Method and device for producing a package for smoking articles

a smoking article and package technology, applied in the direction of box making operations, packaging goods types, paper/cardboard containers, etc., can solve the problem of complex synchronizing means and achieve the effect of rational production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

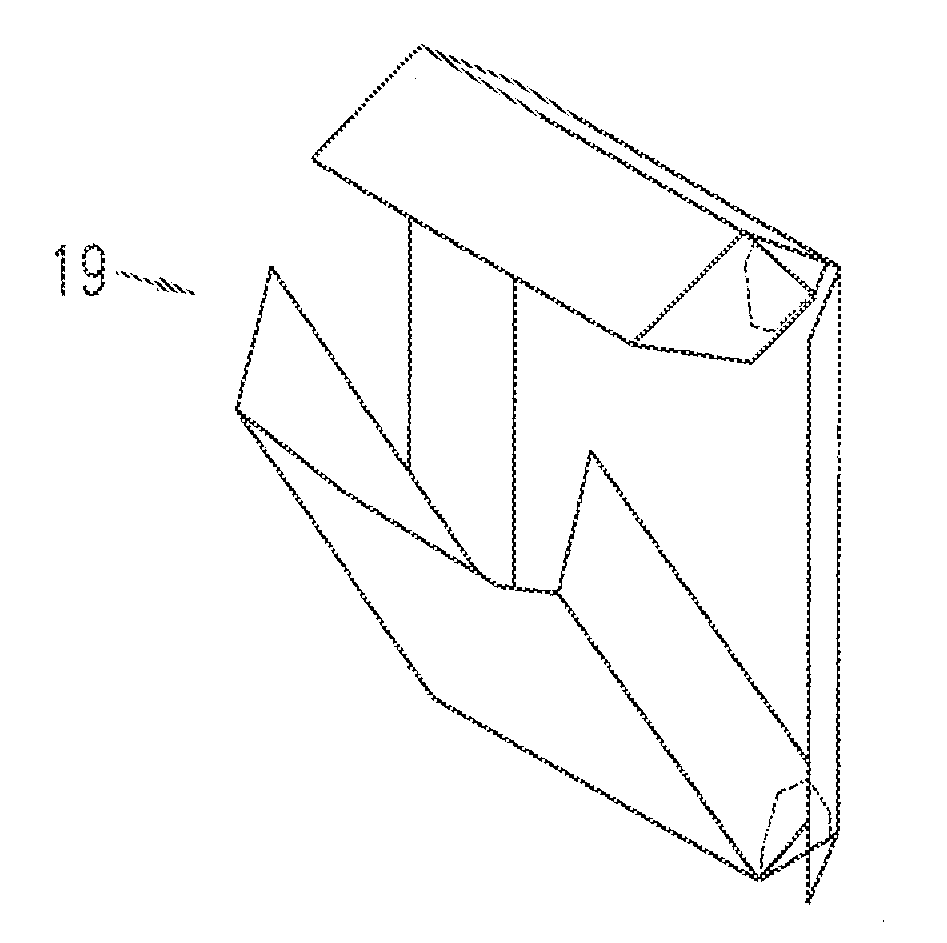

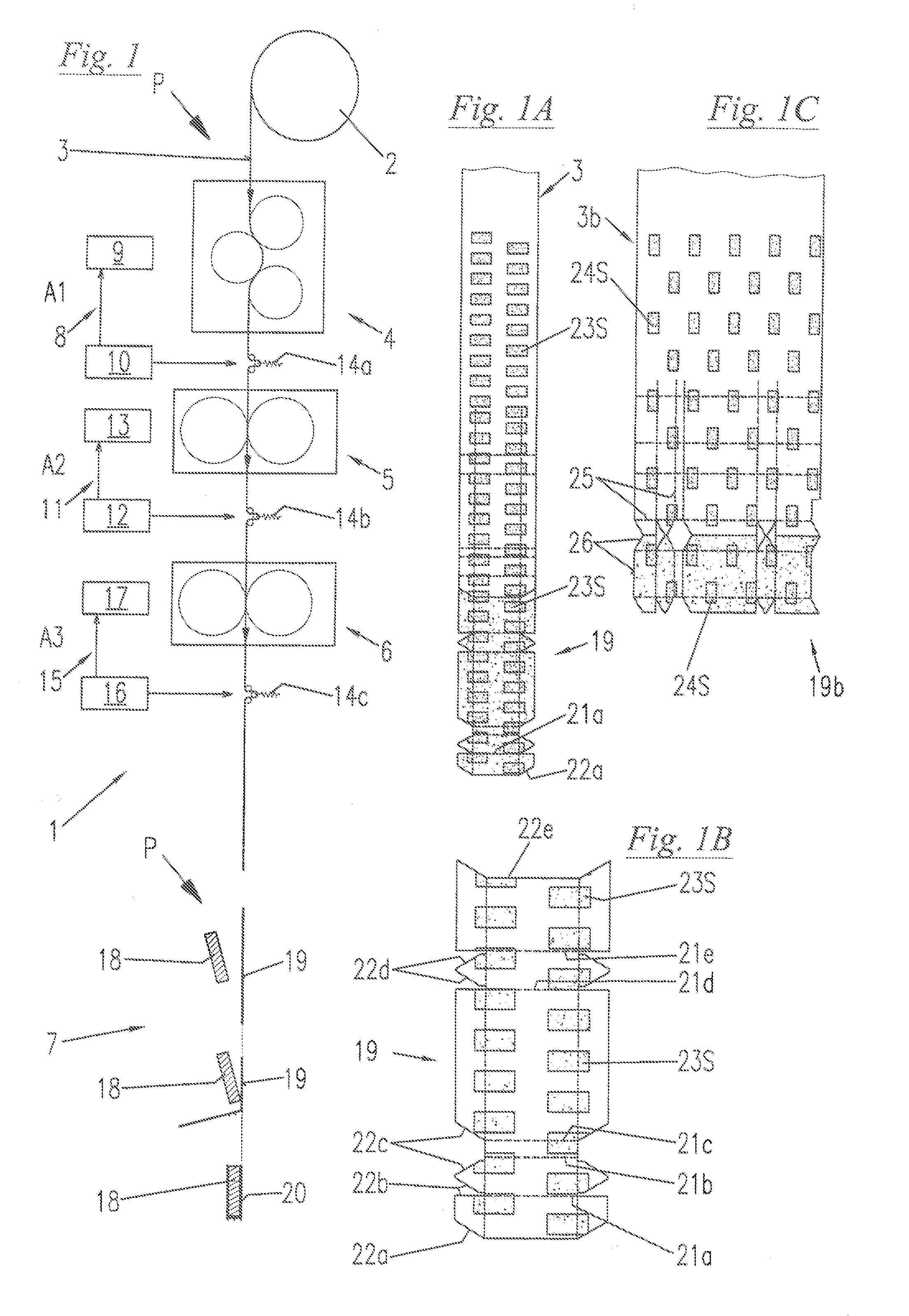

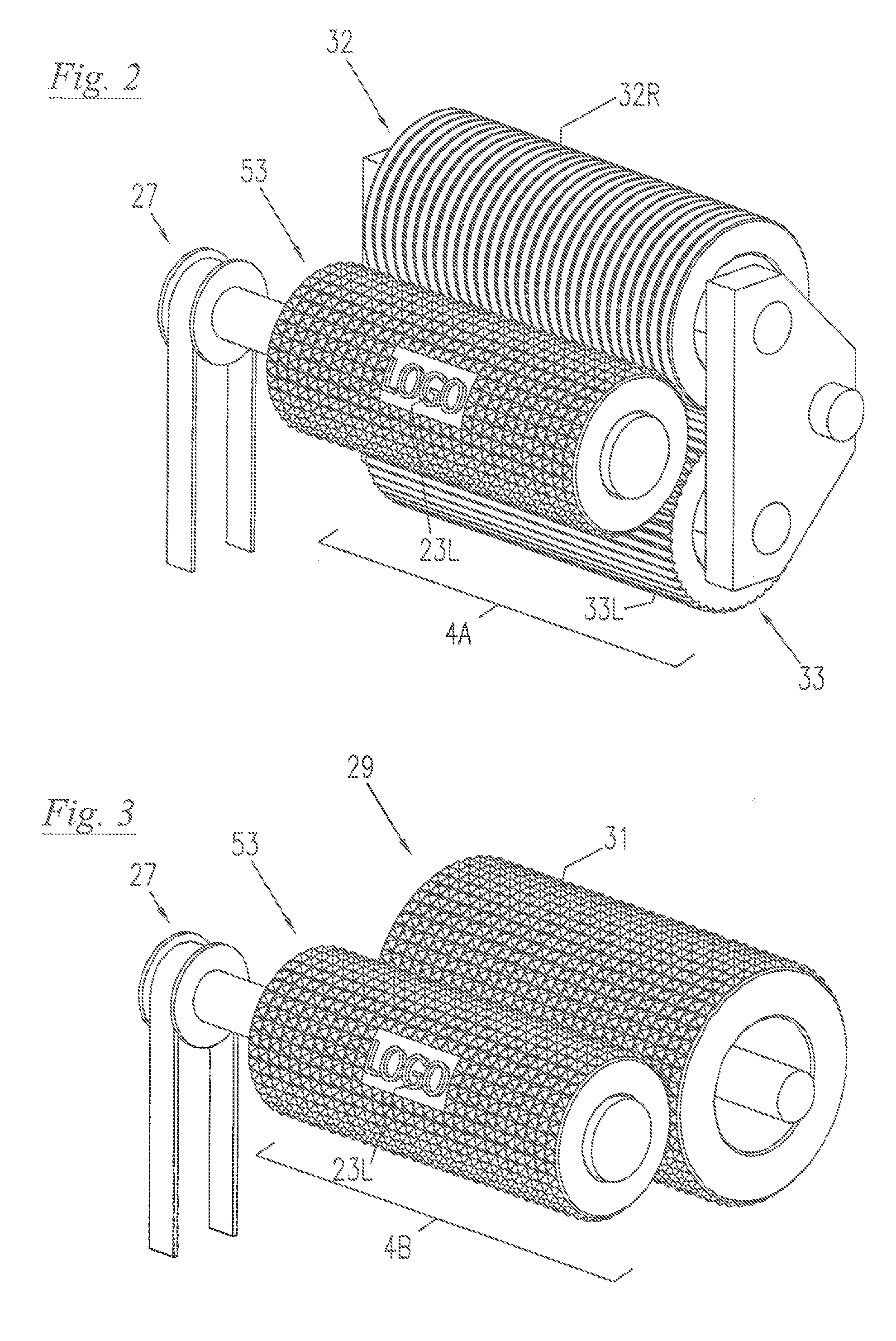

[0024]FIG. 1 shows a simplified flow chart of a possible device for producing a package for cigarettes as it is illustrated in FIGS. 12 and 14. Device 1 according to FIG. 1 comprises a foil strip reel 2 with a foil strip 3 that runs first through an embossing unit 4, then through a creasing unit 5, and finally through a cutting unit 6 in order to subsequently reach a packaging machine 7 as a blank 19.

[0025]The packaging foil, i.e. the foil strip 3 for producing an outer package may consist of a light material, e.g. of paper, thin cardboard, of hybrid foils, i.e. foils having multiple coatings of different materials, or of plastics foils that may be metallized or otherwise coated, or for certain applications, in certain countries where it is still allowed, a metal foil. In the following, this will simply be designated by the term “foil”.

[0026]As a first regulating unit 8, device 1 comprises a synchronizing device that serves for adapting the operating cadence A1 of embossing unit 4 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com