Reaction system for cultivating microalgae and preparing bioenergy

A bioenergy and reaction system technology, applied in the field of bioengineering and clean energy, can solve the problems of environmental constraints, high cost, long growth cycle, etc., and achieve the effect of continuous preparation, low cost and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

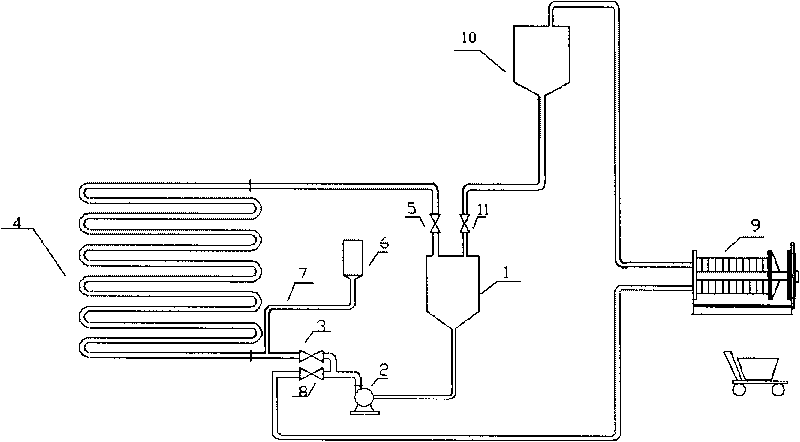

[0037] Embodiment 1: Utilize annular tubular photoreactor to cultivate microalgae

[0038] Add the prepared medium into the filtrate storage tank (10), and press the medium from the filtrate storage tank (10) into the algae liquid collection tank (1) by using the gravity difference. Turn on the algae liquid delivery pump (2), pump the culture medium through the outlet 1 (3) of the algae liquid delivery pump to the glass photoreactor (4), and finally flow back to the algae through the upper port 1 (5) of the algae liquid collection tank. liquid collection tank (1). Then the algae liquid is inserted into the culture medium through the algae liquid collection tank (1). CO 2 The gas is stored in the gas storage tank (6) and passed into the pipeline of the photoreactor through the vent pipe (7).

Embodiment 2

[0039] Example 2: Collection of microalgae from photoreactors

[0040]When collecting microalgae, close the outlet 1 (3) of the algae liquid delivery pump, open the outlet 2 (8) of the algae liquid delivery pump, and pump the algae liquid into the plate and frame filter (9), the algae mud remains on the filter paper, and the remaining medium Pump into the filtrate storage tank (10) for supplementation of culture medium or re-cultivation. The algae mud on the filter paper was collected for the production of bioenergy. Among them, the plate and frame filter is produced by Shanghai Dazhang Filter Equipment Co., Ltd., and the model is BMY5 / 450-30U.

Embodiment 3

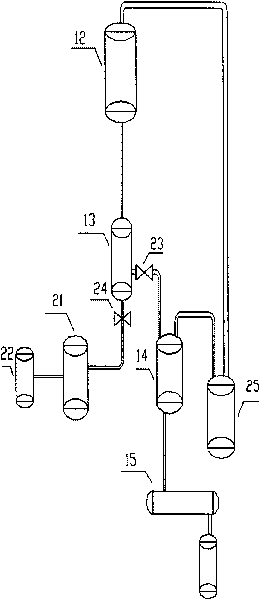

[0041] Embodiment 3: the preparation of biodiesel

[0042] The algae mud is put into the extraction tank (12), and the solvent oil is pressed into the extraction tank (12) from the solvent oil storage tank (25) by nitrogen. Solvent oil is one or a mixture of commonly used n-hexane or n-pentane. After stirring for 30-100 minutes, put all the materials into the extraction and separation tank (13), and after standing for 10-30 minutes, the materials are divided into two layers, and the upper layer of materials is put into the extraction distillation tank (14) through the side port of the extraction and separation tank (23). middle. Control the temperature of extraction still (14) and keep on 60~70 ℃. The solvent oil that distills out flows back to solvent oil storage tank (25) by pipeline. After the distillation is completed, what is obtained by passing the material in the distillation kettle through the oil cooler (15) is microalgae oil.

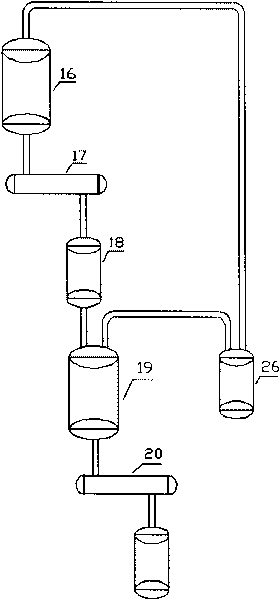

[0043] Put the microalgae oil into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com