Semisolid metal slurry preparation device and method

A semi-solid metal and preparation device technology, which is applied in the field of semi-solid metal slurry preparation device, can solve the problems of troublesome cleaning and disassembly, poor screw working condition, short life, etc., and achieves high efficiency, uniform temperature field distribution, and simplified process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

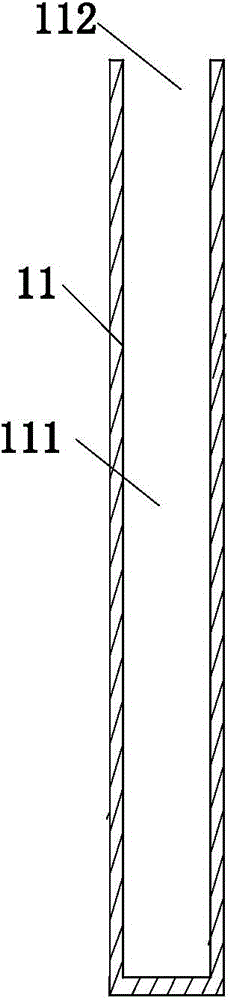

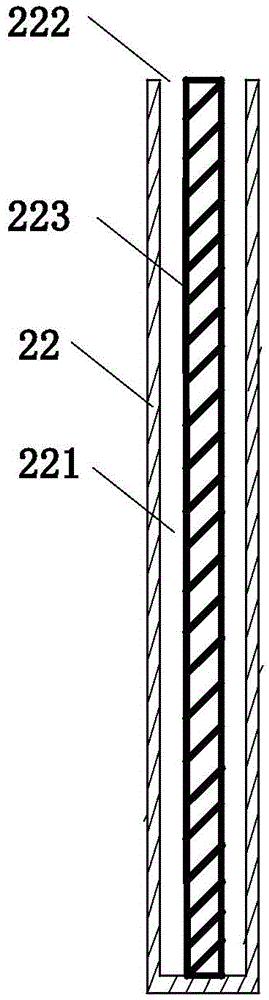

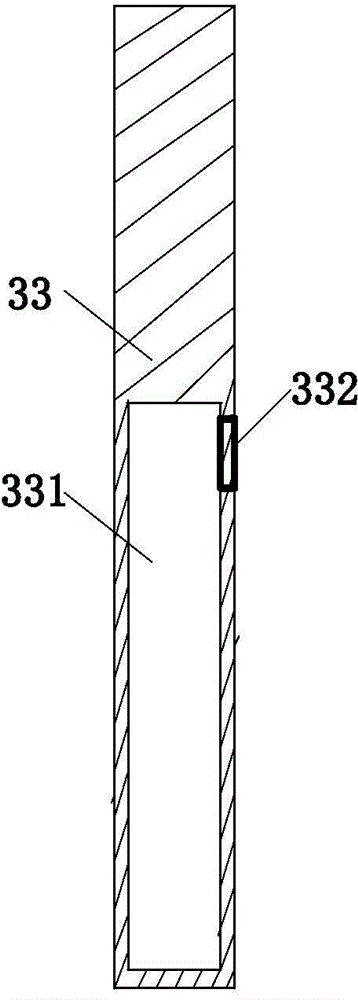

[0044] This embodiment illustrates the use of air-cooled stirring rod technology to prepare semi-solid slurry (specifically, it can be light alloy semi-solid slurry, or other types of metal semi-solid slurry), which can improve the deficiencies of the existing stirring technology, Improve stock preparation quality and production efficiency. Specifically, the semi-solid metal slurry preparation device in this embodiment includes an air supply device, an air guide pipe, a stirring rod, and a holding container for holding molten metal; the holding container can be a crucible or other vessels that can withstand high temperatures The metal melt can specifically be magnesium alloy melt, aluminum alloy melt, zinc alloy melt and composite material melt, etc.; the end of the stirring rod extending into the metal melt in the carrying container is the stirring end, and the inside of the stirring end It has a cavity (inner cavity), and the gas supply device injects cooling gas into the in...

Embodiment 2

[0057] In this embodiment, on the semi-solid metal slurry preparation device shown in Embodiment 1, a method for preparing semi-solid metal slurry by using the semi-solid metal slurry preparation device is illustrated, and the semi-solid metal slurry can be a magnesium alloy , aluminum alloy, zinc alloy and its composite materials and other types of semi-solid slurry. For this method see Figure 4 shown, including:

[0058] Step 401: Prepare the metal melt in the holding container (at this time, the metal melt is obtained through melting, refining and other processes in the holding container), or add the prepared metal melt into the holding container;

[0059] Step 402: Control the stirring end of the stirring rod to stir in the molten metal in the carrying container according to the preset rotation speed and direction, and the gas supply device injects cooling gas into the cavity according to the preset gas flow rate through the air guide tube to achieve cooling Synergy wit...

Embodiment 3

[0063] In order to better understand the present invention, the present invention will be further exemplified below by using a specific semi-solid metal slurry preparation device combined with several specific types of metal solvents.

[0064] See Figure 5 As shown, the semi-solid metal slurry preparation device includes an air supply device 1, an air guide pipe 2, a stirring rod 3 (this example adopts figure 1 The hollow stirring rod of shown structure) and the crucible 5 that is used to hold metal melt 4, the stirring end of stirring rod 3 stretches in the metal melt 4 in the crucible 5, is provided with stirring blade at the stirring end of stirring rod 3 7, to improve stirring efficiency and effect; also includes a thermocouple 6 for detecting the temperature of the molten metal 4; during the stirring process, using the principle of air cooling and stirring, the stirring rod 3 stirs while the gas supply device 1 cools the gas (such as air) is injected into the inner cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com