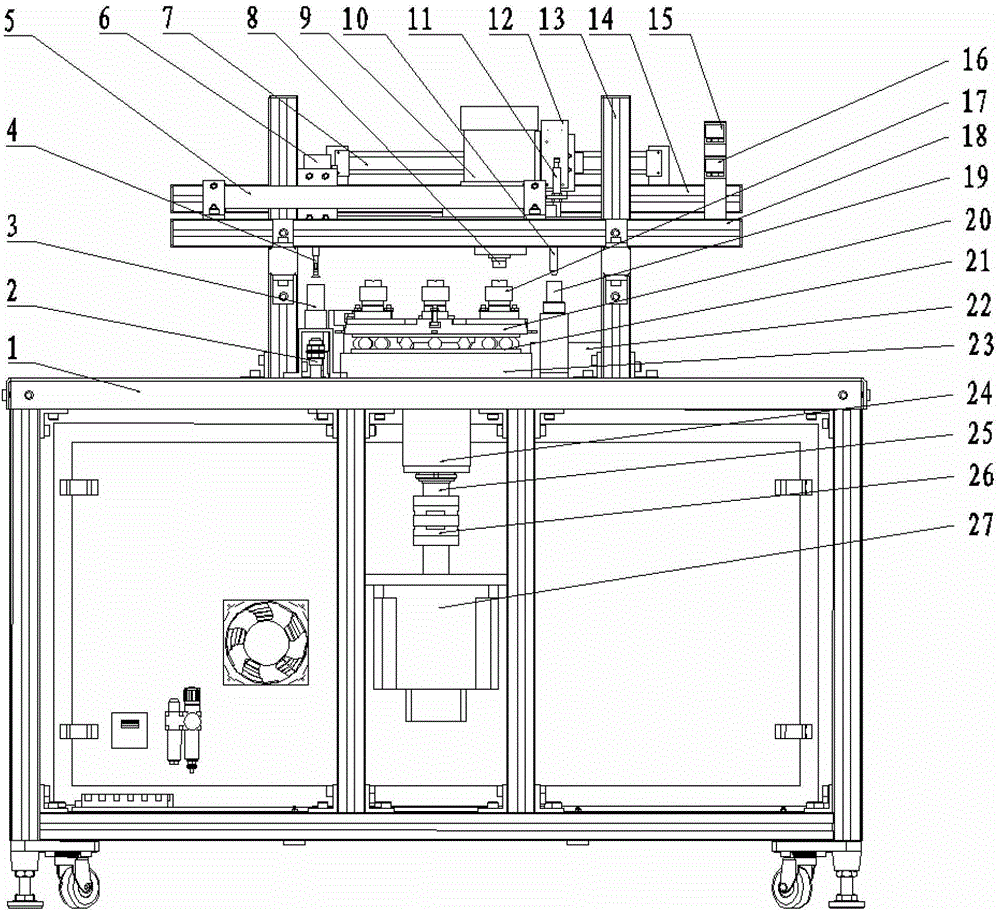

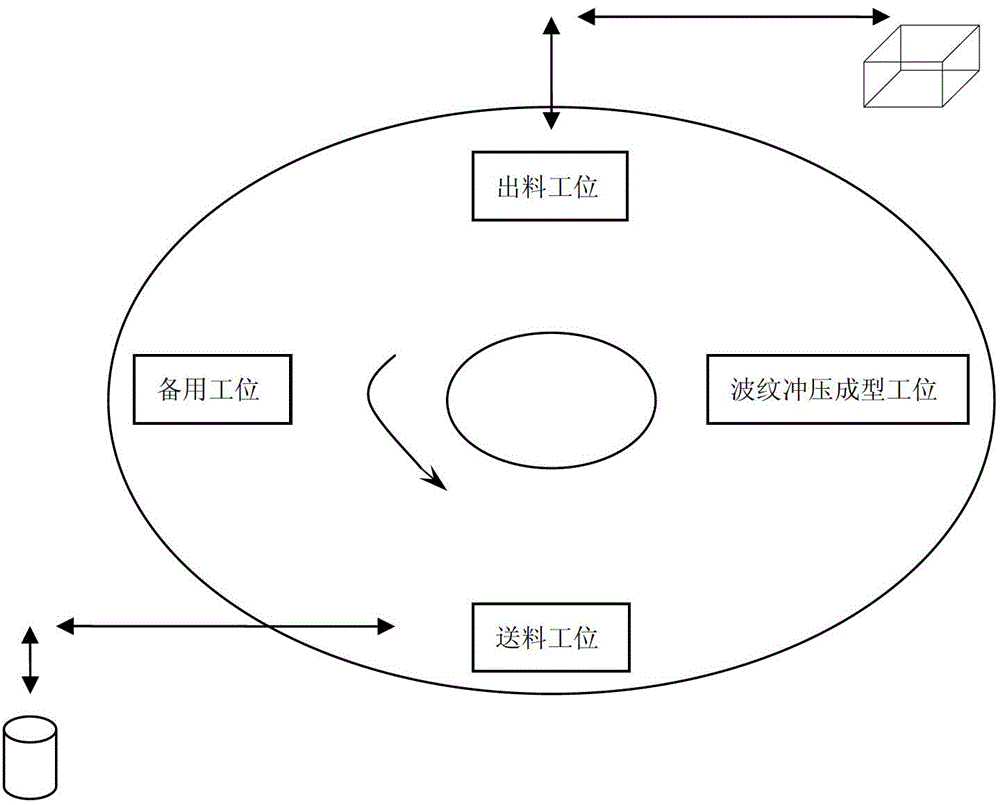

[0043] Such as figure 1As shown, a fully automatic isolation diaphragm corrugated forming machine includes an automatic feeding mechanism, a corrugated stamping forming mechanism, an automatic discharging mechanism, a rotary indexing table mechanism, an overhead support and a control mechanism.

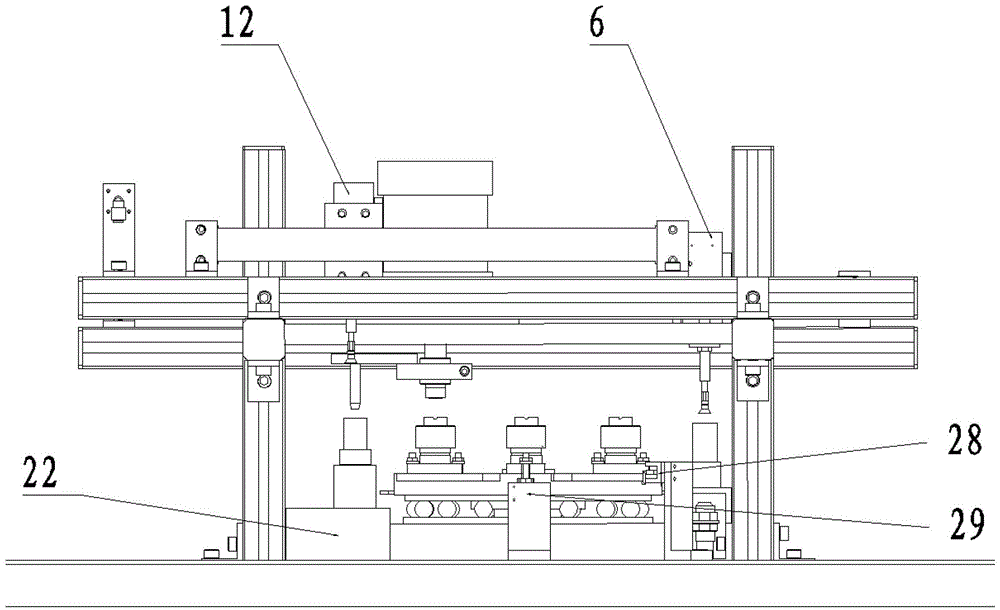

[0044] Both the feeding horizontal movement cylinder and the feeding vacuum pressure digital display switch are fixed on the front crossbeam 18 .

[0045] The working process of the automatic feeding mechanism: the cut-to-be-pressed isolation diaphragm is stacked in the storage tank 3, and a through hole is opened in the center of the storage tank 3, and the programmable logic controller passes through the storage state installed under the through hole. The photoelectric switch 2 detects whether there is a diaphragm, and performs a material shortage alarm if there is no isolation diaphragm; when there is a diaphragm, the feeding vertical movement cylinder 6 descends, and the vacuum su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com