Electric arc furnace vacuum magnesium smelting system and magnesium smelting method thereof

A technology of electric arc furnace and vacuum electric arc furnace, applied in the field of metal smelting system, can solve the problems of high production cost, large investment and production scale, large heat loss, etc., and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

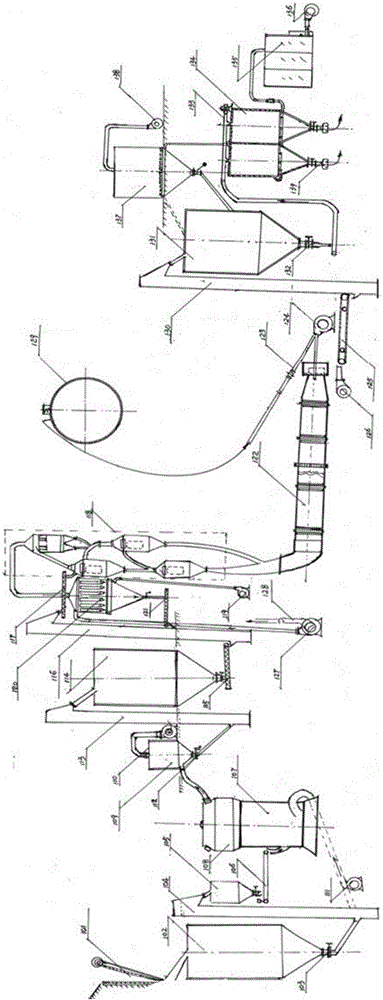

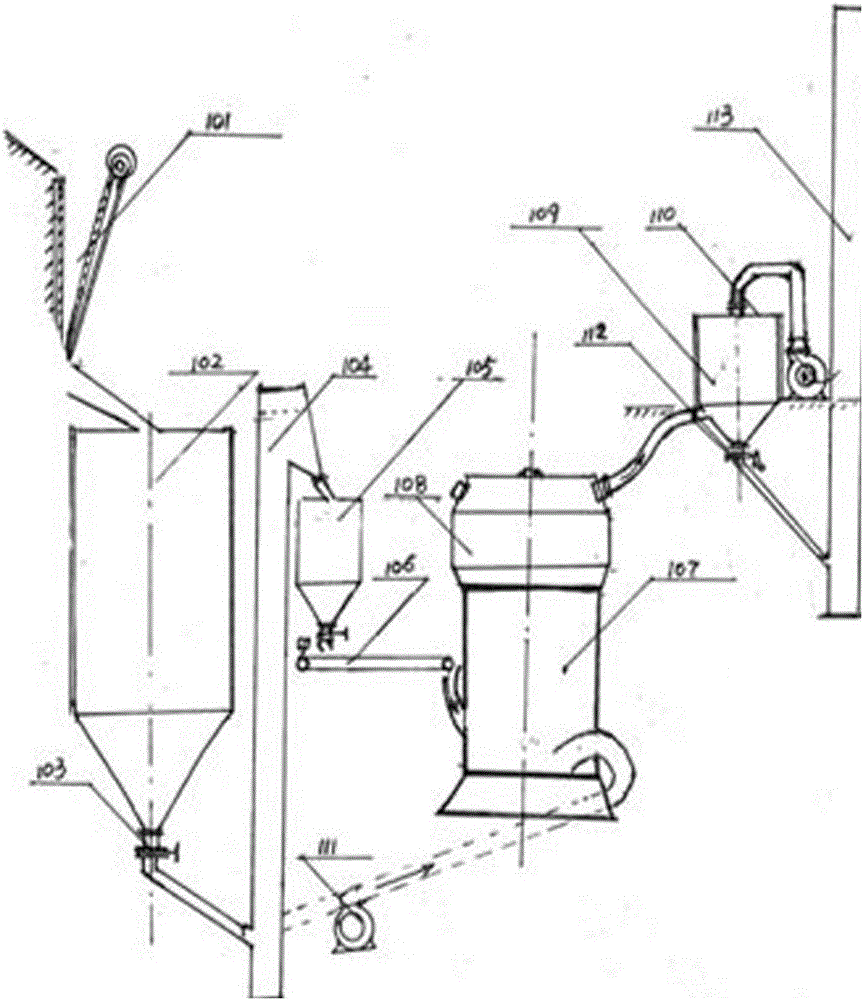

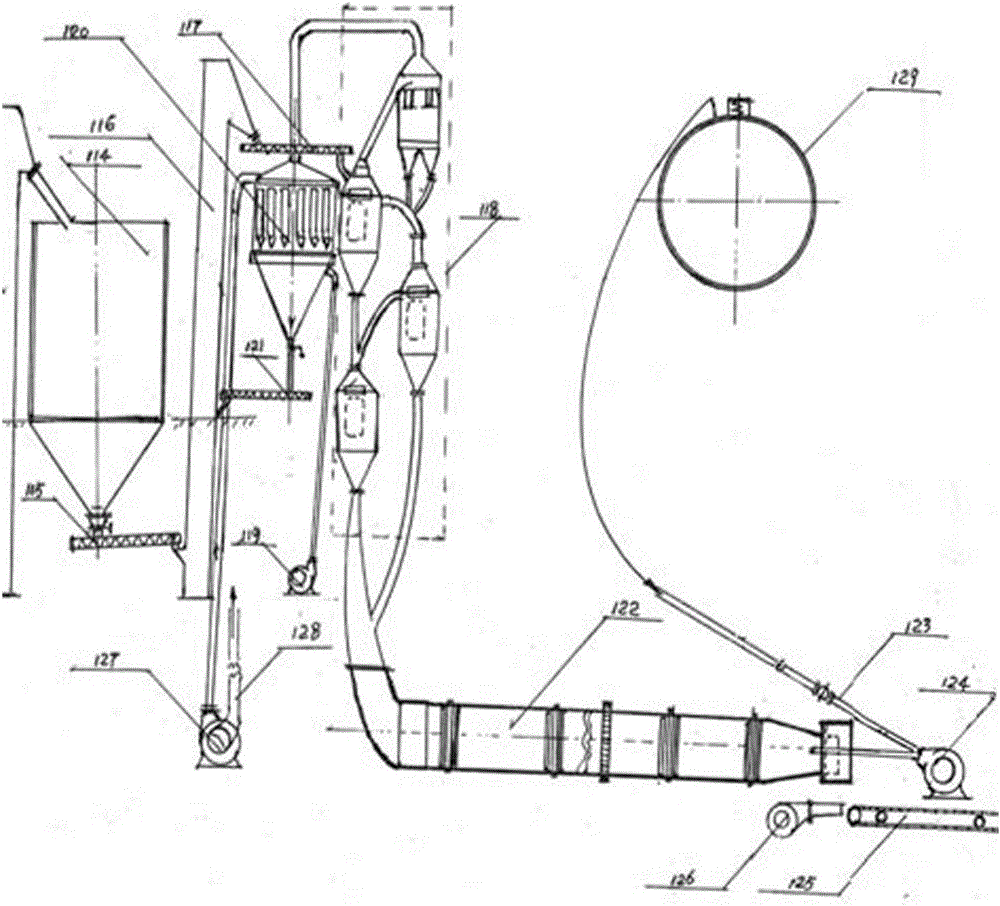

[0050] as attached figure 1 and 2 As shown, this embodiment discloses a vacuum induction furnace magnesium smelting system, including a grinding system, a preheating decomposition system, a calcination system, a secondary heating system, a vacuum reaction system, and a condensation collection system connected in sequence. The collection system is equipped with a dust exhaust and gas collection system; among them:

[0051] The grinding system includes a crusher 101, a storage house 102, a first hoist 104, a grinding head stabilization bin 105, a vertical mill 107, a separator 108, a first dust collector 109, and a second hoist 113 connected in sequence 1. The first storage warehouse 114, the separator 108 is connected to the top of the vertical mill 107, and is connected in series with the first dust collector 109 and the first exhaust fan 110 in seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com