Pulse-resistant steel-wire winding hydraulic rubber pipe

A technology of steel wire winding and steel wire, which is applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., can solve the problems of unreasonable production of steel wire winding hoses, affecting the quality and life of hydraulic hoses, and easy displacement of the skeleton layer. Achieve the effect of improving quality and life, improving service life and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

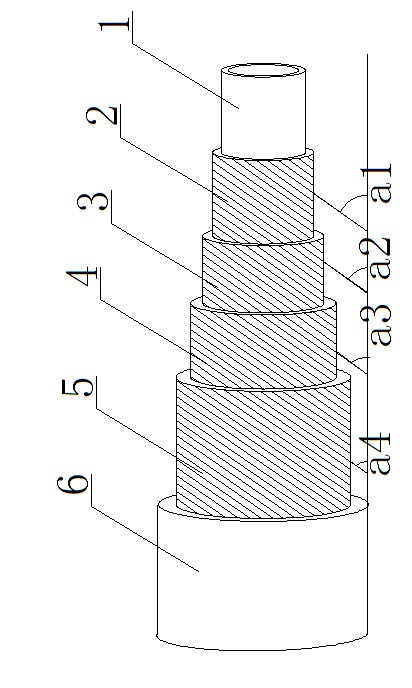

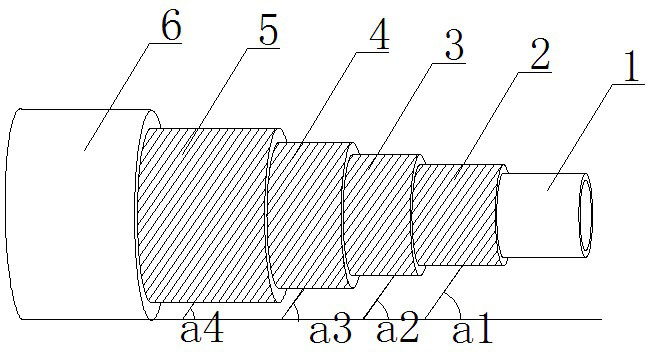

[0012] Such as figure 1 The shown pulse-resistant steel wire wound hydraulic hose includes an inner germ tube 1 and an outer protective layer 6. A steel wire skeleton is wound on the outer wall of the inner germ tube 1. The steel wire skeleton has four layers of steel wires from inside to outside. The outer diameter of the helix of the four-layer steel wire helical winding layer is different, and the angle of the helix of the four-layer steel wire helical winding layer is also different.

[0013] The present invention is illustrated by taking the inner diameter of the inner germ tube as 25 mm as an example: the inner diameter of the inner germ tube 1 is 25 mm, the helix angle a1 of the first layer of steel wire 2 is 54.7 degrees, the outer diameter is 31.1 mm, and the stroke is 68 mm. The helix angle a2 of the layer steel wire 3 is 54.5 degrees, the outer diameter is 32.6 mm, and the stroke is 72 mm. The helix angle a3 of the third layer steel wire 4 is 55 degrees, the outer d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com