Production method of low torque yarns and device thereof

A production device and low-torque technology, applied in textiles and papermaking, etc., can solve the problems of high production energy consumption and complex structure, and achieve the effects of simple production process, low noise and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

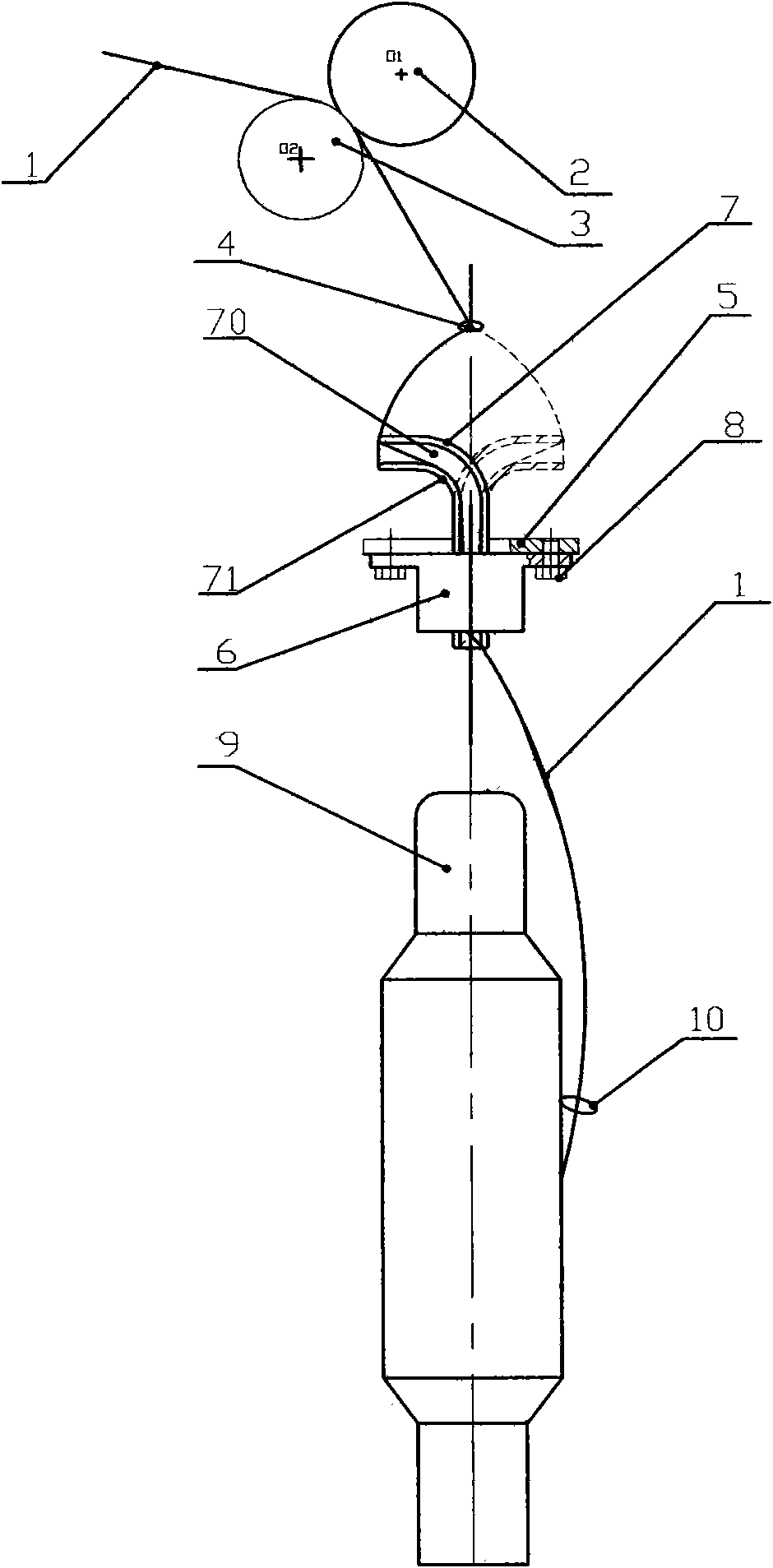

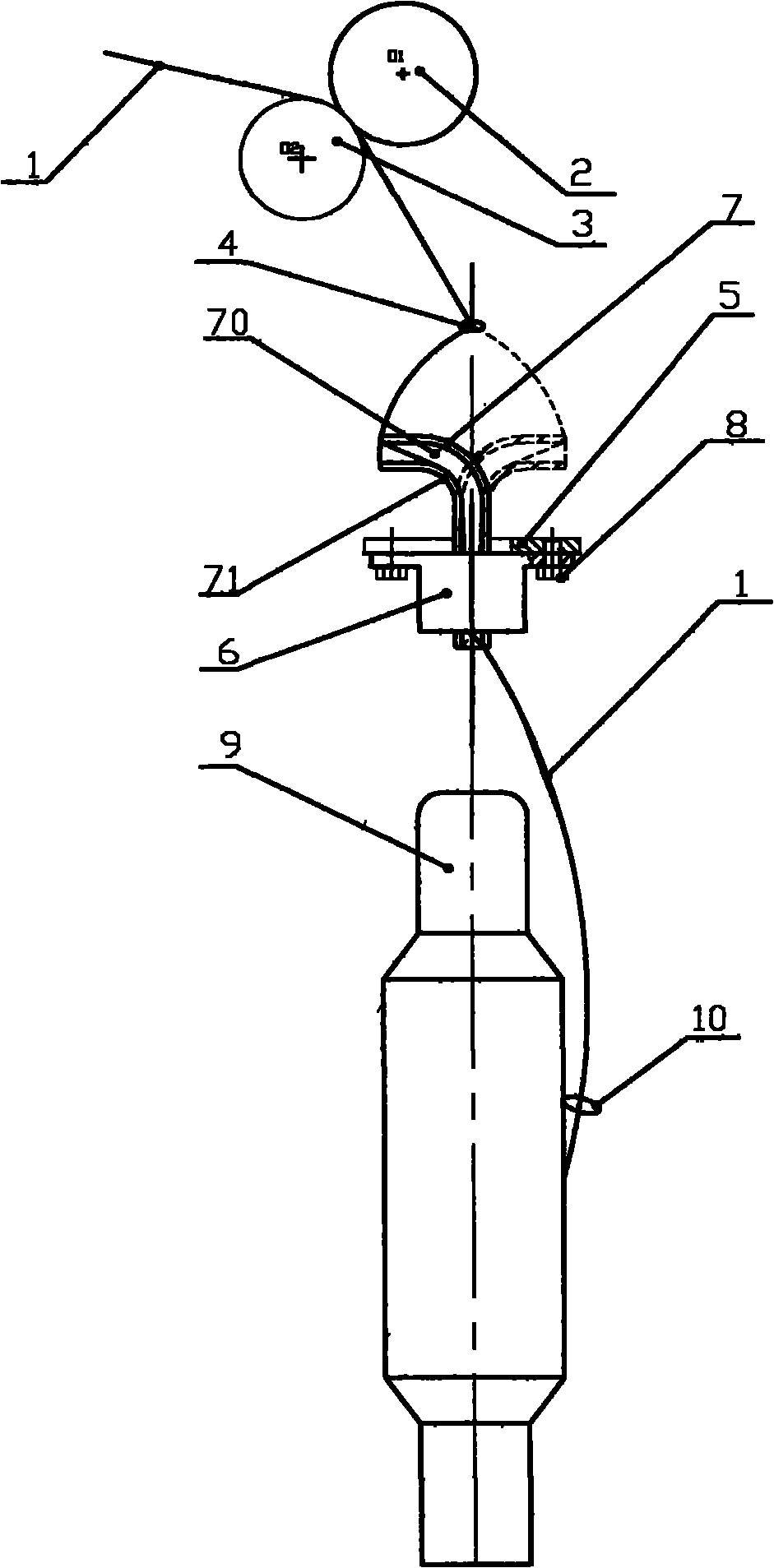

[0016] Such as figure 1 As shown, a kind of low-torque yarn production device of the present invention includes spinning spindle 9, and a yarn false twisting device is arranged at the position above spinning spindle 9, and the yarn false twisting device includes a first guide Yarn ceramic piece 4, yarn false twist shaft 7, support seat 5, rotary power driver 6, etc., wherein: the first yarn guide porcelain piece 4 is set on a group of drafting rollers composed of top roller 2 and bottom roller 3 Below, the yarn false twisting shaft 7 is installed under the yarn guide ceramic part 4, the yarn false twisting shaft 7 is linked with the rotary power driver 6, and the rotary power driver 6 is connected to the support seat 5 through a set of bolts 8, and the support seat 5 Connected to the fuselage, the rotary power drive 6 can be driven by general mechanical force or magnetic force or electric force. The traveler 10 is installed on the spinning spindle 9 .

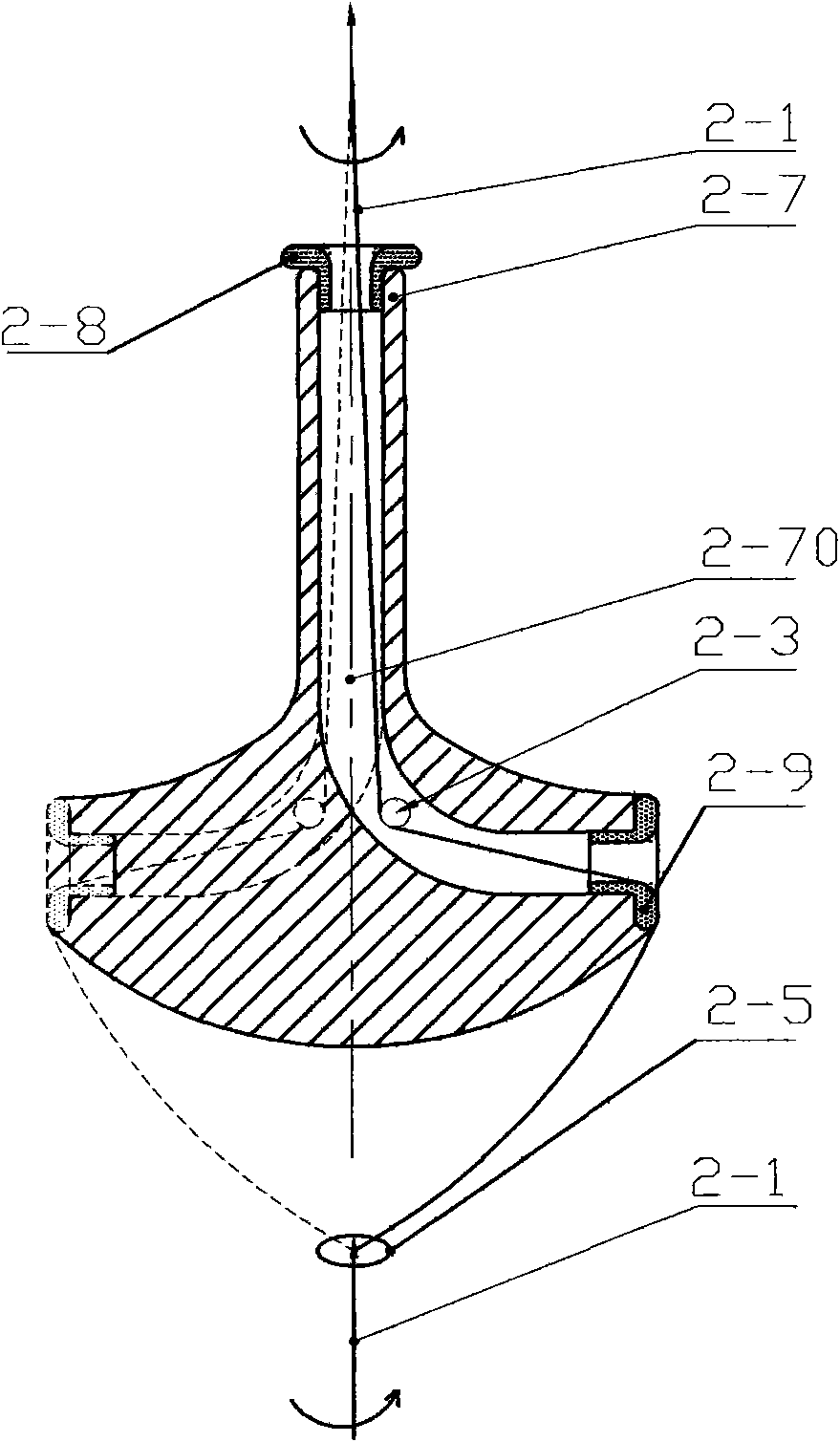

[0017] An inner hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com