Patents

Literature

104results about How to "Rational production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

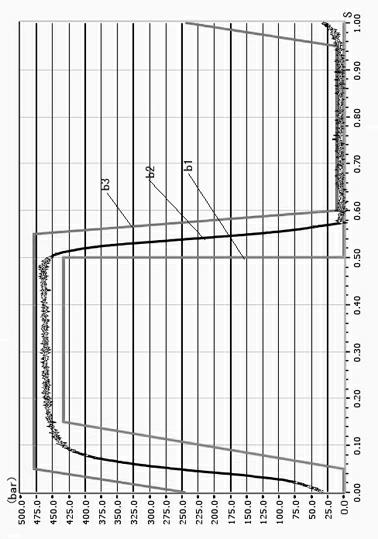

Method for producing fatty acid methyl ester and equipment for realizing the same

InactiveUS7045100B2Avoid disadvantagesRational productionPressurized chemical processFatty acid esterificationAlcoholTransesterification

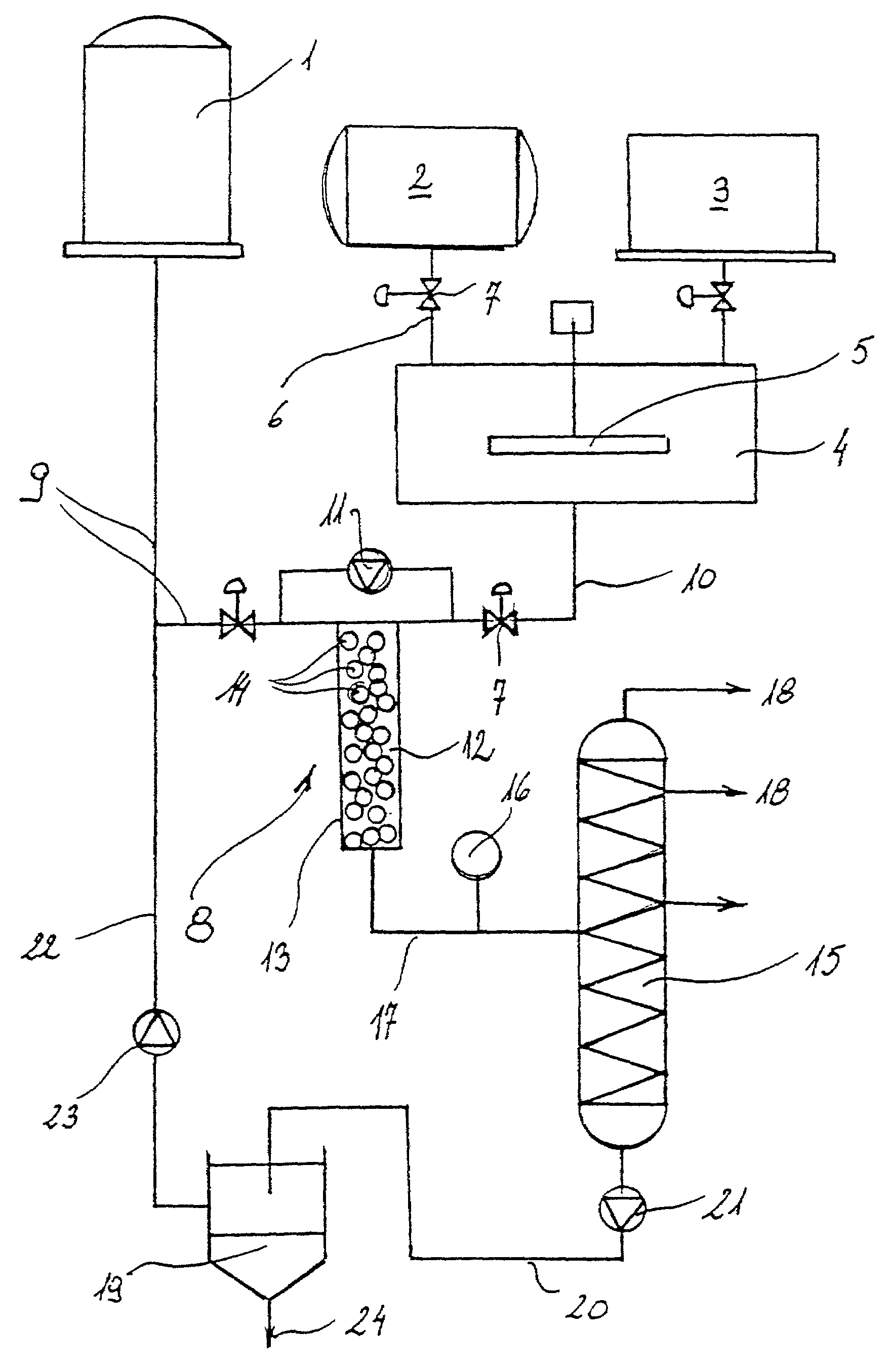

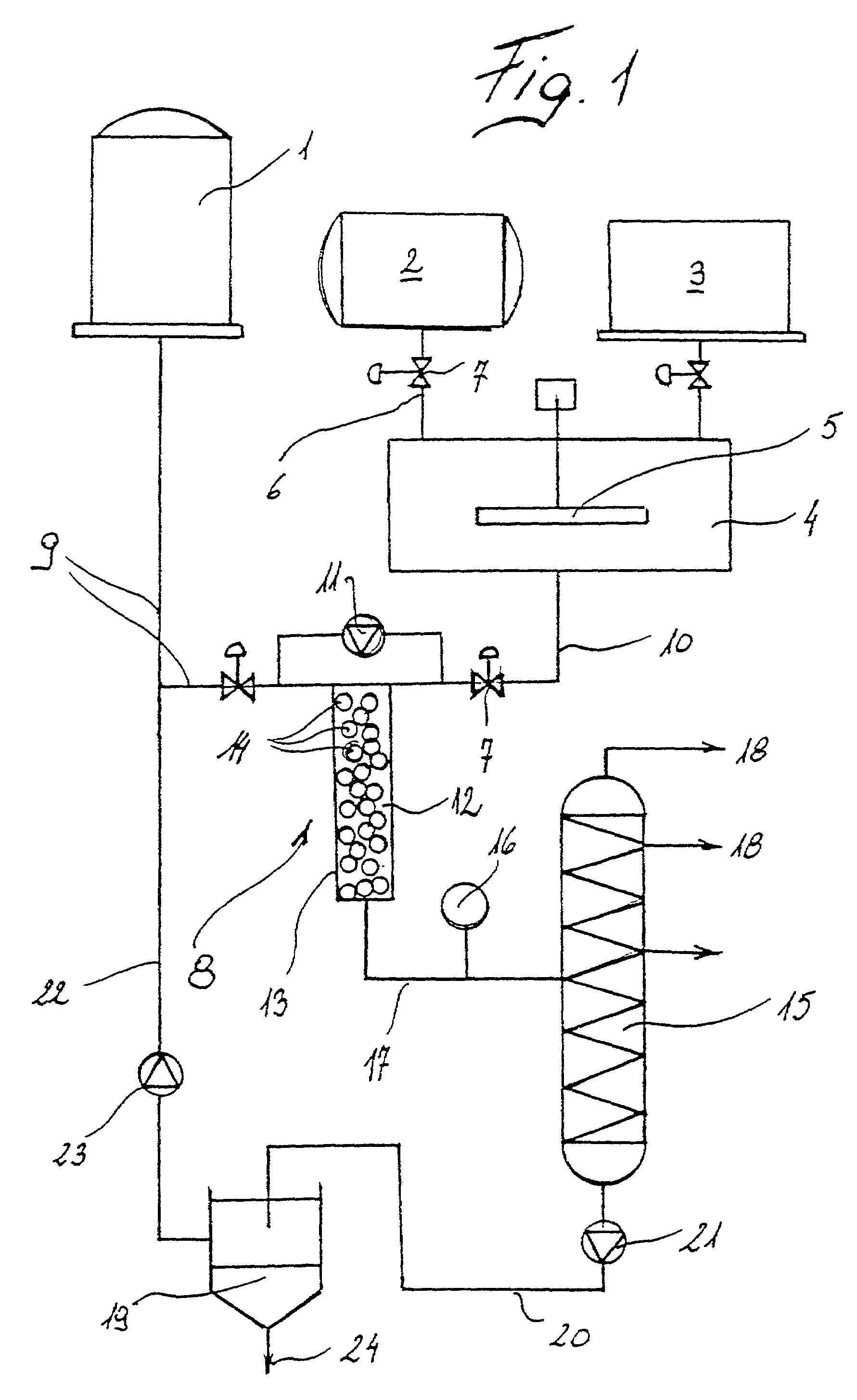

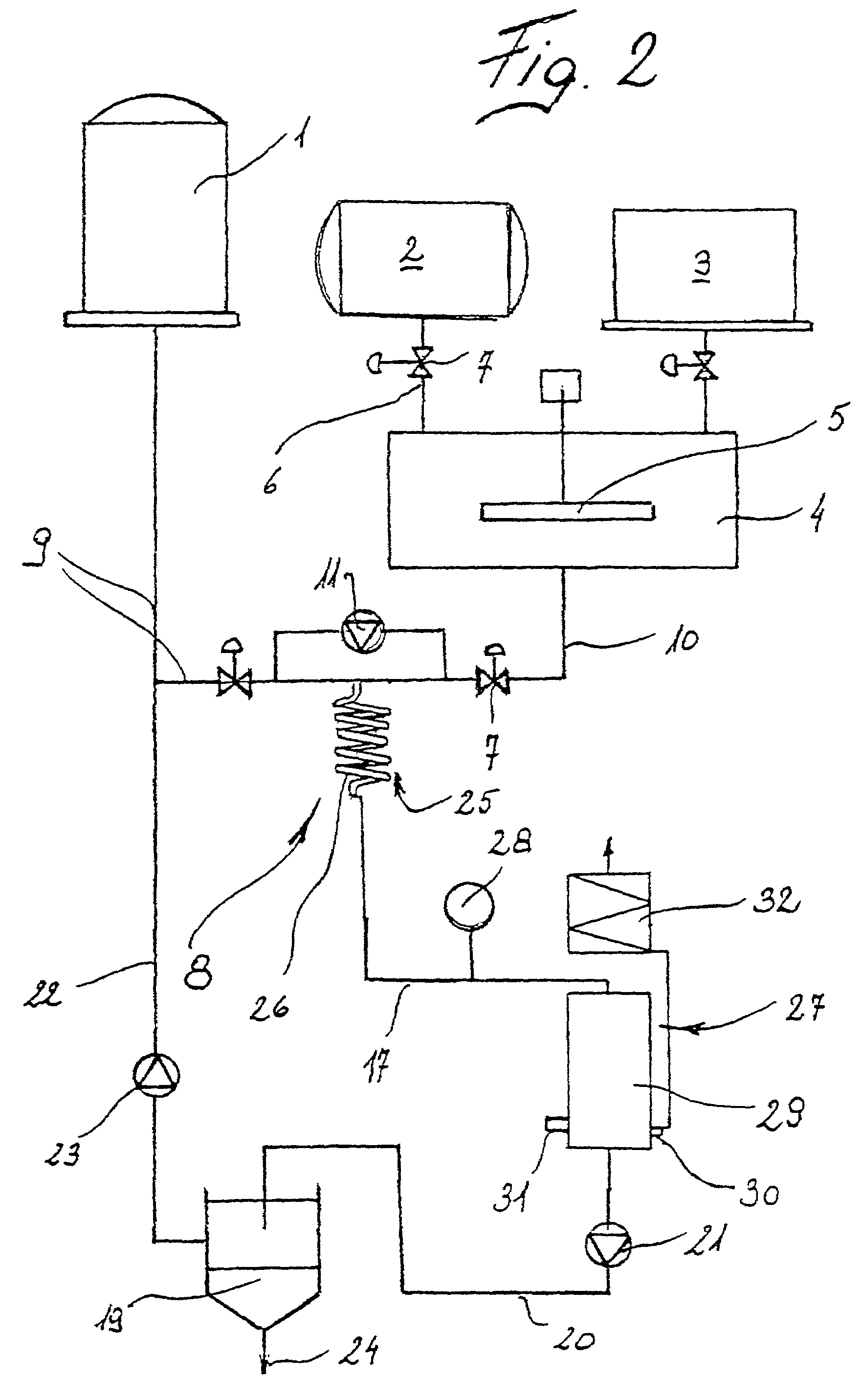

Method for producing fatty acid methyl ester, including compounding saturated and unsaturated higher fatty substances from at least one of vegetable and animal with an alkaline solution dissolved in alcohol to form a mixture. The method also includes emulsifying the mixture to reach a chemical balance state in a reaction section, wherein fats are transesterified into fatty acid methyl ester, wherein border surfaces of the mixture are enlarged by dynamic turbulence in the reaction section and the transesterification is performed under pressure, and wherein the pressure is reduced during transesterification. The method further includes after reaching a chemical balance state, separating residues from the fatty acid methyl ester in a phase separation section. Apparatus for producing fatty acid methyl ester.

Owner:AMERICAN RENEWABLE FUELS

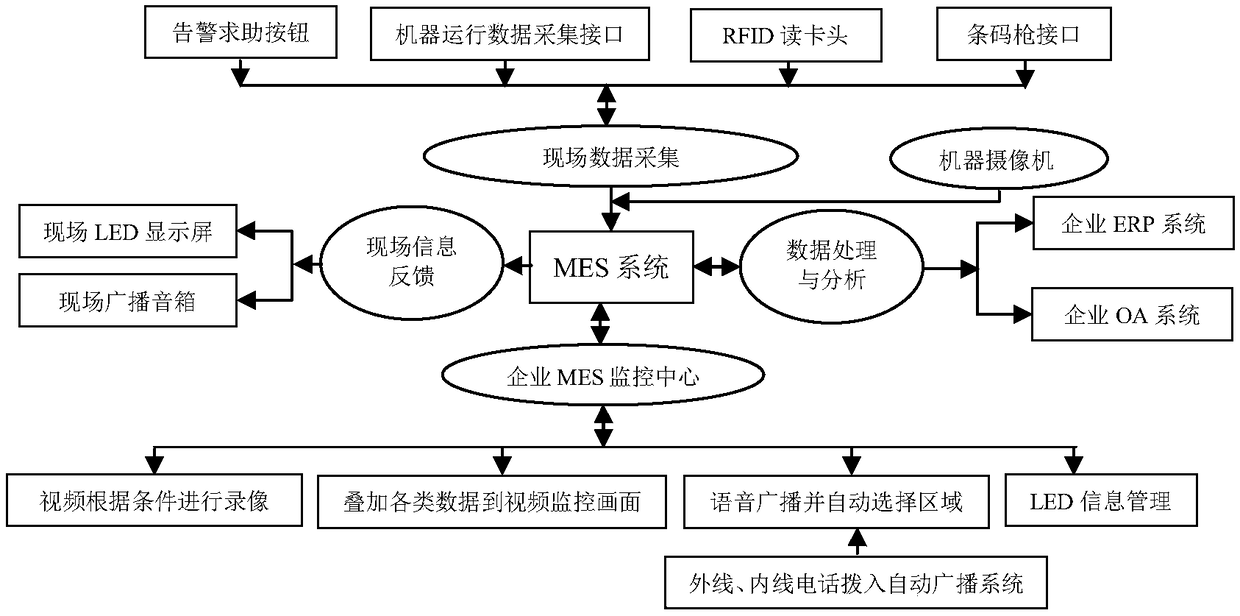

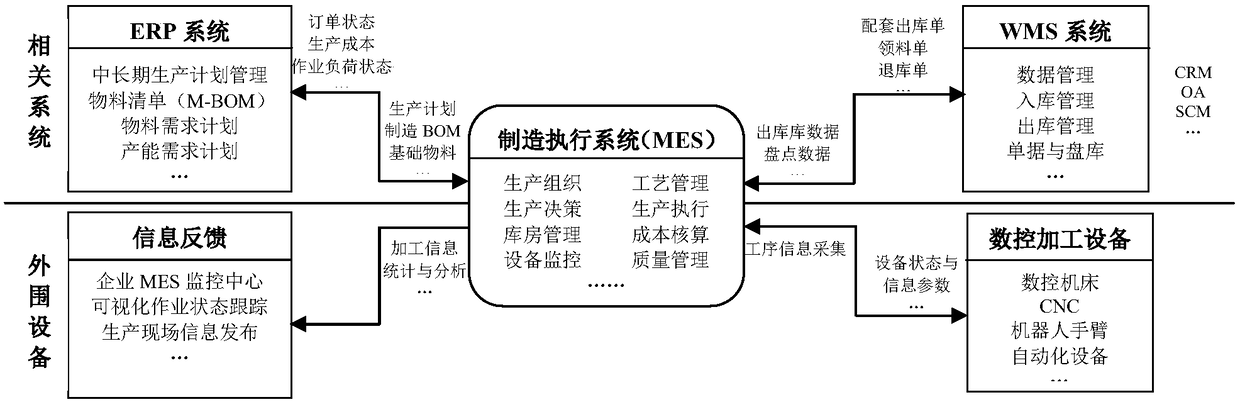

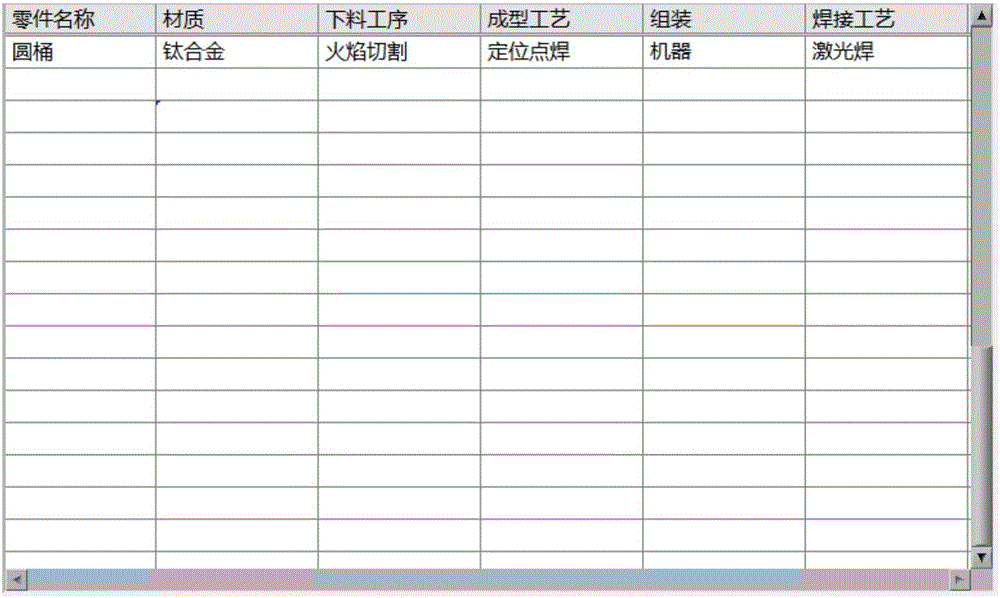

MES platform for mass customization of furniture

InactiveCN108596422AUnderstand and control production equipmentReal-time monitoring of the production siteBuying/selling/leasing transactionsResourcesMass customizationManagement unit

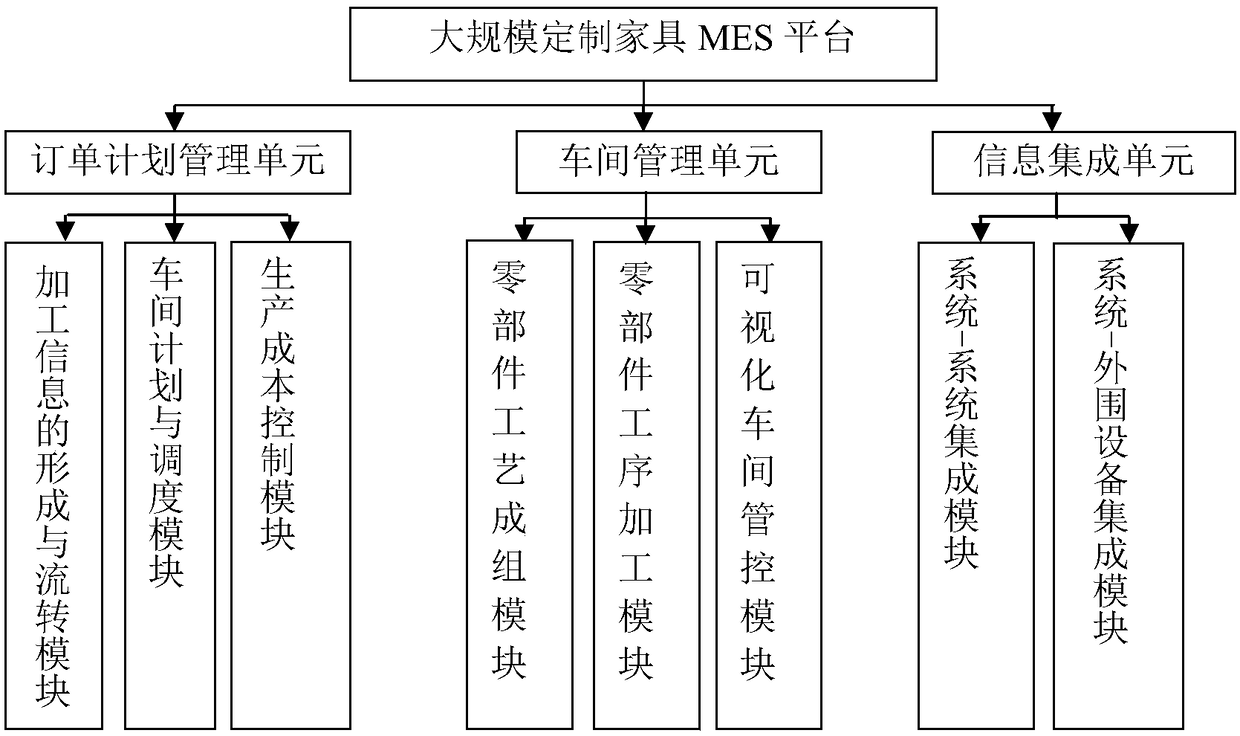

The invention provides an MES platform for mass customization of furniture, and the platform comprises an order planning management unit, a workshop management unit and an information integration unit, wherein the order planning management unit is used for following up the order status and processing process in the management system. The workshop management unit is used for carrying out the real-time monitoring of the various operational specifications and technical requirements of a workshop and corresponding interaction processing, and feeding back various processing results to a productionsite in various modes so as to improve the production scheduling speed of the component processing required by an order. The information integration unit is used for achieving the sharing of the orderdata and the component processing data required for the order between the units and the transmitting of data between the devices. The invention has the beneficial effects that the MES platform improves the production scheduling speed of the component processing by controlling the workshop, overcomes the difficulty of implementing the information management in the processing workshop, and improvesthe labor efficiency.

Owner:NANJING FORESTRY UNIV

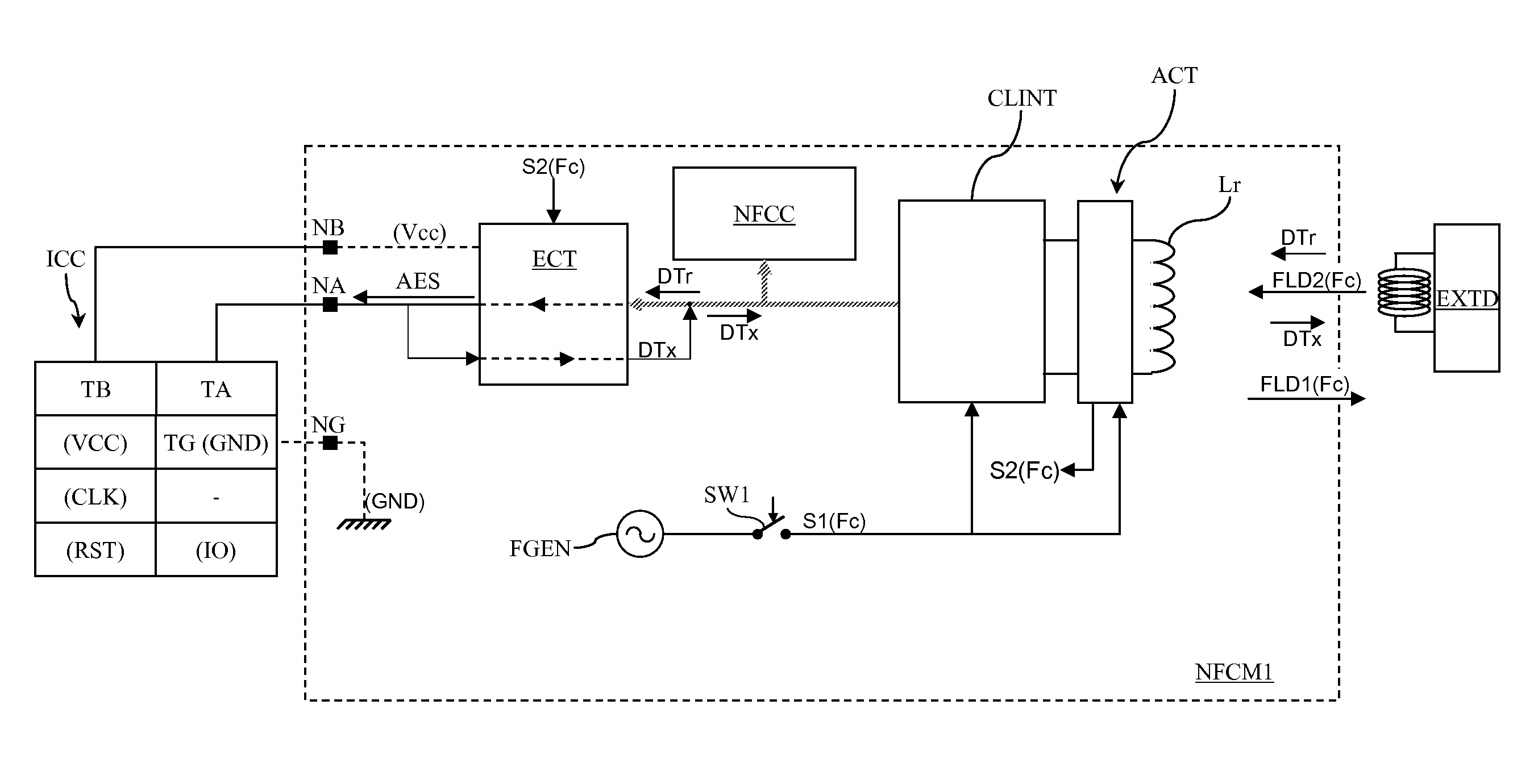

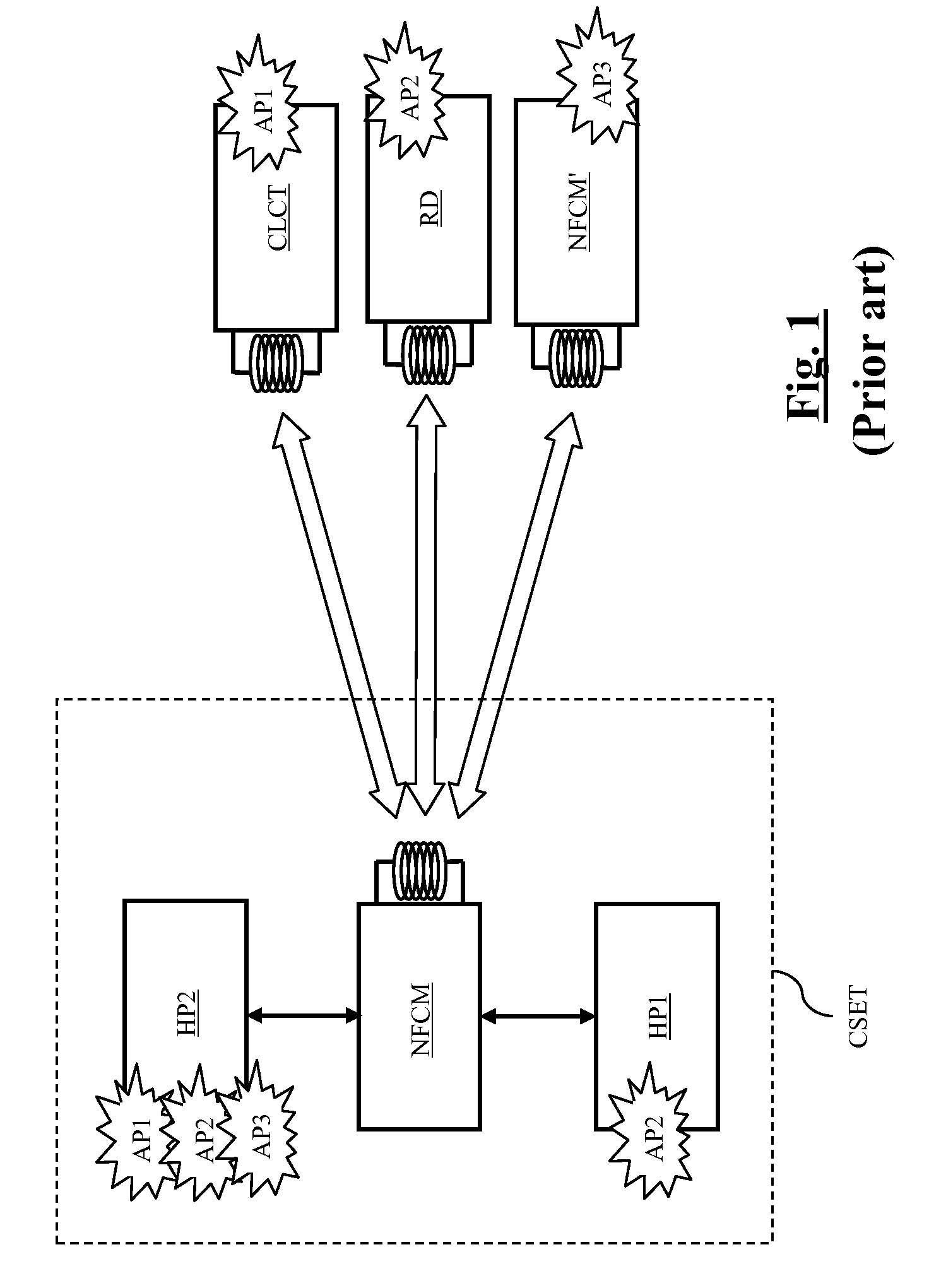

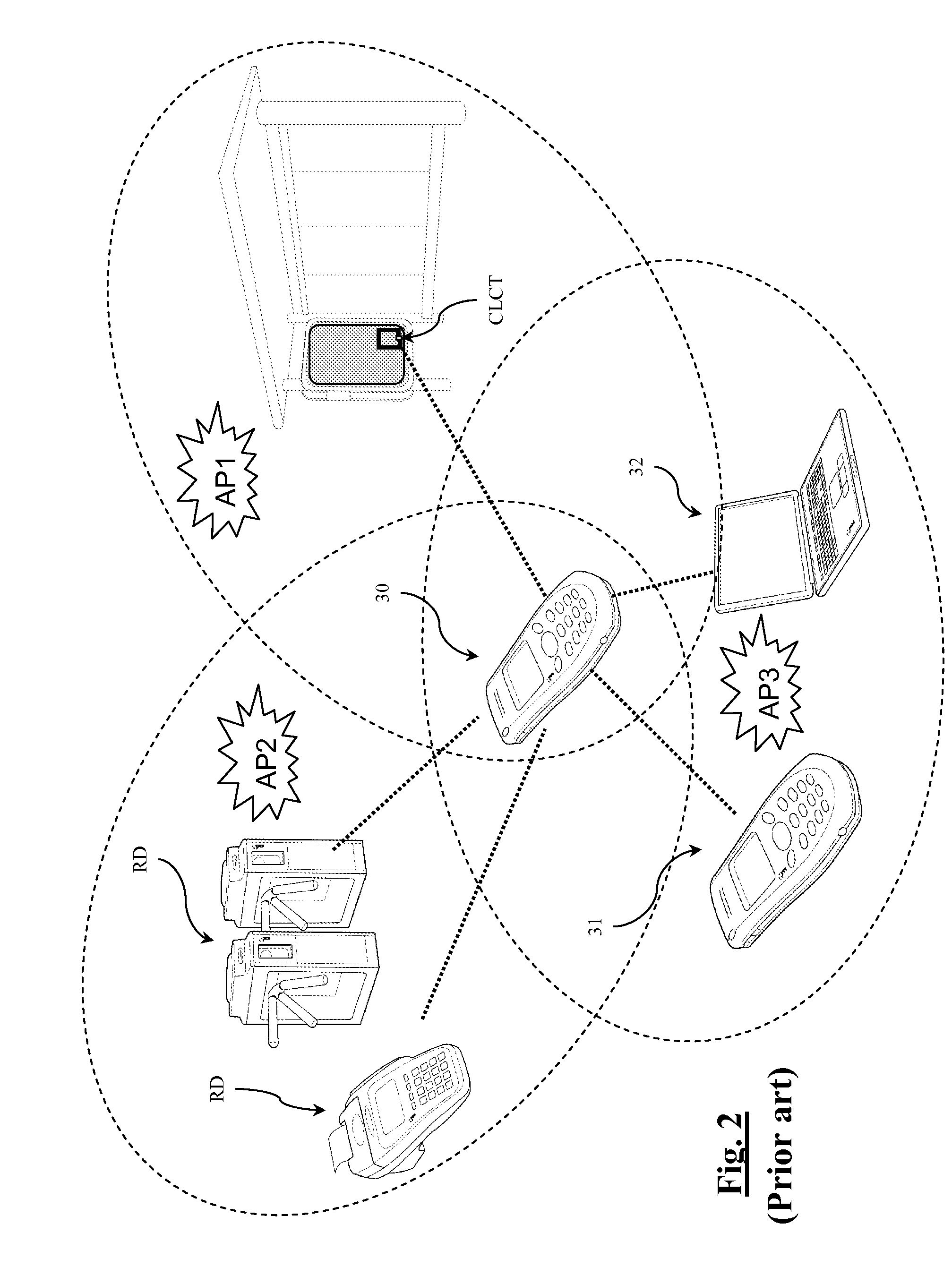

Method for connecting a contactless integrated circuit to a NFC component

InactiveUS20080064346A1Rational productionMinimize changesMemory record carrier reading problemsRecord carriers used with machinesSignal onEngineering

A method for exchanging data with an integrated circuit includes antenna connection terminals. The method includes not connecting the antenna connection terminals of the integrated circuit to an antenna, applying an alternating emulation signal at least to a first antenna connection terminal of the integrated circuit, by way of a wire link, in order to emulate the presence of an antenna signal on the first antenna connection terminal, sending data to the integrated circuit by injecting them in the emulation signal, and receiving data sent by the integrated circuit by taking them from the emulation signal.

Owner:INSIDE CONTACTLESS SA

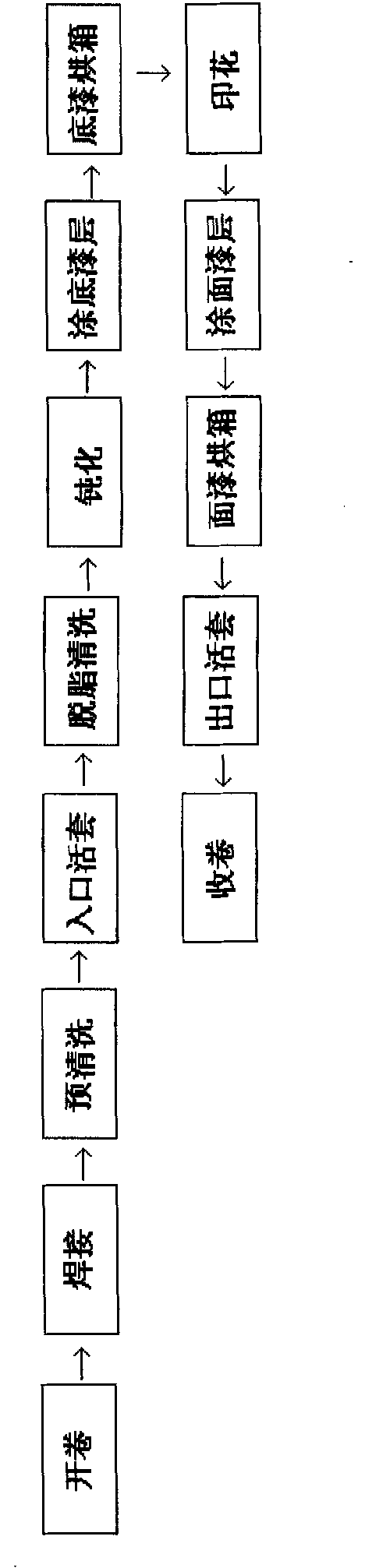

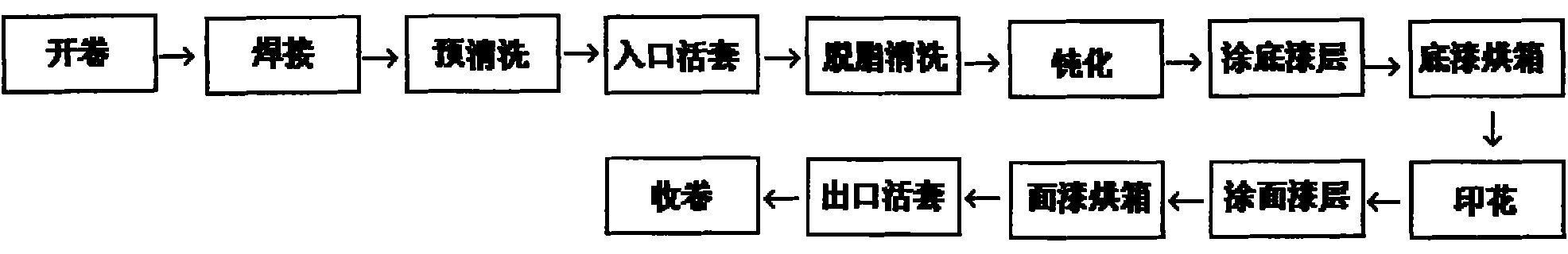

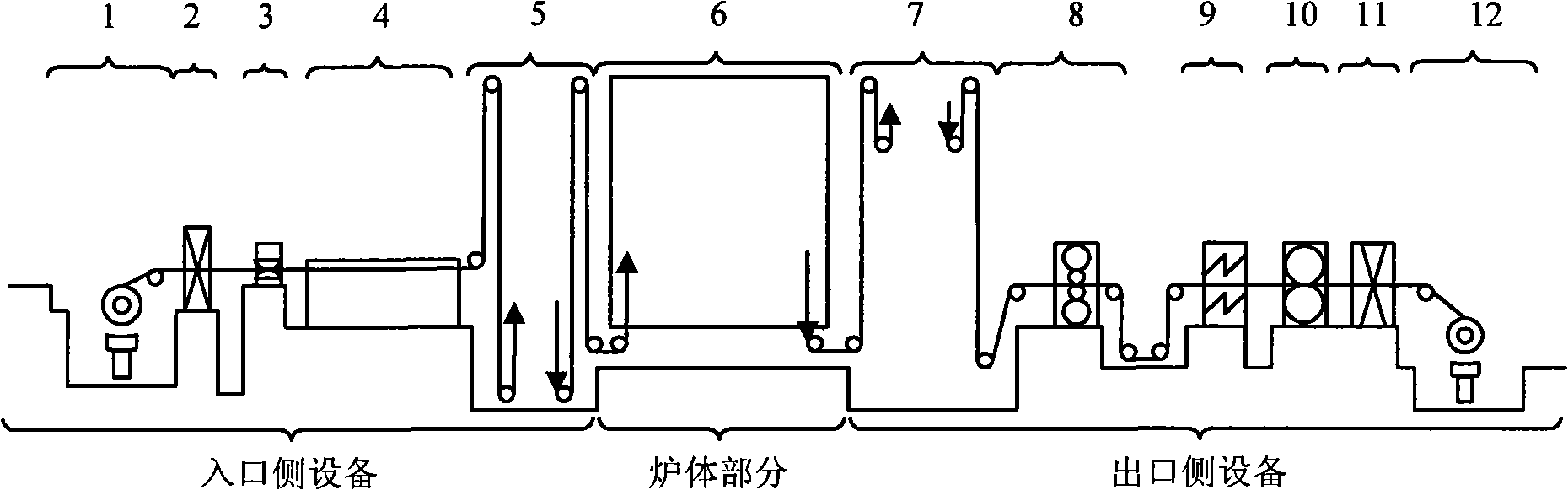

Continuous processing method of printed color coated steel plates at normal temperature

InactiveCN101912839ALong-term aging resistanceLong shelf lifePretreated surfacesCoatingsSheet steelAnti ageing

The invention relates to a continuous processing method of printed color coated steel plates at normal temperature, which comprises the following steps: A) uncoiling and butting; B) degreasing and cleaning; C) carrying out passivation treatment; D) coating a primer layer; E) printing at the normal temperature; and F) coating a finish coat layer. The method can lead patterns of the color coated steel plates to be the same with those of coating layers of the steel plates, and even realize longer anti-aging performance and longer shelf life; simultaneously, the printing does not need to bake during the production process and only needs to pass through a curing furnace twice, the production is more convenient and reasonable, and the production cost is saved.

Owner:CHANGSHU HUAYE STEEL STRIP

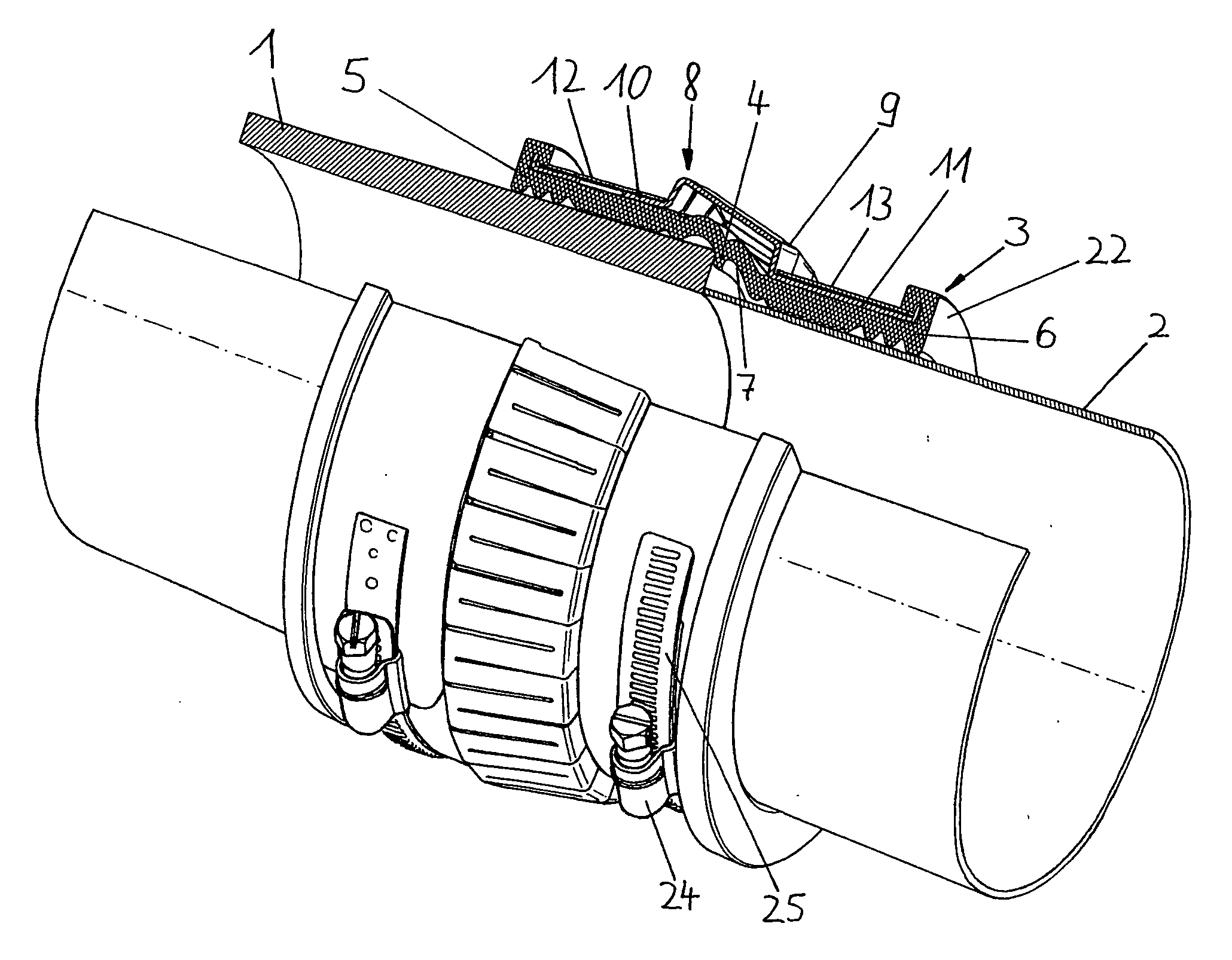

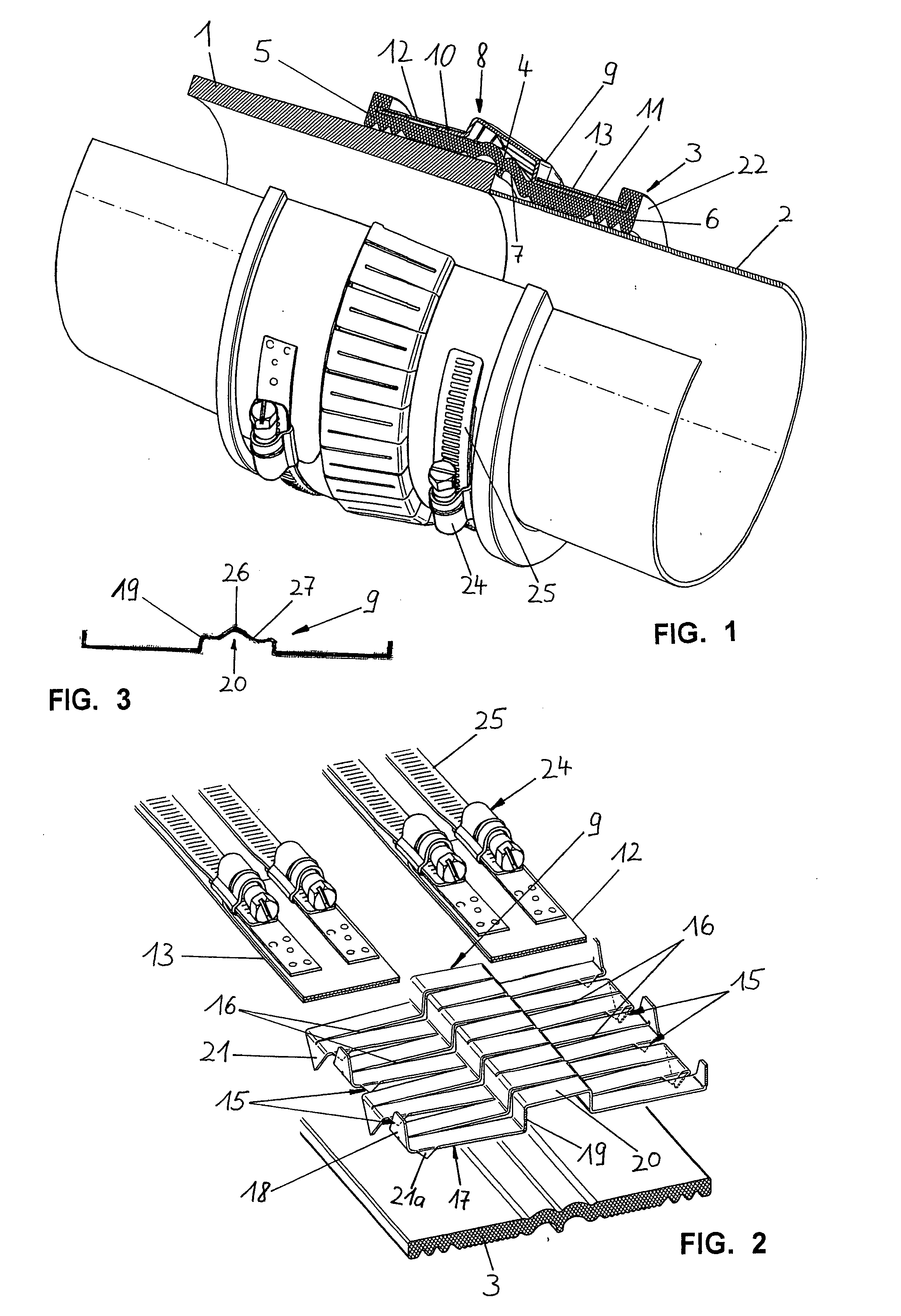

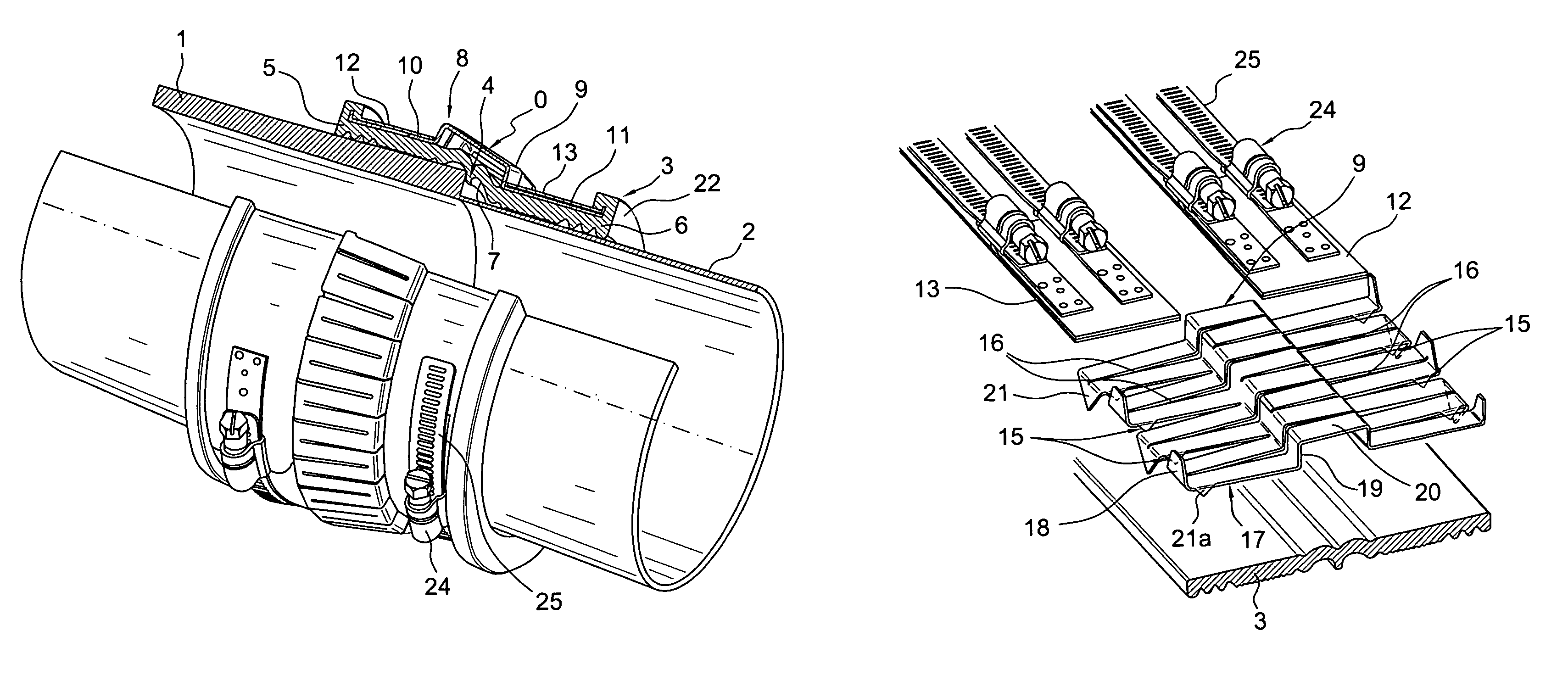

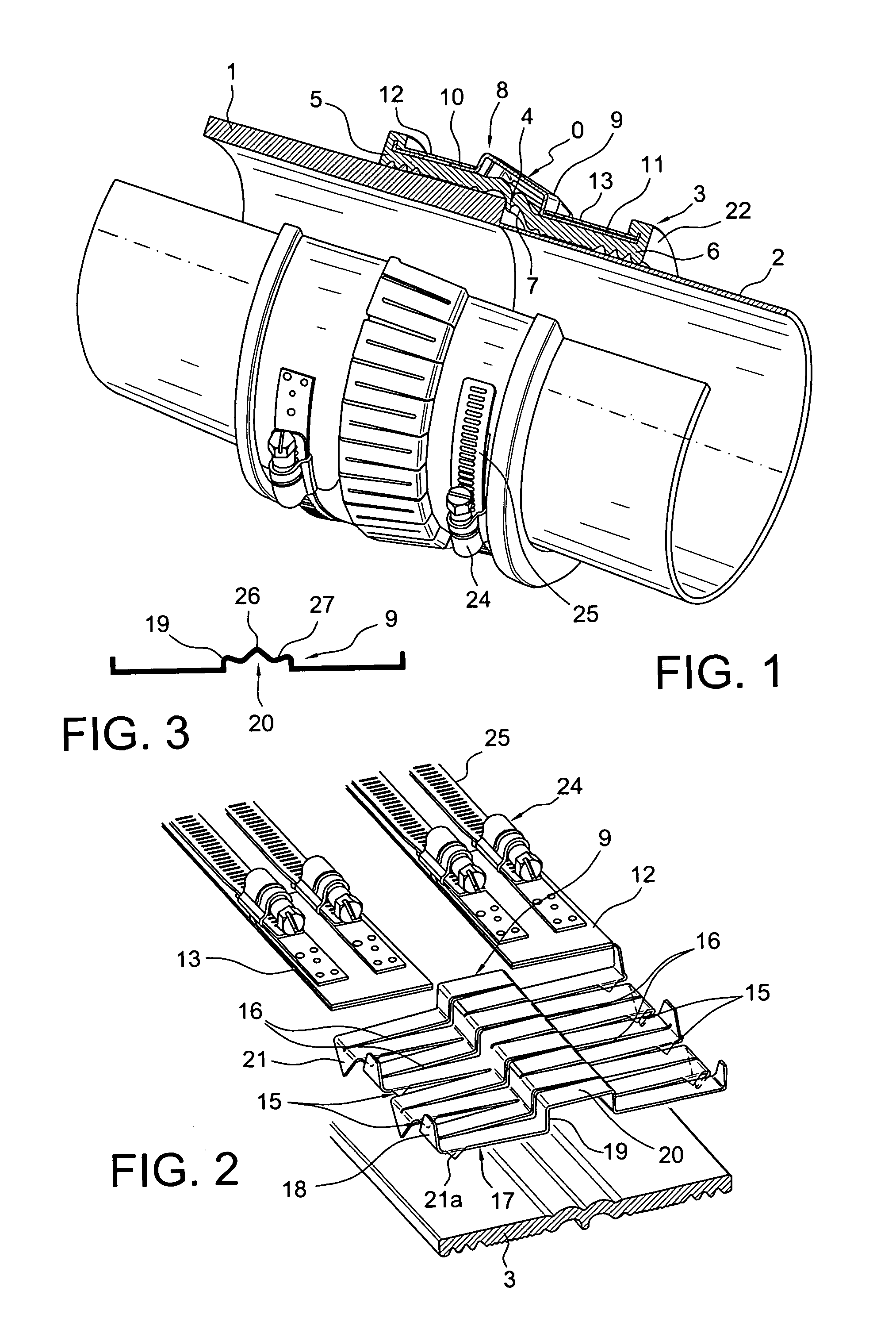

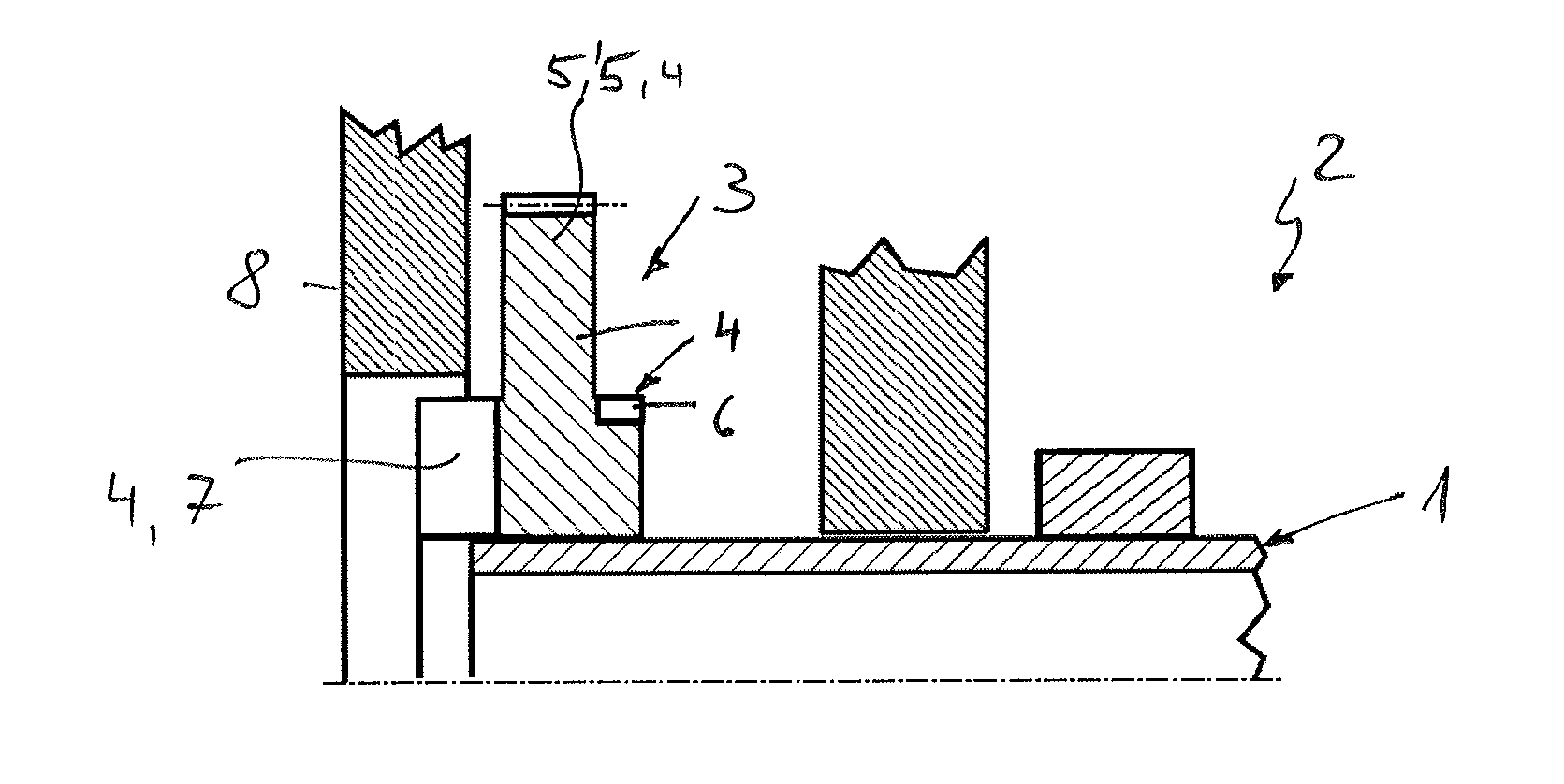

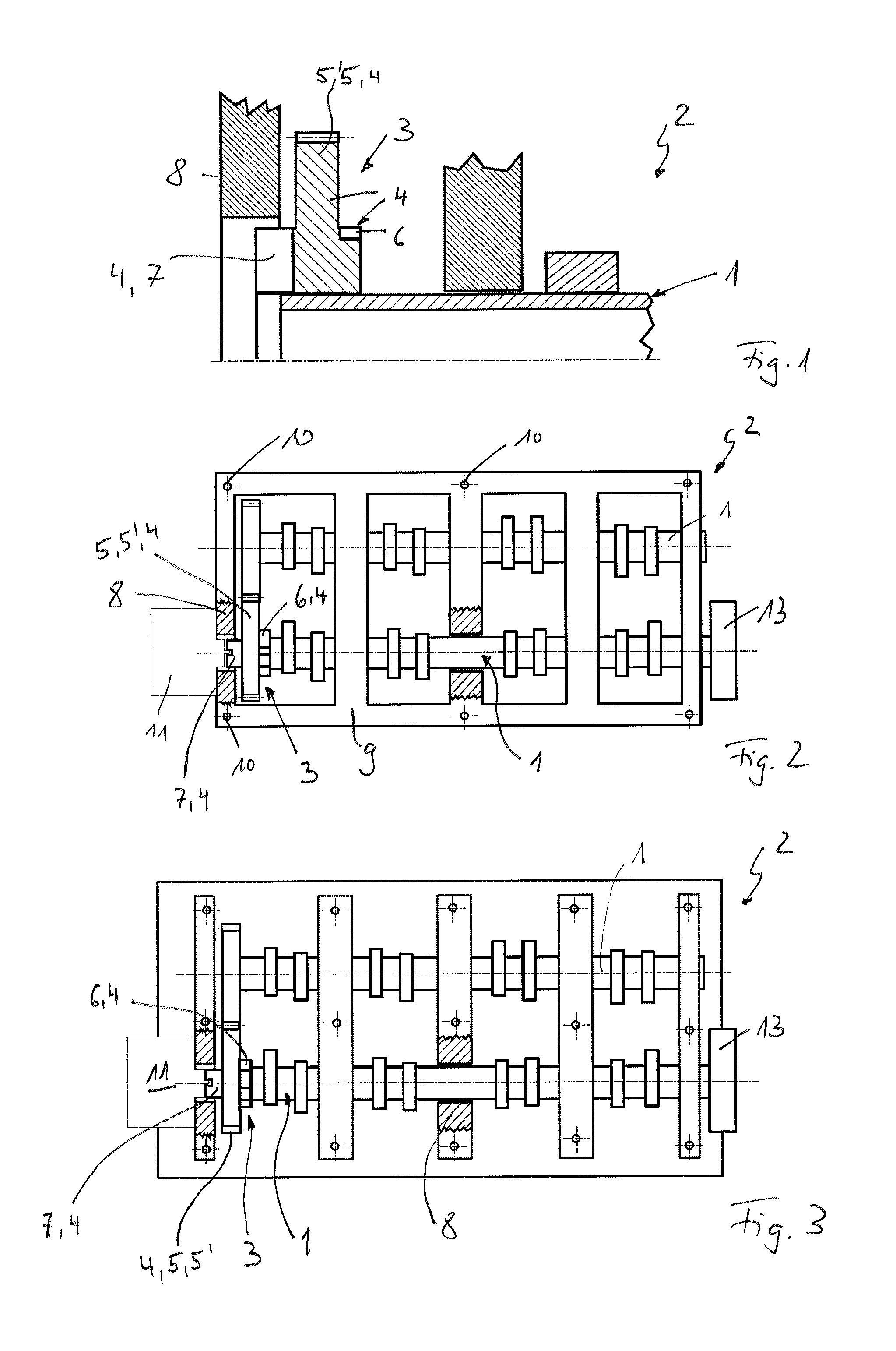

Device for connecting two pipes with different external diameters

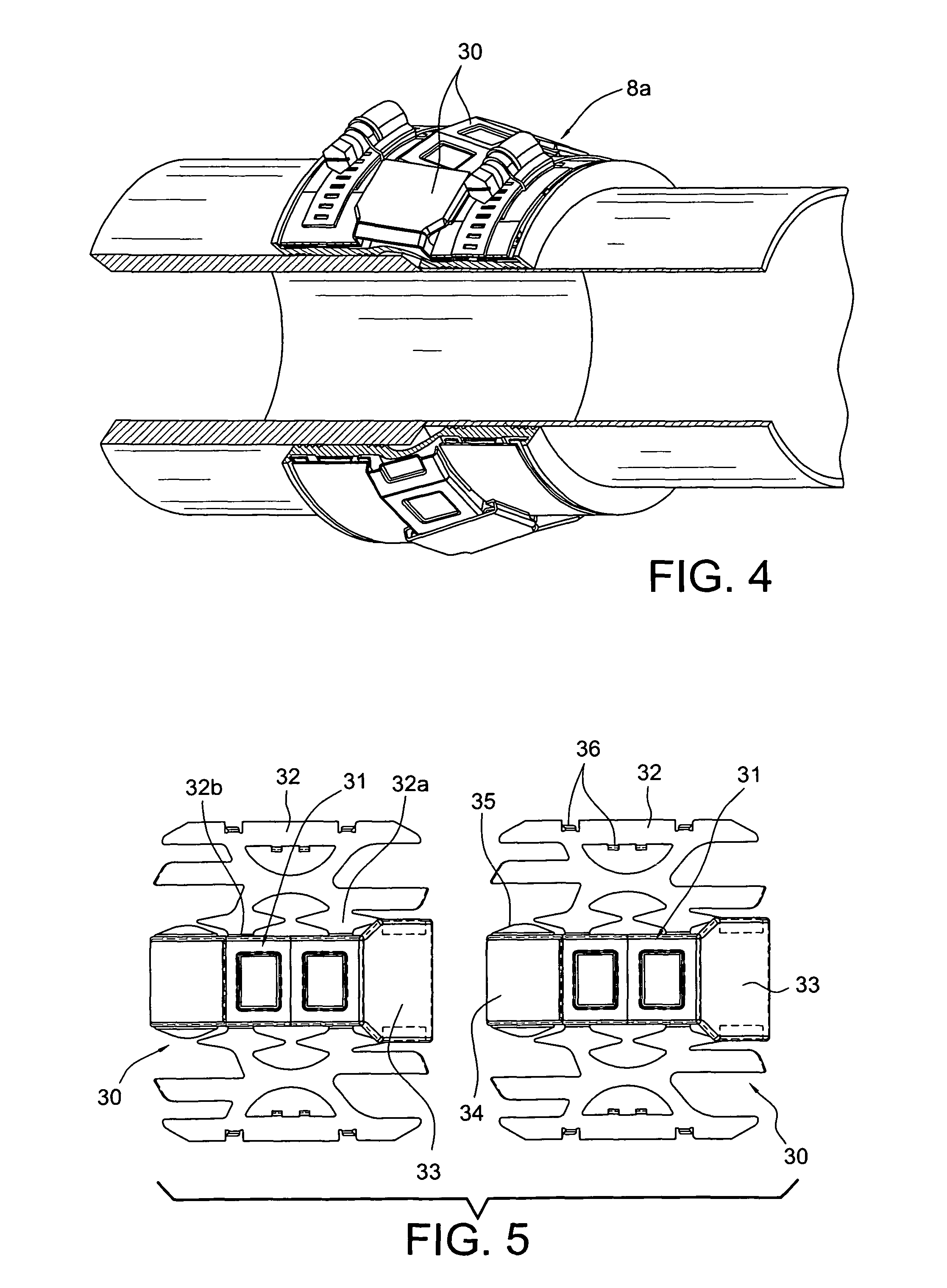

ActiveUS20090160183A1Improve sealingBetter sealing arrangementSleeve/socket jointsPipe elementsButt jointConical forms

For a device for connecting two pipes (1, 2) with different external diameters using a sleeve arrangement which bridges the butt joint between the ends of the pipe (1, 2) facing each other and contains at least a fixing sleeve (8, 8a) which can take up the clips (12, 13) for the two pipes (1, 2) and if necessary a sealing sleeve (3) which is surrounded by the fixing sleeve (8, 8a), high economy and safety can be achieved by the fact that each sleeve of the sleeve arrangement has cylindrical contact sections (5, 6; 10, 11) which can be adjusted to the different external diameters of the two pipes (1, 2) and are connected by a central section (7, 9) which can take a conical form to suit the diameter difference wherein the contact sections (5, 6) of the sleeve next to the external circumference of the two pipes (1, 2) can be brought into direct contact with the two pipes (1, 2) and the contact sections (10, 11) of the fixing sleeve (8, 8a) contain encircling mounting channels assigned to the clips (12, 13) and wherein the fixing sleeve (8) takes the form of a closed encircling ring which is suitable for three-dimensional deformation.

Owner:FELBER WINFRIED

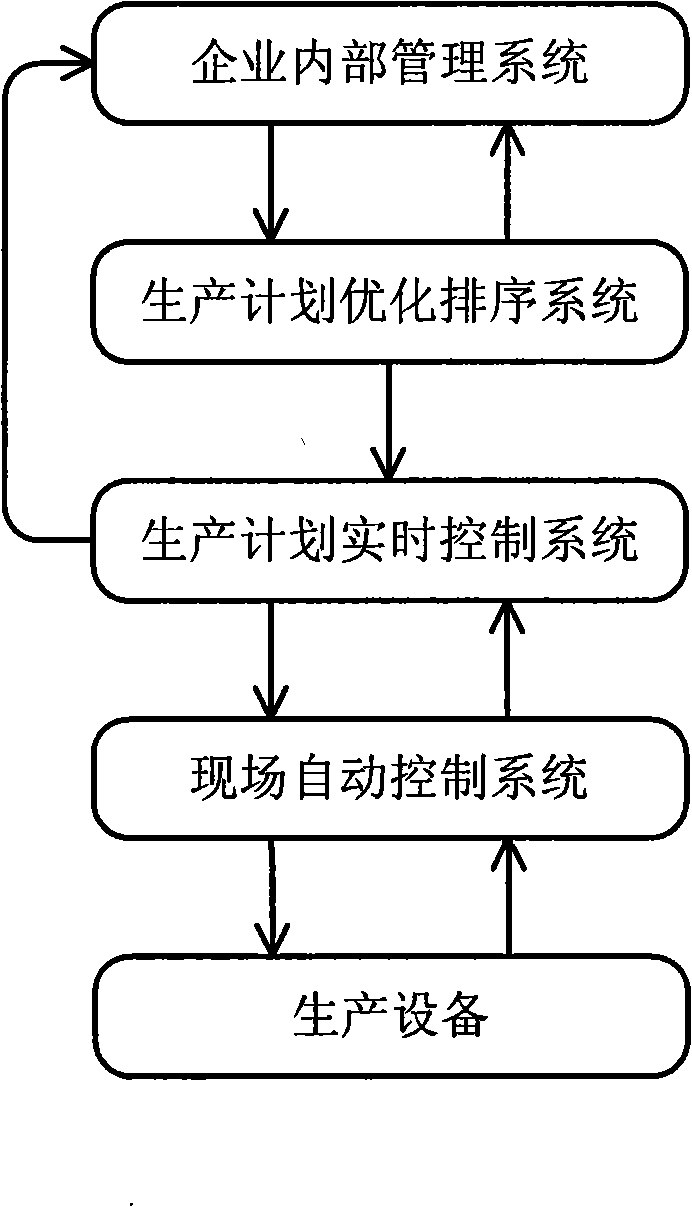

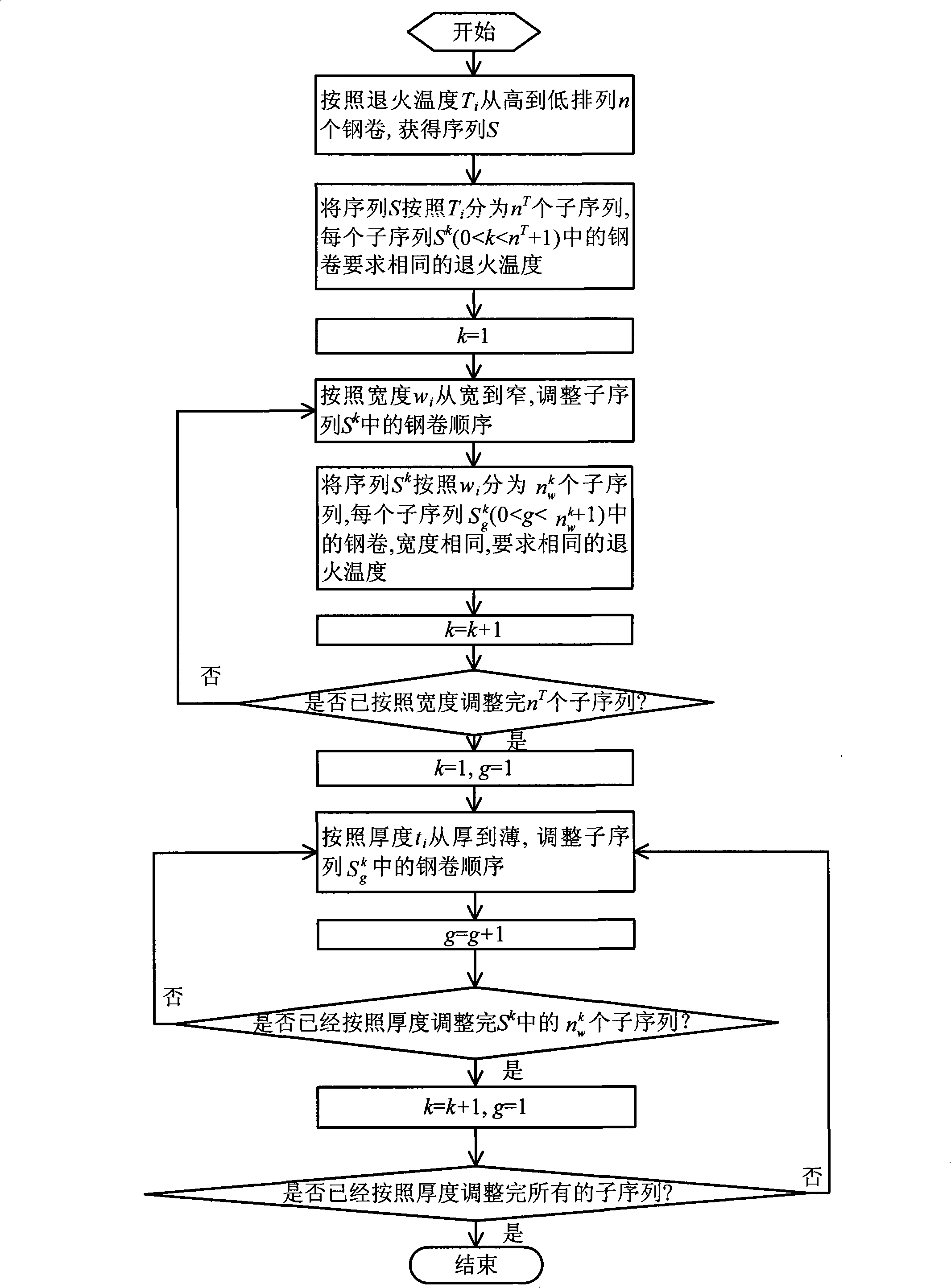

Cold rolling continuous annealing units steel coil optimizing ordering method and its system

ActiveCN101334660AReduce adjustmentSmooth execution of the planTotal factory controlProgramme total factory controlNeighborhood searchMetallic materials

The invention provides an optimum cold rolling continuous annealing unit steel coil sorting method and a system thereof, belonging to the field of metal material processing information technique; the optimum method comprises the steps as follows: 1: the candidate steel coil is respectively sorted from highness to lowness and from lowness to highness according to the annealing temperature so as to form two initial sorting proposal; each initial sorting proposal is optimized by adopting width preference sorting or thickness preference sorting so as to obtain a plurality of groups of initial feasible sorting proposals; 2: the sorting proposal with the minimum optimum object value is selected out of the initial steel coil sorting proposals so as to be taken as the initial feasible production plan; 3: the initial feasible production plan is adjusted by using exchanging neighborhood tabu searching and alternative path conversion neighborhood searching and by taking the minimum optimum sorting model object value as the object. The corresponding system is provided on the basis of the method of the invention; therefore, switching during the execution process of the production plan is reduced, the transition is smooth, the product quality is improved and the yield is improved.

Owner:NORTHEASTERN UNIV

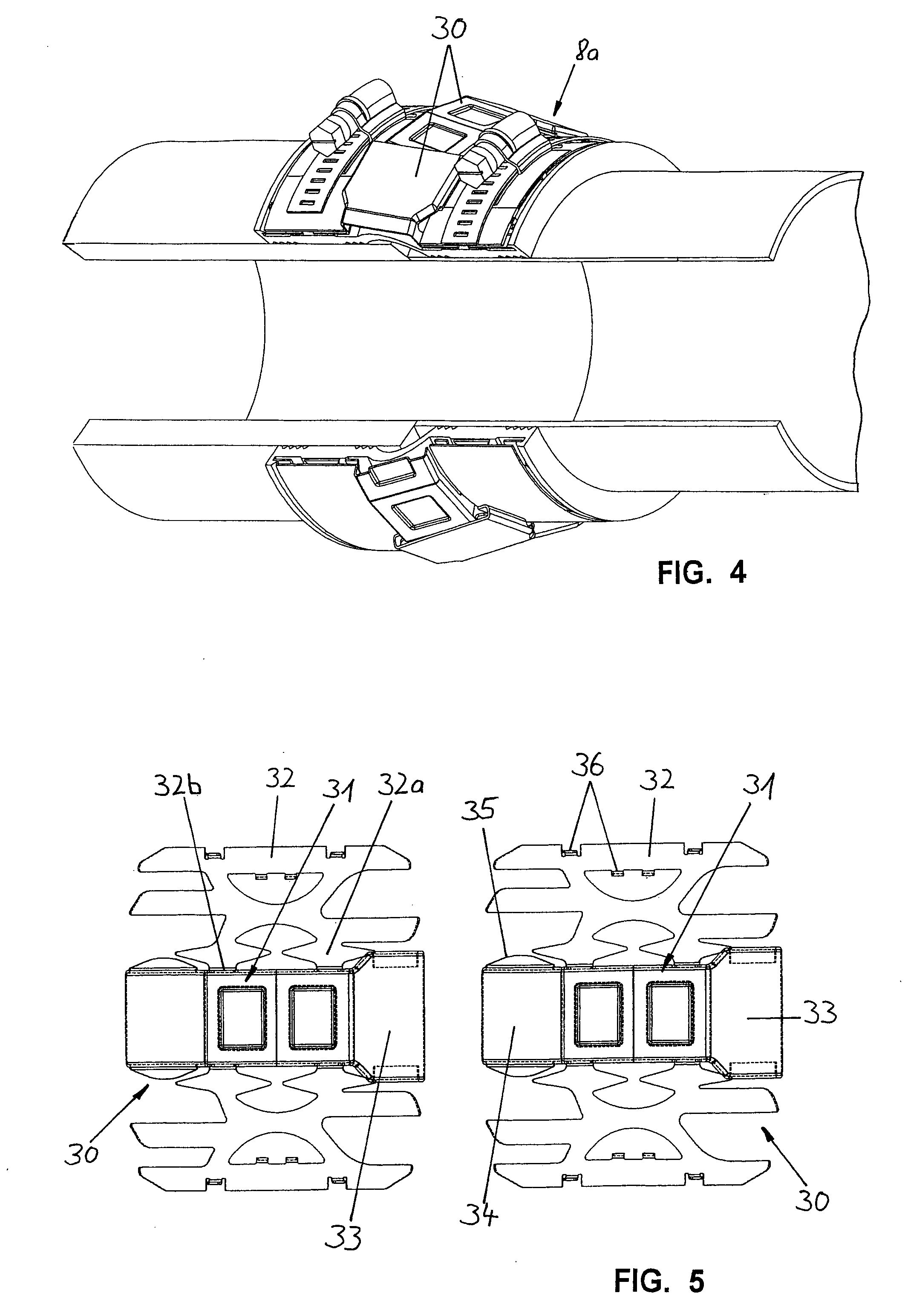

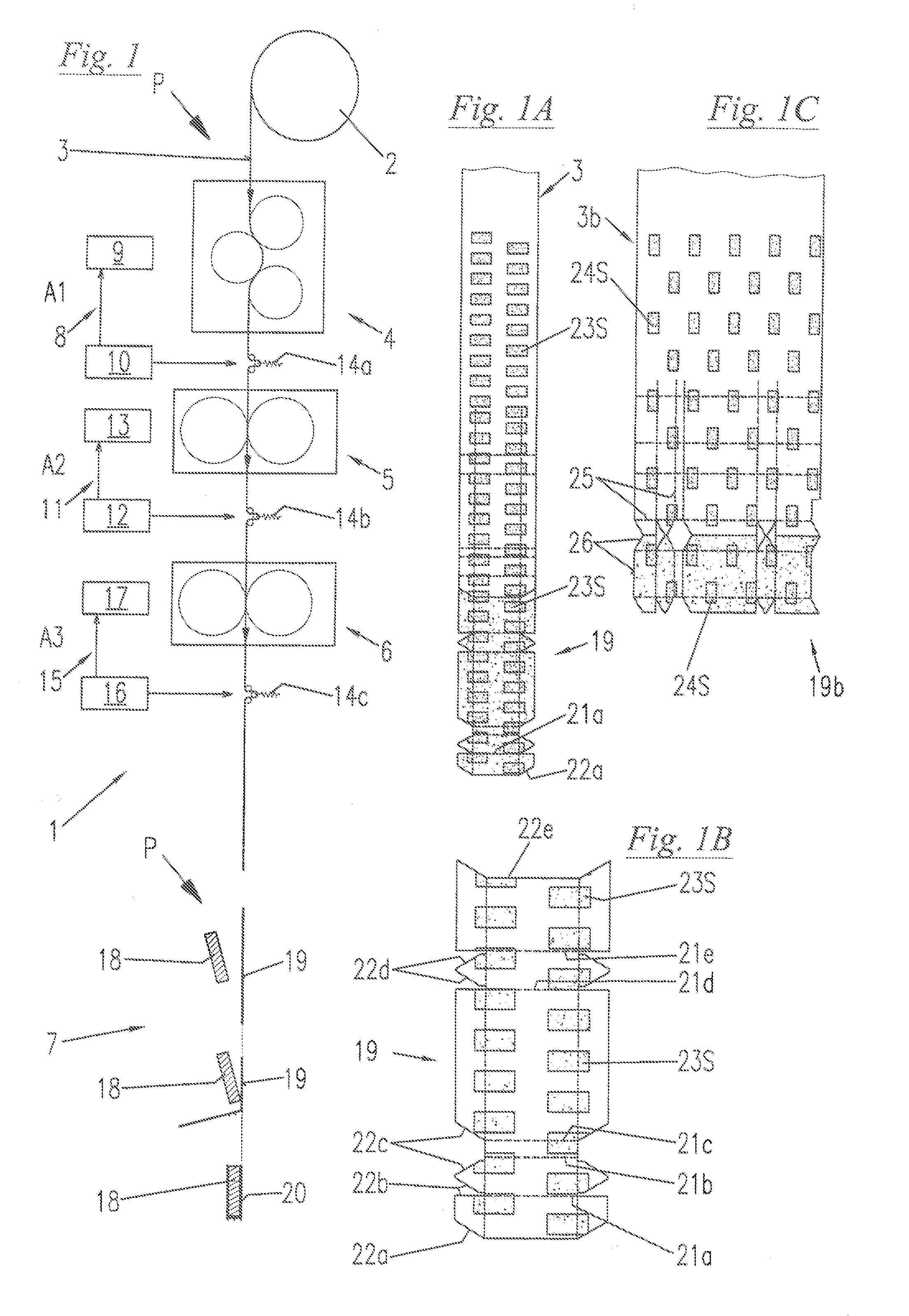

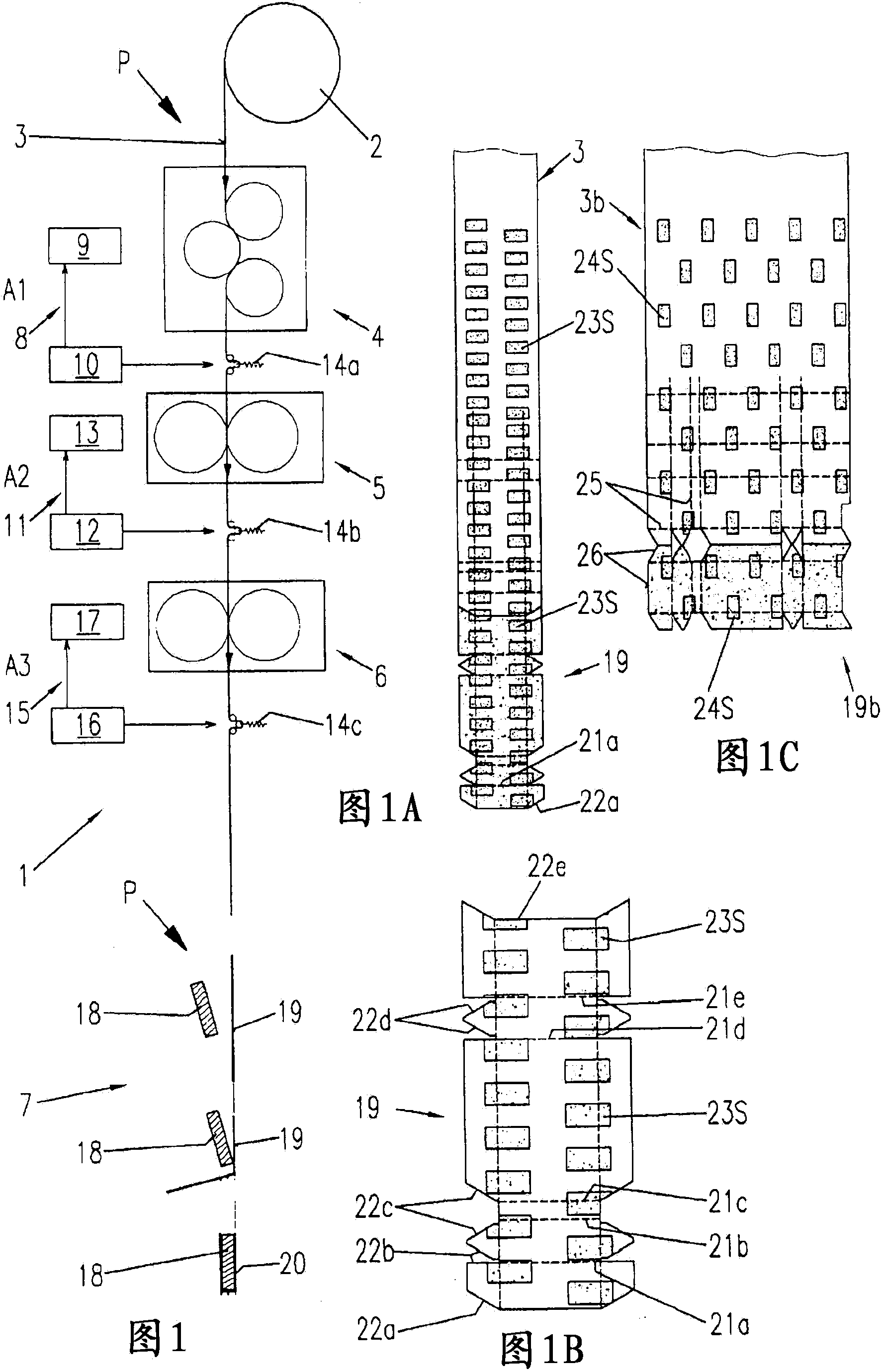

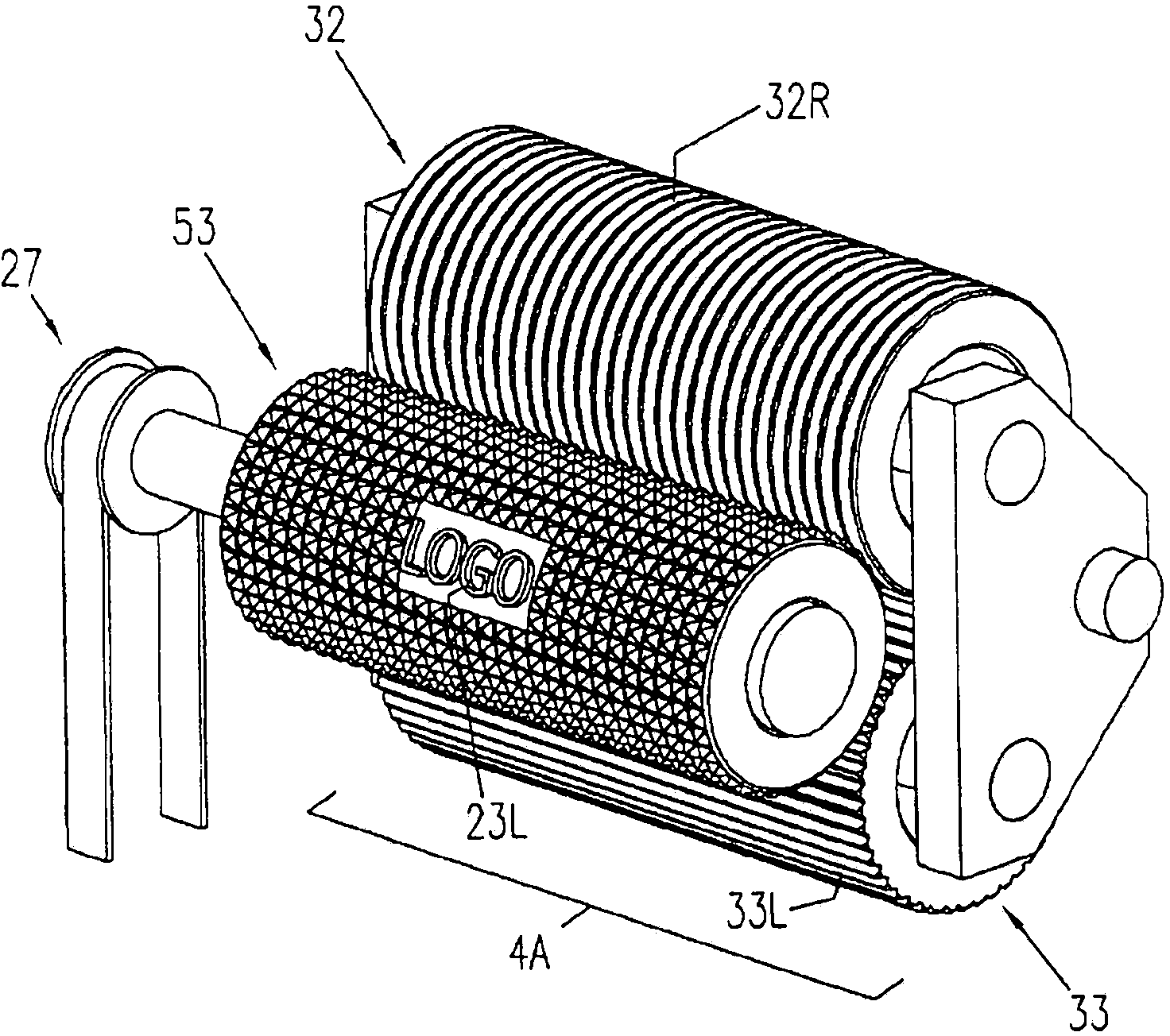

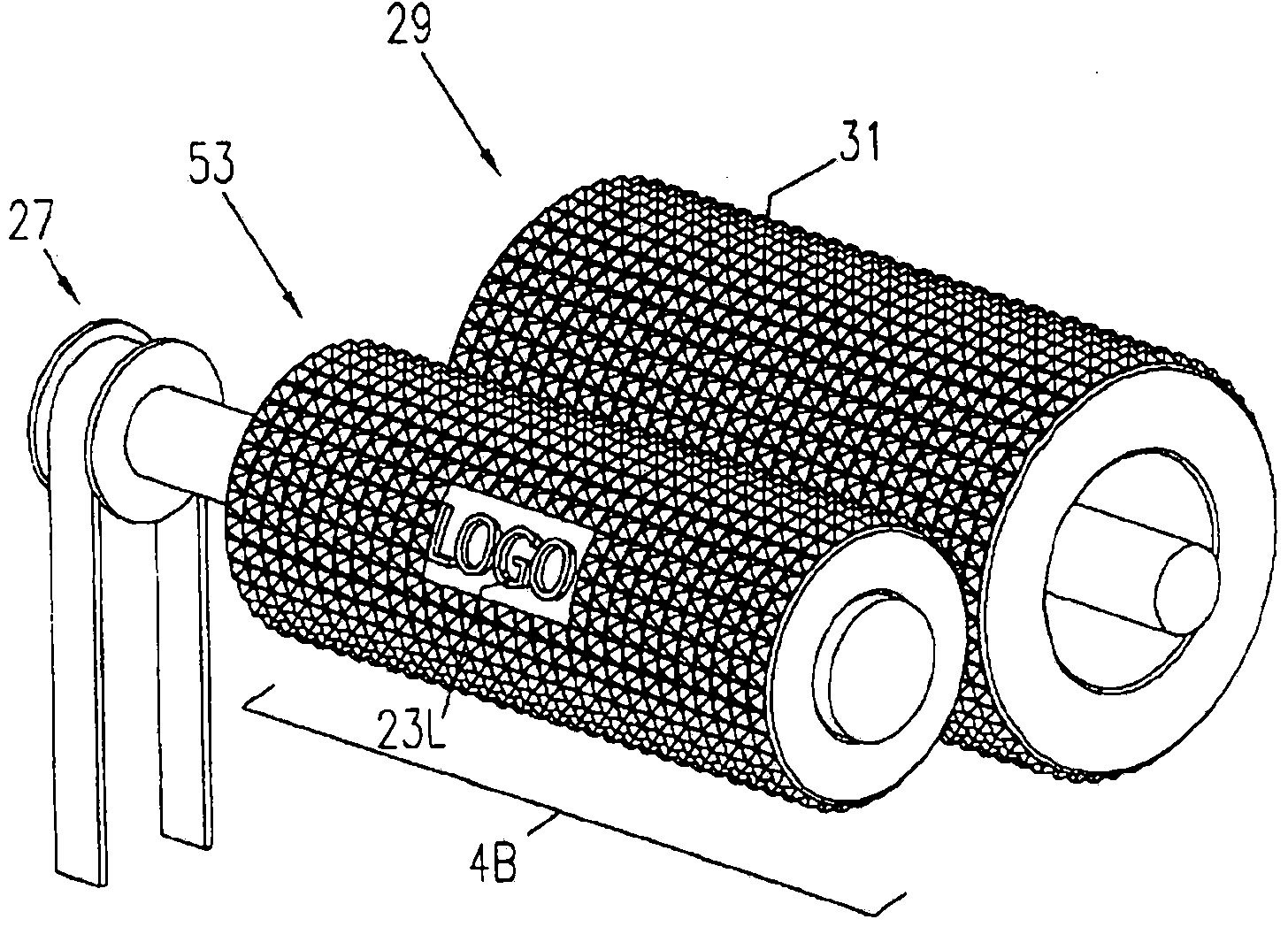

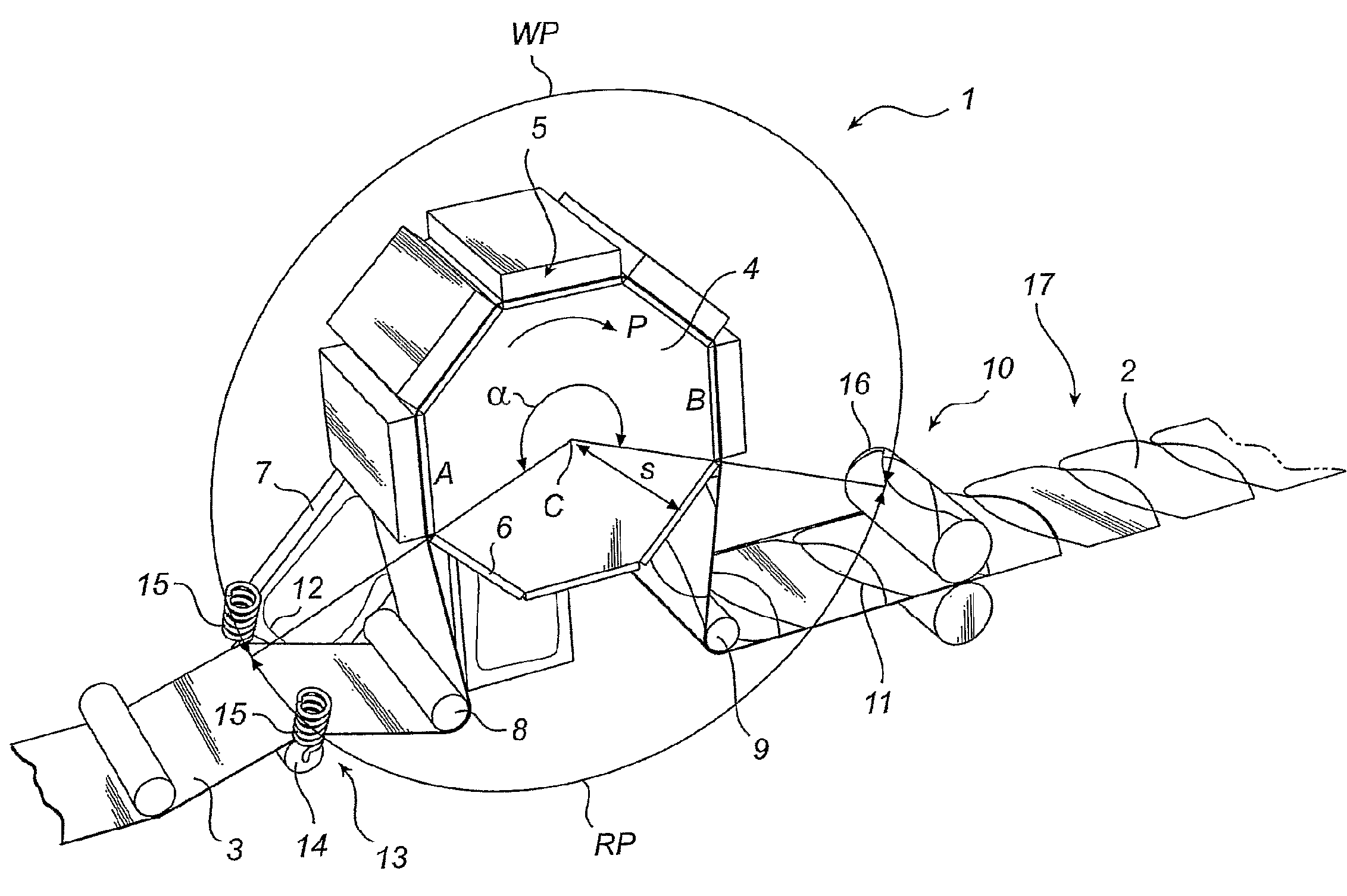

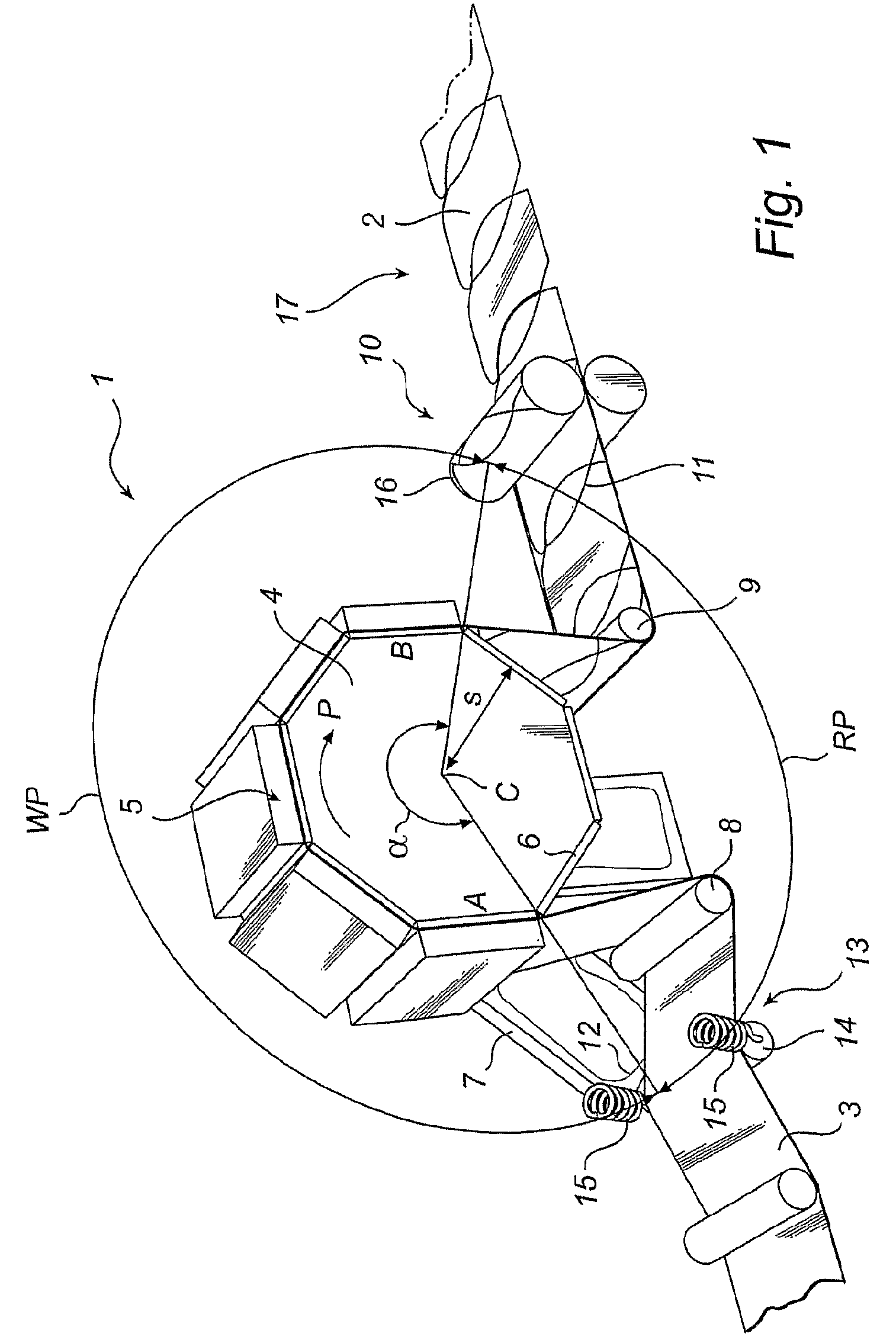

Method and device for producing a package for smoking articles

InactiveUS20140059977A1Rational productionMore productiveMechanical working/deformationPackaging cigaretteEngineeringOverwrap

In the method for producing a package for bar-shaped smoking articles that has at least one outer layer intended to receive the bar-shaped smoking articles and to hold the package together, a foil strip that is suitable for the outer layer and is taken from a reel is embossed and / or provided with creasing breaks online in time with the work cadence (P) of the packaging machine and subsequently cut to size. The resulting blank is then folded around the bar-shaped smoking articles in the packaging machine. On one hand, this method allows packaging the cigarettes directly in the outer wrapper without an innerliner, and on the other hand, to strongly rationalize and simplify the entire packaging process and to apply a large variety of signs of all kinds that are perceptible visually, tactually, acoustically or by olfaction.

Owner:BOEGLL GRAVURES SA

Preparation method of titanium dioxide pigment special for laminated paper

ActiveCN102532952AImprove light resistanceGood light fastnessInorganic compound additionPigment physical treatmentPhysical chemistrySlurry

The invention discloses a preparation method of a titanium dioxide pigment special for laminated paper. The method specifically comprises the following steps of: preparing titanium dioxide rutile primary product into slurry, dispersing by using phosphorus compound-containing solution and grinding; heating the ground slurry and preserving heat; adding water-soluble cerium salt solution to adjust the pH value of the slurry and slaking to form a first cover layer; adding phosphorus compound-containing solution and zirconium salt solution to adjust the pH value of the slurry and slaking to form a second cover layer; adding aluminum salt solution to adjust the pH value of the slurry and slaking to form a third cover layer; filtering and washing filter cakes with de-ionized water, drying, aero-pulverizing and performing gas-solid separation to obtain a finished product. The method has a high-efficiency and rational production process; the prepared titanium dioxide pigment has high light resistance, high coverage capacity, superior retention and low isopotential point and has excellent dispersion performance in a weakly alkaline application system.

Owner:中信钛业股份有限公司

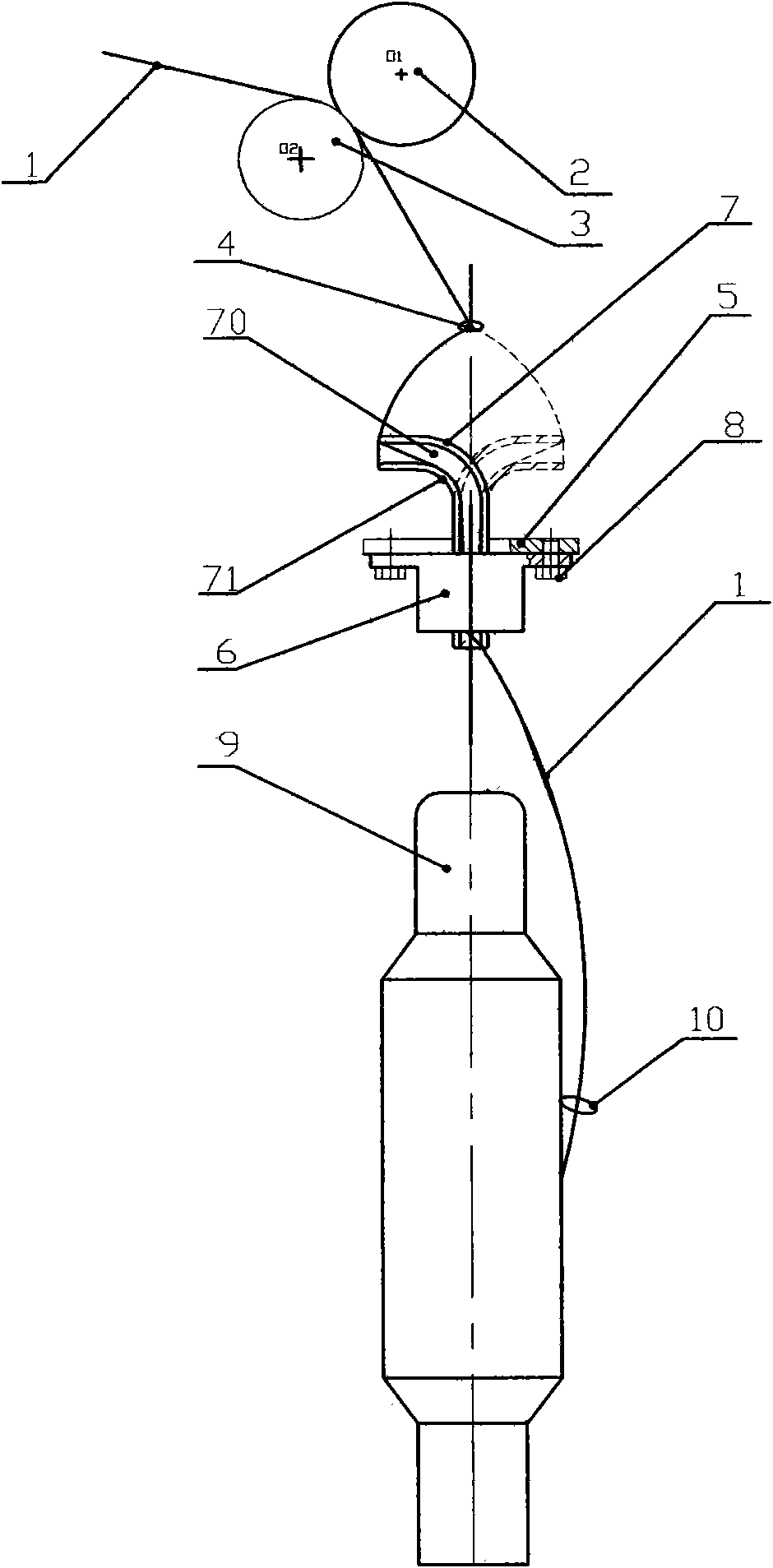

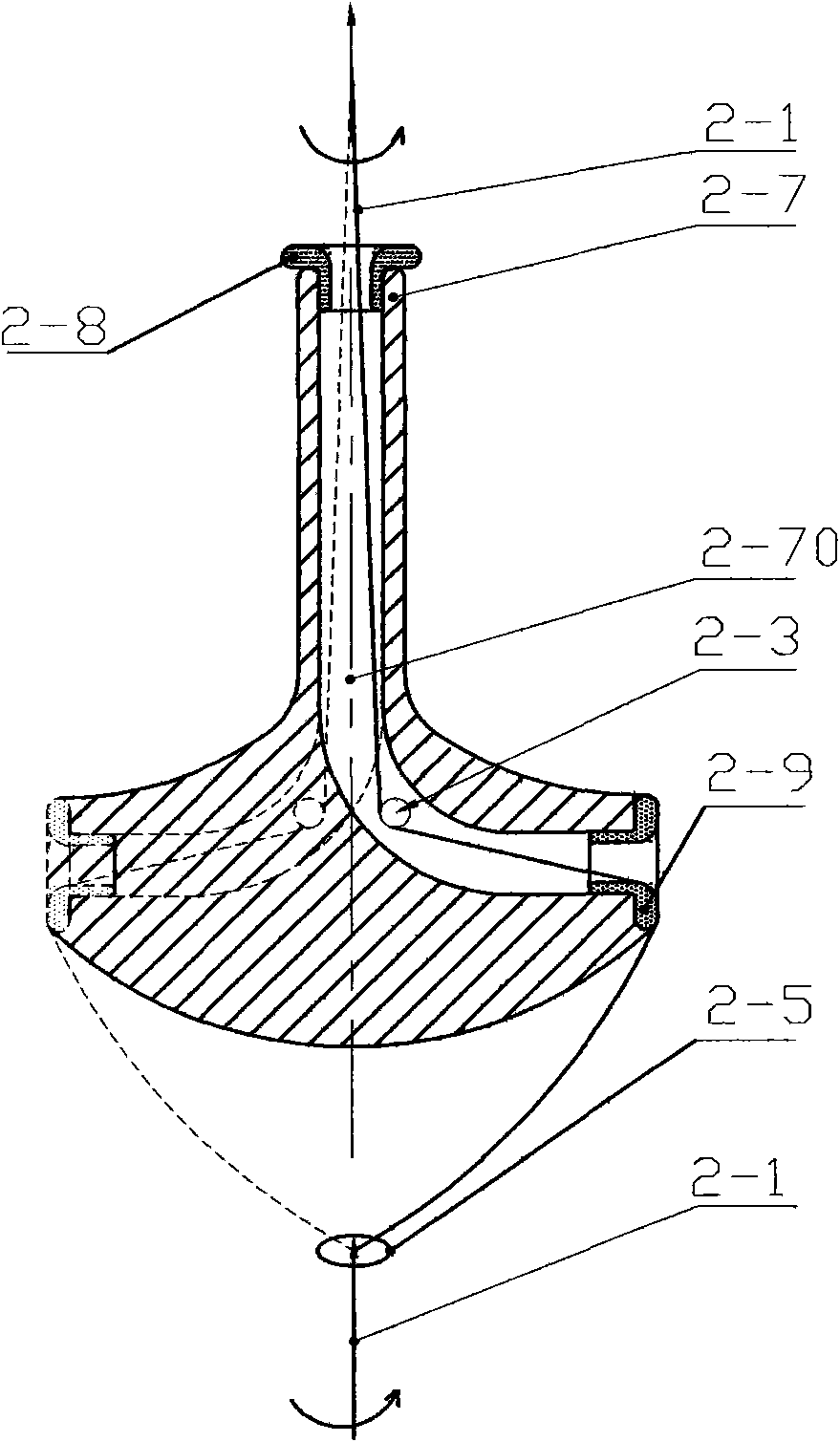

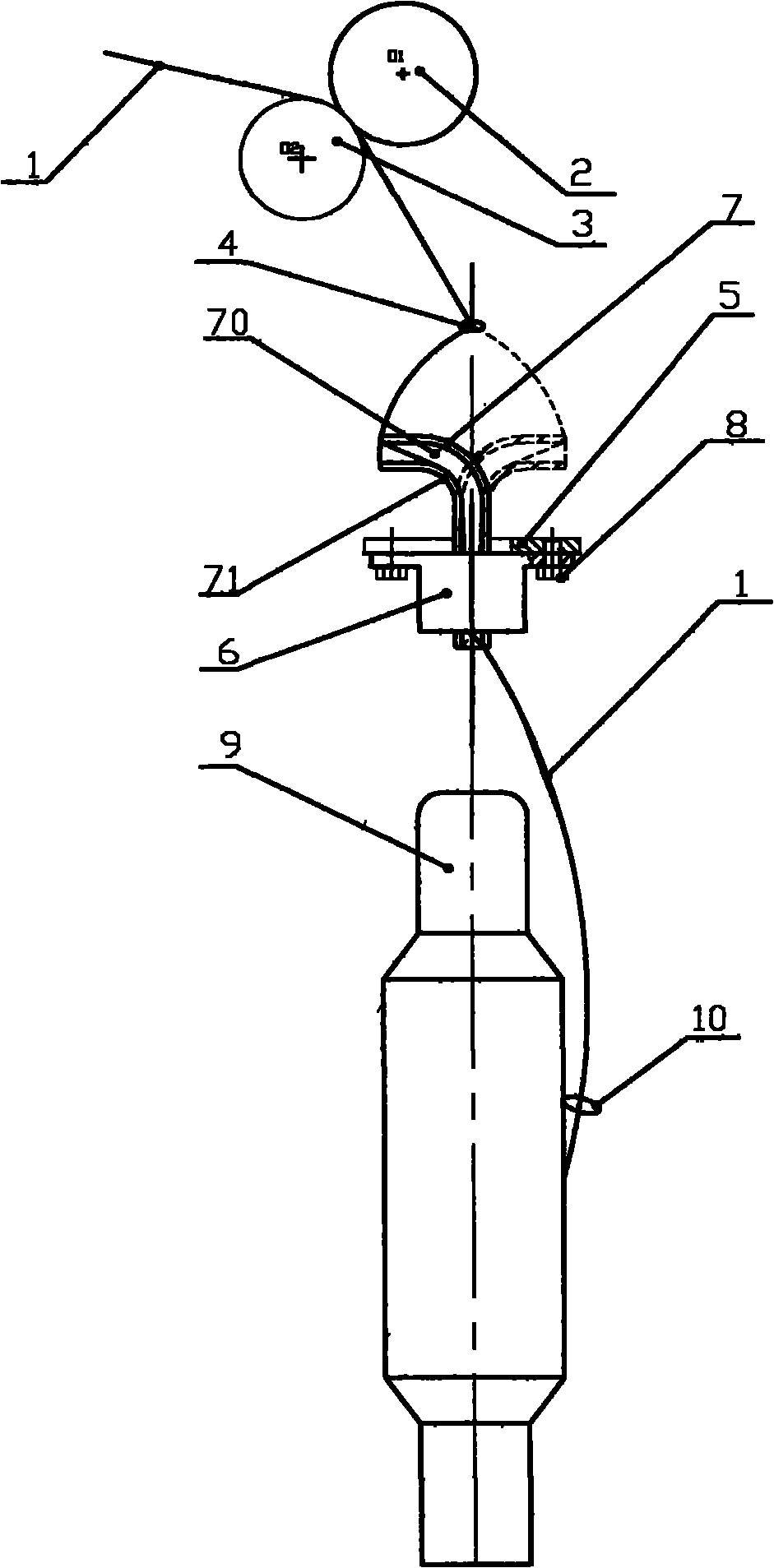

Production method of low torque yarns and device thereof

InactiveCN101967706ASimple production processReduce energy consumptionTextiles and paperYarnEngineering

The invention discloses a production method of low torque yarns and a device thereof, which are used for producing the low torque yarns and belong to the technical field of yarns production in textile machinery. A newly invented yarn false twisting device is mainly adopted and installed at the position above a spinning spindle. The yarn false twisting device ensures that the produced yarns are twisted according to the set number of turns and the degree of twist of a direction of twist opposite to that generated by the spinning spindle after the yarns are drafted by a front roller and a front leather roller, and two degrees of twist are generated for the yarns between the yarn false twisting device and a spinning spindle steel traveler: in one degree of twist, the number of turns formed by the yarn false twisting device is equal to the set number of turns, and the direction of twist is the same as that generated by the spinning spindle; and the other degree of twist is generated by the spinning spindle steel traveler. The three degrees of twist are superposed, the degree of twist generated by the spinning spindle steel traveler is finally formed inside the yarns, and the yarns are wound on a tube of the spinning spindle to complete the whole production process of the low torque yarns.

Owner:绍兴华裕纺机有限公司

Aqueous blackboard paint

The invention discloses an aqueous blackboard paint which solves the problem of solvent release of existing solvent type blackboard paints. The aqueous blackboard paint comprises the following components in parts by mass: 260 parts of water, 1 part of dispersant, 1.5 parts of a wetting agent, 200 parts of emulsion, 1 part of a defoamer, 200 parts of pigment, 120 parts of filler, 15 parts of coalescing agents and 3 parts of thickener. The preparation method comprises the following steps of: during preparation, adding water into a reaction kettle, adding the wetting agent, the dispersant and the defoamer at 100-300 r / m, and stirring for 30-40 minutes; adding the pigment and filler under stirring, and dispersing for 1-1.5 hours at 500-800 r / m; then, adding the emulsion, and stirring for 30 minutes at 800-1000 r / min; pumping the materials to a grinding miller, and grinding the materials till the fineness is below 45 microns; and pumping the grinded materials to a proportioning kettle, adding the coalescing agents, the defoamer and the thickener, and adjusting the viscosity to discharge and package so as to obtain a finished product. According to the paint provided by the invention, various film forming matters in different performances are adopted to compound and modify, so that demands of the blackboard paint such as high hardness, scrubbing resistance, wear resistance and color residual prevention are satisfied.

Owner:SHANXI HUABAO NEW MATERIALS CO LTD

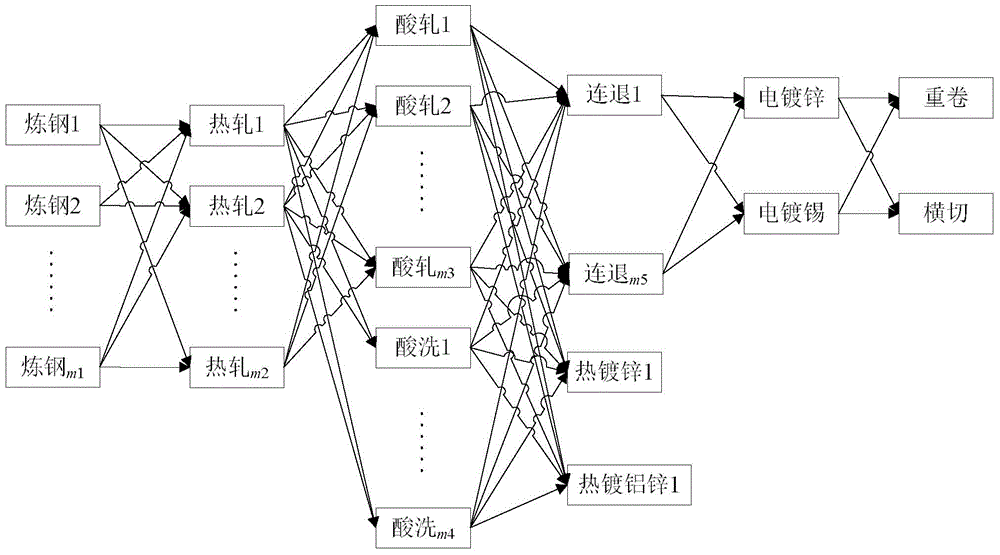

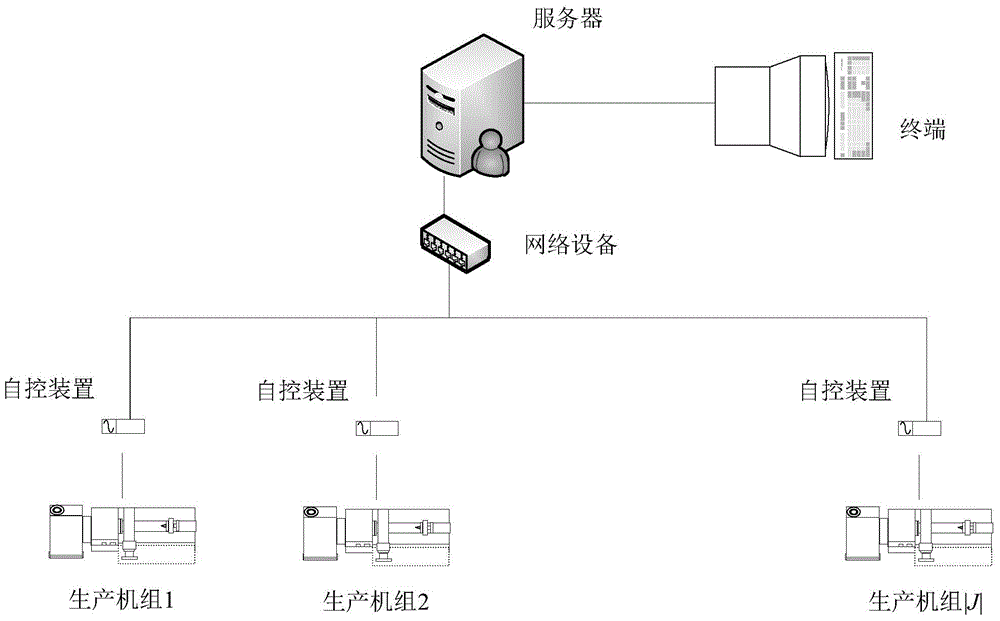

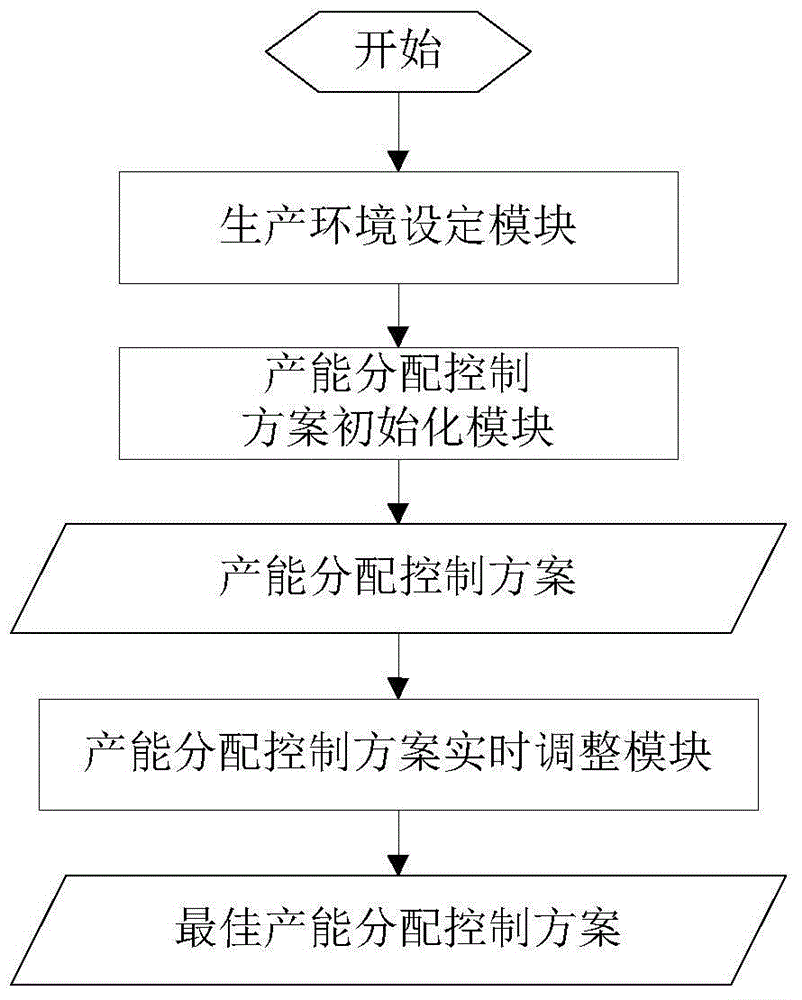

Complete flow unit productivity allocation control method for metallurgical enterprise

ActiveCN104635683AMeet needsSmooth demandTotal factory controlProgramme total factory controlDistribution controlComputer science

The invention provides a complete flow unit productivity allocation control method for a metallurgical enterprise. The complete flow unit productivity allocation control method comprises the steps that a complete flow unit productivity allocation control model of the metallurgical enterprise is established according to the production state of each unit and the contractual processing route of the metallurgical enterprise; the productivity allocation situation of each unit is determined, including the contract selection situation and the contract processing sequence of each unit, and the stability estimation index value of the complete flow unit productivity allocation control scheme of the metallurgical enterprise is calculated; the productivity distribution control is carried out according to the complete flow unit productivity allocation control scheme of the metallurgical enterprise and the corresponding production contract , and the complete flow unit productivity allocation control scheme of the metallurgical enterprise is adjusted in real time; the complete flow unit optimal productivity allocation control scheme of the metallurgical enterprise is issued to the complete flow unit for productivity distribution control. According to the complete flow unit productivity allocation control method for the metallurgical enterprise, the productivity allocation scheme is established by coordinating the units, so that the requirements of production equipment are met to the greatest extent, the production of each unit can be carried out stably, the production process is more reasonable, and the production switching is reduced.

Owner:NORTHEASTERN UNIV

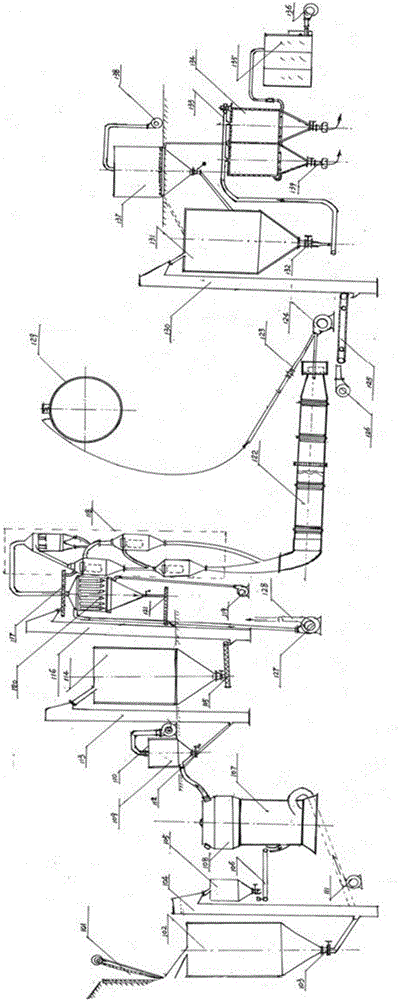

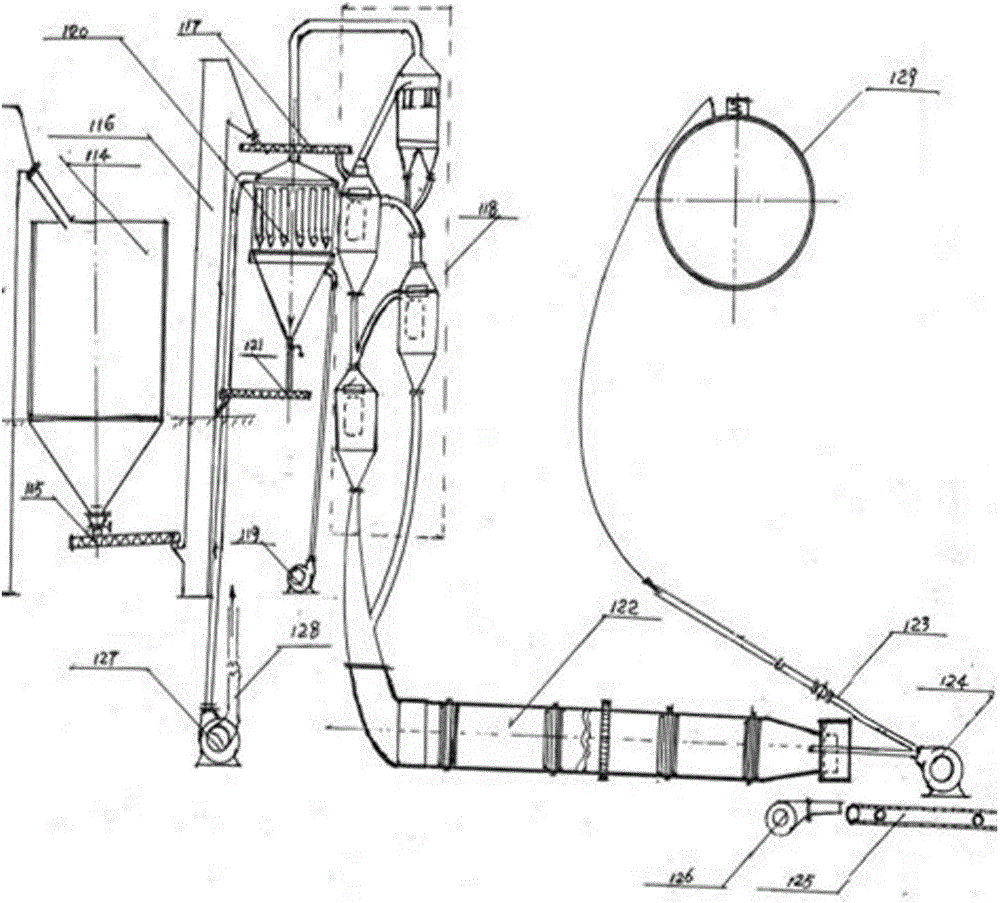

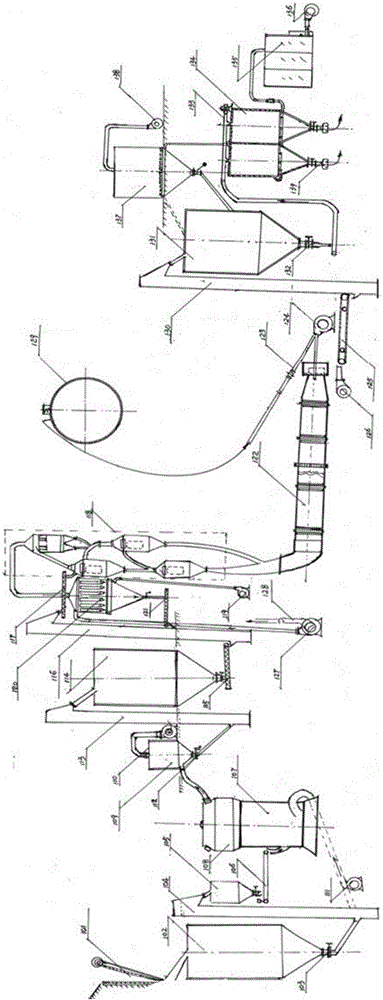

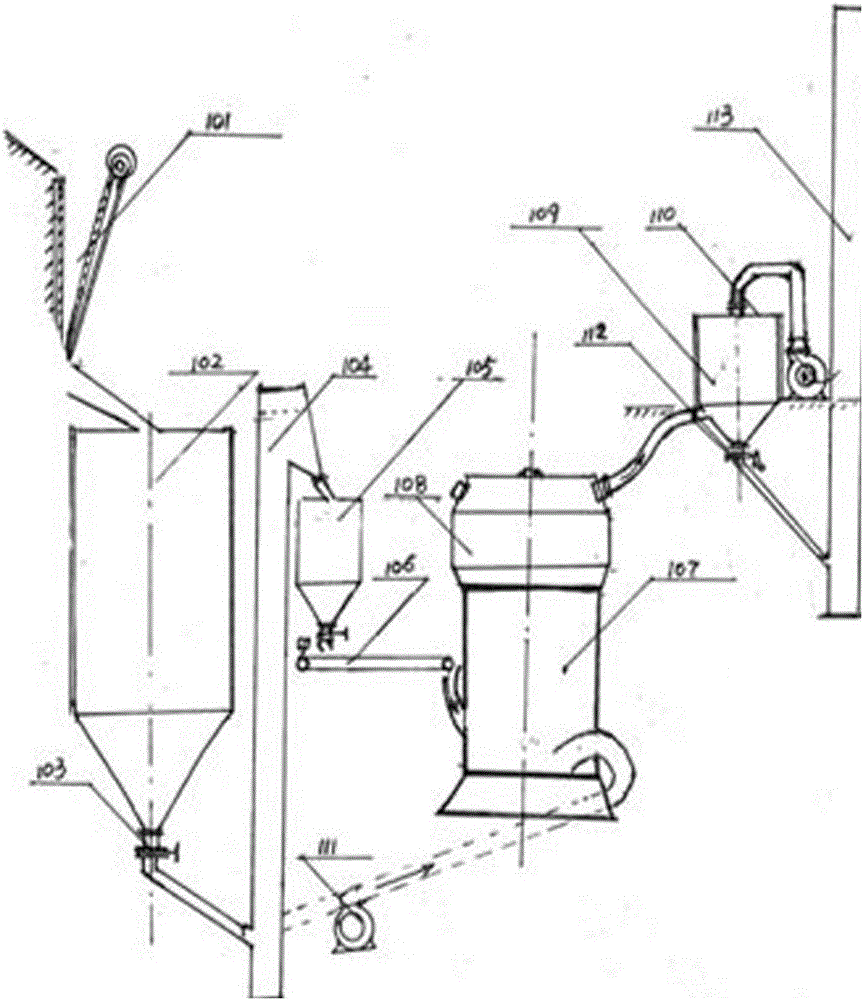

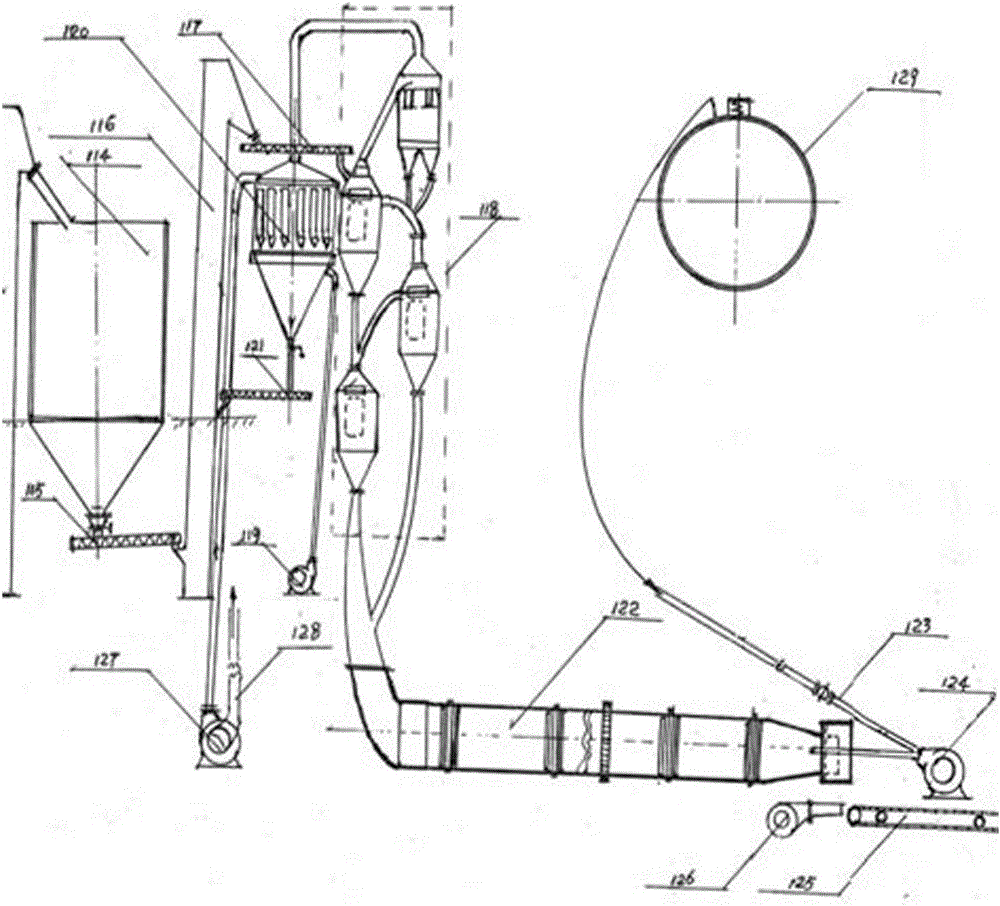

Molten carbon heating type induction furnace based vacuum magnesium production system and magnesium production method thereof

InactiveCN106011500AEfficient collectionContinuous productionProcess efficiency improvementGas emission reductionMelting tankThree stage

The invention discloses a molten carbon heating type induction furnace based vacuum magnesium production system. The system is characterized by comprising a pulverizing system, a preheating decomposing system, a roasting system, a secondary heating system, a vacuum reaction system and a condensing collecting system which are sequentially connected. The magnesium production method of the system comprises three stages, namely, the preparation stage, the induction furnace based vacuum magnesium production stage, and the starting and stopping stage after finishing. According to the system and the method, magnesium-contained powder which is pulverized, decomposed and heated is utilized; a melting tank in which iron is molten into liquid is subjected to vacuum treatment and then charged with argon; high-temperature carbon powder and the magnesium-contained powder are sprayed in the melting tank to reduce so as to produce magnesium steam; the magnesium steam is converted into molten magnesium after being collected and condensed, wherein the molten magnesium is coarse magnesium which is refined to obtain a magnesium ingot. The system and the method are reasonable and compact in production process, complete in equipment coordination and process, fast to react, short in reacting time, and high in production efficiency, and can reduce more than 1 / 3 of the production cost.

Owner:狄保法

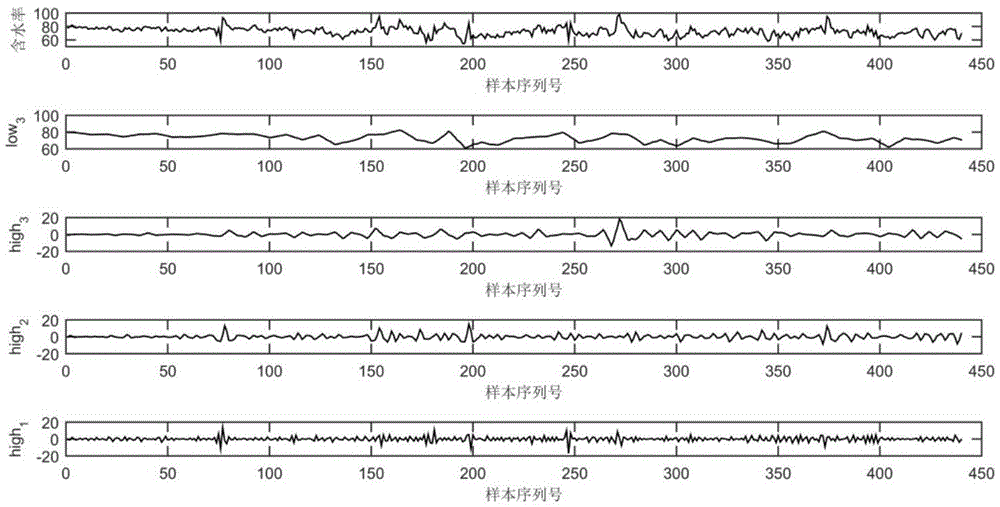

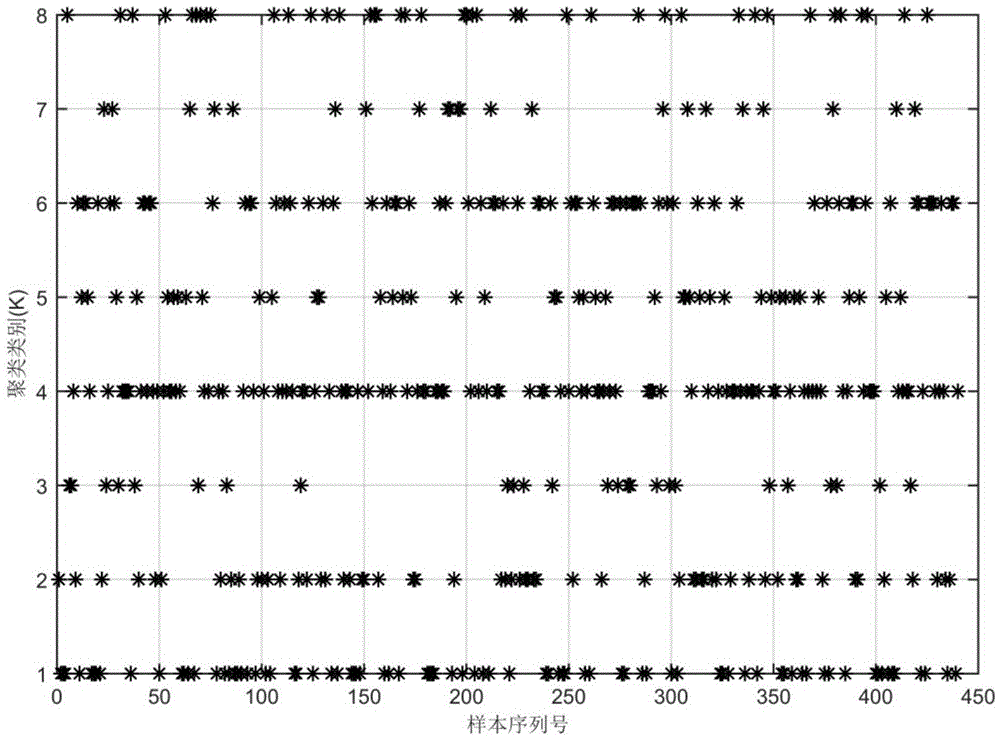

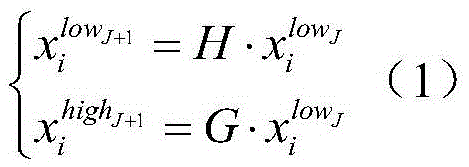

Oil-well oil water content multi-model prediction method based on time sequence

InactiveCN105631554ATimely evaluation of production statusRational productionForecastingCharacter and pattern recognitionCluster algorithmLearning machine

The invention relates to an oil-well oil water content multi-model prediction method based on a time sequence, and the method is characterized in that the method comprises the following steps: 1), building an oil-well oil water content data set through employing historical data: {xi, i=1, 2,...,N}; 2), carrying out the pre-processing of the data in the oil-well oil water content data set {xi, i=1, 2,...,N} through employing a wavelet analysis method; 3), carrying out the classification of {xi} Wave through employing a neighbor propagation cluster algorithm; 4), enabling the data in each cluster to be represented in a following time sequence mode (shown in the description); 5), building a time sequence model of each cluster according to an extreme learning machine algorithm, and obtaining a prediction value through employing the time sequence models. The method solves problems that a conventional manual sampling method of oil-well oil water content consumes time and labor and affects the production monitoring and the instantaneity of oil extraction data.

Owner:BOHAI UNIV

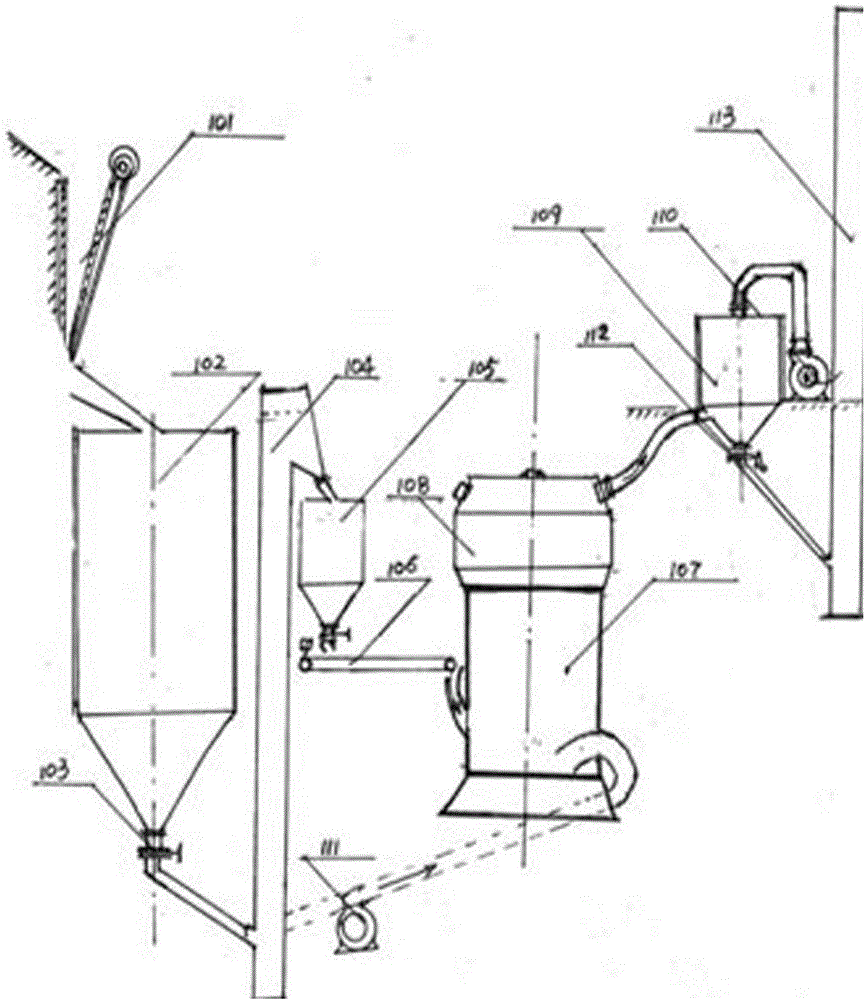

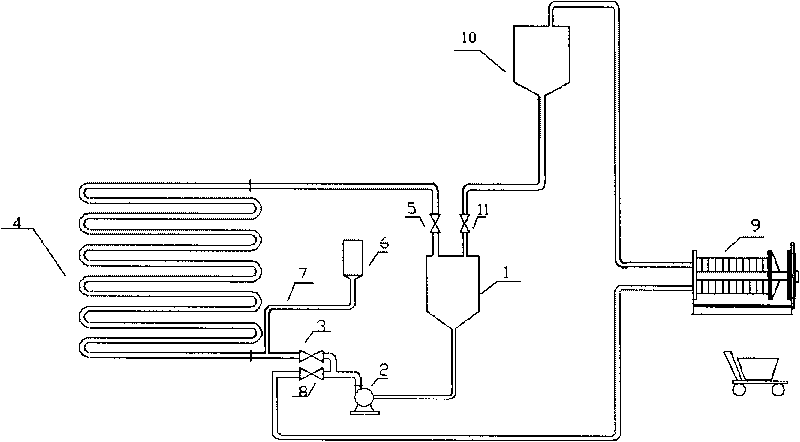

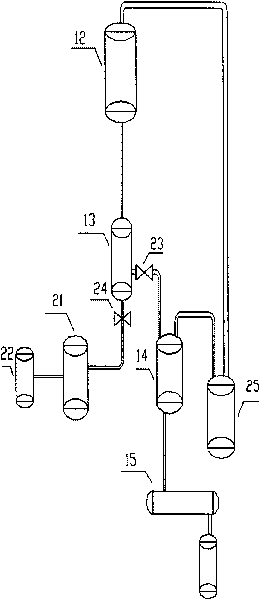

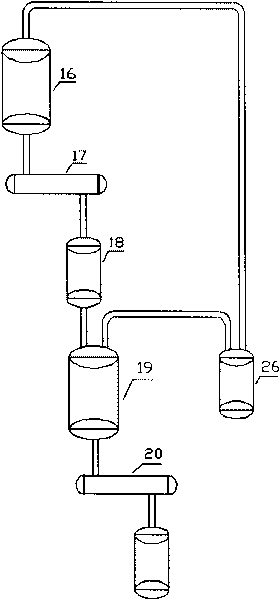

Reaction system for cultivating microalgae and preparing bioenergy

ActiveCN101748053AContinuous preparationContinuous productionBioreactor/fermenter combinationsBiological substance pretreatmentsEnvironmental engineeringOil production

The invention provides a reaction system for cultivating microalgae and preparing bioenergy, which comprises a microalgae cultivation system and a bioenergy preparation system, in particular to an algae suspension collecting tank (1), an algae suspension delivery pump (2), a photoreactor (4), a gas storage tank (6), a plate frame filter (9), a filtrate storage tank (10), an extraction tank (12), an extraction separating tank (13), an extraction distilling still (14), a grease cooler (15), an ester exchange reaction kettle (16), an ester exchange cooler (17), an ester exchange separating tank (18), an ester exchange distilling still (19), a finished product cooler (20), a fermentation tank (21), a gas collecting tank (22), a solvent oil storage tank (25), a methanol storage tank (26) and the like. The reaction system integrates an algae photoreactor, a collecting device, an oil extraction device, an esterification device and a fermentation device into a whole, realizes the continuousness of raw material oil production and bioenergy preparation and has compact structure, high utilization rate and low cost.

Owner:ENN SCI & TECH DEV

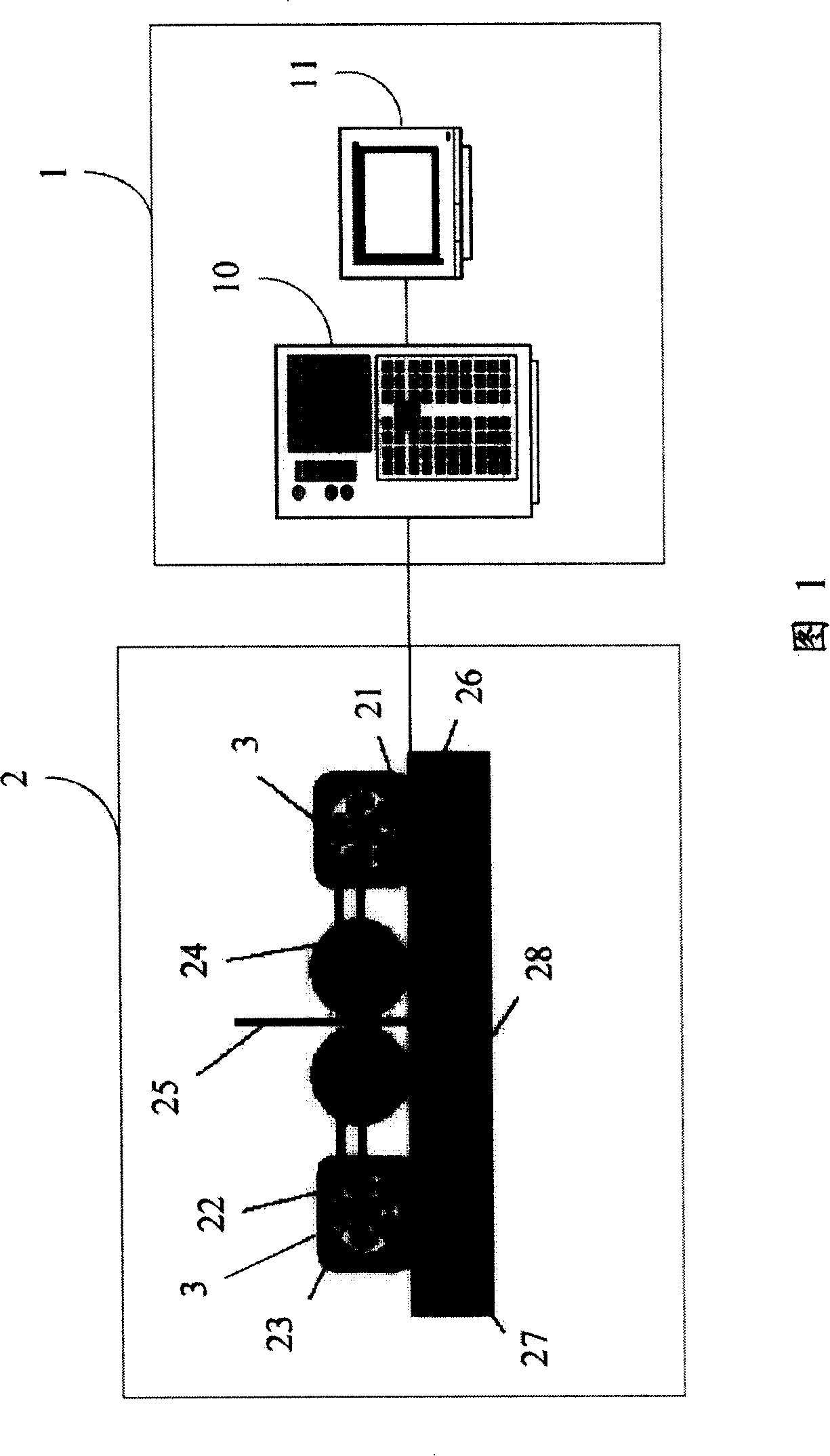

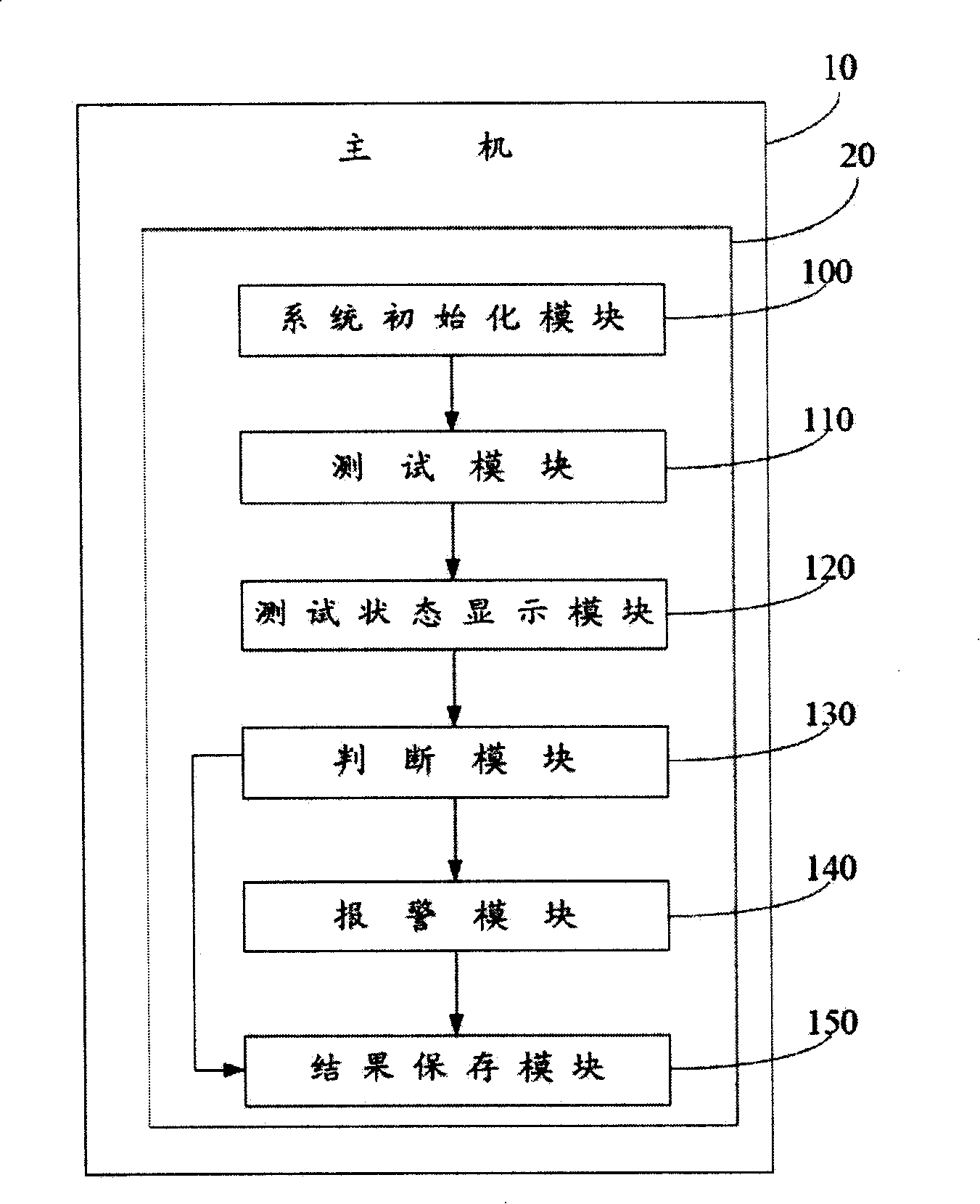

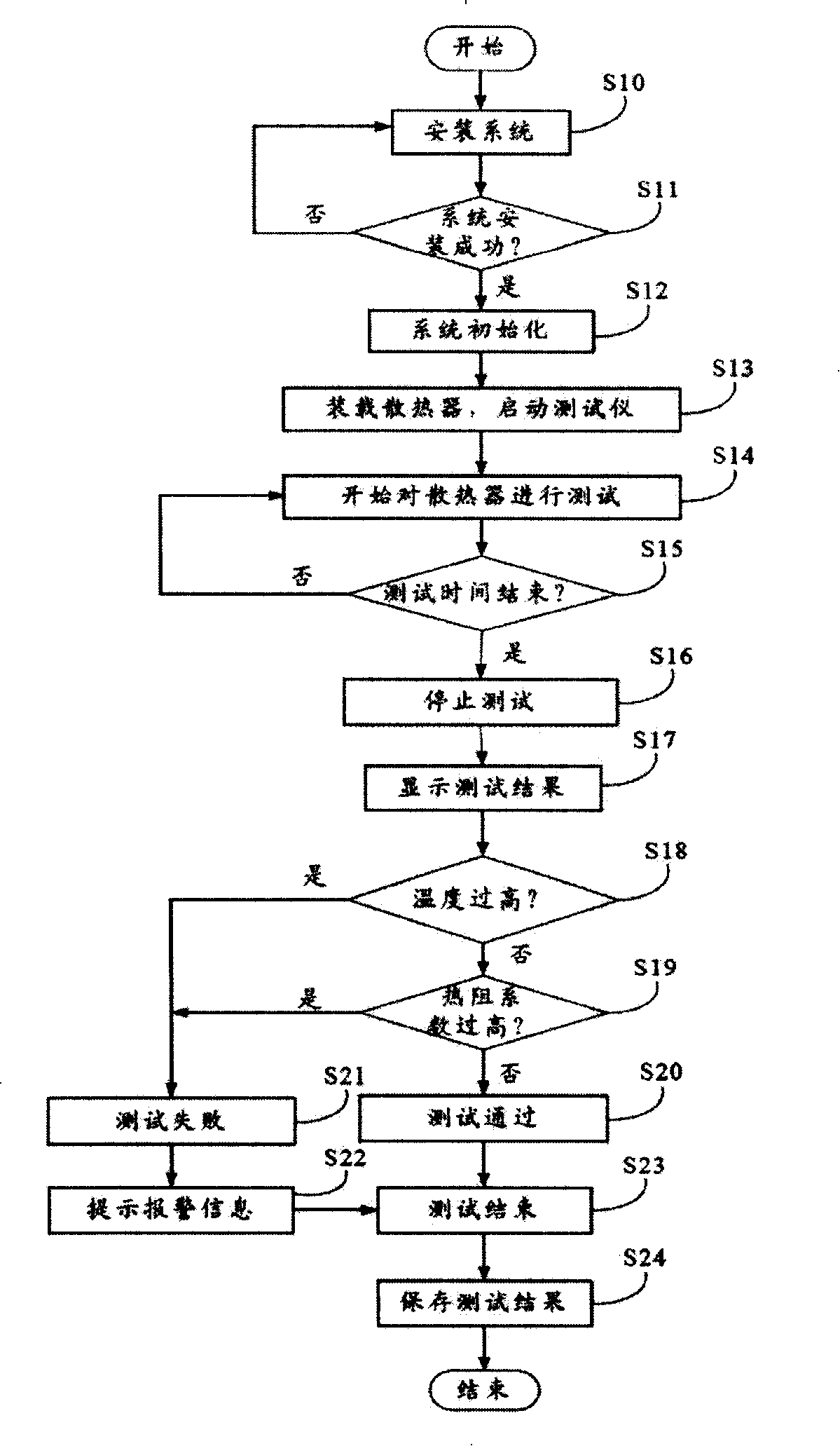

Heat radiator thermal resistivity tester and test system and method

InactiveCN101191780ARealize measurementRational productionMaterial thermal conductivityMaterial heat developmentTester deviceEngineering

The invention provides test method for thermal resistance coefficient of radiator, including the following procedures that: the initialization is set; a radiator thermal resistance coefficient tester is started; within the preset test time, the temperatures on the central position and the edge position of the radiator and the thermal resistance coefficient of the radiator are measured; after the test time is over, whether the temperatures on the central position and the edge position of the radiator are more than corresponding preset values respectively is judged; if the temperatures on the central position and the edge position of the radiator are less than corresponding preset values respectively, whether the thermal resistance coefficient of the radiator is more than a preset value is judged; if the thermal resistance coefficient of the radiator is less than a preset value, the radiator passes the test. The invention also provides a radiator thermal resistance coefficient tester and a test system. Compared with prior art, the radiator thermal resistance coefficient test method and the test system have the advantages of realizing the measurement of the thermal resistance coefficient of the radiator and the collection and analysis of the test data, thereby making the production more reasonable.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Device for connecting two pipes with different external diameters

ActiveUS8651532B2Rational productionReliable self-centeringSleeve/socket jointsPipe connection arrangementsButt jointConical forms

A device for connecting two pipes with different external diameters using a sleeve arrangement which bridges the butt joint between the ends of the pipe facing each other. The device contains at least a fixing sleeve which can take up the clips for the two pipes, and, if necessary, a sealing sleeve which is surrounded by the fixing sleeve. High economy and safety can be achieved by the fact that each sleeve of the sleeve arrangement has cylindrical contact sections which can be adjusted to the different external diameters of the two pipes and are connected by a central section which can take a conical form to suite the diameter difference wherein the contact sections of the sleeve next to the external circumference of the two pipes can be brought into direct contact with the two pipes, and the contact sections of the fixing sleeve contain encircling mounting channels assigned to the clips, and wherein the fixing sleeve takes the form of a closed encircling ring which is suitable for three-dimensional deformation.

Owner:FELBER WINFRIED

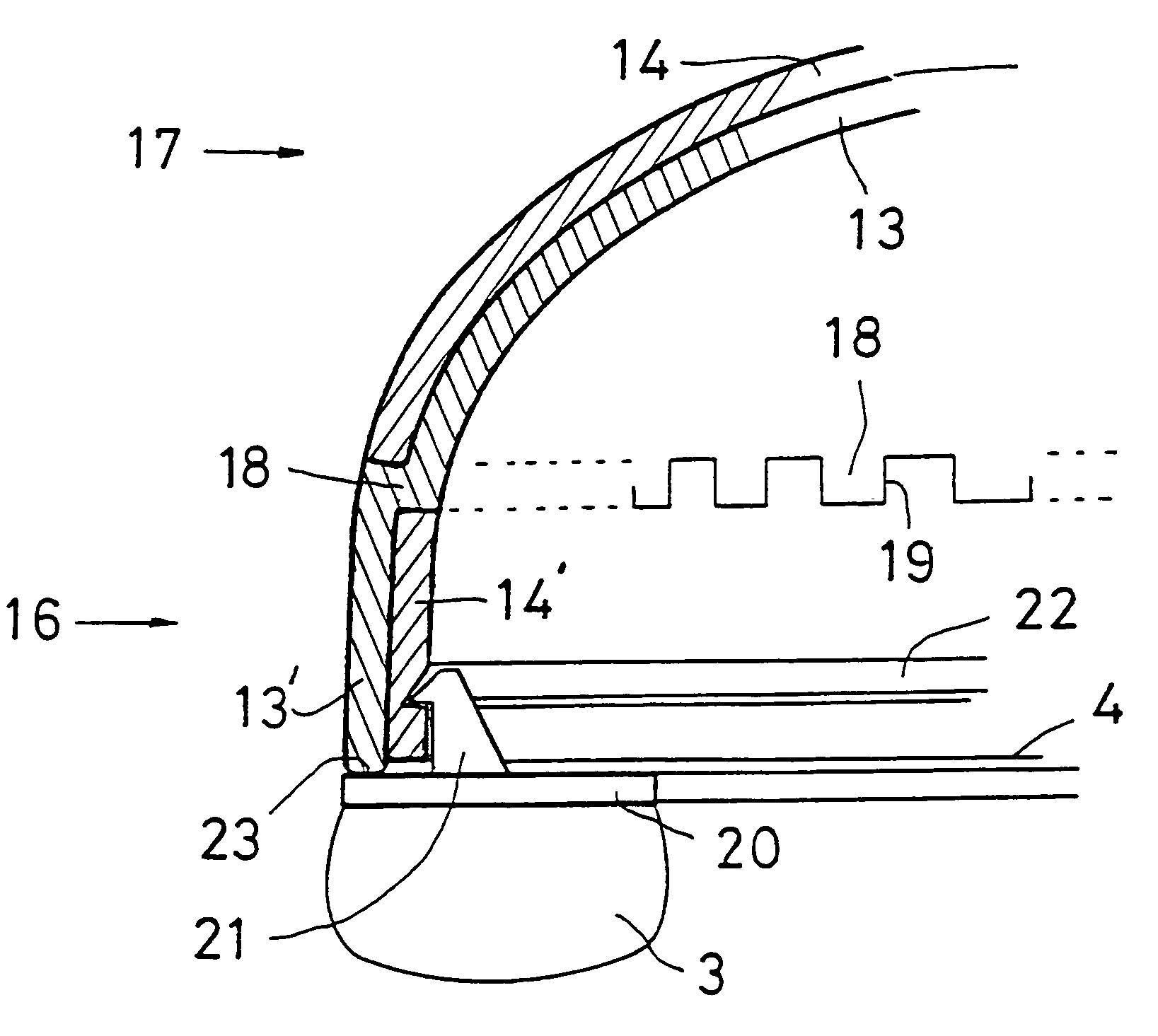

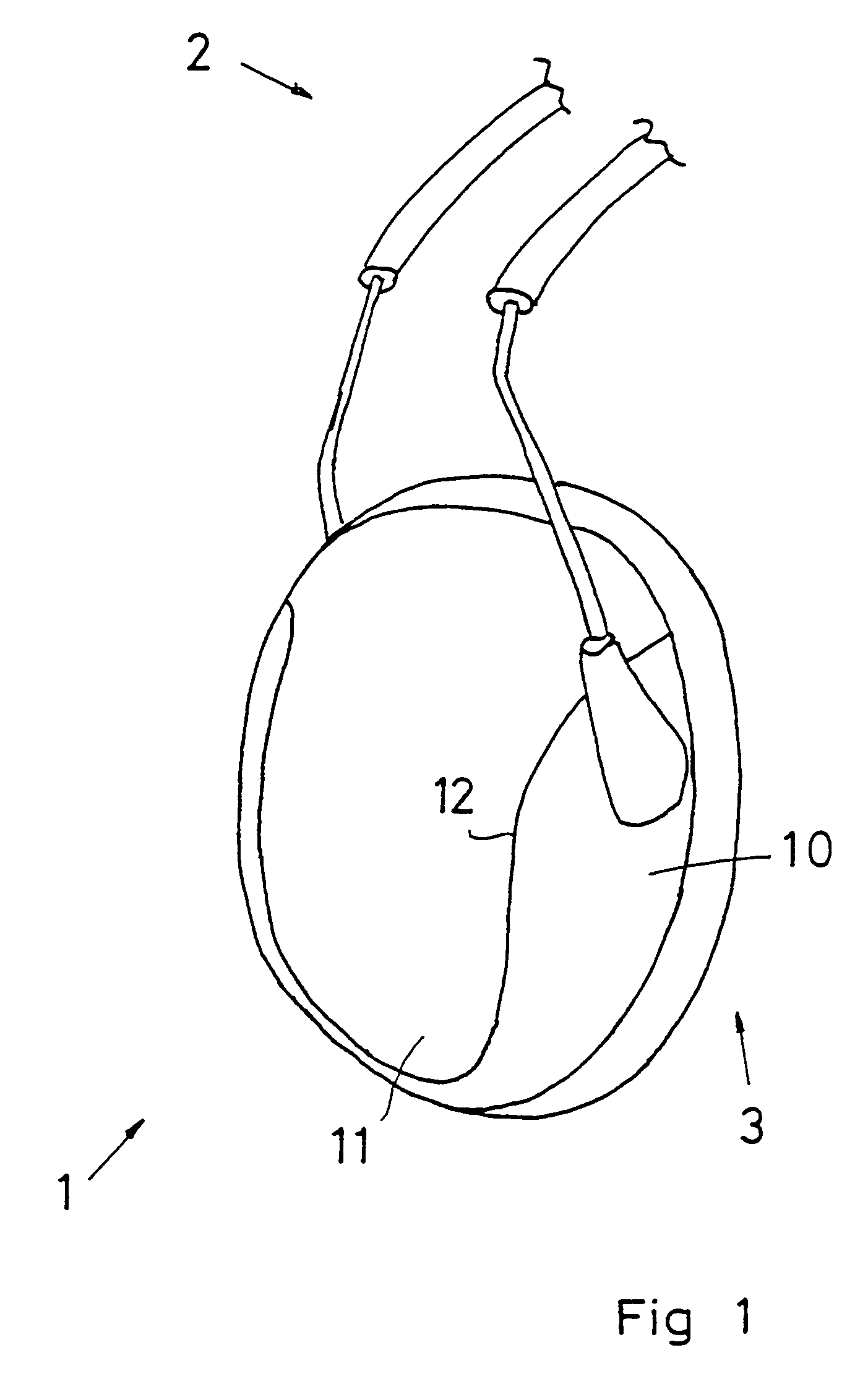

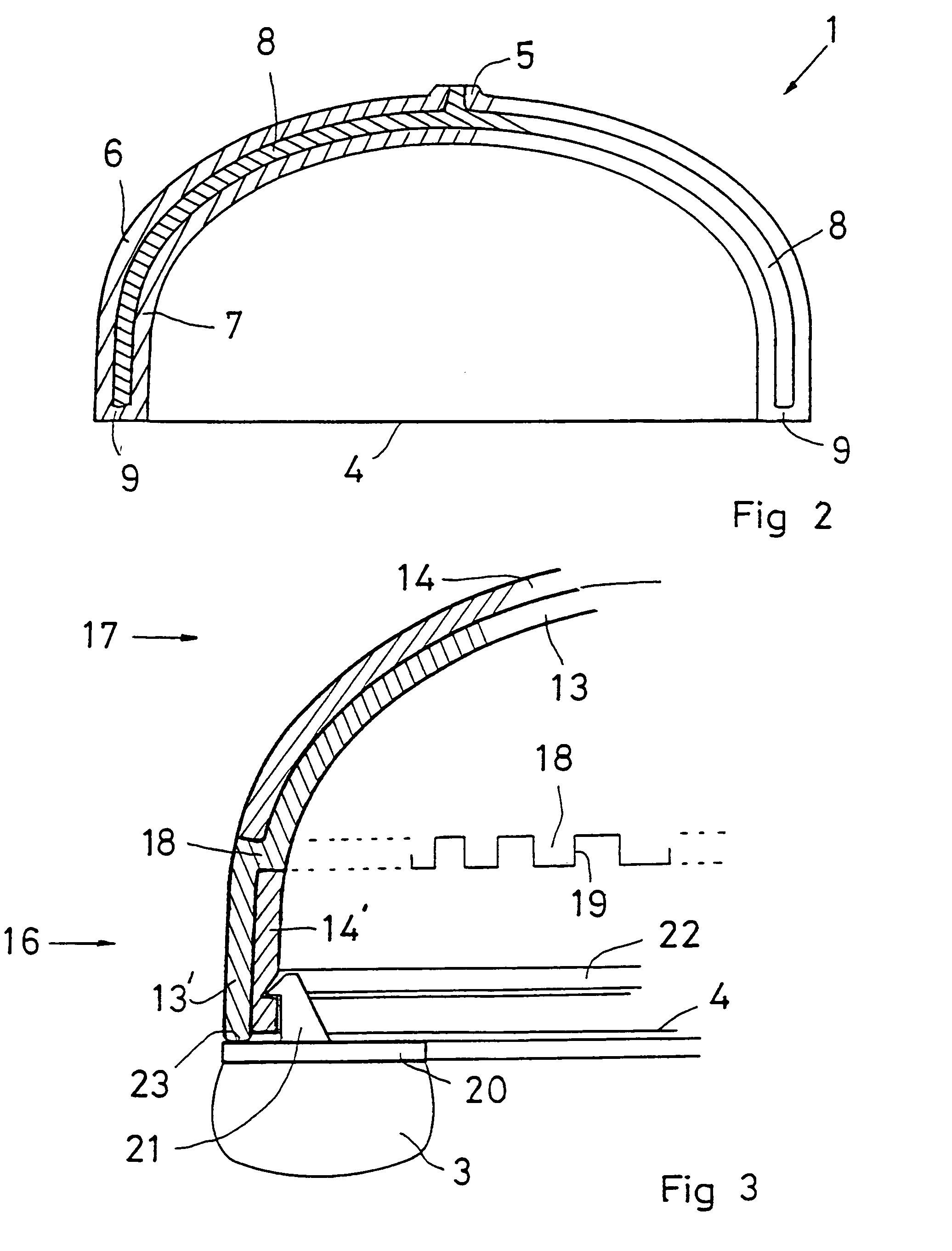

Method of producing a hood, and a hood produced according to the method

InactiveUS7036157B1Improves sound-suppression capabilityRational productionEarpiece/earphone attachmentsHatsPlastic materialsEngineering

The disclosure relates to a method of producing a hood for a hearing protector by injection moulding of plastic material. The hood is injection moulded to a single contiguous piece employing at least two plastic materials possessing different properties in at least one respect. The plastic materials may be both homogeneous and in porous or foamed form. A hood for a hearing protector is produced from plastic by injection moulding. The hood includes at least two portions or layers which are united to one another. The portions or layers consist of plastic materials with different properties in at least one respect.

Owner:3M INNOVATIVE PROPERTIES CO

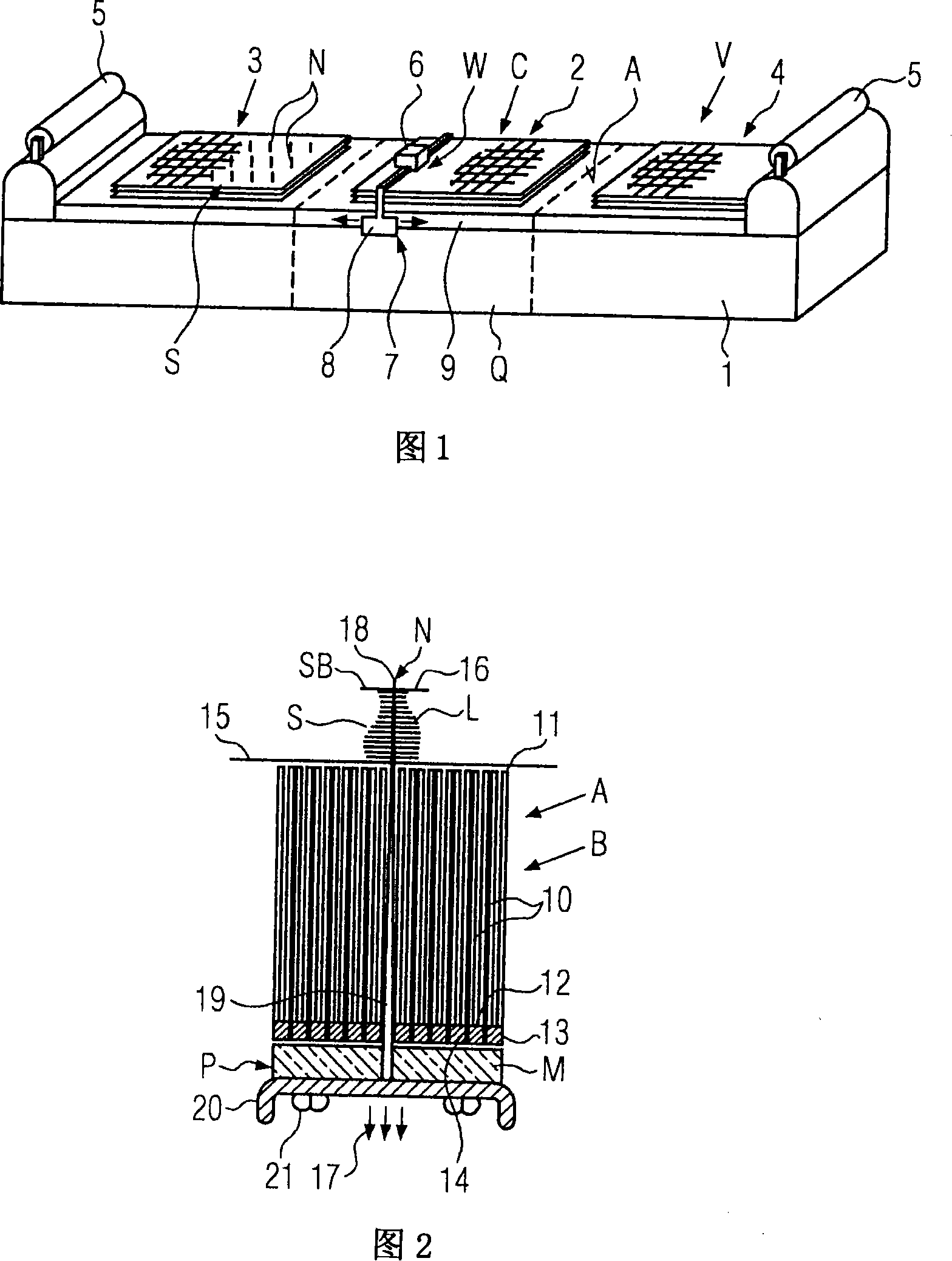

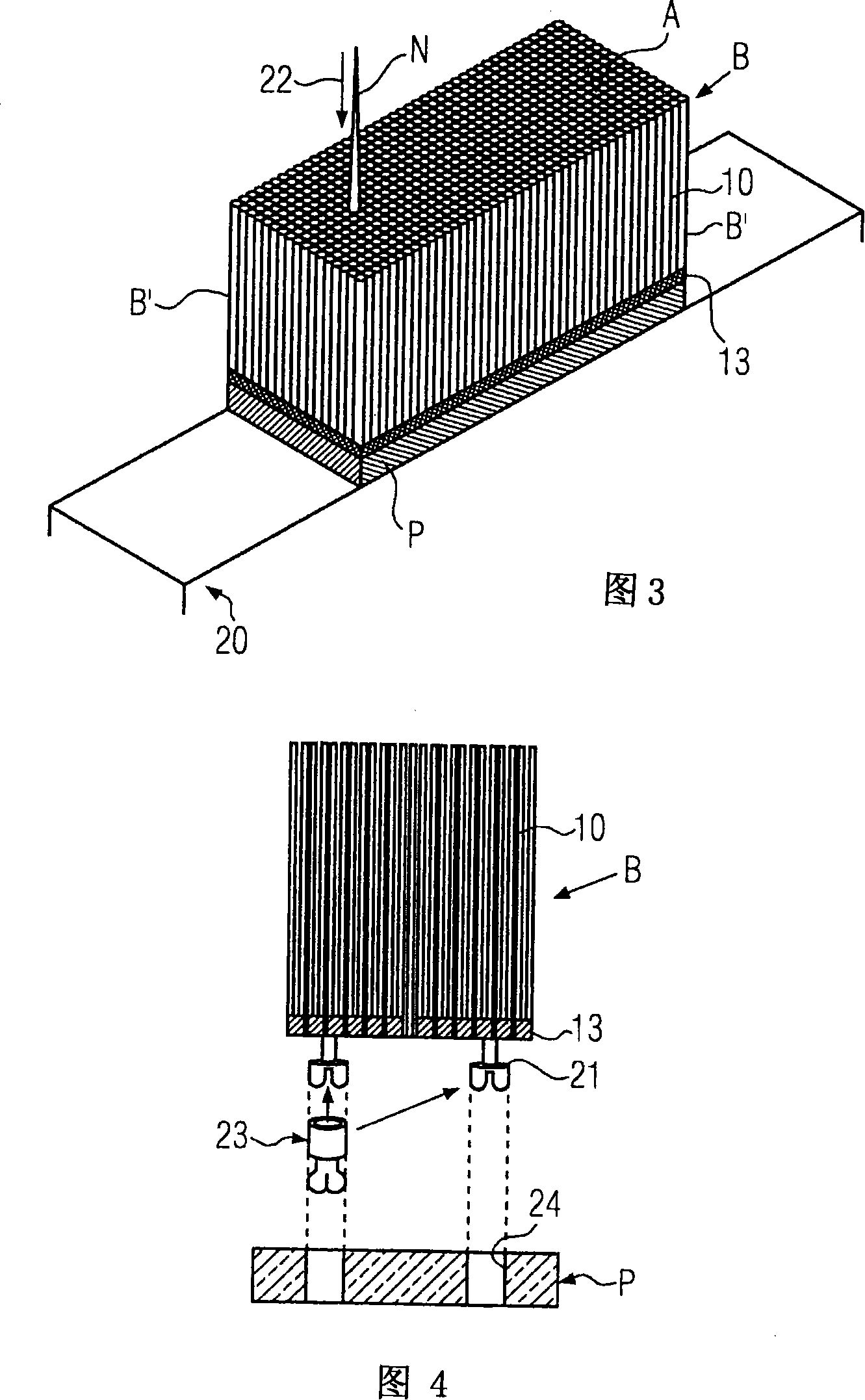

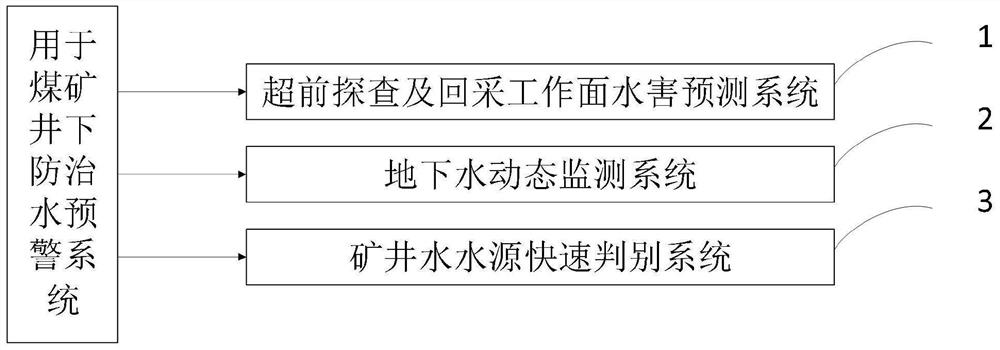

Method and apparatus for pattern cutting

InactiveCN101135111APrecise positioningDoes not affect movementSevering textilesMetal working apparatusBristleBiomedical engineering

A method for tailoring material constituted by pattern material is provided, wherein multilayer cloth layers (L) are aligned with each other accurately through inserted needle (N) according to the position selected by the pattern, the lamination with needles is positioned on a tailoring backing plate (A) and enters into a tailoring cutter (W) thereof to cut the tailoring layers, before the cloth layers are aligned, the needle (N) is positioned in the tailoring backing plate (A), the lamination (S) is formed directly on the tailoring backing plate (A) and perforated by the needle, the lamination with needles is guaranteed without relative position change relative to the tailoring backing plate (A) by the needle before being positioned through the negative pressure, before fixing tailoring, the needle (N) of the lamination is removed when necessary. In a device used in the method, the tailoring backing plate (A) is a bristle layer (B, B') provided with a needle bed layer (P) for positioning needles inserting into bristle (10) temporarily, the length of each needle is at least equal to the summation of the height of the lamination, the thickness of the needle bed layer and the bristle length on the eedle bed layer.

Owner:ESCADA SE

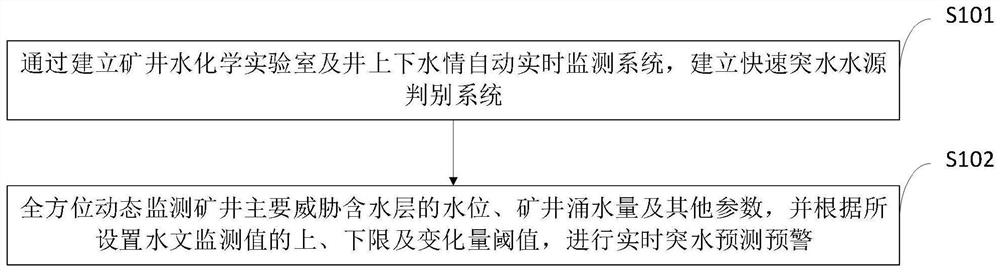

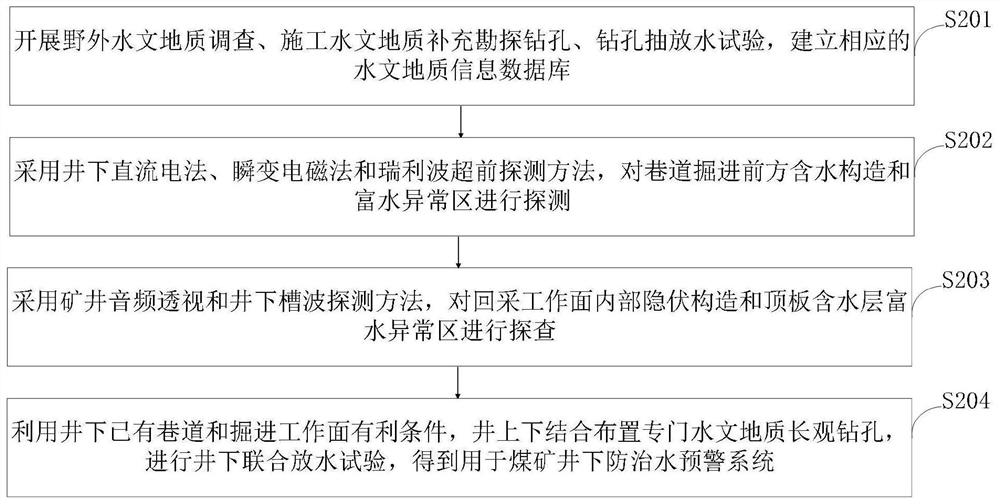

Coal mine underground water prevention and control early warning system and method and application

PendingCN114046178AAccurate detectionEffective predictionSurveyMining devicesHydrometryChemical database

The invention belongs to the technical field of coal mine early warning, and discloses a coal mine underground water prevention and control early warning system and method and application, and the method comprises the following steps: an advanced exploration and stope face water disaster prediction system carries out coal mine water-containing structure and water guide condition detection, and determines stope face water disaster prevention and control technical measures; the underground water dynamic monitoring system acquires and analyzes corresponding data of underground water by using the mining area hydrological dynamic monitoring system; the mine water source rapid discrimination system is based on existing mine data, adopts geophysical prospecting, drilling and geochemical prospecting methods to carry out testing, analysis and determination of mining area water chemical background characteristics, establishes a mining area water chemical database, establishes a discrimination model of water quality of different aquifers in a well field, and rapidly discriminates various water bursting sources. According to the method, mine water inrush prediction and early warning can be carried out in time, targeted water prevention and control measures can be taken in a targeted mode, and safe, economical and reasonable production of a mine and comprehensive utilization of water resources are guaranteed.

Owner:云南滇东雨汪能源有限公司 +1

Electric arc furnace vacuum magnesium smelting system and magnesium smelting method thereof

The invention discloses an electric arc furnace vacuum magnesium smelting system. The electric arc furnace vacuum magnesium smelting system is characterized by comprising a grinding system, a preheating-decomposition system, a calcination system, a secondary heating system, a vacuum reaction system and a condensate collection system which are sequentially connected with one another. A magnesium smelting method of the electric arc furnace vacuum magnesium smelting system comprises the following stages: preliminary preparation; electric arc furnace vacuum magnesium smelting; and startup and shutdown after reaction completion. The electric arc furnace vacuum magnesium smelting system and the magnesium smelting method disclosed by the invention have the advantages that magnesium-containing powder obtained after grinding, decomposition and heating is subjected to vacuum treatment in a molten pool where iron is molten into liquid iron, and then argon gas is injected and high-temperature magnesium powder is sprayed, so that magnesium steam is generated after reduction; after collection and condensation, the magnesium steam turns into liquid magnesium to form rough magnesium; then, a magnesium ingot is cast through refining; the production process is reasonable, compact, matching in equipment, complete in technology, rapid in reaction process, short in time and high in production efficiency; and the production cost is reduced by 1 / 3 or above.

Owner:狄保法

Preparation process of neopentyl polyol oleate

InactiveCN104945247ATake advantage ofReduce high energy consumptionOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePolyol

The invention relates to a preparation process of neopentyl polyol oleate. The preparation process comprises the following steps: by aiming at different batches of purchased neopentyl polyol and oleic acid, firstly determining a theoretical molar ratio required by a complete esterification reaction between neopentyl polyol and oleic acid according to the number of hydroxide radicals in molecules of utilized neopentyl polyol or mixed neopentyl polyol, or carrying out multiple small experiments according to a previous experience molar ratio of neopentyl polyol or mixed neopentyl polyol to oleic acid, ending the experiment when the acid value of a small experiment sample is less than or equal to 1.5mgKOH / g and synthetic liquid and water is well separated, and producing by taking the raw material batch and raw material ratio of the last small experiment as the raw material ratio for large-scale production. The preparation process has the advantages that the raw materials can be adequately utilized, and troubles in after-treatment of products are reduced.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +2

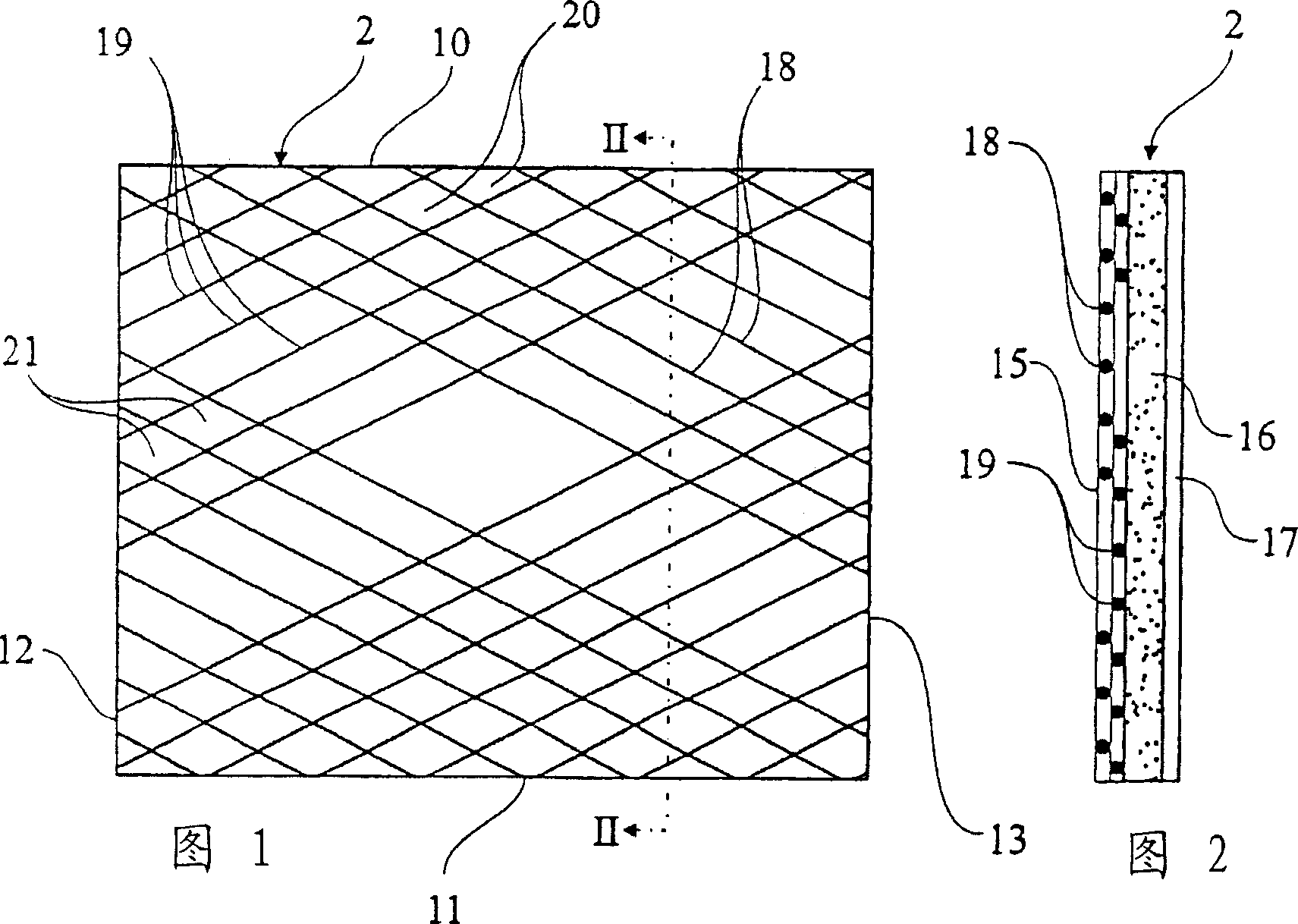

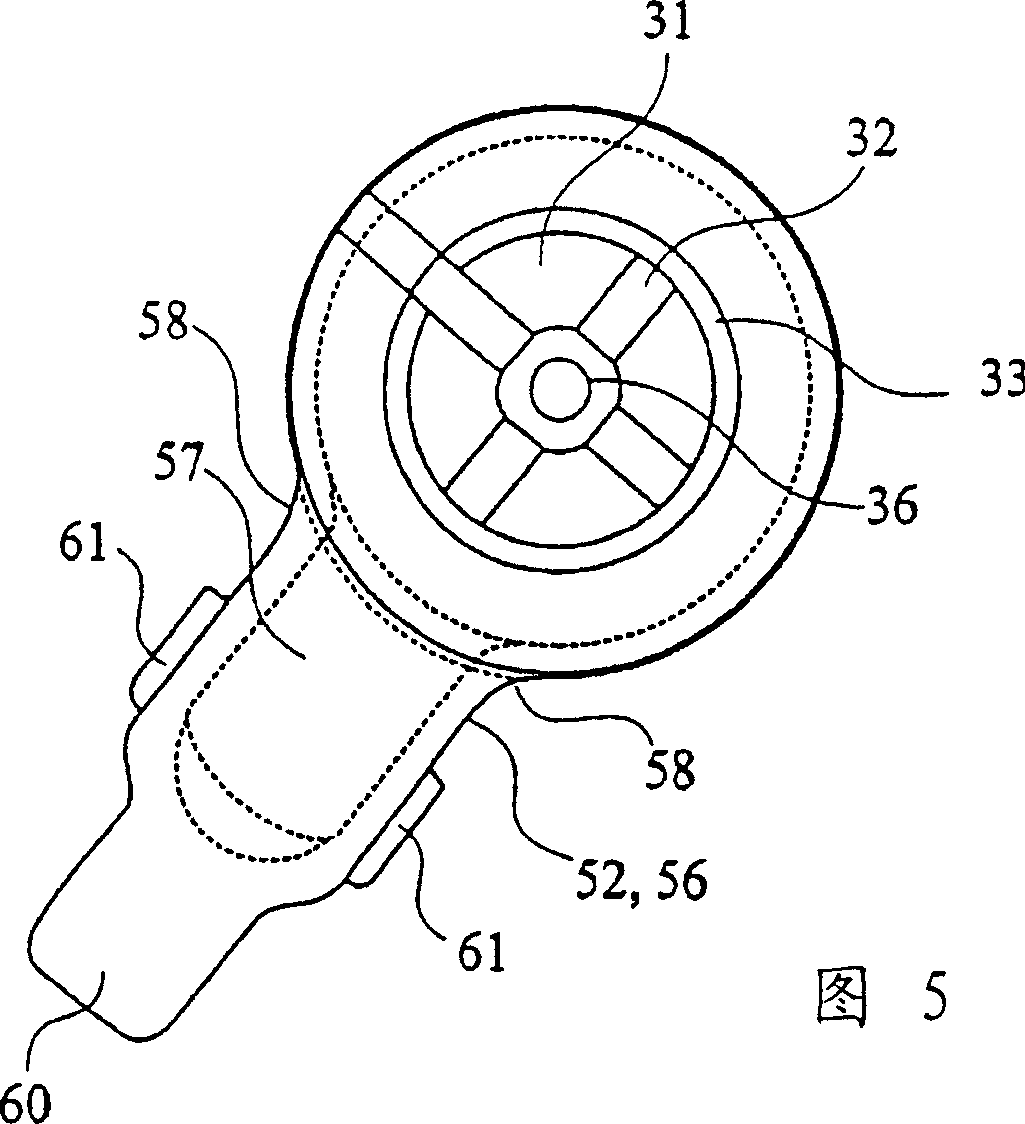

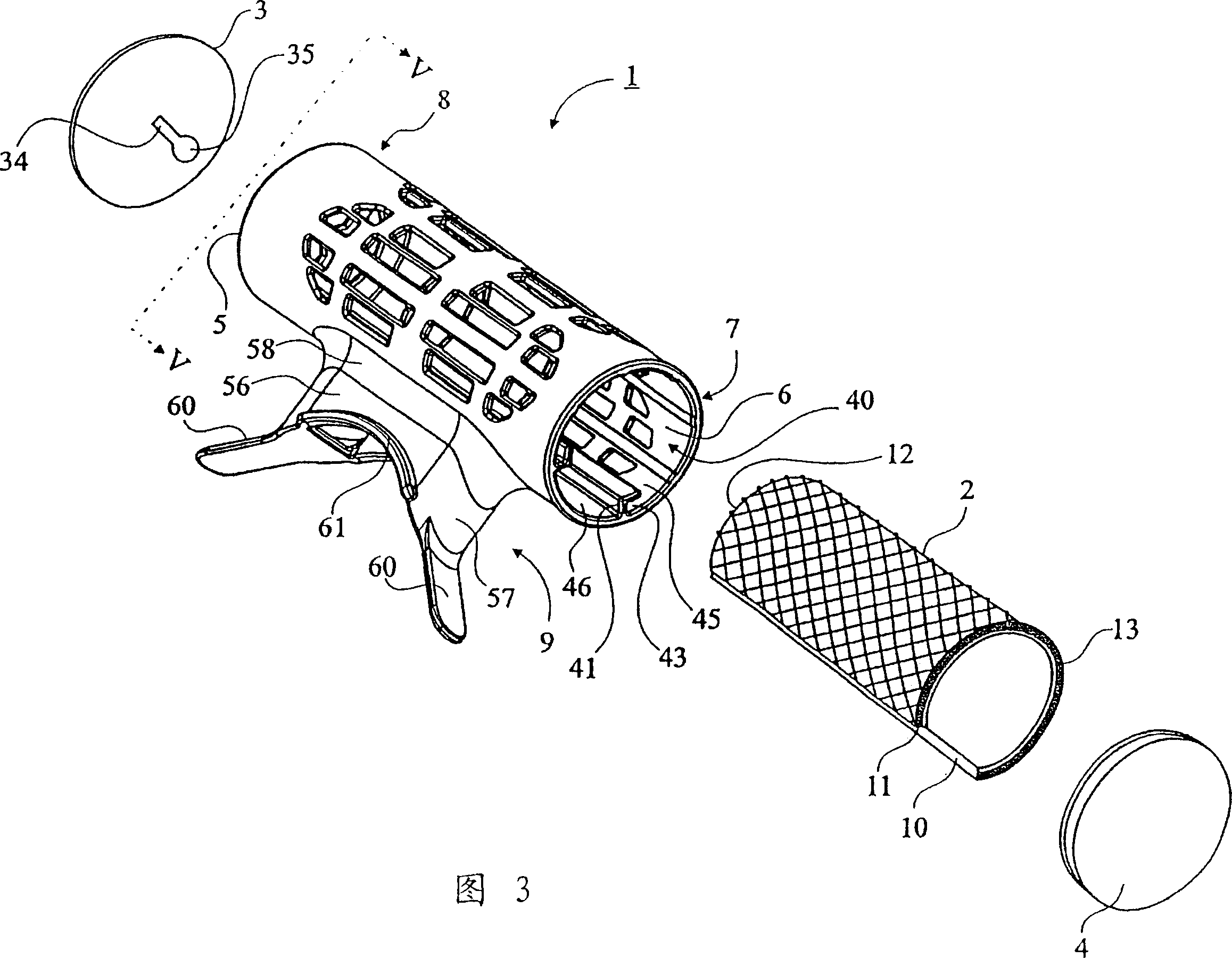

Breathing protective device

The respiratory protection device comprises a filter body (1) having a filter (8) with a filter chamber (40) and a first wall part (45) with a plurality of through holes (47, 47a), at least one The filter (2) in the filter part in the wall part, and the mouthpiece (9) which is arranged to be introduced and received in the user's mouth and the opening in the second wall part (46) of the filter part (8) There is an air passage between ( 53 ) and an opening ( 54 ) at the end of the mouthpiece to be introduced into the user's mouth. The feature is: the filter part (8) has a first end (5), a second end (7) and first and second wall parts (45, 46) extending between the two ends, the filter part is elongated, when the mouth When the profile is inserted into the user's mouth, it extends parallel to the line between the corners of the user's mouth. The first wall part of the filter part has a plurality of through holes (47, 47a) in at least one area, which in the area where the through holes are placed The middle and inner sides extend straight in the direction of the long axis of the filter, the filter part is placed in the filter part chamber, along the second wall part and covers the opening of the wall part, a stopper arranged at the first end is closed during inhalation and opened during exhalation A return valve (3, 33), at least one passage (40) for exhaled air extending between the opening of the first wall part of the filter part and the check valve at the first end of the filter part.

Owner:FILTORO AB

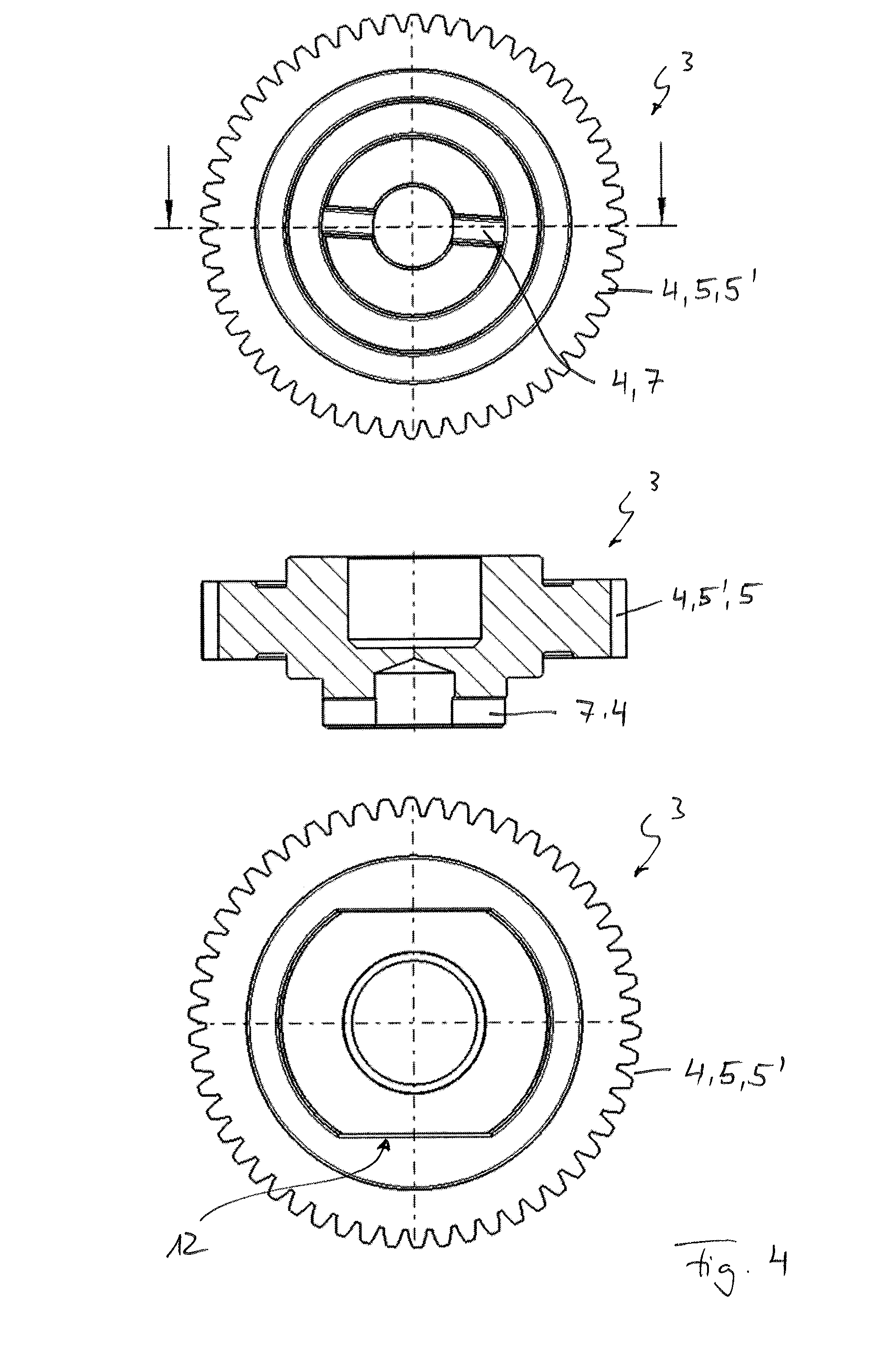

Camshaft

InactiveUS20140165935A1Easy to manufactureLighter in construction weightValve drivesMachines/enginesExternal combustion engineInternal combustion engine

A camshaft of an internal combustion engine may include at least one function device connected therewith via a shaft-hub connection. The function device may include at least two different function elements each operable for different function

Owner:MAHLE INT GMBH

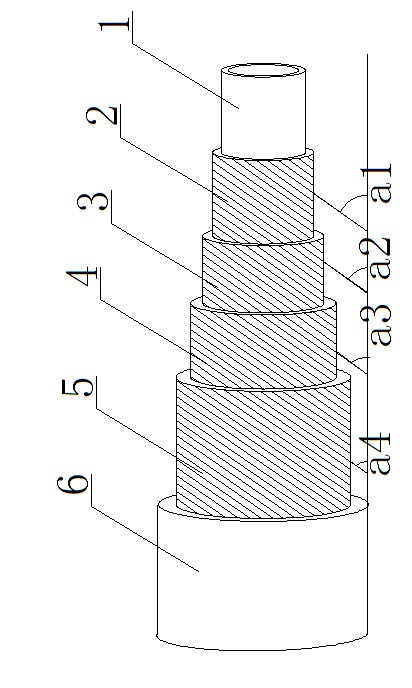

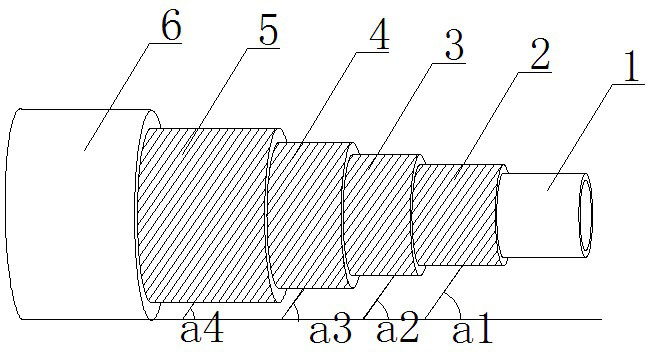

Pulse-resistant steel-wire winding hydraulic rubber pipe

The invention discloses a pulse-resistant steel-wire winding hydraulic rubber pipe. The pulse-resistant steel-wire winding hydraulic rubber pipe comprises an inner-layer blank pipe and an outer-layer protecting layer, wherein a steel wire skeleton is wound on the outer wall of the inner-layer blank pipe, and is formed by four-layer steel wires and middle films which are spirally wound in sequence from inside to outside; and the outer diameters of the spiral lines of the spiral winding layers of the four-layer steel wires are different, and the angles of spiral lines of the spiral winding layers of the four-layer steel wires are also different. The pulse-resistant steel-wire winding hydraulic rubber pipe is optimally designed for the arranging mode of the steel-wire skeleton of ultrahigh-pressure winding rubber pipes, gets out of the original situation that the matching of the winding angles of the steel wire skeleton and the angles of all the layers of steel wires is designed and determined by experience, guarantees more reasonable production of the steel-wire winding rubber pipe, and enables the quality and the service life of the product to be greatly improved. The pulse-resistant steel-wire winding hydraulic rubber pipe disclosed by the invention has the advantages that by application of the technical analysis and the optimized design, the structure of the steel wire skeleton of the original hot-oil-resistant ultrahigh pressure winding rubber pipe is more reasonable, and further the service life of the rubber pipe is greatly prolonged; 3-5 ten-thousand times in the original design is increased to be more than 9 ten-thousand times after the optimal design by a finished-product pulse test; and the service life of the hot-oil-resistant high-performance steel-wire winding rubber pipe product is greatly prolonged.

Owner:LUOHE LETONE RUBBER

Producing method of dried muskmelon

InactiveCN103976302AImprove the ability of deep processingReduce wasteConfectionerySweetmeatsMusk melonProcess engineering

The invention discloses a producing method of dried muskmelon. The method includes: selecting fresh muskmelon, cleaning, sterilizing, peeling, taking flesh, cutting into slices, hardening, performing color protecting, blanching, performing solute osmosis, drying and reshaping. Beneficial effects of the producing method are that: the producing method overcomes the color browning problem of the muskmelon, preserves the original color and flavor of the muskmelon, enhances the deep processing capability of agricultural and sideline products, adopts rejected muskmelon as the raw material for deep processing of the muskmelon so as to achieve full utilization of raw materials, reduces waste of the muskmelon resource, completes muskmelon industrial production through producing downstream muskmelon products, increases the kinds of the agricultural and sideline products subjected to deep processing in Xinjiang, and enriches the market; and the producing method utilizes the resources reasonably and protects the environment.

Owner:丁保林

Lightweight wood-plastic mixed granules containing straws and production method thereof

The invention discloses lightweight wood-plastic mixed granules containing straws and a production method thereof, and relates to the technical field of plastic raw material granules. After natural straws, cork powder, polypropylene and plastic aid are mixed, the mixture is extruded and granulated through double screws; the density of the formed granules can be 900kg / m<3>, and the raw materials or the wastes can be separated together with the polypropylene in a centrifugal separation system; and the mixed granules have low machining temperature, good mechanical strength and excellent machinability, and can be repeatedly machined and formed without changing the density. By the production method, the consumption of non-degradable petroleum-based plastic can be reduced, oil crisis is retarded, and an innocent treatment and a good purpose are provided for agricultural wastes; and the production method is favorable for saving resources and protecting the environment.

Owner:JIANGSU JINHE HI TECH

Method and device for producing a package for smoking articles

ActiveCN103492169ARational productionEnvelopes/bags making machineryMechanical working/deformationCardboardMetal foil

The method involves forming an outer layer that accommodates bar-shaped smoking articles and holds a package together. A printed or plain foil strip (3) is embossed and / or provided with creasing breaks in a process cycle (P) of a packaging machine (7), where the foil strip is suitable for the outer layer. The strip is cut, and the resulting blank (19) is folded around the articles in the packaging machine. The outer layer is made of a light material e.g. paper, thin cardboard, hybrid foils, multi-layer coated foils of different materials or paper- and plastic foils or metal foil. An independent claim is also included for a device for producing a package for rod-shaped smoking articles.

Owner:BOEGLL GRAVURES SA

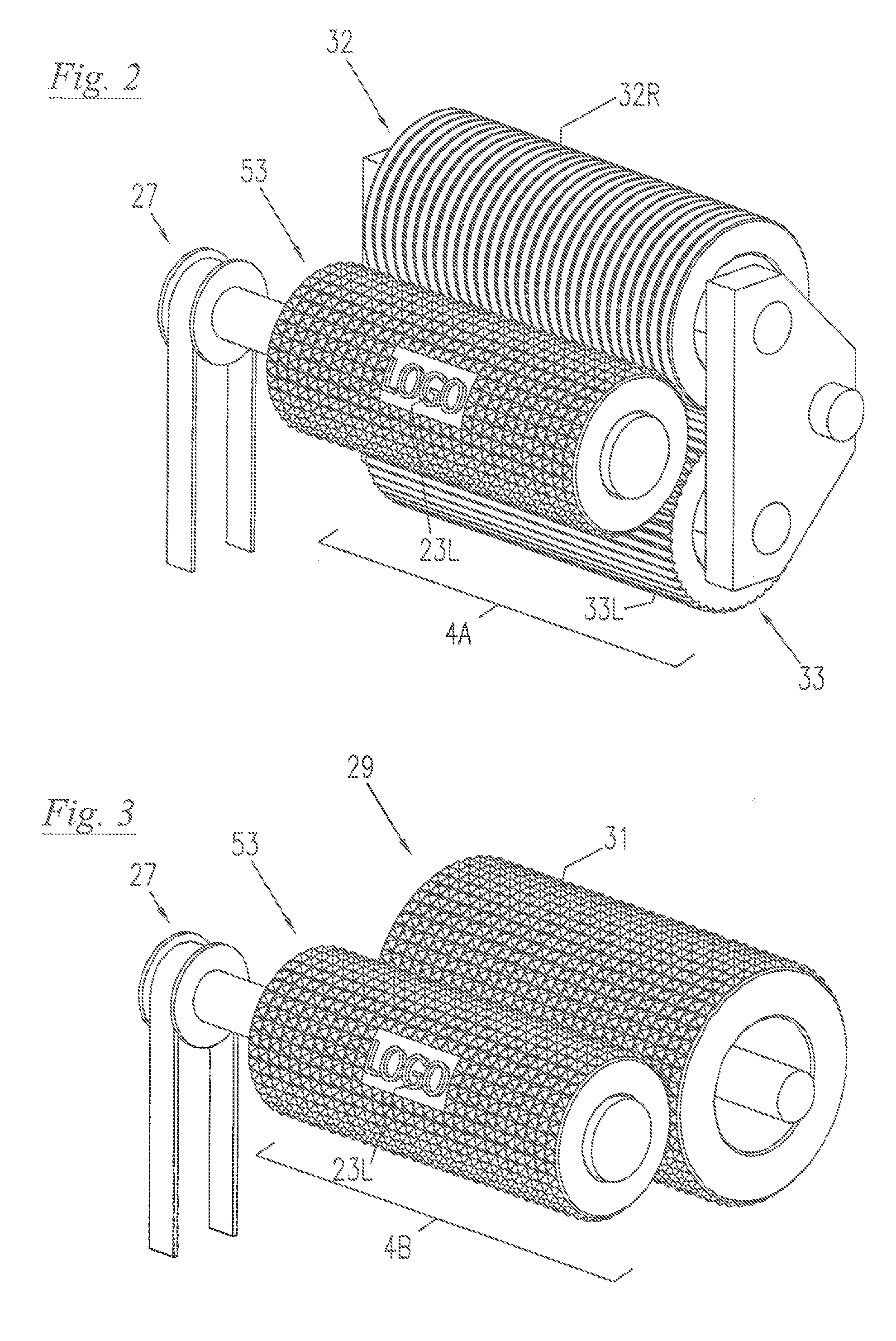

Device and method for producing container blanks

ActiveUS7674219B2Rational productionEasy accessEnvelopes/bags making machineryBag making operationsEngineeringTool path

A device for producing container blanks from a material web having a plurality of tools supported by a rotary tool holder. The tool holder is on rotation arranged to move each tool along a working path along which each tool is engageable with the material web for joining of opposite wall portions of the material web along connecting portions, and a return path along which each tool is disengageable from the material web. Each tool is arranged to be moved together with the material web when the tool is moved along the working path and the tool holder acts as a deflector for the material web when this moves together with the respective tools along the working path. The present invention also relates to a corresponding method for producing container blanks.

Owner:ECOLEAN

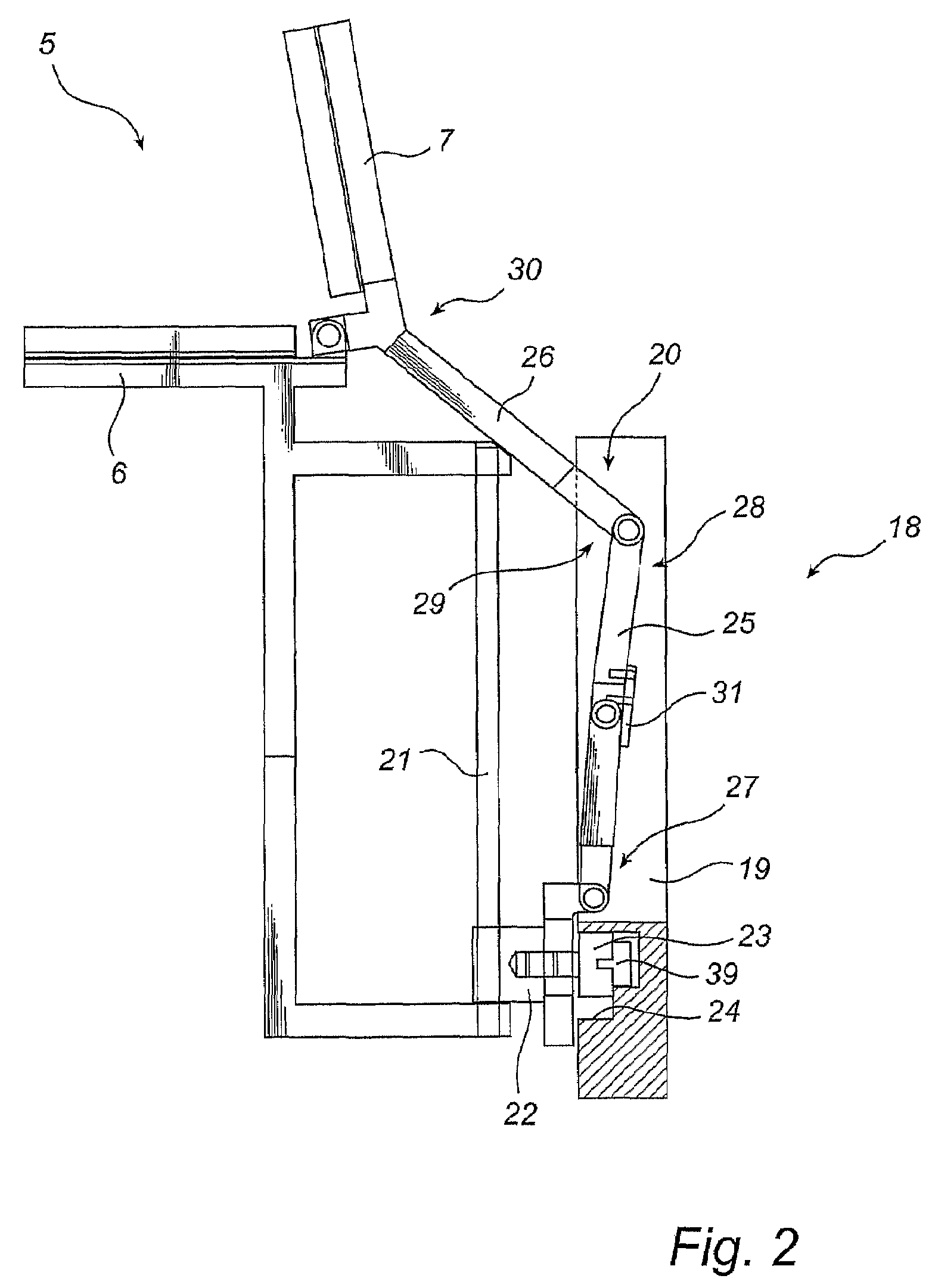

Management system for digital welding workshop

InactiveCN106563898AImprove practicalityIncrease productivityData processing applicationsWelding/cutting auxillary devicesProduction scheduleWork status

The invention discloses a management system for a digital welding workshop. The system comprises an equipment state management module, a quality analysis module, a production scheduling module and a technology assigning module; the quality analysis module analyzes the stability of welds and monitors defects of the welds; the equipment state management module acquires and displays the current working state and the historical working state of equipment; the production scheduling module sequences existing orders and determines the time when each task is conducted; and the technology assigning module assigns manually input technological parameters to the equipment through hardware circuits. Functions and the practicability of the quality analysis module are enriched, and the sequence of workpiece assembly processes is guided by the production scheduling module, so that the process of a processed product from a raw material to the final product is more reasonable and specific; and welding technology parameters are fixed by the technology assigning module, the non-standard operation of manual adjustment is avoided, the digital degree and the production efficiency of the workshop are improved, the production process of the workshop is standard and reasonable, and an administrator manages the workshop conveniently.

Owner:NANJING UNIV OF SCI & TECH

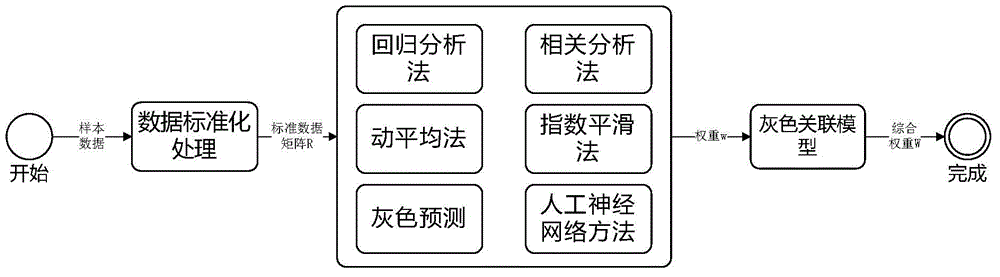

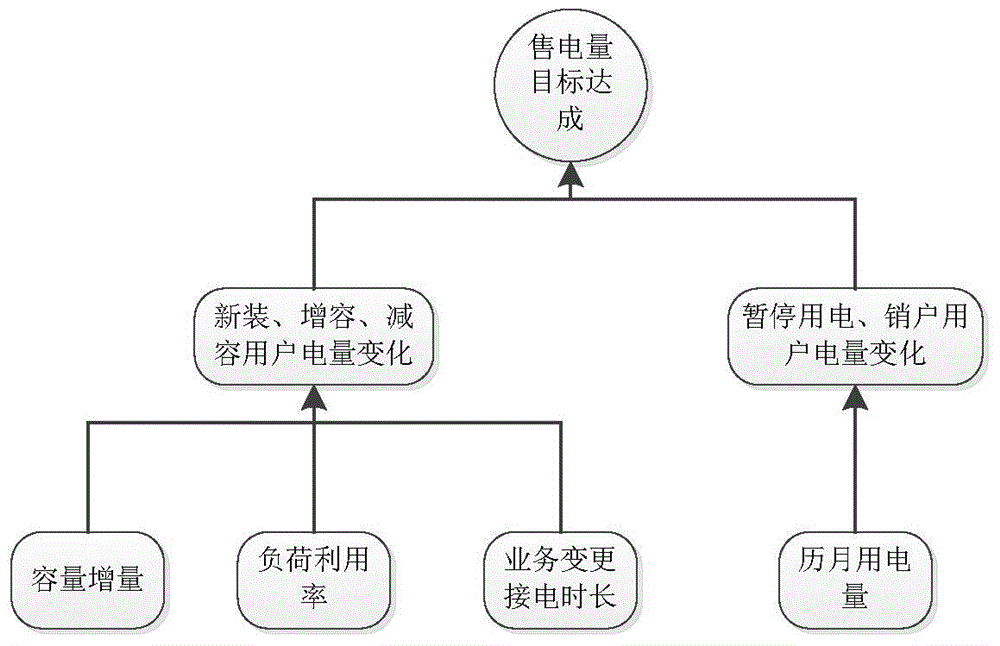

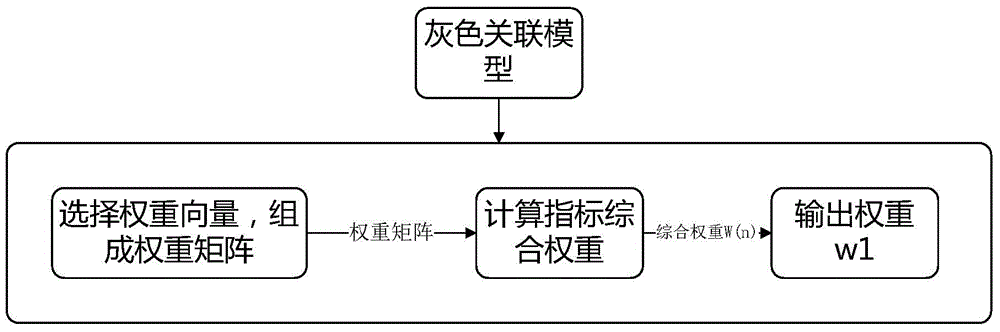

Method for short-term or long-term prediction of electricity sales amount changes of enterprises based on grey correlation

The invention discloses a method for short-term or long-term prediction of electricity sales amount changes of enterprises based on grey correlation. The method comprises the following steps: S1, obtaining capacity increment, load utilization rate, (power connection duration in business change), electricity-consumption-pausing electric quantity data and account-cancellation electric quantity data, generating index data, and performing dimensionless treatment on the index data; S2, substituting the index data into a weight model library for calculation, and generating an index weight matrix; S3, calculating comprehensive weight of each index according to a grey correlation algorithm; S4, performing short-term (long-term) prediction on the electricity sales amount changes of the enterprises according to the comprehensive weight of the index. The method can improve the short-term or long-term prediction precision of the electricity sales amount changes of the enterprises.

Owner:LONGSHINE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com