Patents

Literature

103results about "Specific bags/box making" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexible multi-compartment container with peelable seals and method for making same

InactiveUS6846305B2Increase capacityIncrease storage capacityWrappersMedical devicesThermoplasticDiluent

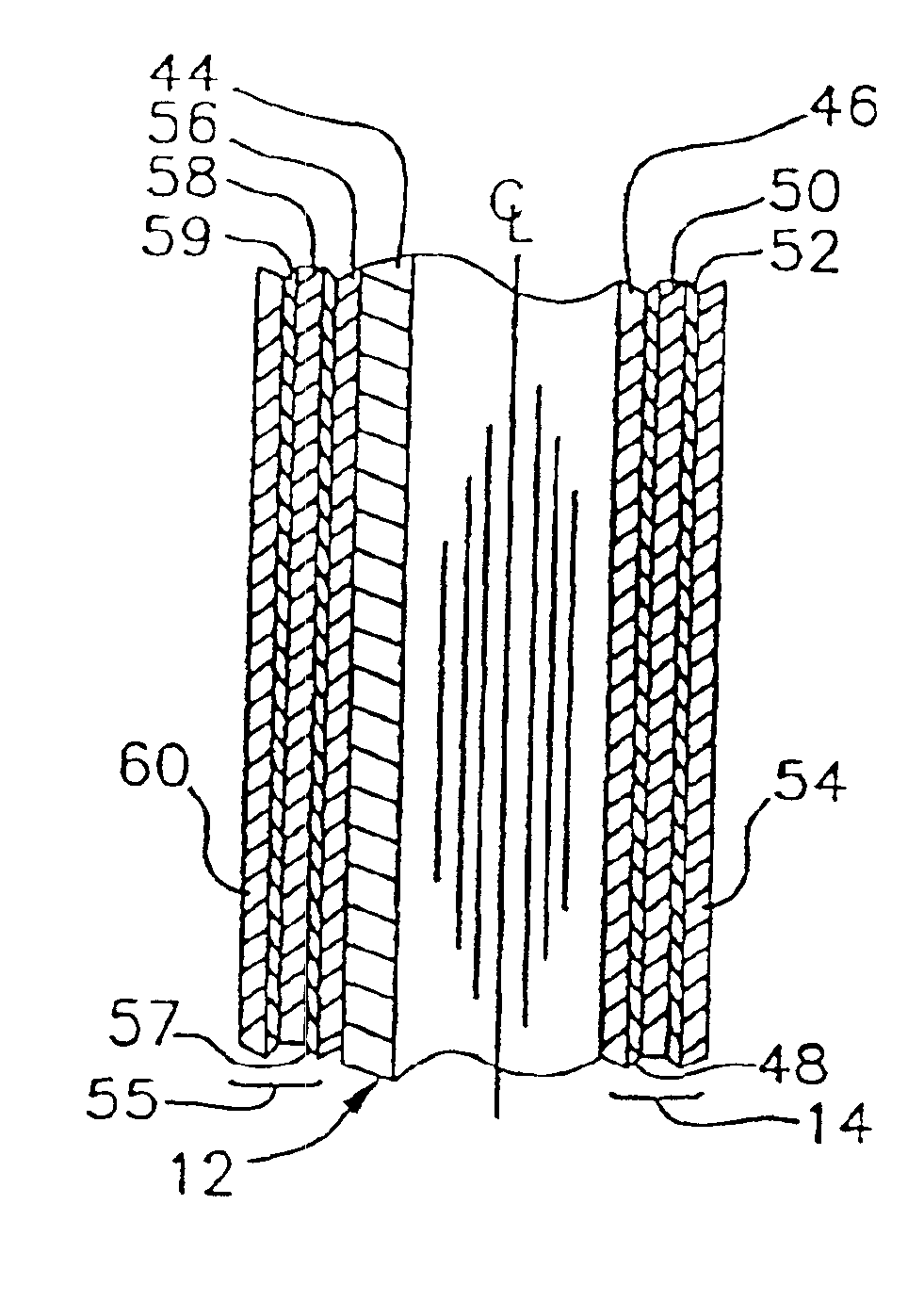

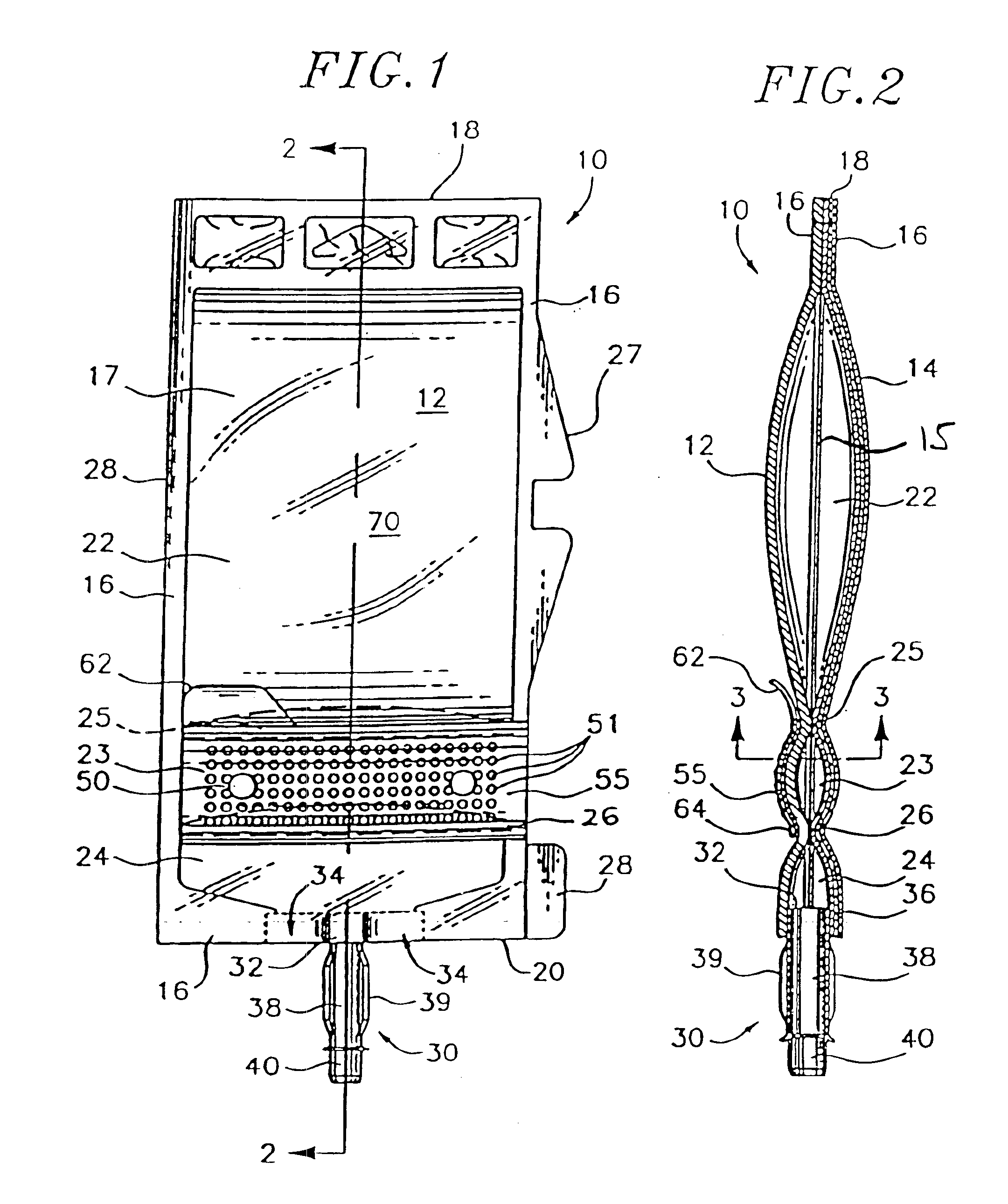

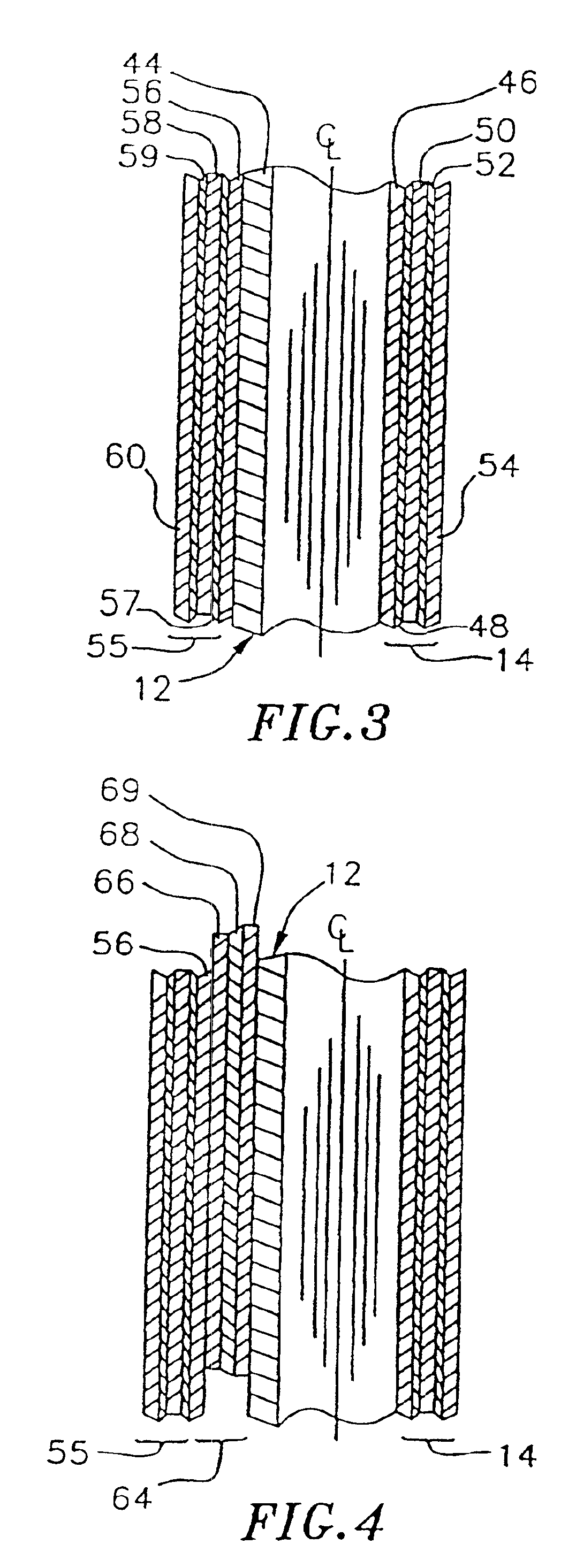

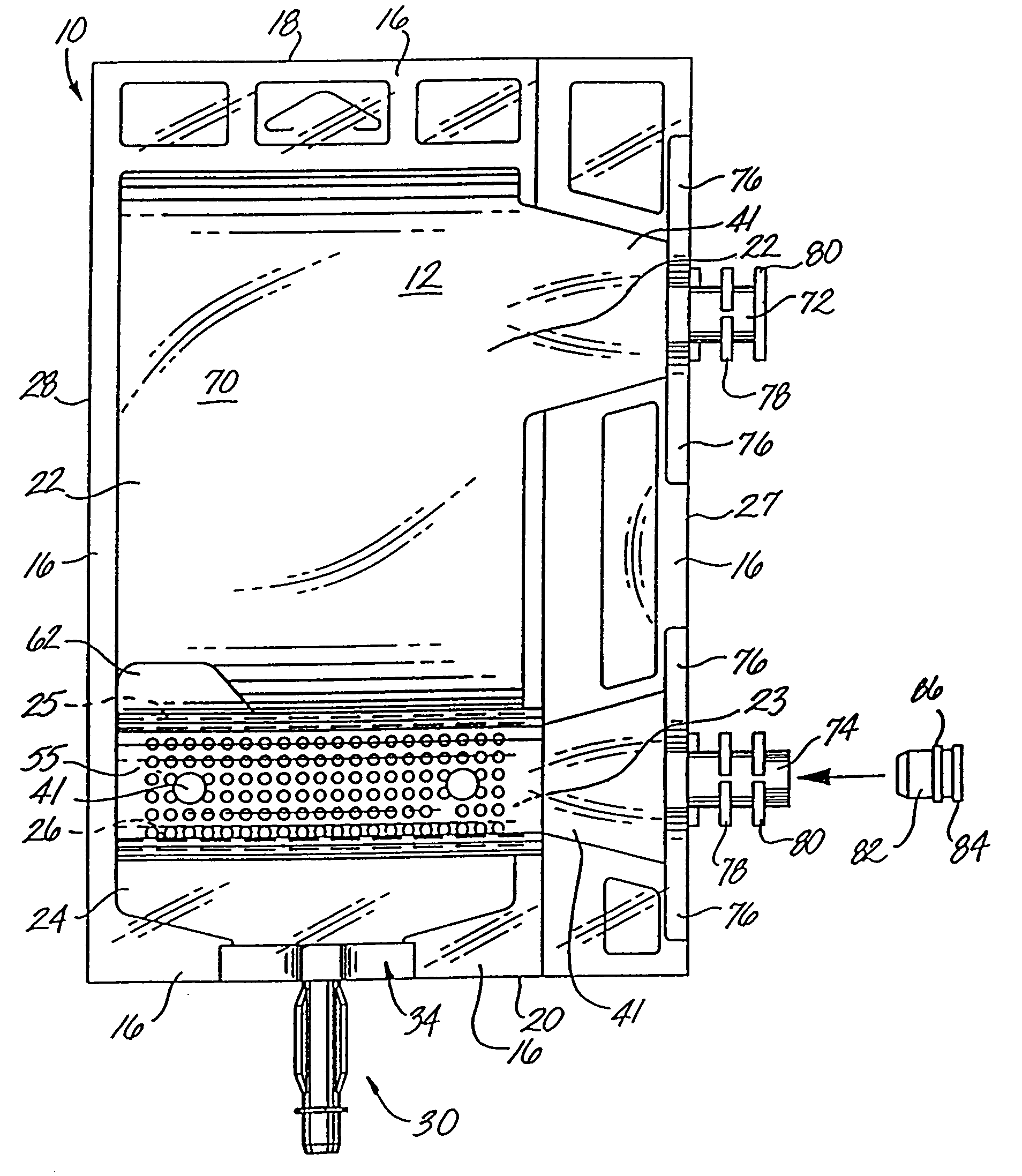

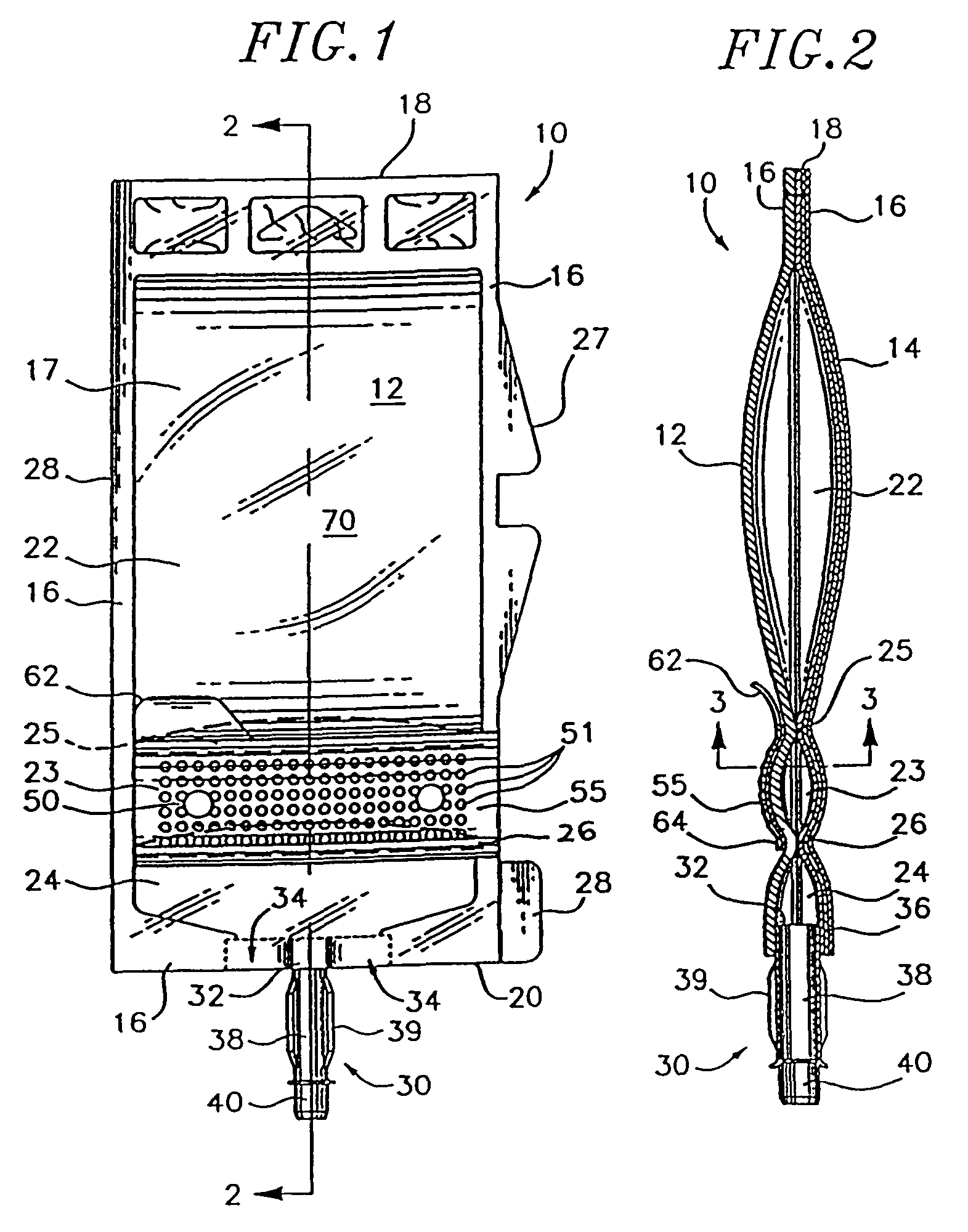

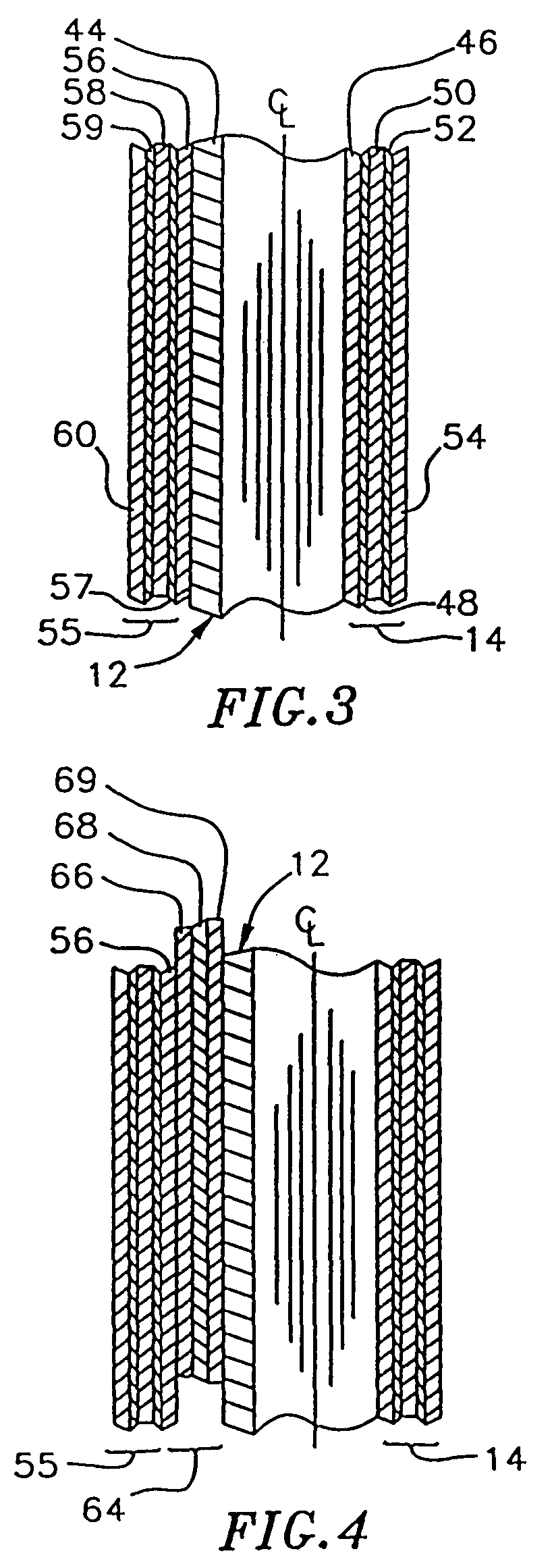

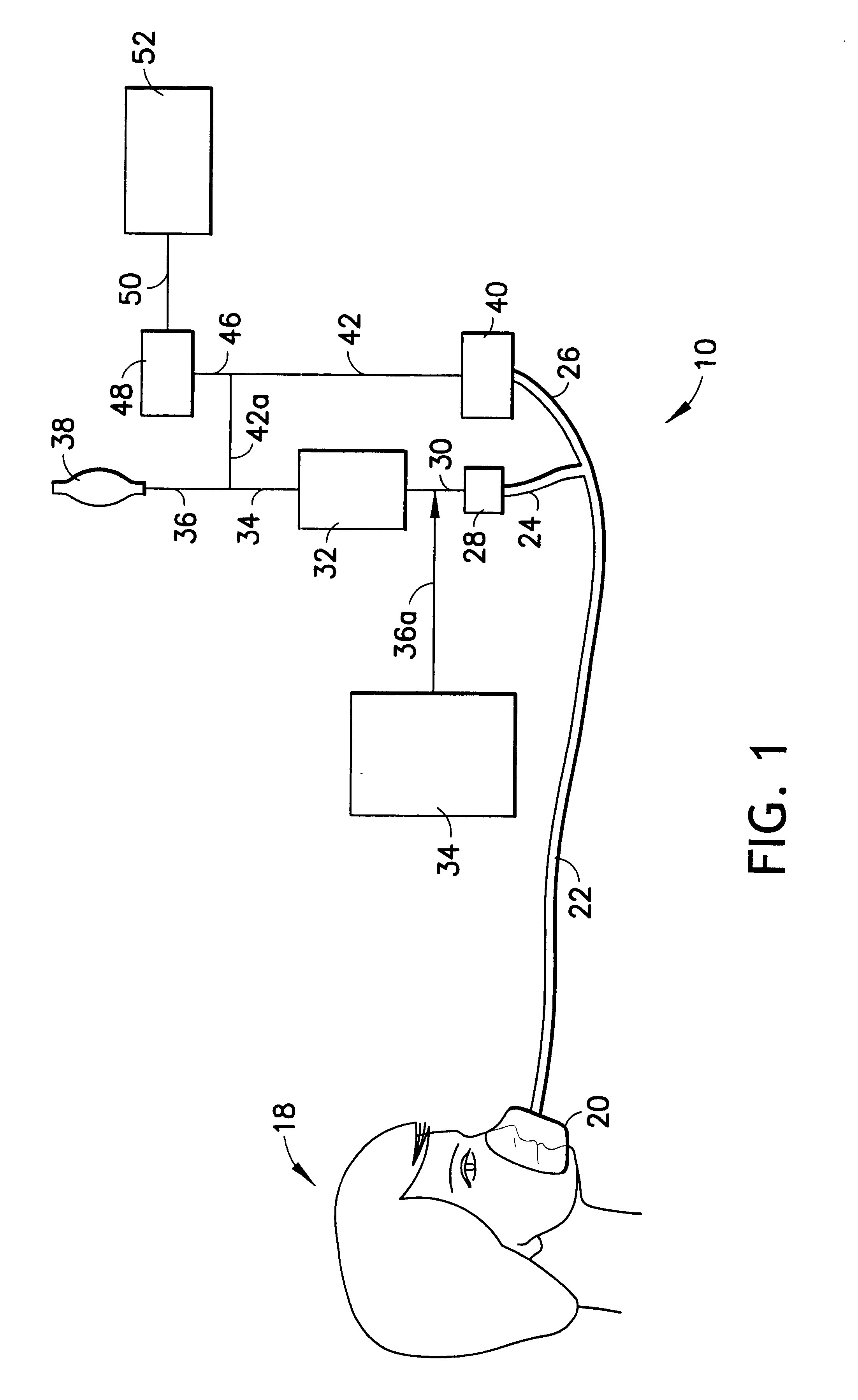

A flexible container is provided for the storage and administration of medical solutions. The container incorporates a transparent front sheet made from a planar layer of a polymer and an opposing rear sheet. The rear sheet is made from a planar laminate layer. The front and rear sheets are sealed together along a common peripheral edge to form a volume enclosure. The volume enclosure is constructed of materials having high oxygen and moisture barrier properties which allows the container thermoplastic to be stored for extended periods of time without degrading the contents. The volume enclosure is then inflated with a pressurized gas to permanently stretch the front and rear sheets outwardly and to thereby increase the volume capacity of the container. An alternative embodiment of the container incorporates multiple compartments, separated by peelable seals, for containing a diluent and a medicament. The seals are ruptured by manipulation of the container to thereby mix the contents together for delivery through standard IV arrangement to a patient.

Owner:B BRAUN MEDICAL

Flexible multi-compartment container with peelable seals and method for making same

InactiveUS6996951B2Increase storage capacityIncrease capacityEnvelopes/bags making machineryBoxes/cartons making machineryThermoplasticDiluent

A flexible container is provided for the storage and administration of medical solutions. The container incorporates a transparent front sheet made from a planar layer of a polymer and an opposing rear sheet. The rear sheet is made from a planar laminate layer. The front and rear sheets are sealed together along a common peripheral edge to form a volume enclosure. The volume enclosure is constructed of materials having high oxygen and moisture barrier properties which allows the container thermoplastic to be stored for extended periods of time without degrading the contents. The volume enclosure is then inflated with a pressurized gas to permanently stretch the front and rear sheets outwardly and to thereby increase the volume capacity of the container. An alternative embodiment of the container incorporates multiple compartments, separated by peelable seals, for containing a diluent and a medicament. The seals are ruptured by manipulation of the container to thereby mix the contents together for delivery through standard IV arrangement to a patient.

Owner:B BRAUN MEDICAL

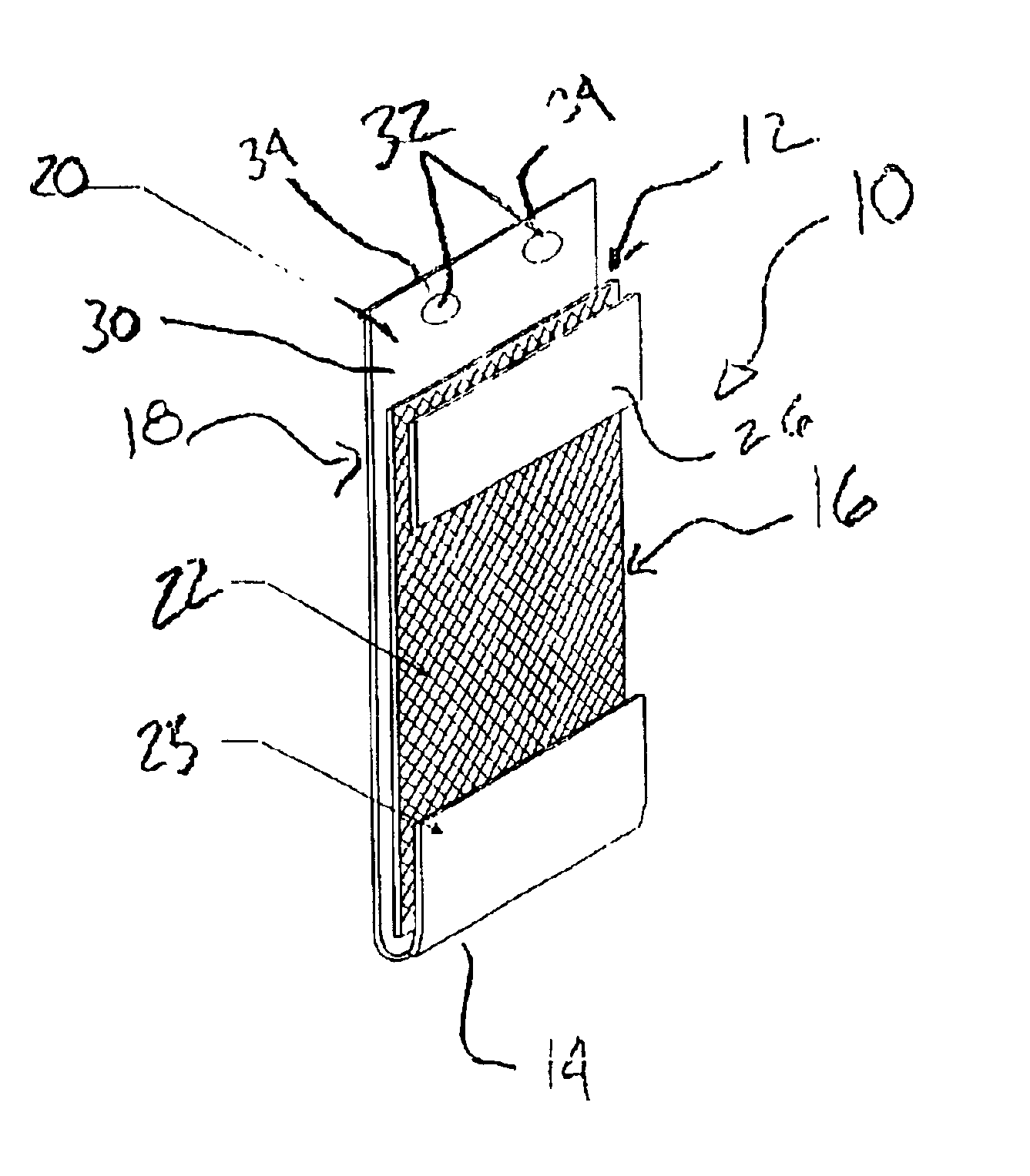

Reusable food storage bag and process for making a reusable storage bag

InactiveUS20140270590A1Easy to cleanTighter closurePackage recyclingBag making operationsEngineeringFood storage

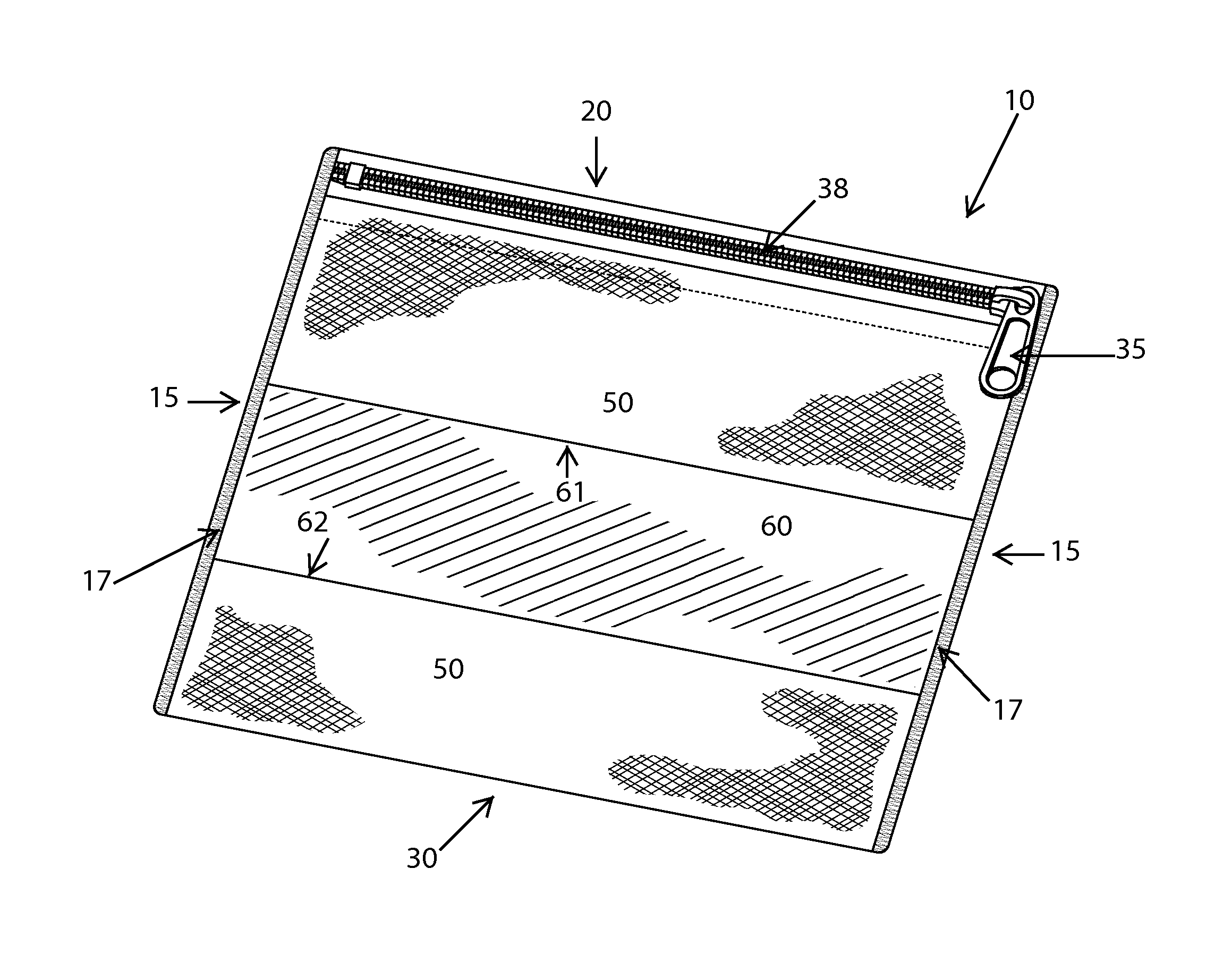

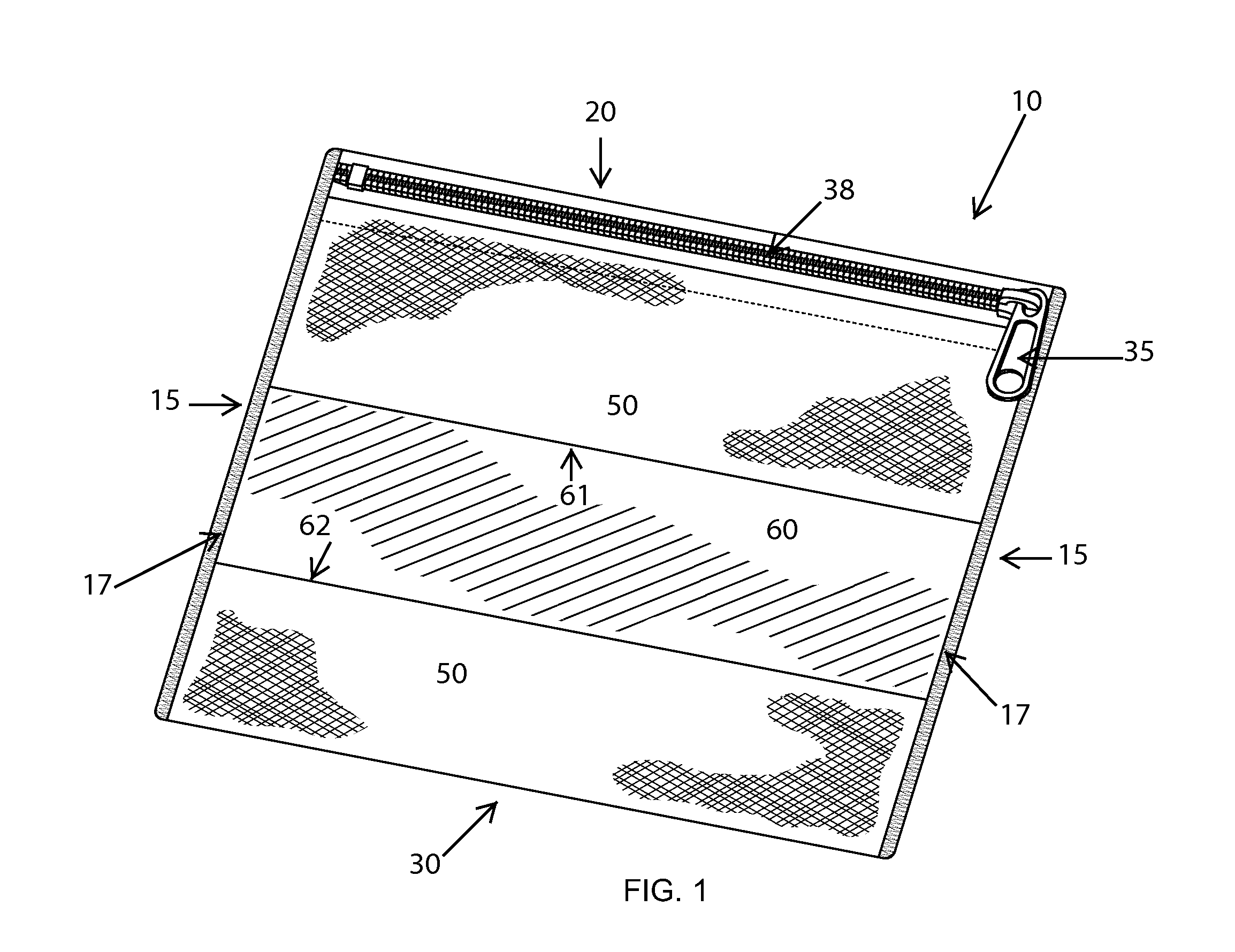

The present invention is a washable and reusable storage bag comprising a plastic coated canvas made from cotton and polyethylene. The storage bag comprises a front panel having a zipper and a back panel, a bottom edge and a top edge, and two side edges. The bag further comprises a rectangular transparent polyurethane window in the front panel, preferably in the shape of a rectangle. Two opposing sides of the transparent polyurethane window are heat sealed to the plastic coated canvas to create a liquid tight seal between the transparent polyurethane window and the plastic coated canvas. The outside of the storage bag can be customized with, e.g., designs, branding, and / or advertising. The storage bags can be hand washed, put in the dishwasher or put in the washing machine and clothes dryer.

Owner:OSTROY LEE RACHEL

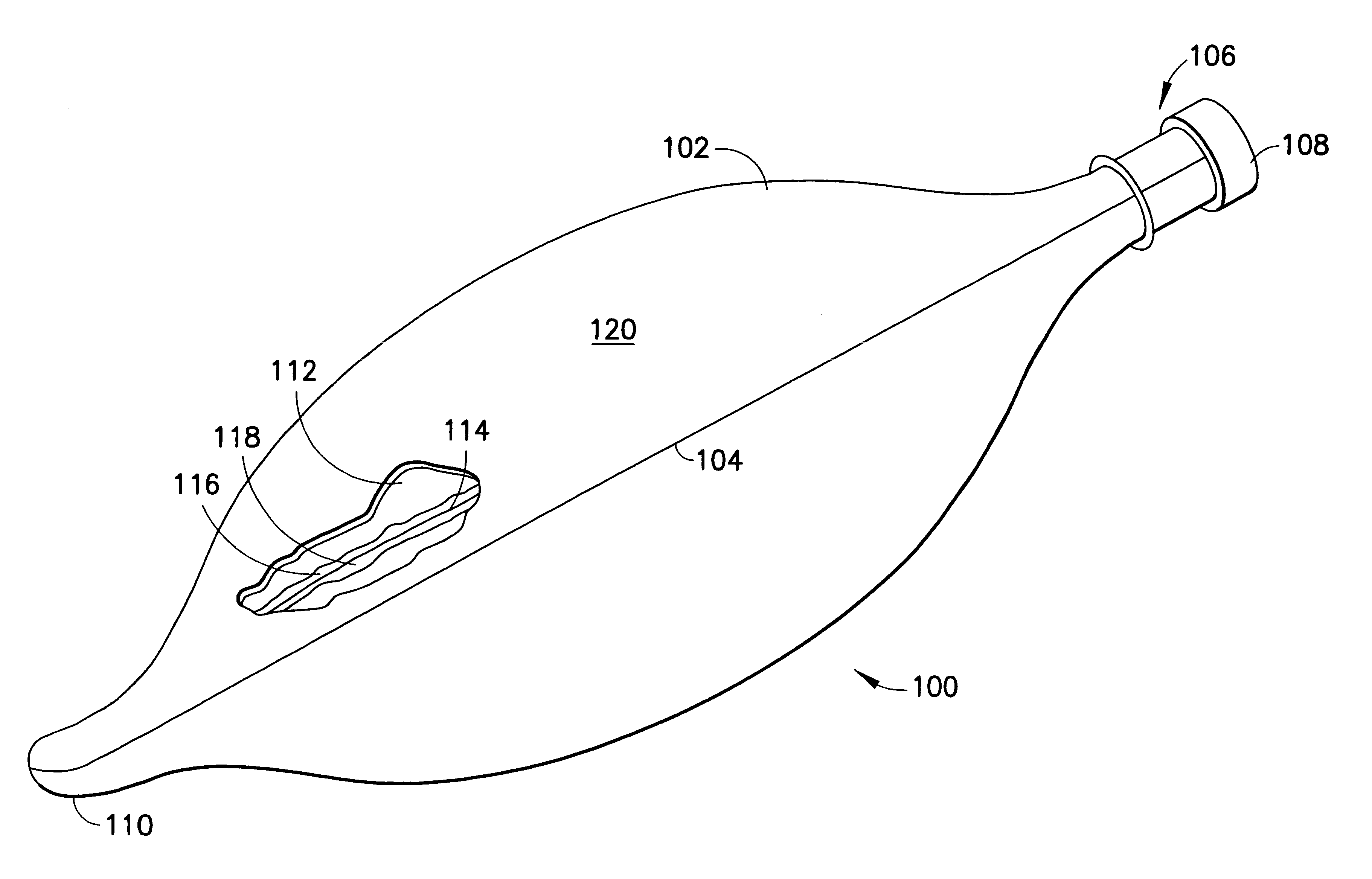

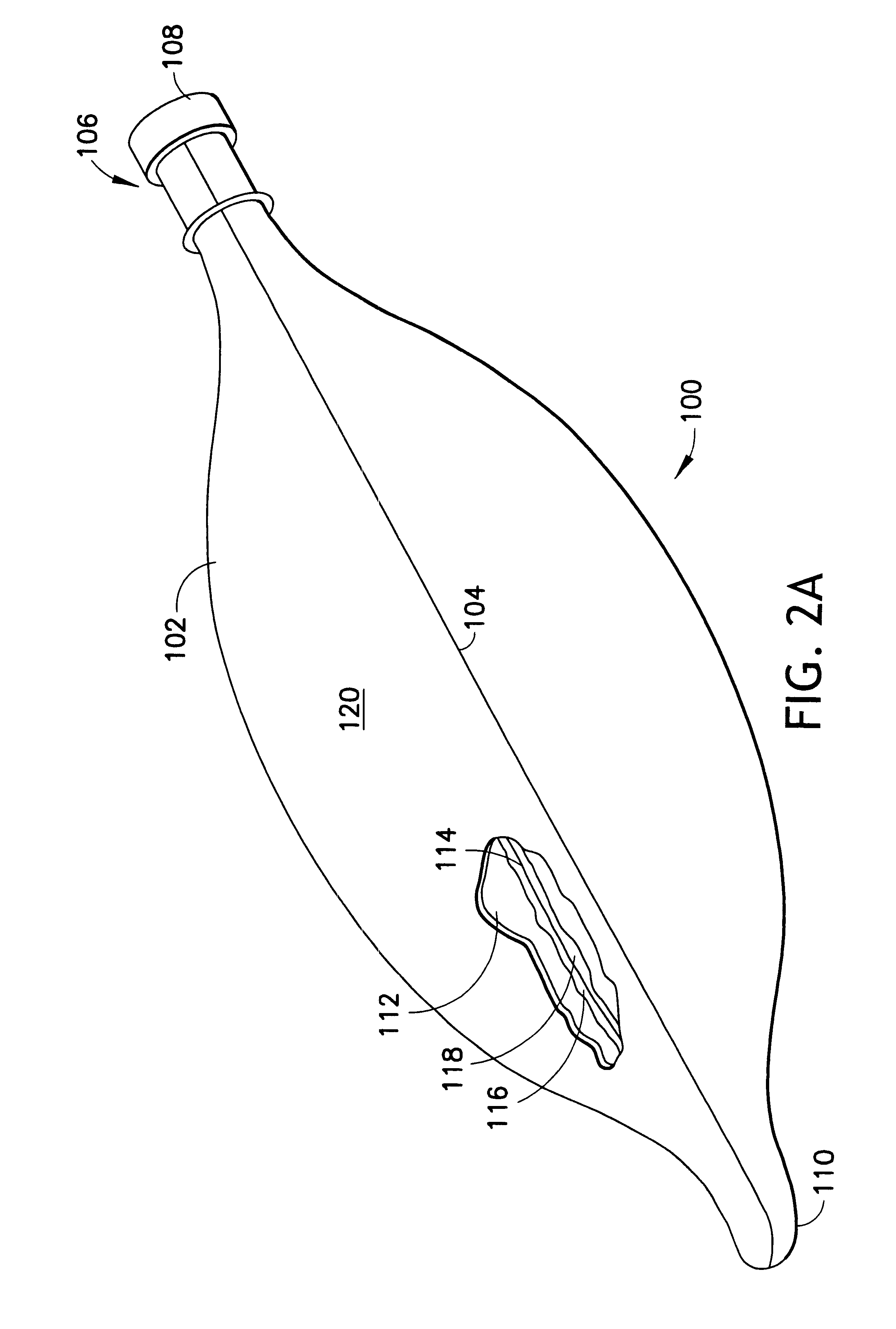

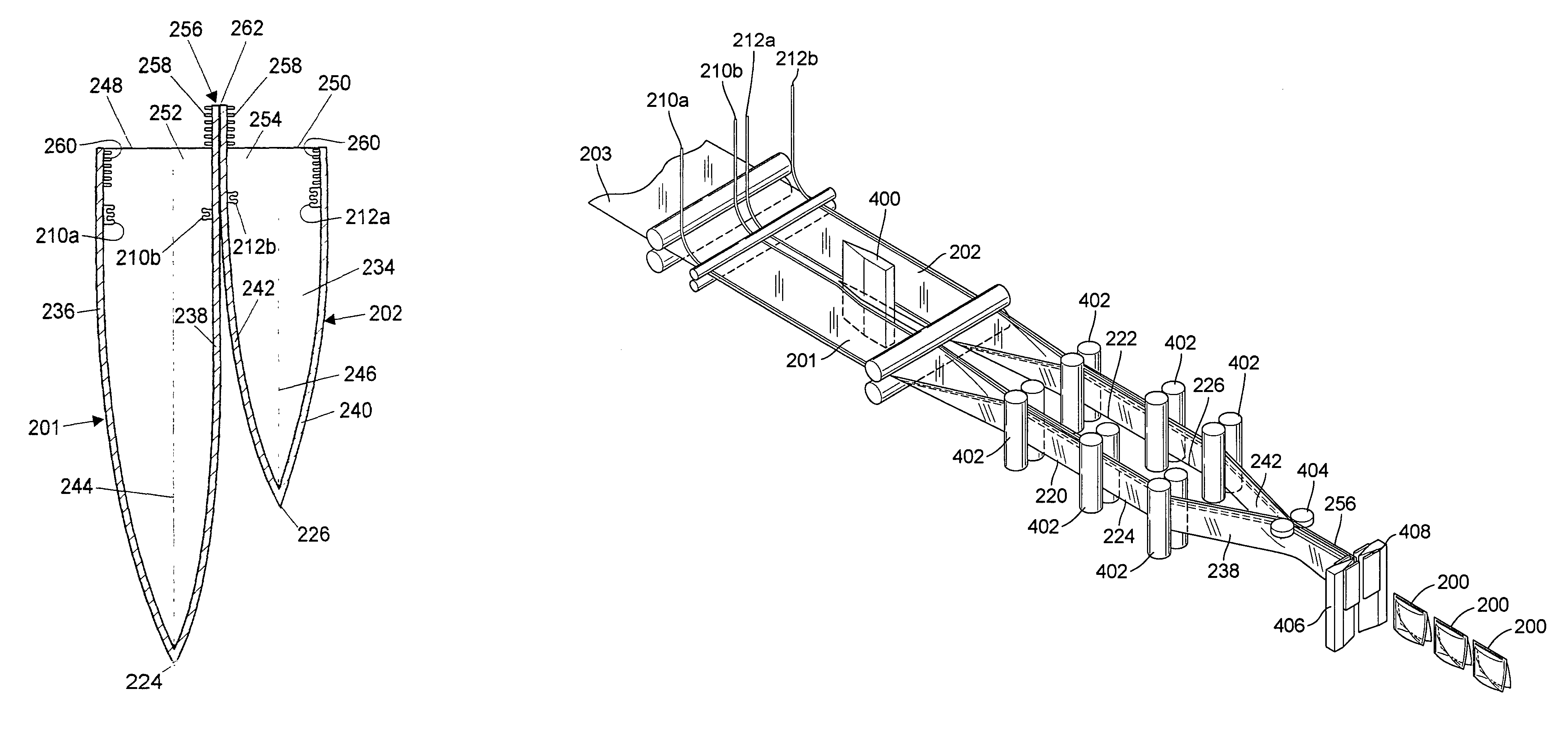

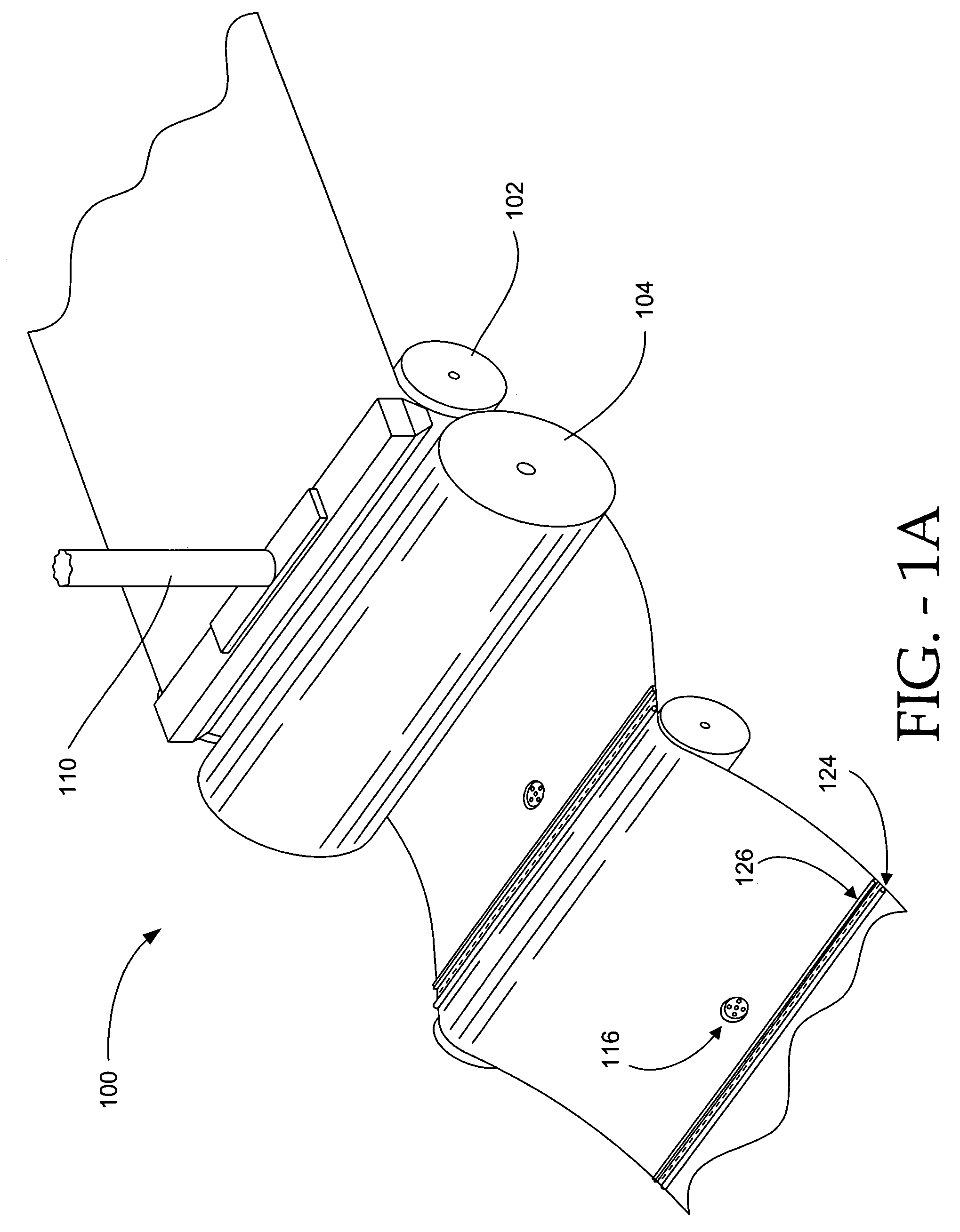

Film welded reservoir bag for breathing circuit and method of making the same

A pulmonarily sized bag formed of a non-latex material, including a bag body formed of panels of resin film material welded to one another along a weld line defining a seam of the bag body bounding an interior volume of the bag. The seam includes an interior seam portion in the interior volume, and an exterior seam portion at an exterior surface of the bag. One of the interior seam portion and exterior seam portion comprises free edges of the seam, and the other one of such seam portions is devoid of free edges. The bag is formable by various techniques, including radio frequency welding, impulse heating, solvent bonding, etc., and is usefully employed in a breathing circuit to obviate the necessity of using latex breathing bags.

Owner:POLYZEN INC

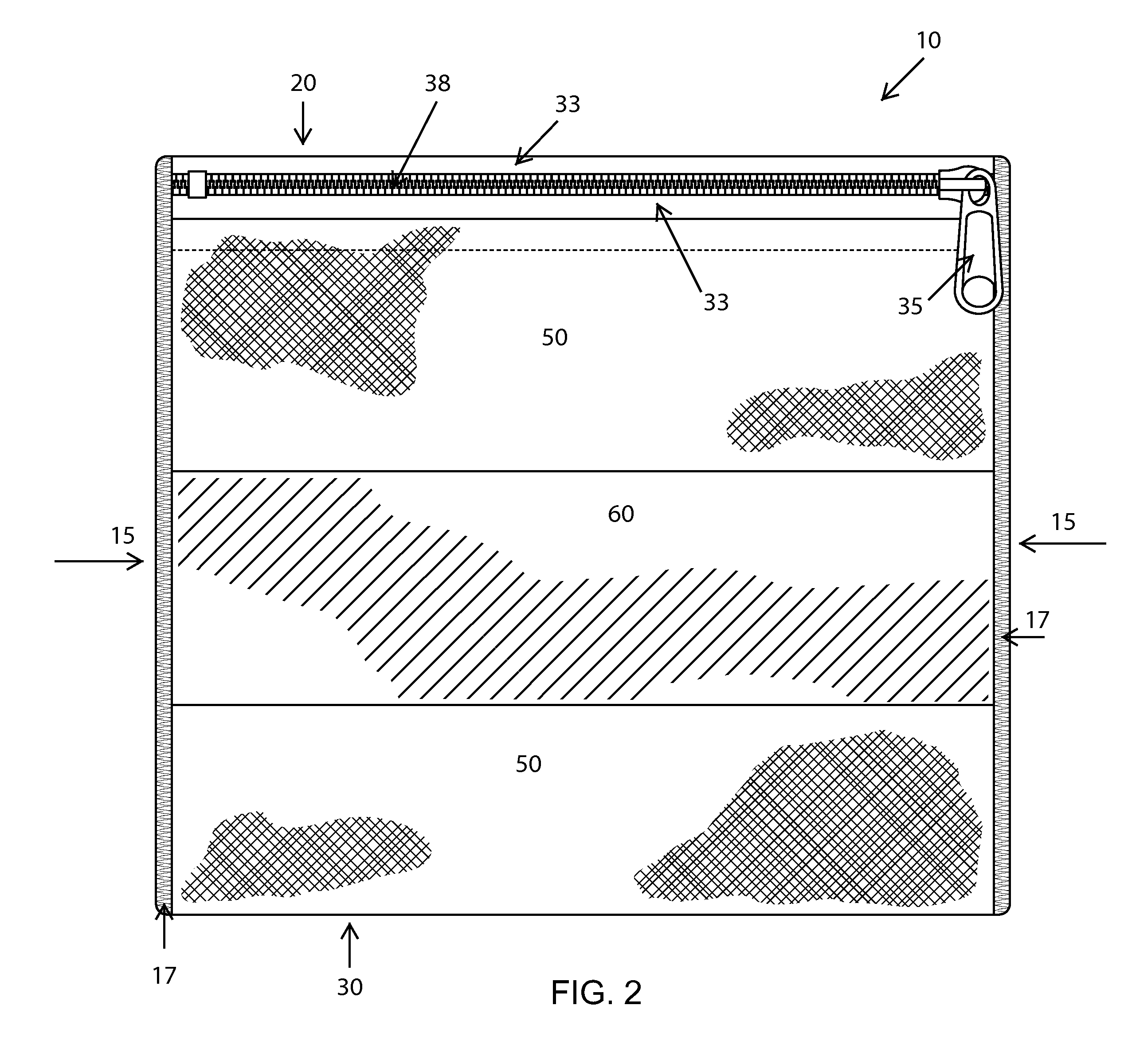

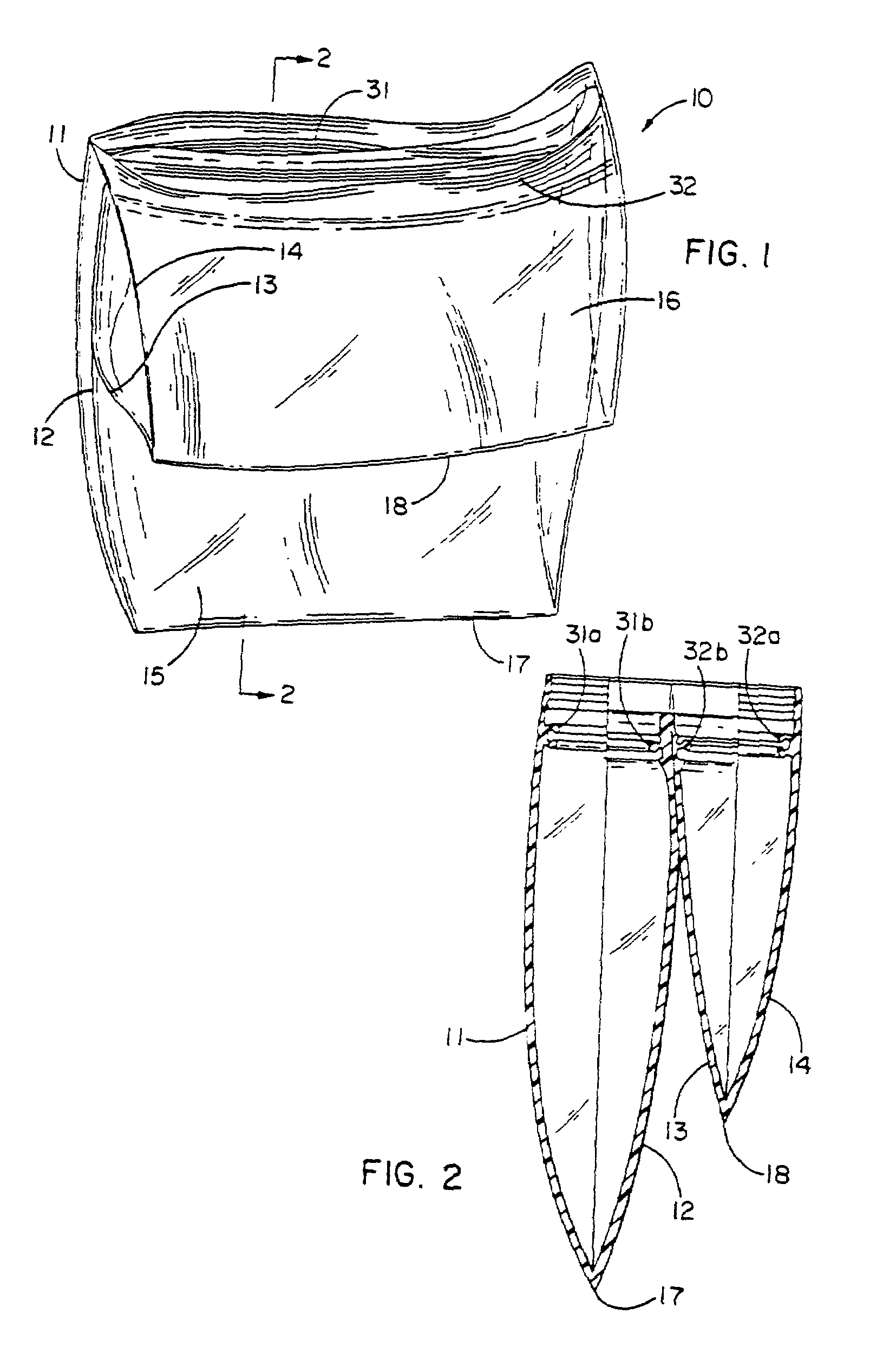

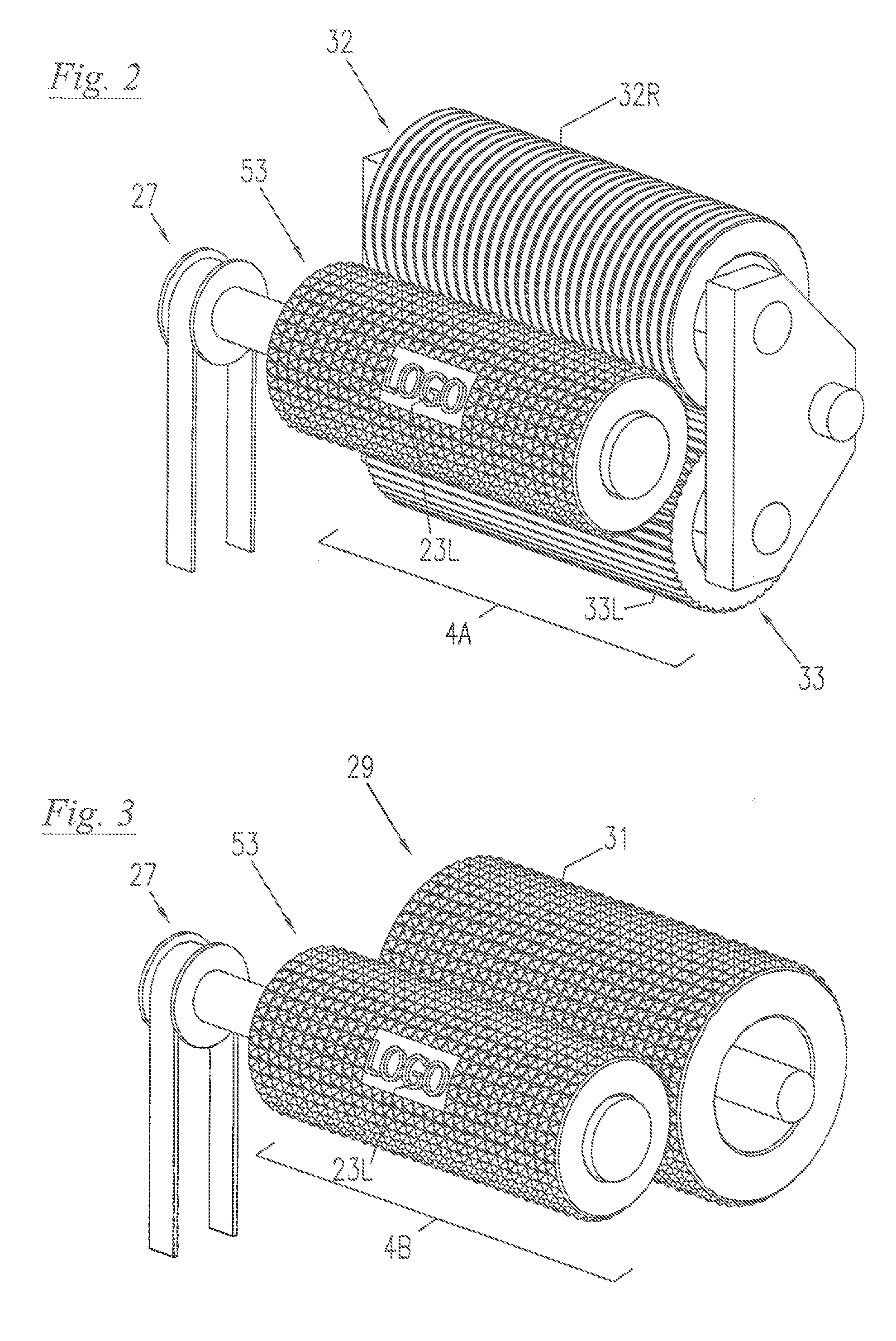

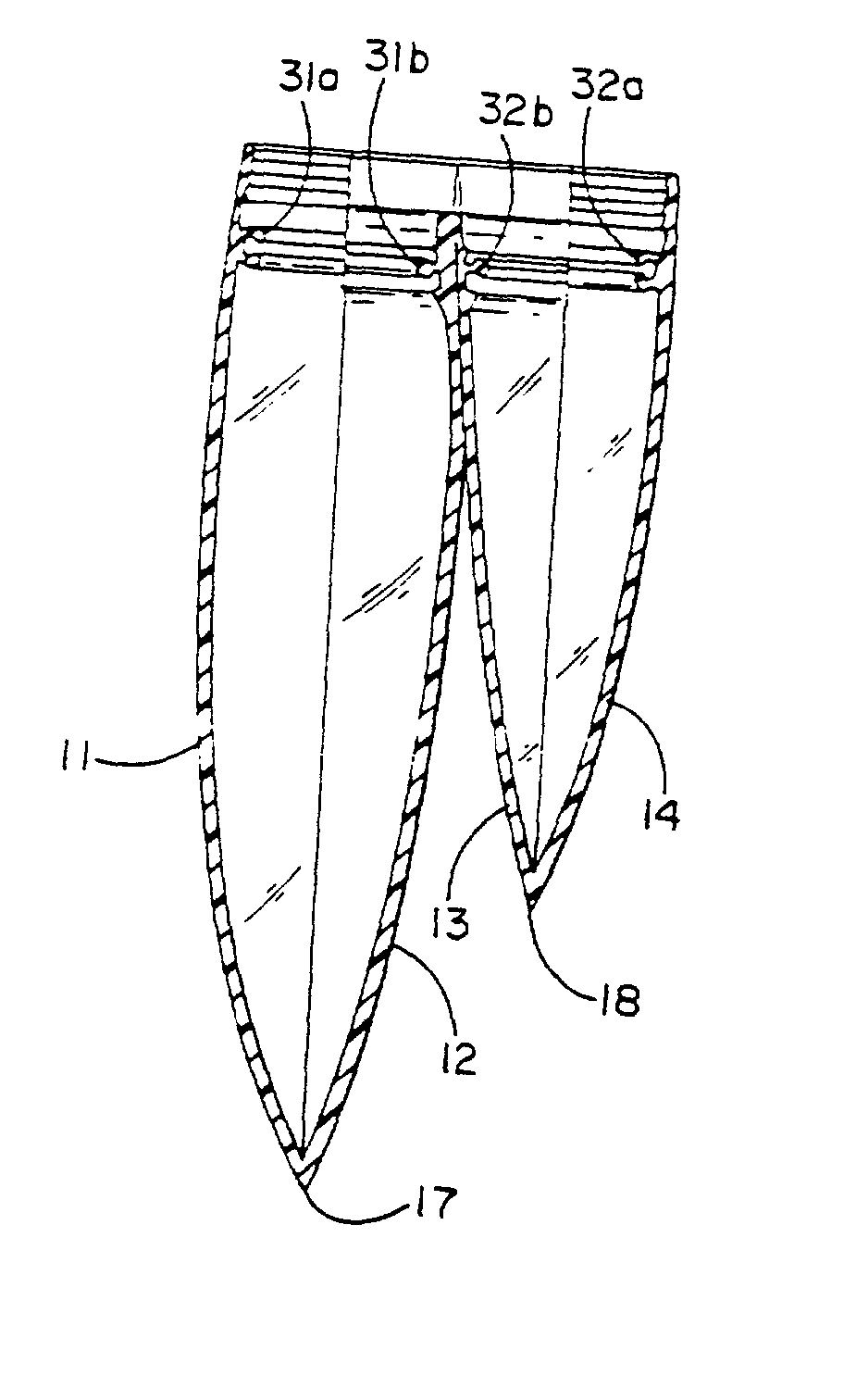

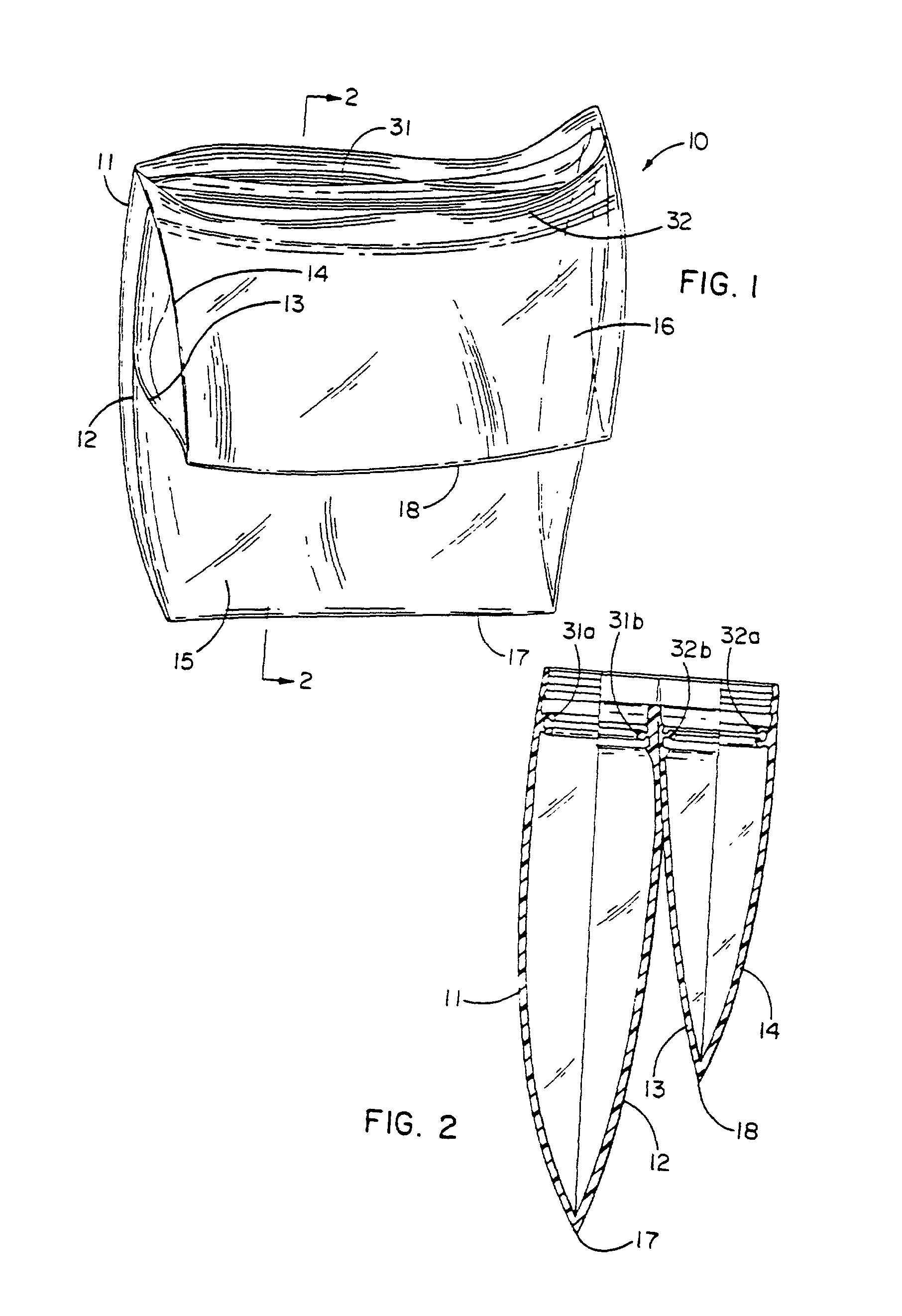

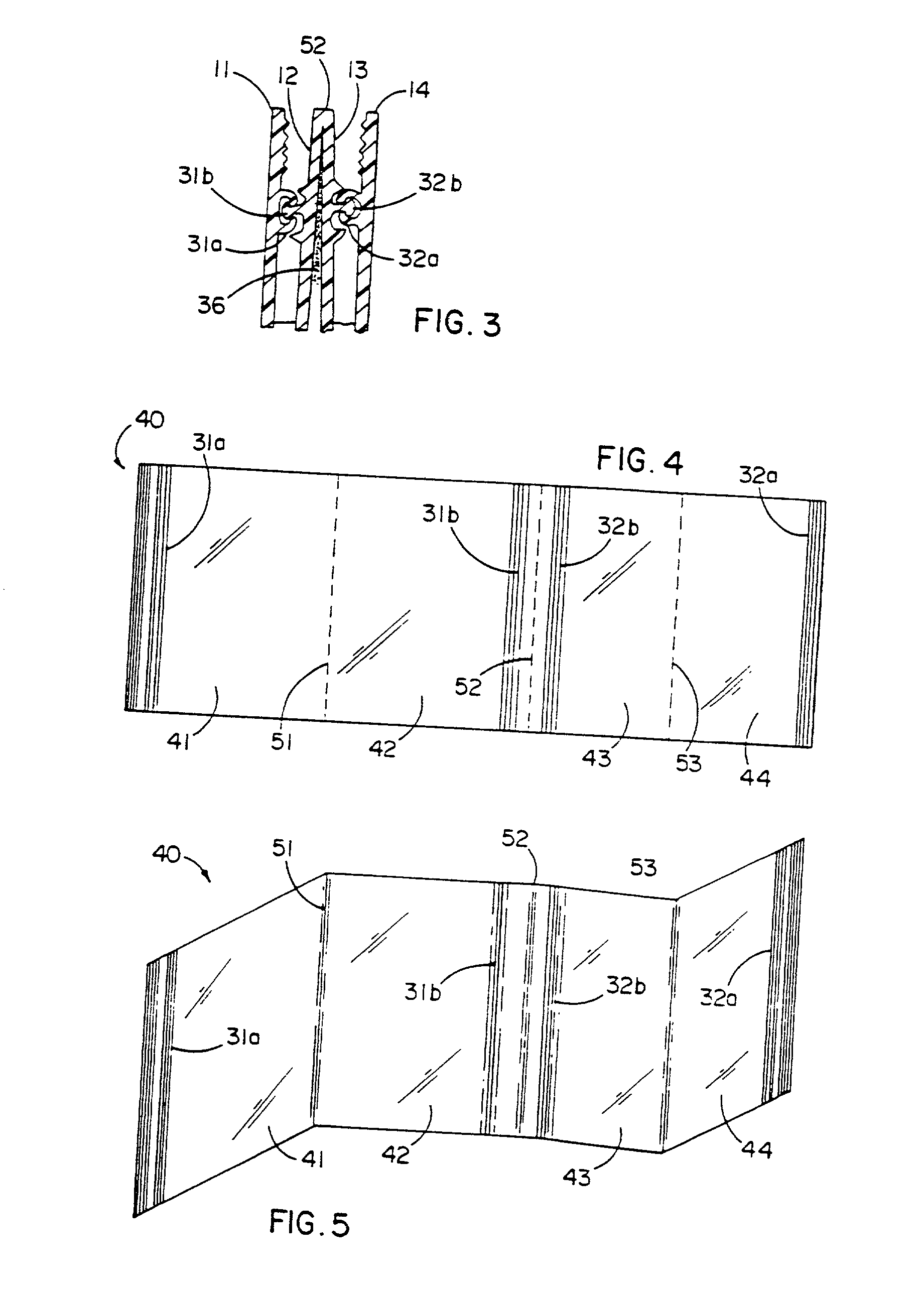

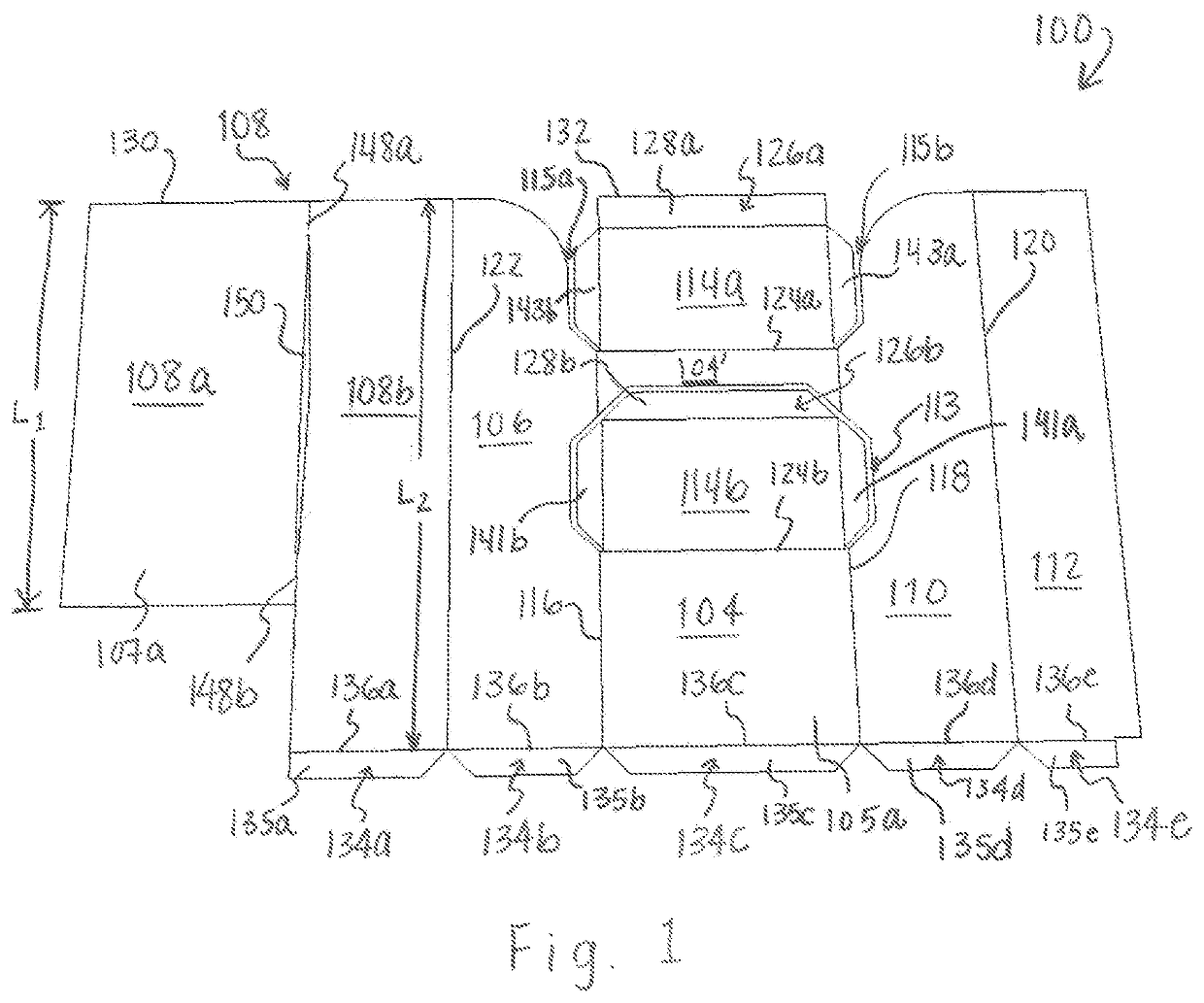

Method for making a multicompartment thermoplastic bag

A method of making a multicompartment reclosable thermoplastic bag having at least two compartments is disclosed. Each compartment has a top, a bottom, two side edges, and two opposing sidewalls joined at the side edges and the bottom. Each compartment has a closure across the top thereof, which are arranged back-to-back and aligned. The compartments are attached together proximate the tops of the compartments, and the bottoms of the compartments are free from being attached to each other. Processes for making such bags from one or more webs are also disclosed.

Owner:SC JOHNSON & SON INC

Method for manufacturing a sealable bag having an integrated zipper for use in vacuum packaging

A method for manufacturing a bag for use in vacuum packaging comprises forming a first panel having a receiving feature and a second panel having an insertion feature, such that the insertion feature can be removably connected with the receiving feature, thereby forming a zipper. Each panel comprises a gas-impermeable base layer and a heat-sealable inner layer molded from melt-extruded resin. The first panel is overlapped with the second panel, and three of four edges of the panels are heated such that the inner layers bond at the heated edges and the unbonded edge can be opened or closed via the zipper. Optionally, the bag can include a valve structure for evacuating the bag. This description is not intended to be a complete description of, or limit the scope of, the invention. Other features, aspects, and objects of the invention can be obtained from a review of the specification, the figures, and the claims.

Owner:SUNBEAN PROD INC

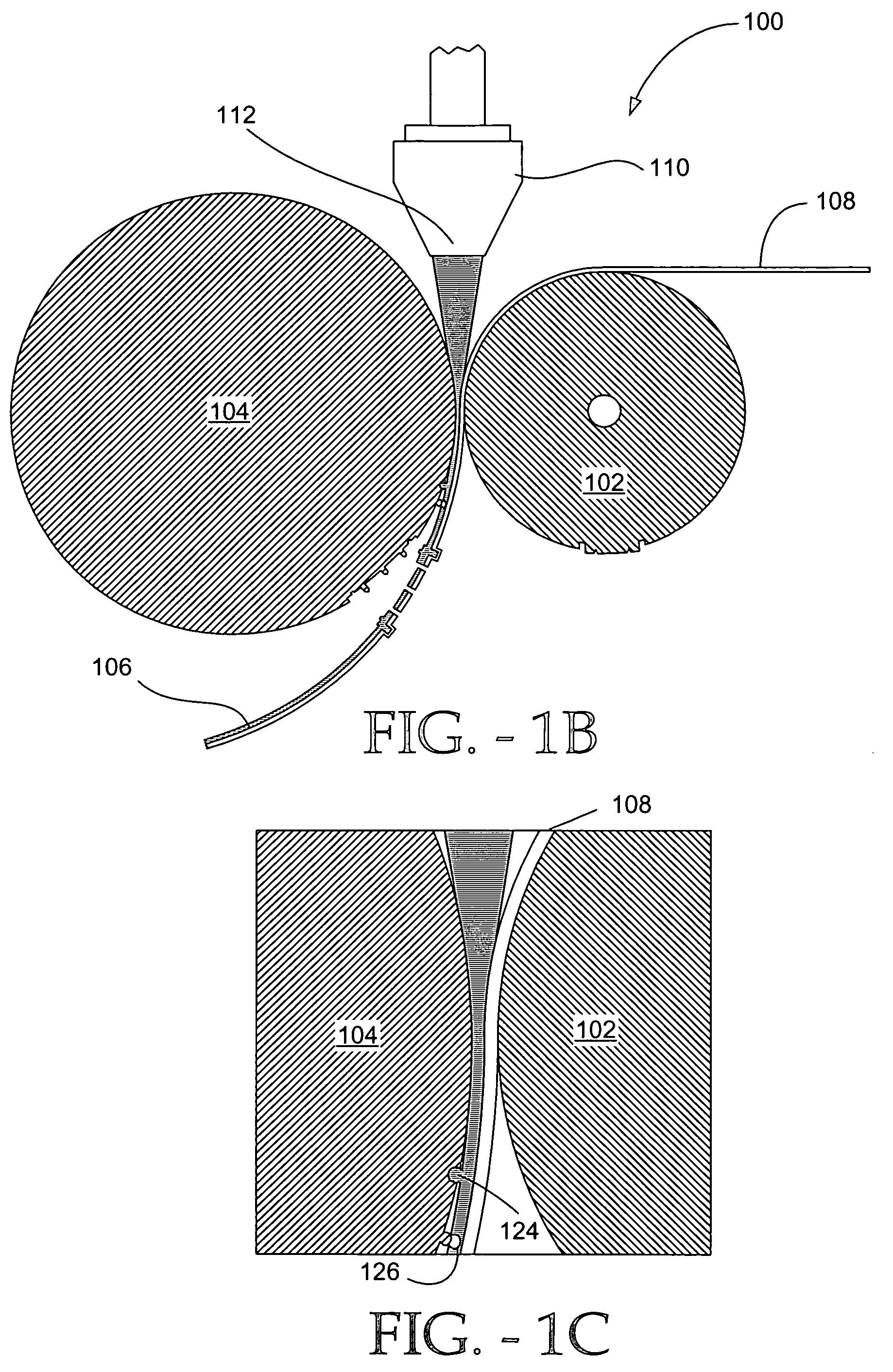

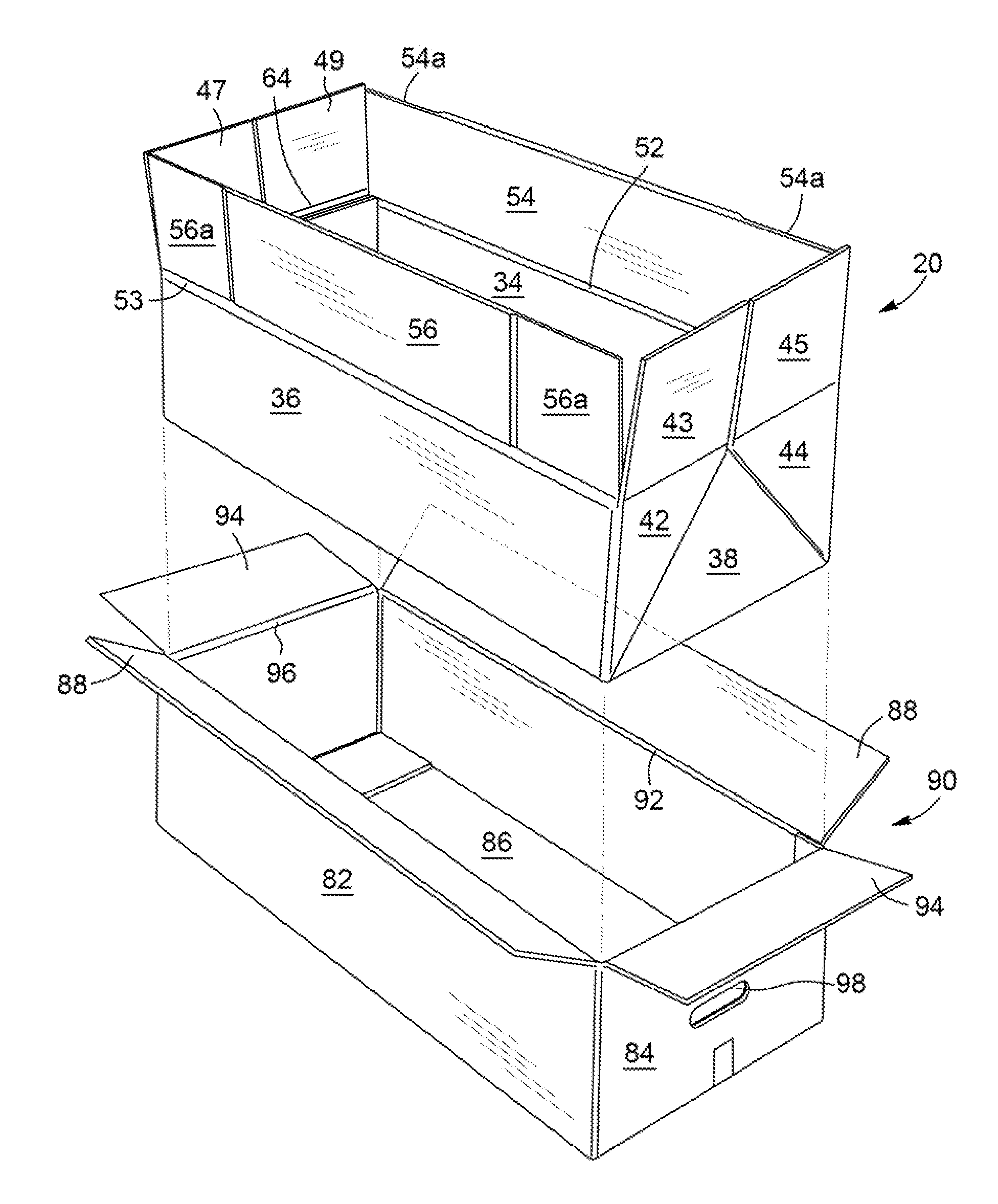

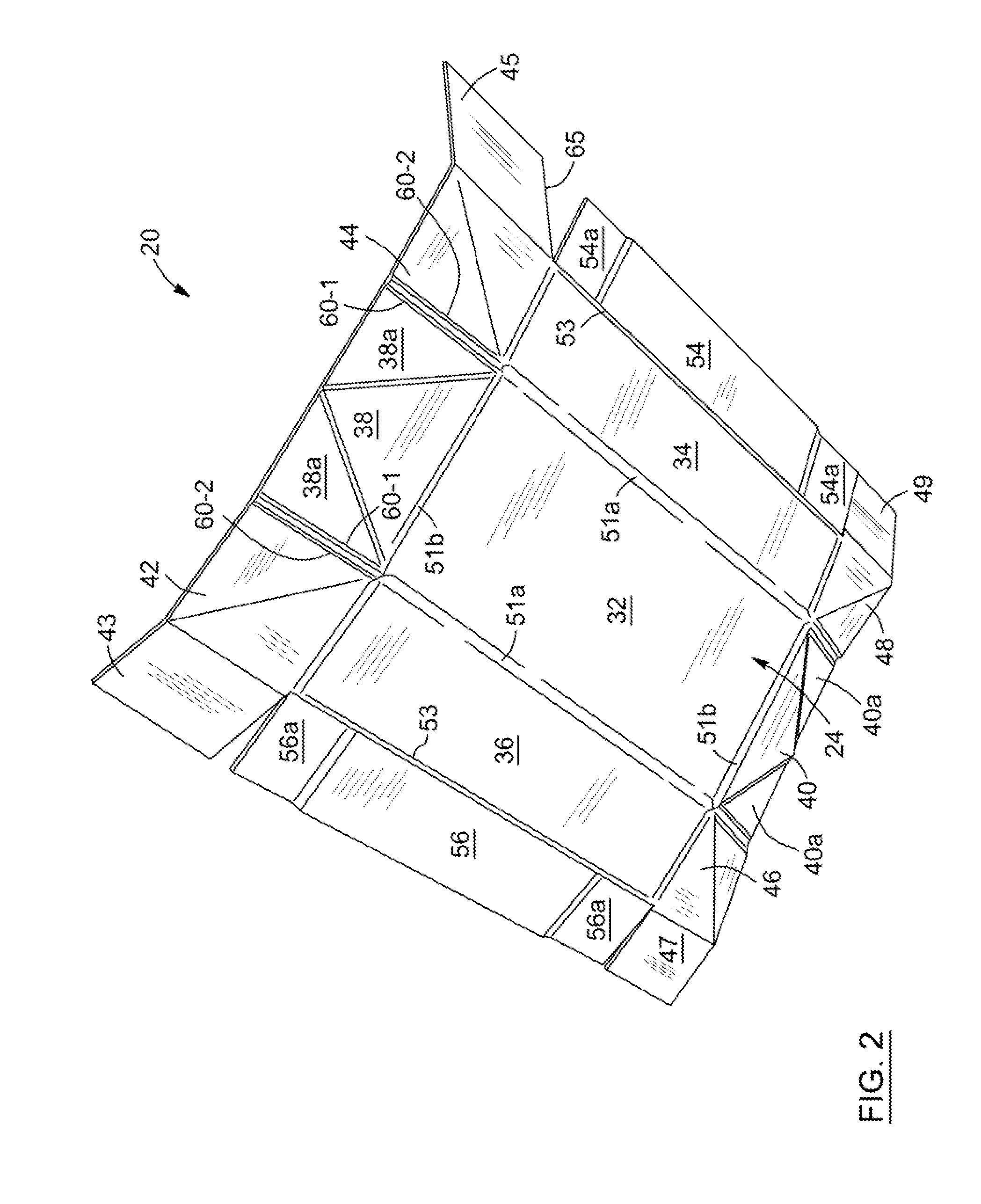

Thermal container, thermal liner for same and dies for making the thermal liner

A thermal liner for a container comprises a bottom panel hingedly connected to a pair of opposed medial end panels and a pair of opposed side panels; four outer end panels each being hingedly connected along a first edge to a corresponding side panel and along a second edge to a corresponding medial end panel and being foldable along a diagonal thereof; a pair of opposed side flaps each being hingedly connected along an edge to a corresponding side panel; and end flaps hingedly connected along a first edge to one of a corresponding outer end panel or a corresponding side flap and having a free edge adjacent to the other one of the corresponding end panel or the corresponding side flap. There is also provided a thermal container comprising such a liner and a pair of dies for forming the thermal liner are also described.

Owner:FRESH BAILIWICK

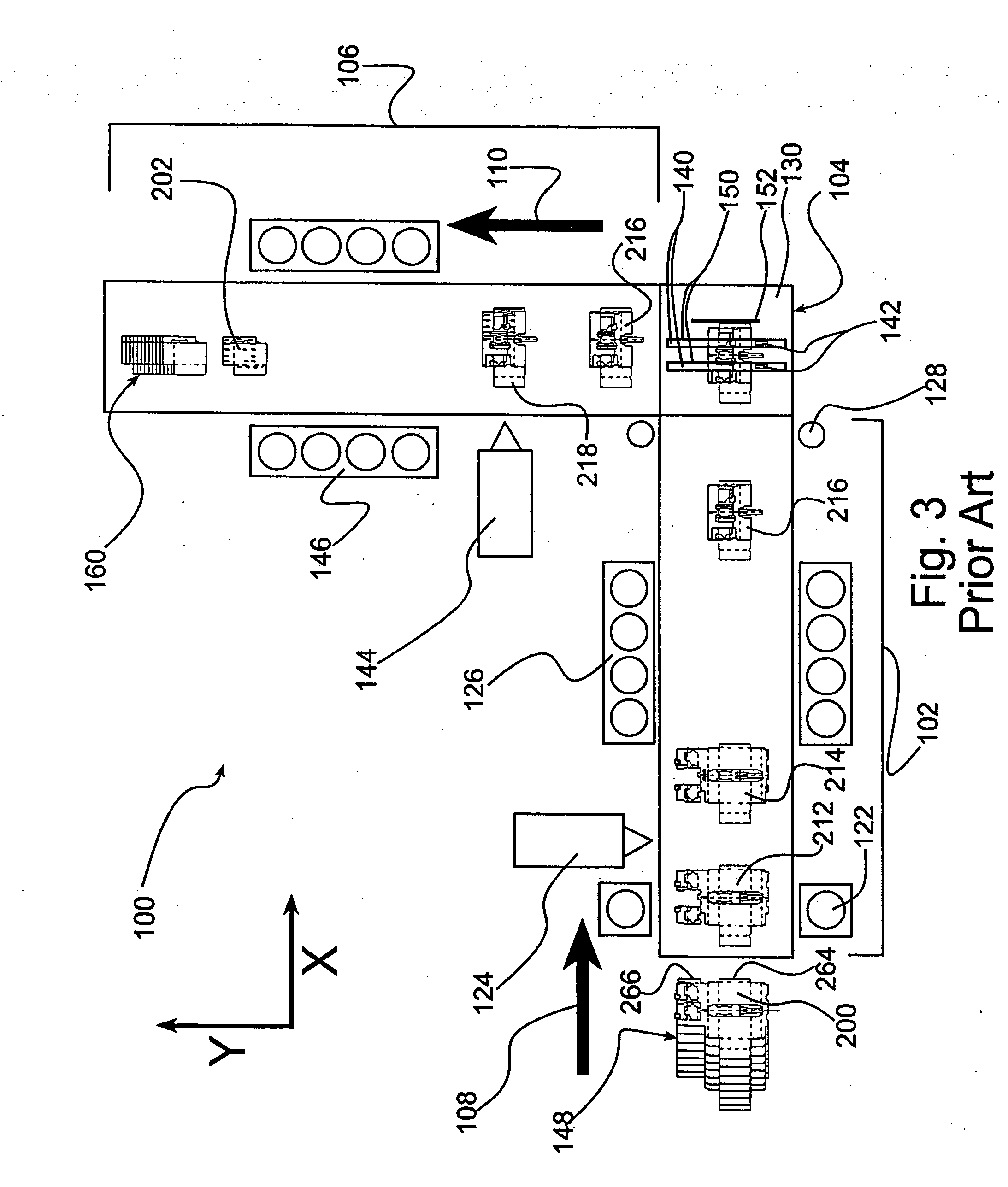

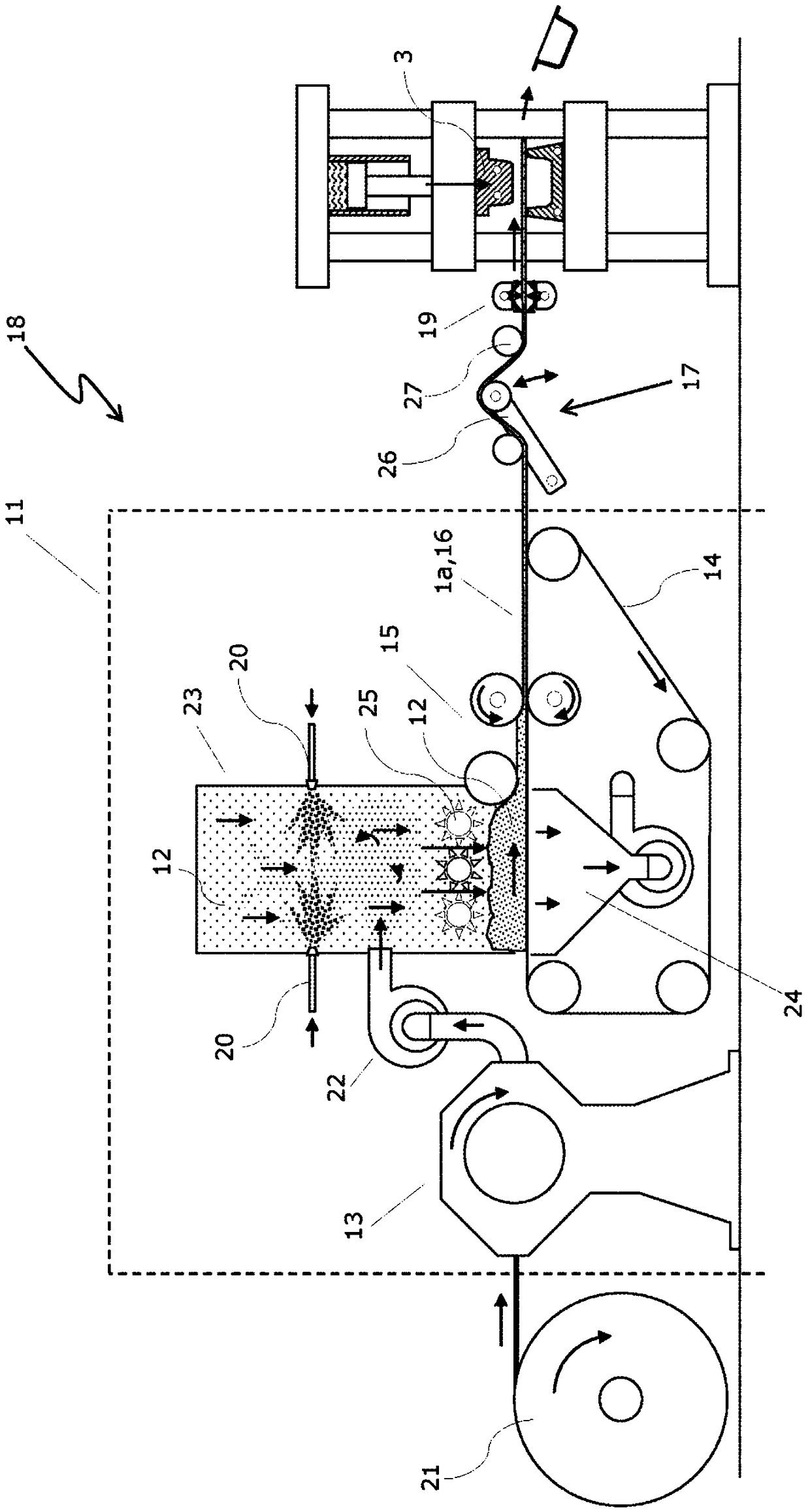

Plastic bag producing apparatus

InactiveCN1509863AEnvelopes/bags making machineryBag making operationsPlastic filmContinuous manufacturing

Owner:TOTANI GIKEN KOGYO CO LTD

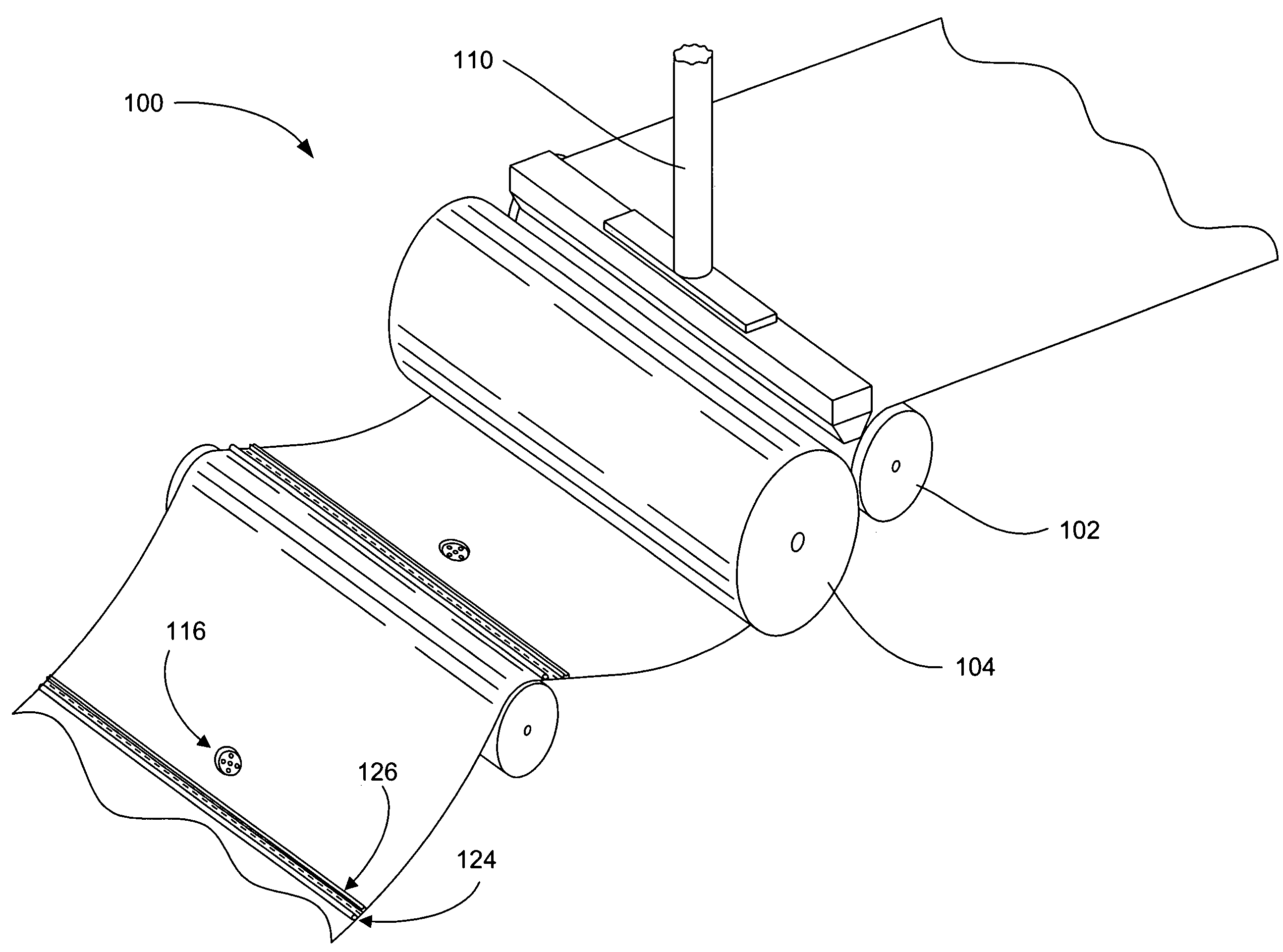

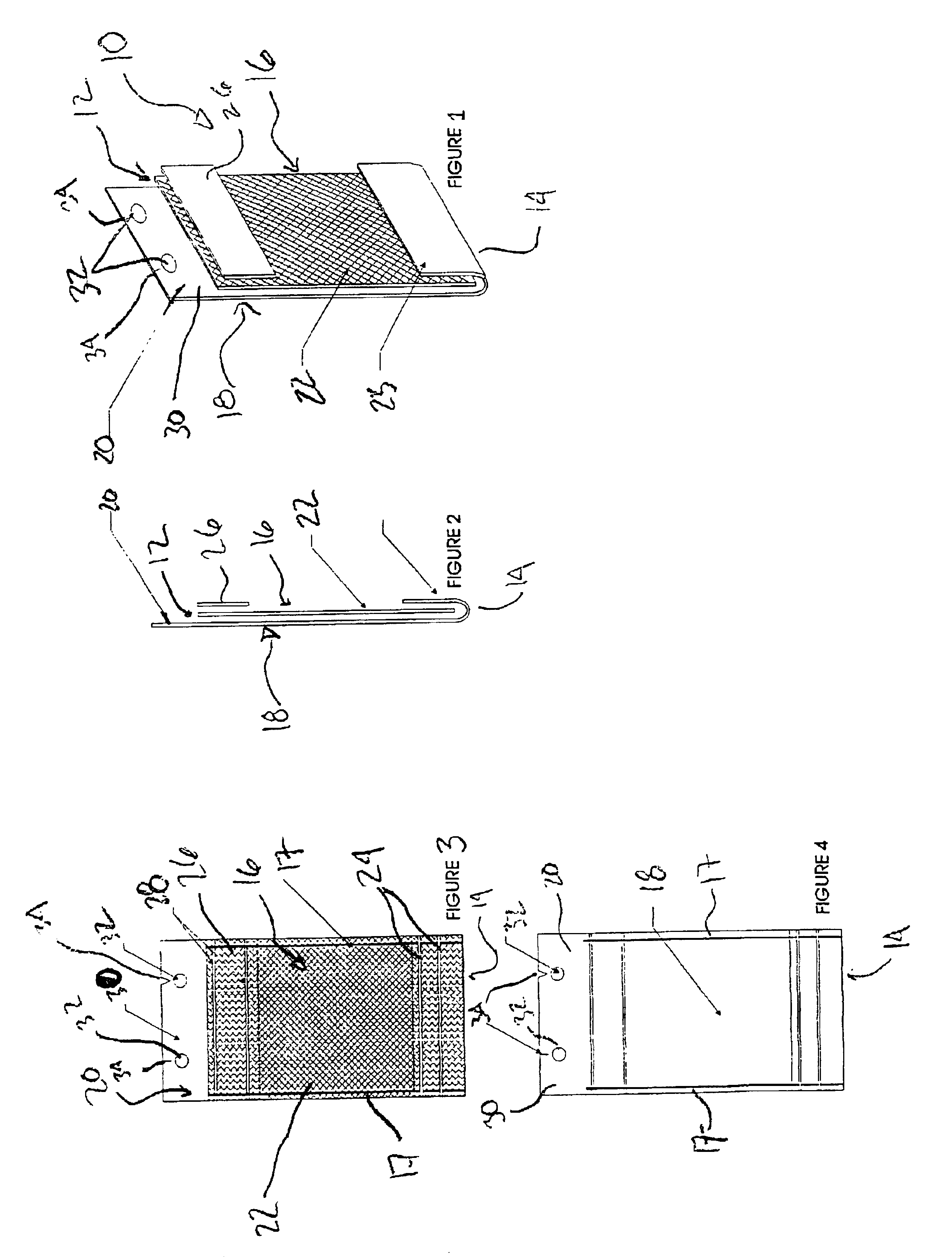

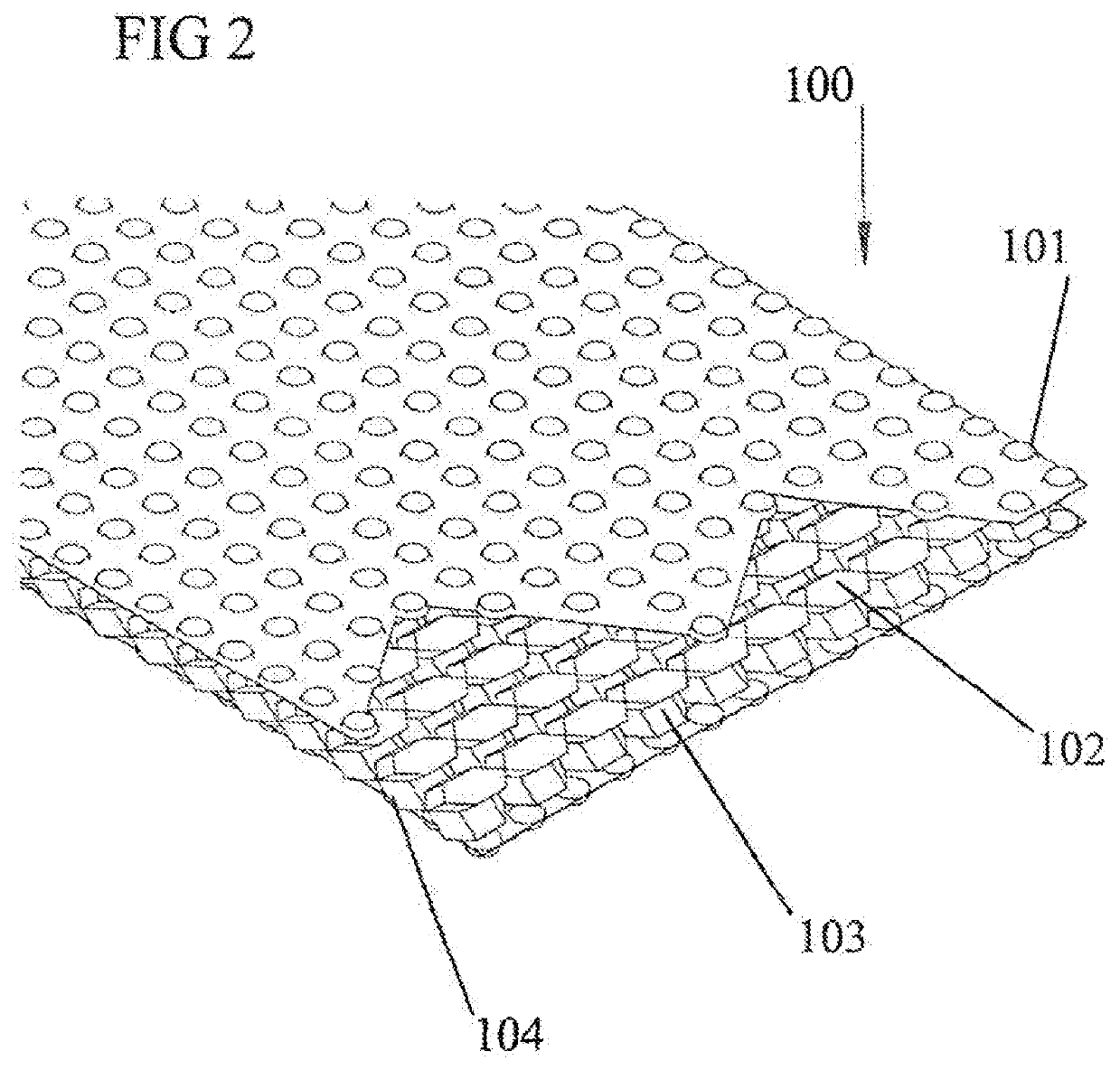

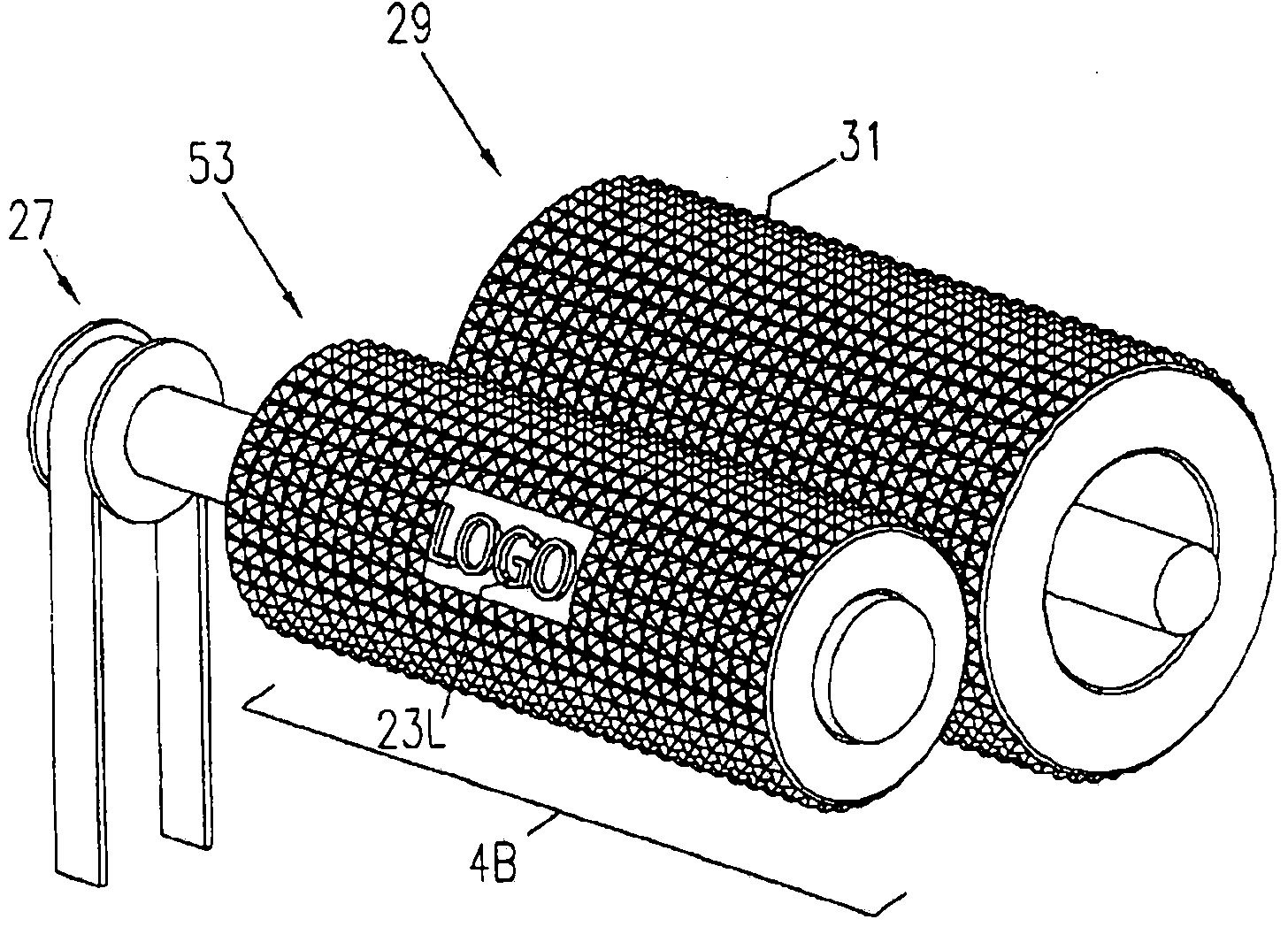

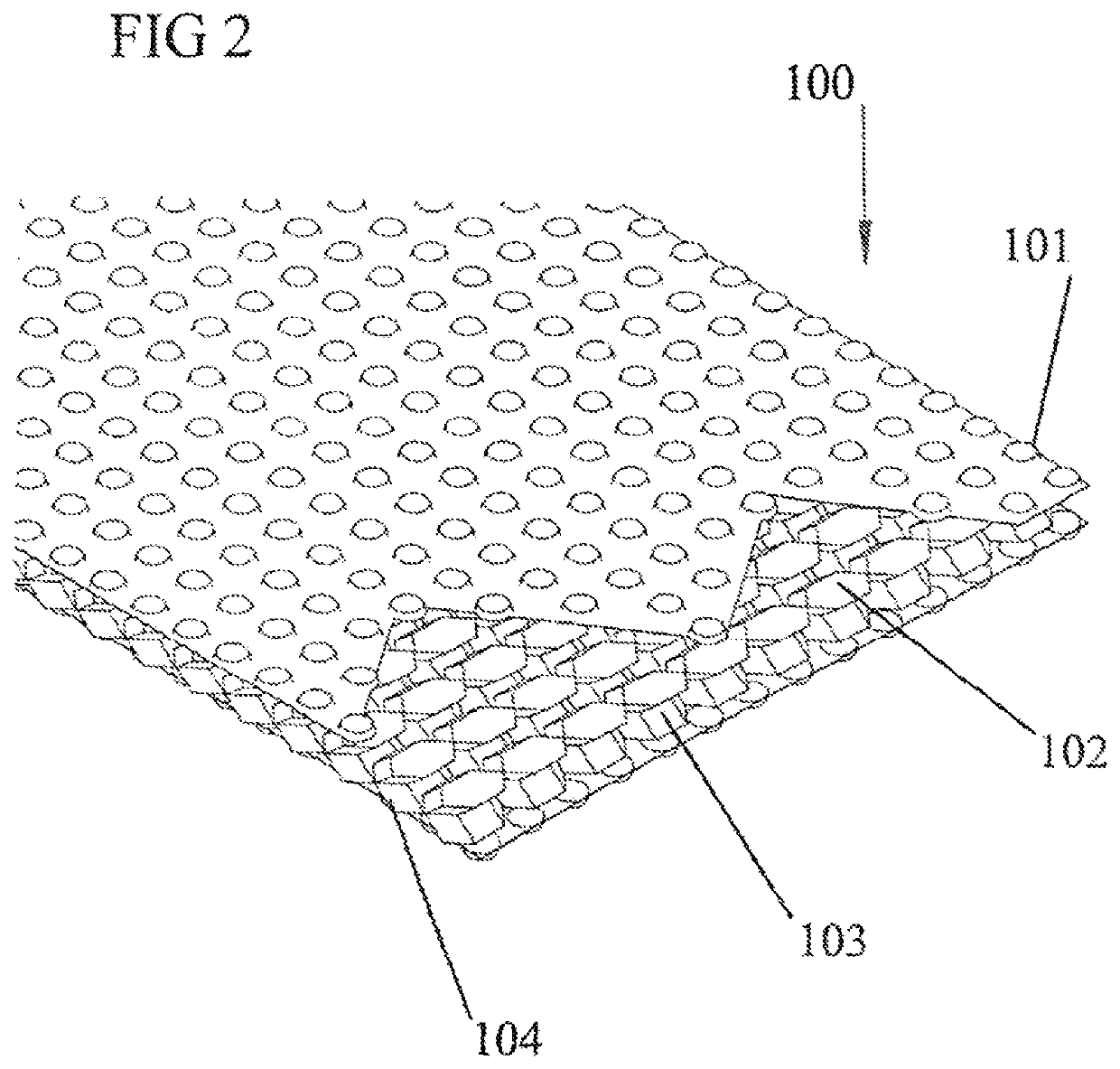

Vented breathable bag for perishable products

InactiveUS6866620B2Make fastPerishable product bagsEnvelopes/bags making machineryBoxes/cartons making machineryProduction lineAutonomation

A process for making successive product bags on an automated production line, comprises the steps of: a) providing a mesh sheet and first and second plastic sheets on rolls, unwinding the mesh sheet and the first and second plastic sheets from the rolls, b) while the sheets are advanced through the production line, folding one longitudinal edge portion of the second plastic sheet over the mesh sheet, c) sealing the folded portion of the second plastic sheet to one longitudinal side of the mesh sheet and the first plastic sheet to an opposed longitudinal side of the mesh sheet to form a master web, and d) sealing and cutting the master web along longitudinally spaced-apart lines transverse to a direction of travel of the sheets to thereby produce a succession of individual bags having one panel at least partly made of a mesh material.

Owner:FRIEDMAN HERSHEY

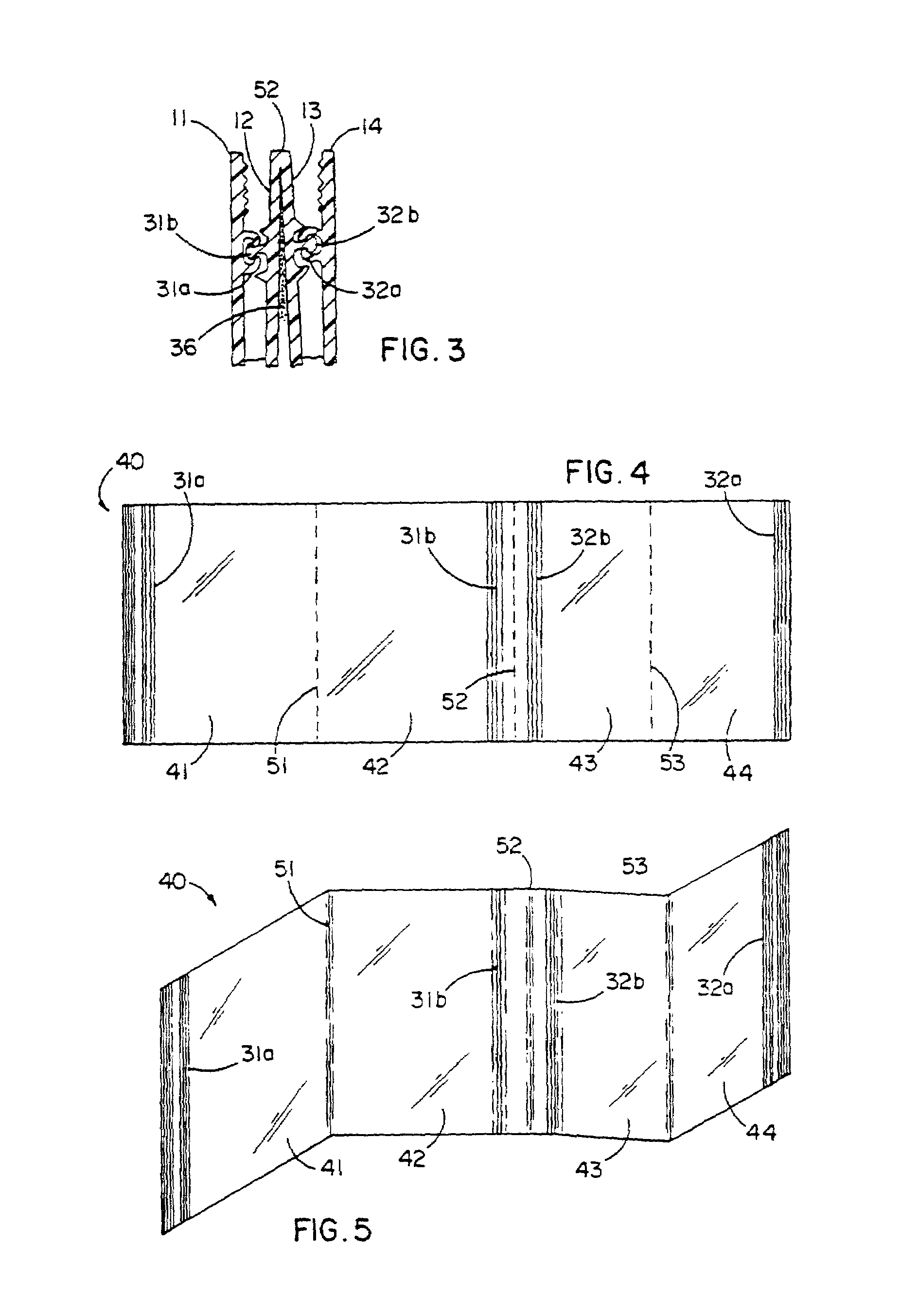

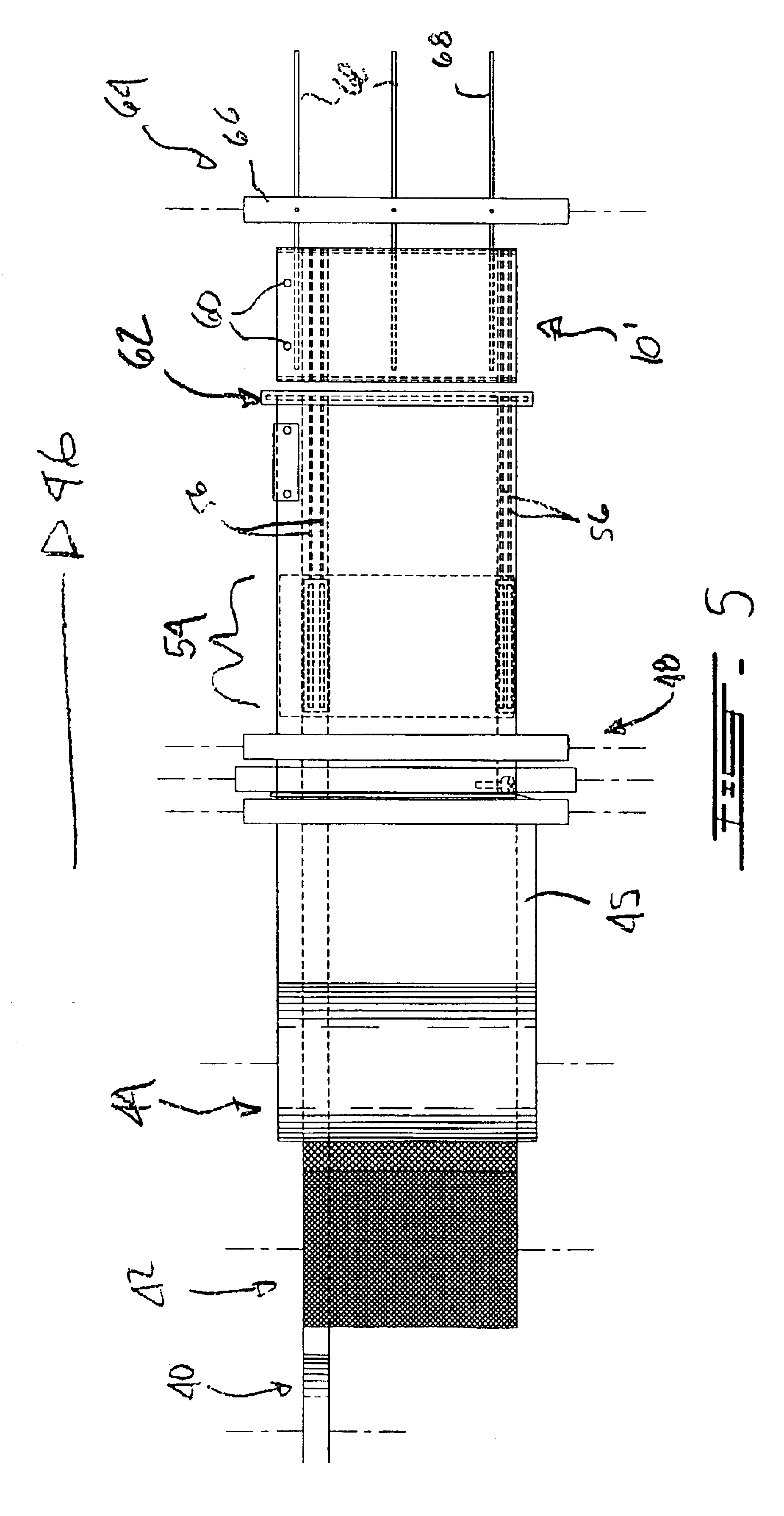

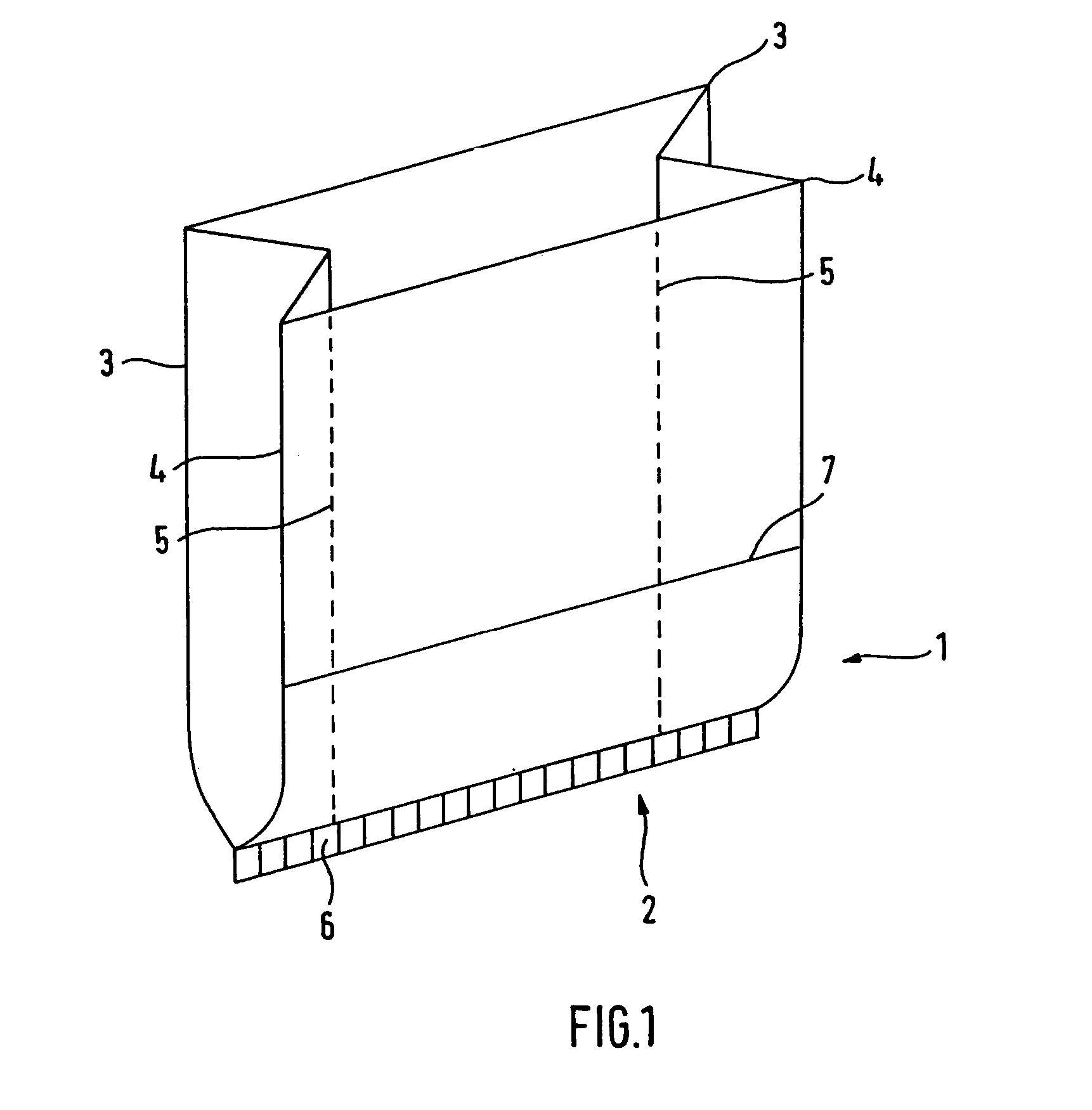

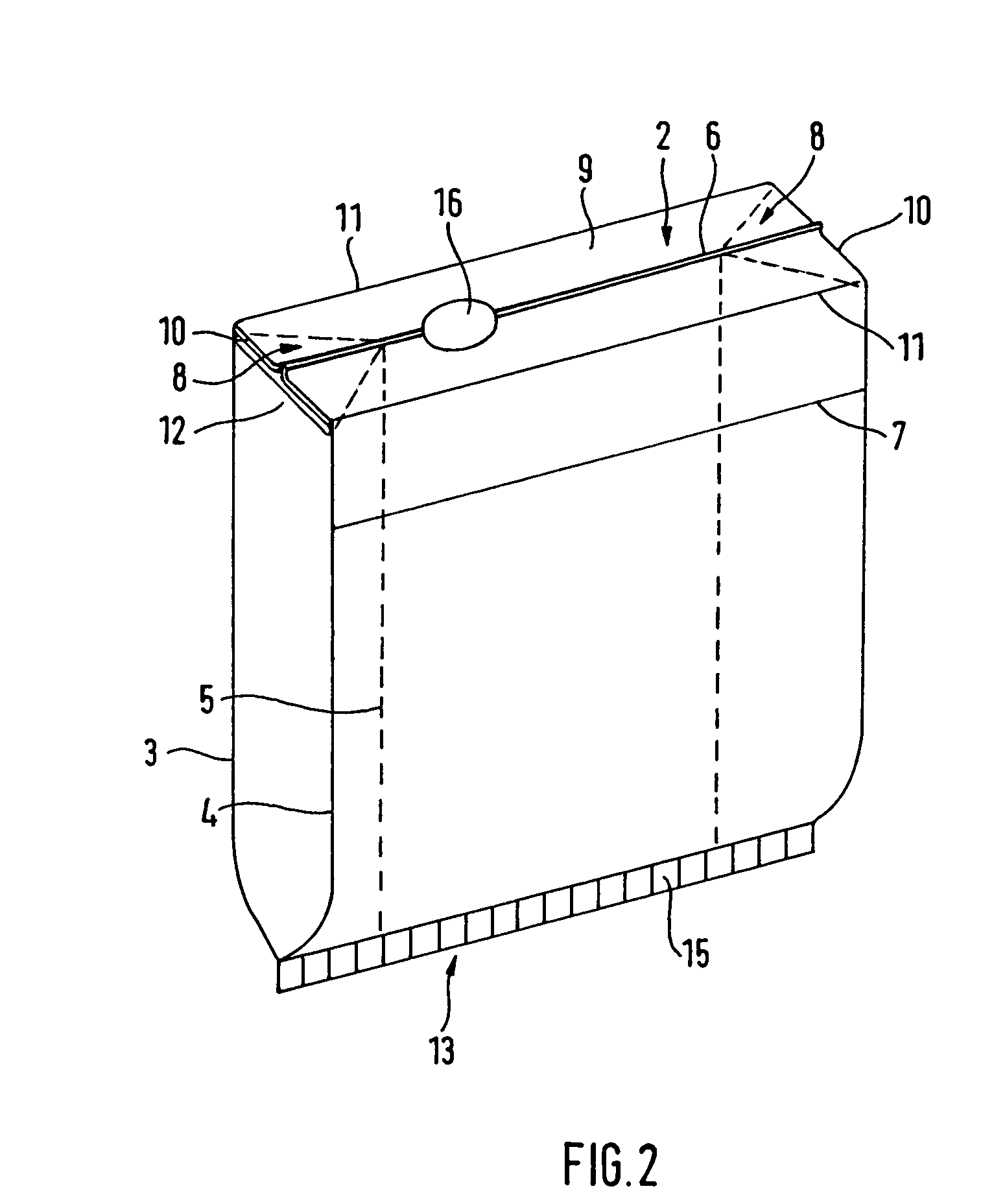

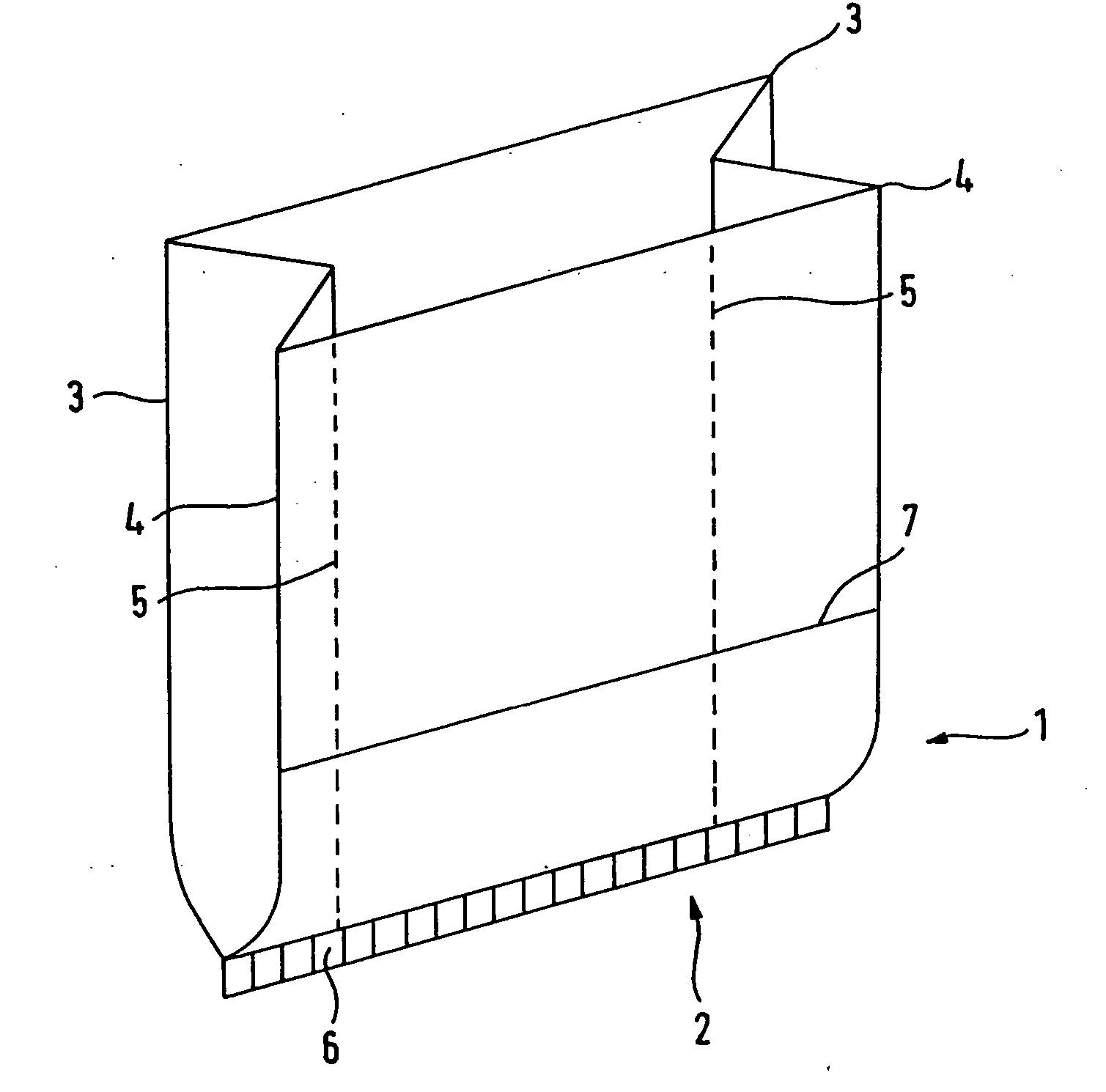

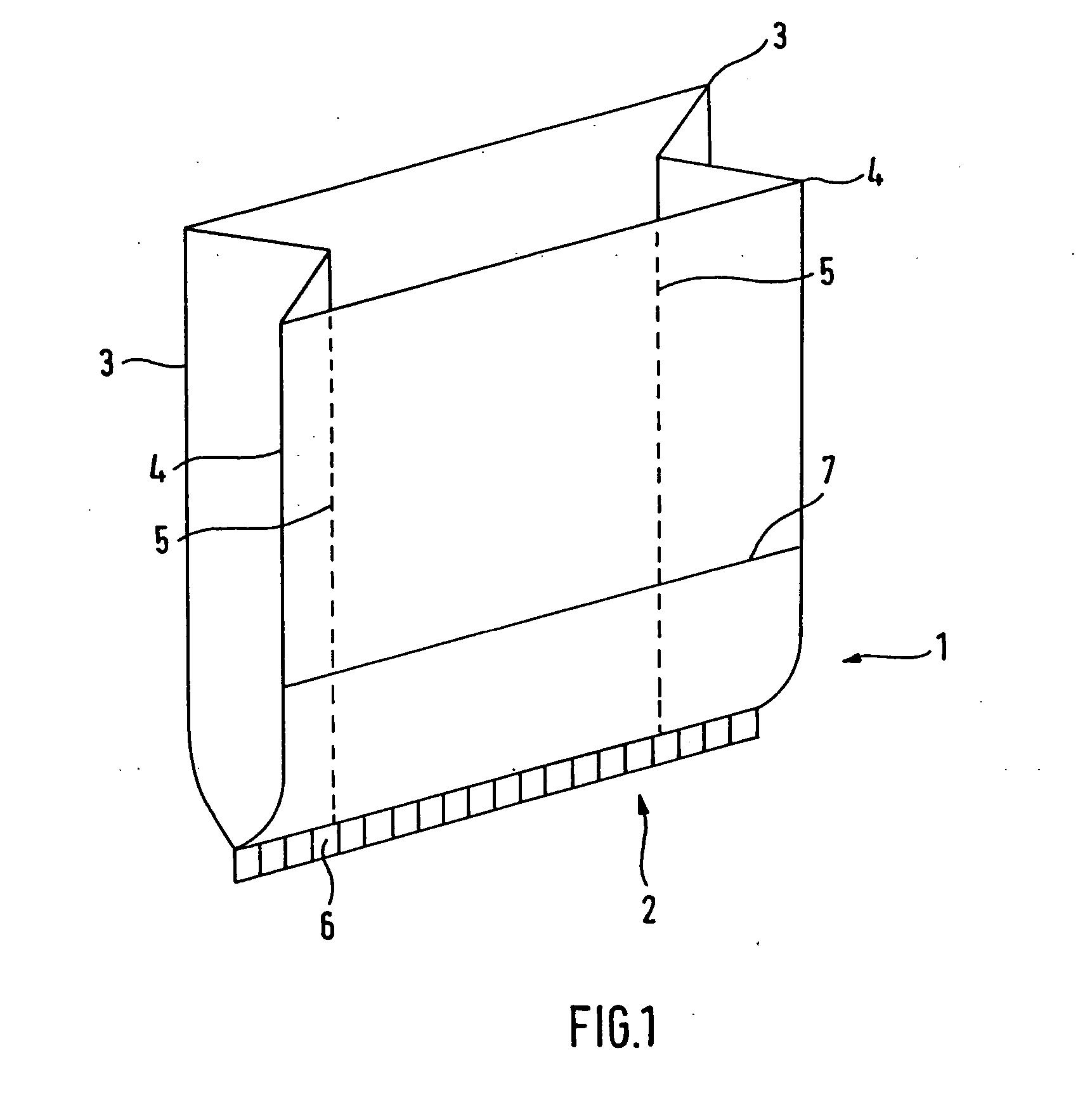

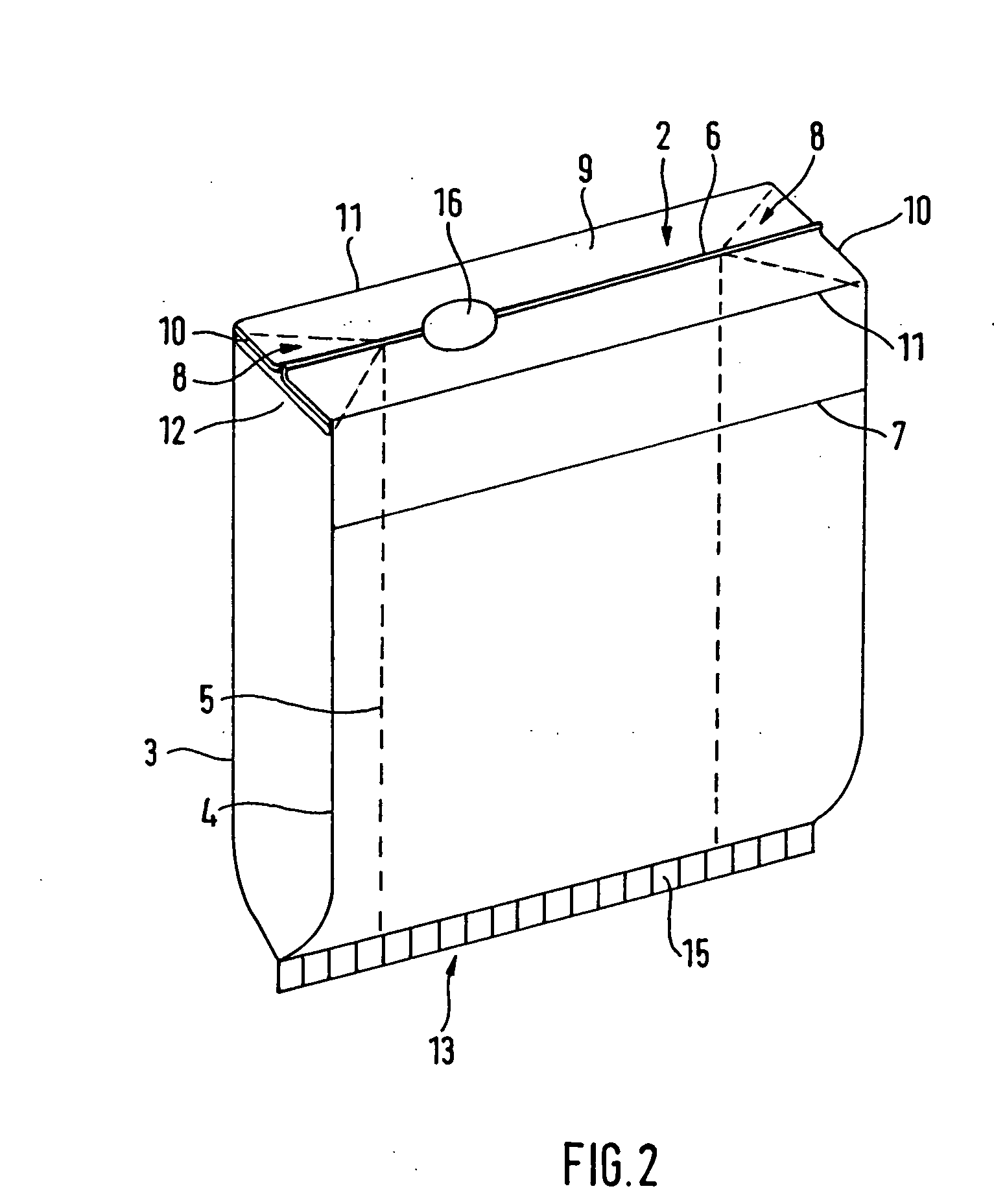

Filter bag and method for the production thereof

ActiveUS8002862B2Low flexural strengthEasy to installEnvelopes/bags making machineryMechanical working/deformationFolded formWeld seam

Described is a filter bag for a vacuum cleaner which may include a tubular bag with a closed free end area and an opposed, at least partially closed area as well as with a retaining plate. The bag is made from a bag material having at least one non-woven layer, and the at least partially closed area is folded forming a bottomPlies of the bag material which lie the one above the other are formed in areas, and is at least partially closed by a weld seam extending centrally in the bottom, the plies of the bag material which lie the one above the other being at least partially connected to one another.

Owner:EUROLIFTERS HLDG NV

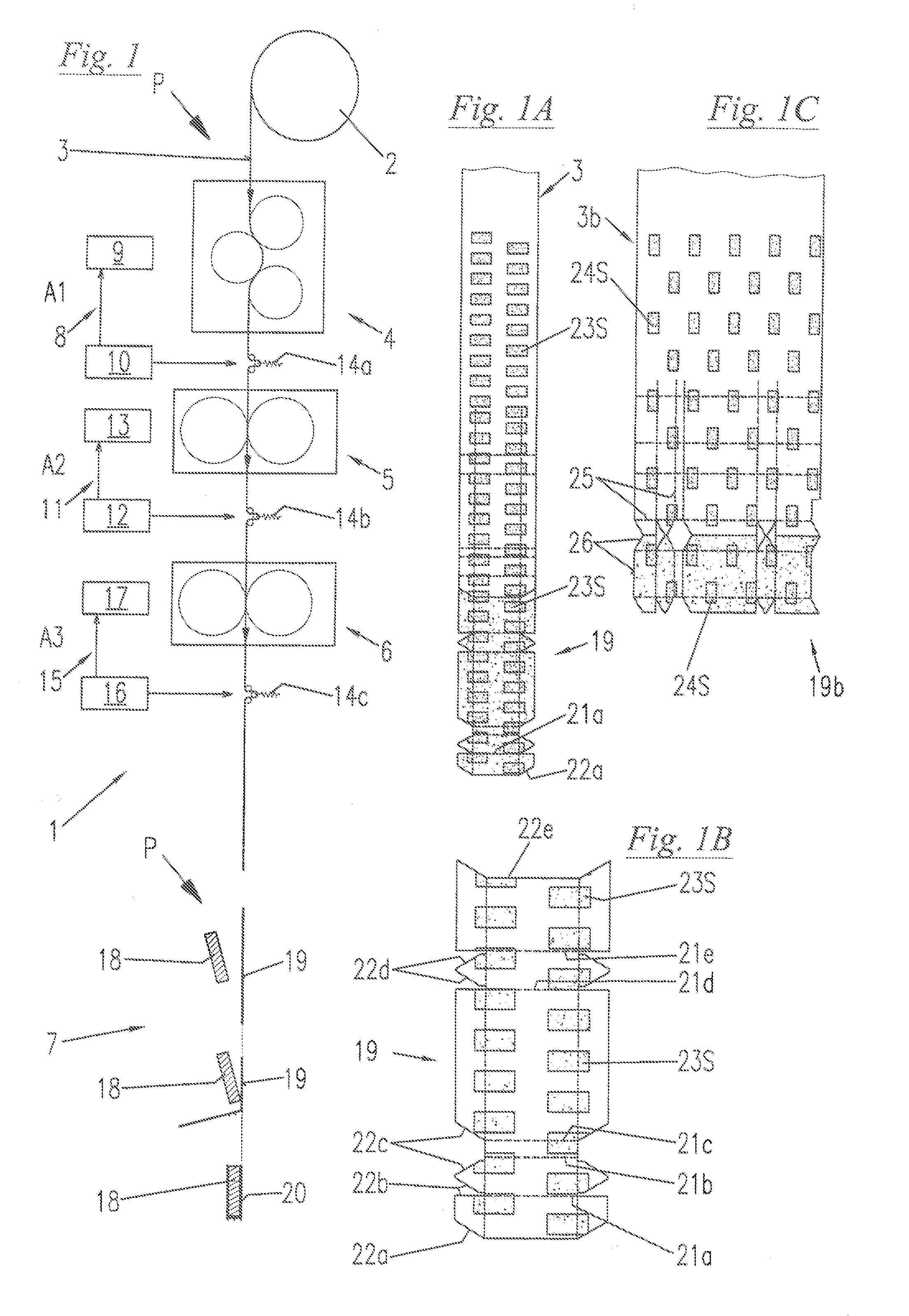

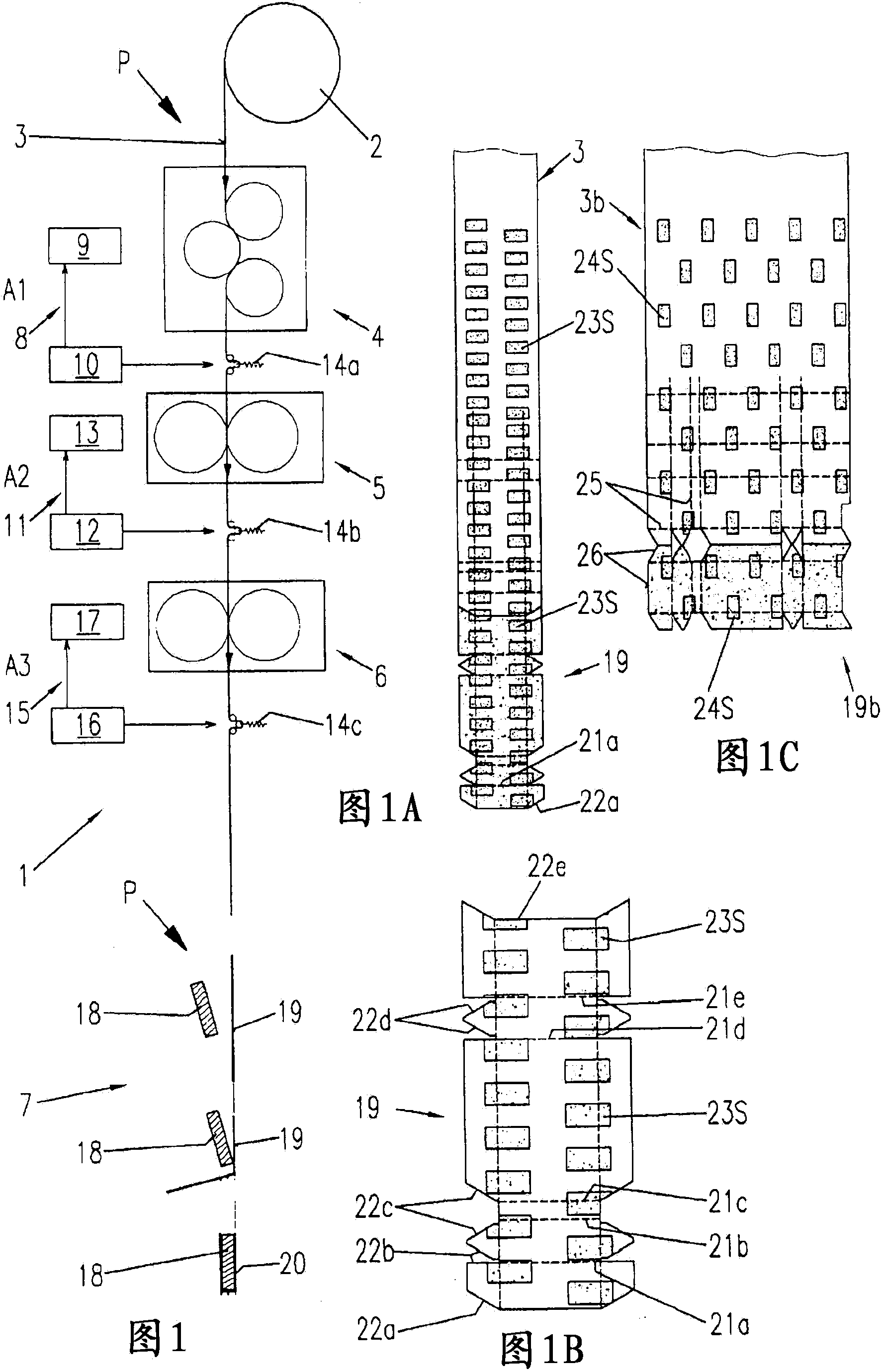

Method and device for producing a package for smoking articles

InactiveUS20140059977A1Rational productionMore productiveMechanical working/deformationPackaging cigaretteEngineeringOverwrap

In the method for producing a package for bar-shaped smoking articles that has at least one outer layer intended to receive the bar-shaped smoking articles and to hold the package together, a foil strip that is suitable for the outer layer and is taken from a reel is embossed and / or provided with creasing breaks online in time with the work cadence (P) of the packaging machine and subsequently cut to size. The resulting blank is then folded around the bar-shaped smoking articles in the packaging machine. On one hand, this method allows packaging the cigarettes directly in the outer wrapper without an innerliner, and on the other hand, to strongly rationalize and simplify the entire packaging process and to apply a large variety of signs of all kinds that are perceptible visually, tactually, acoustically or by olfaction.

Owner:BOEGLL GRAVURES SA

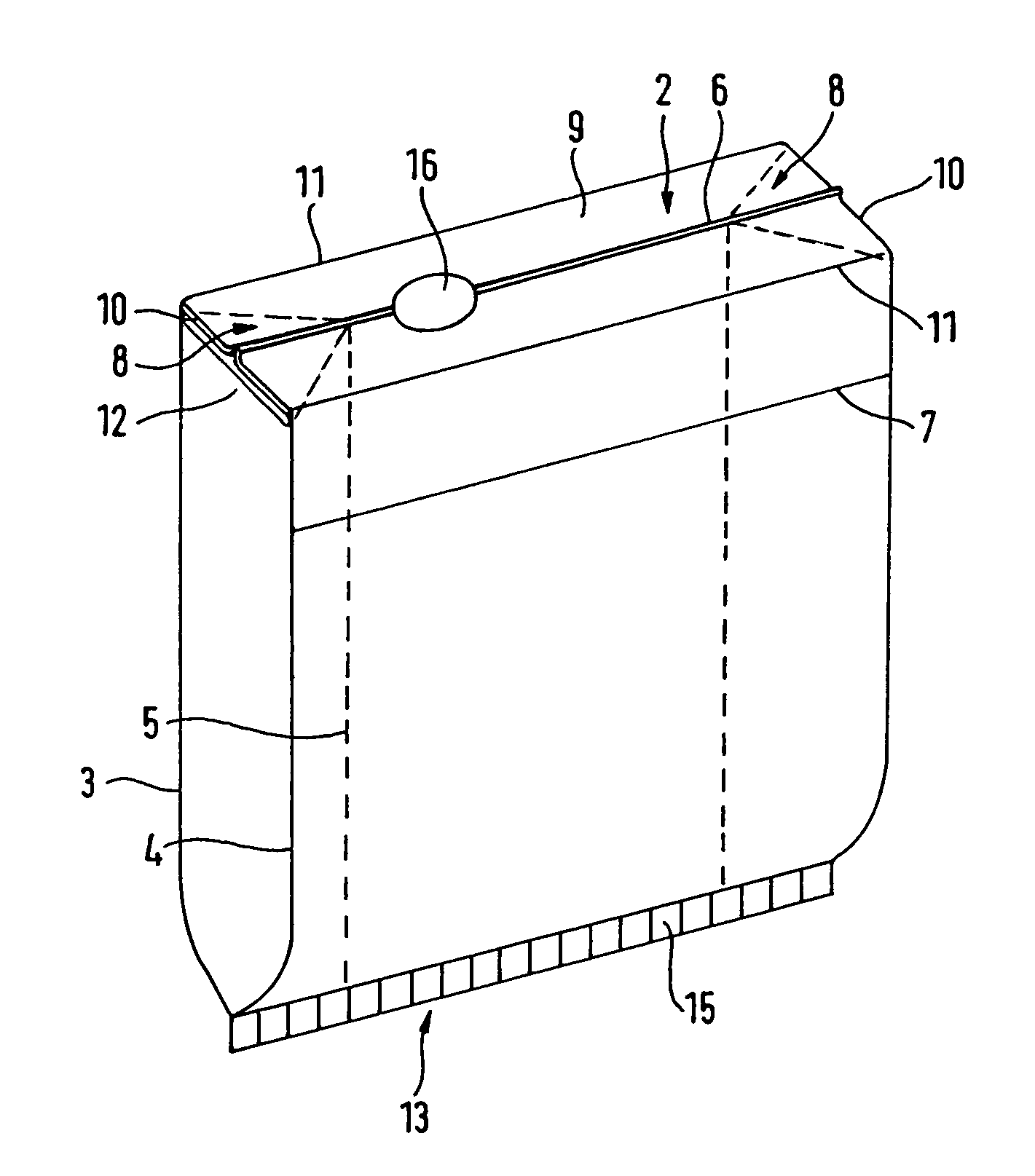

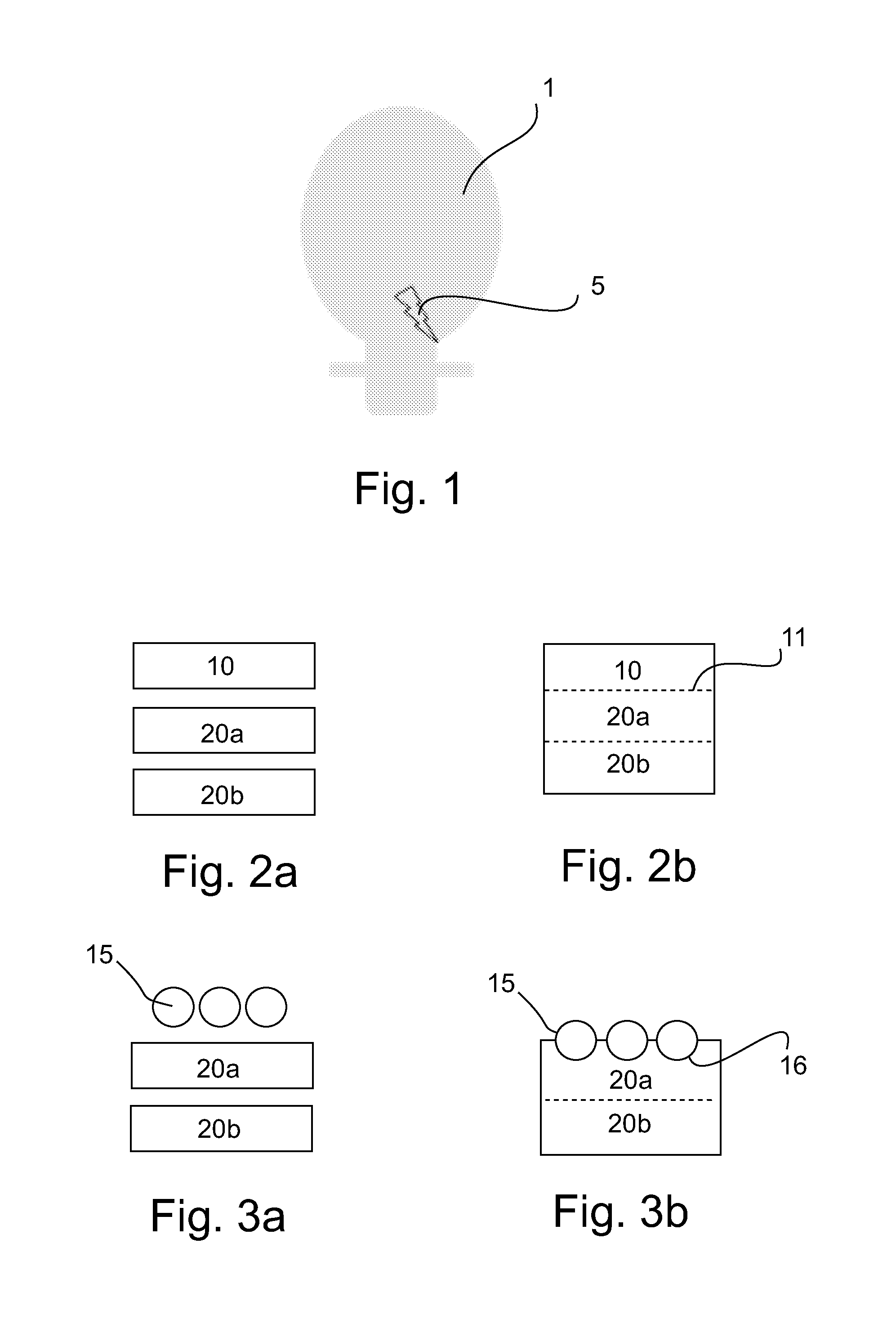

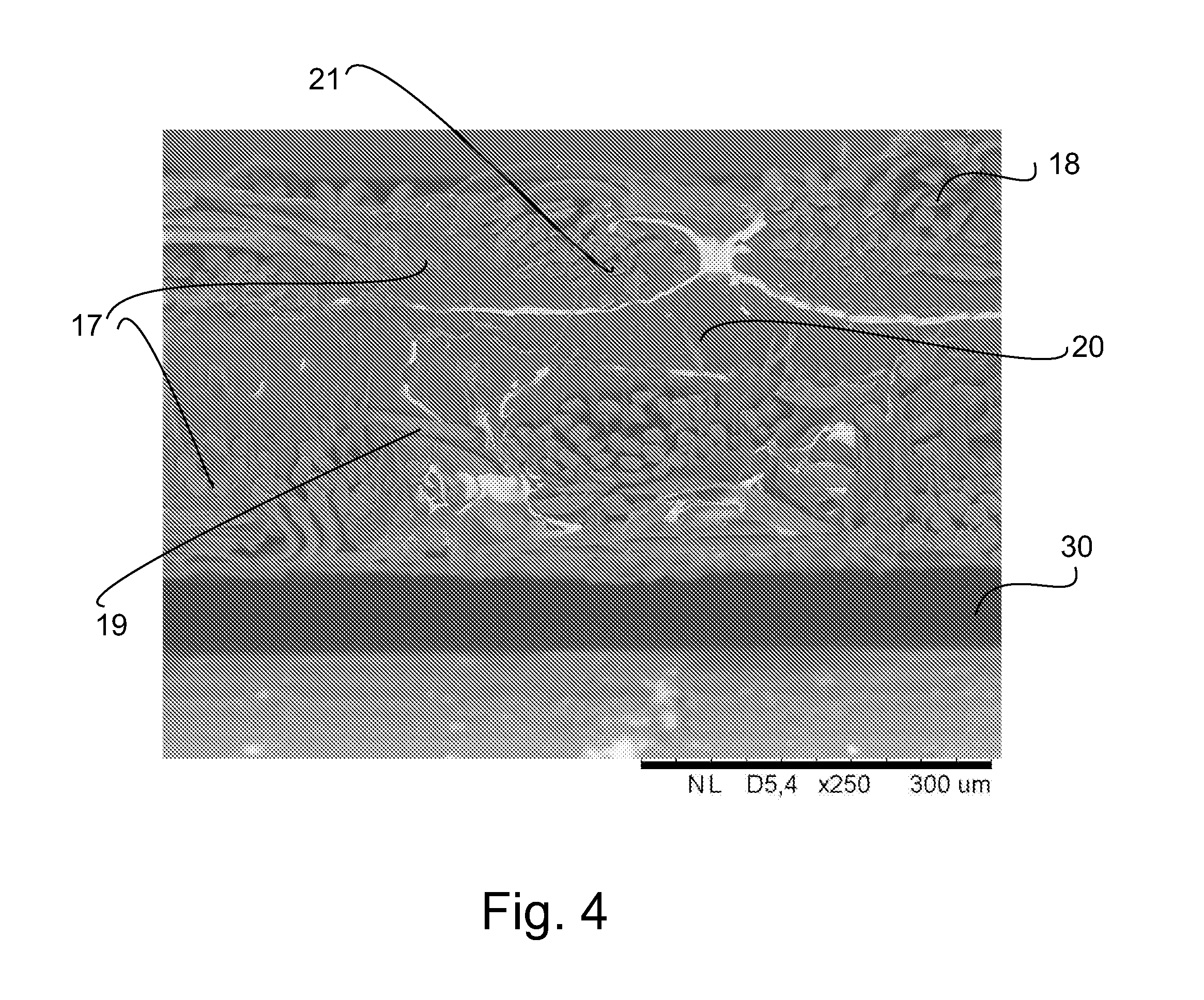

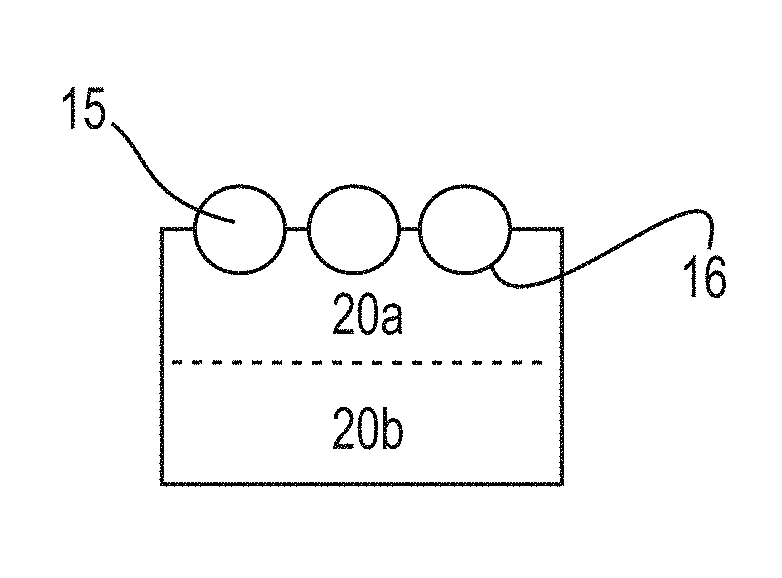

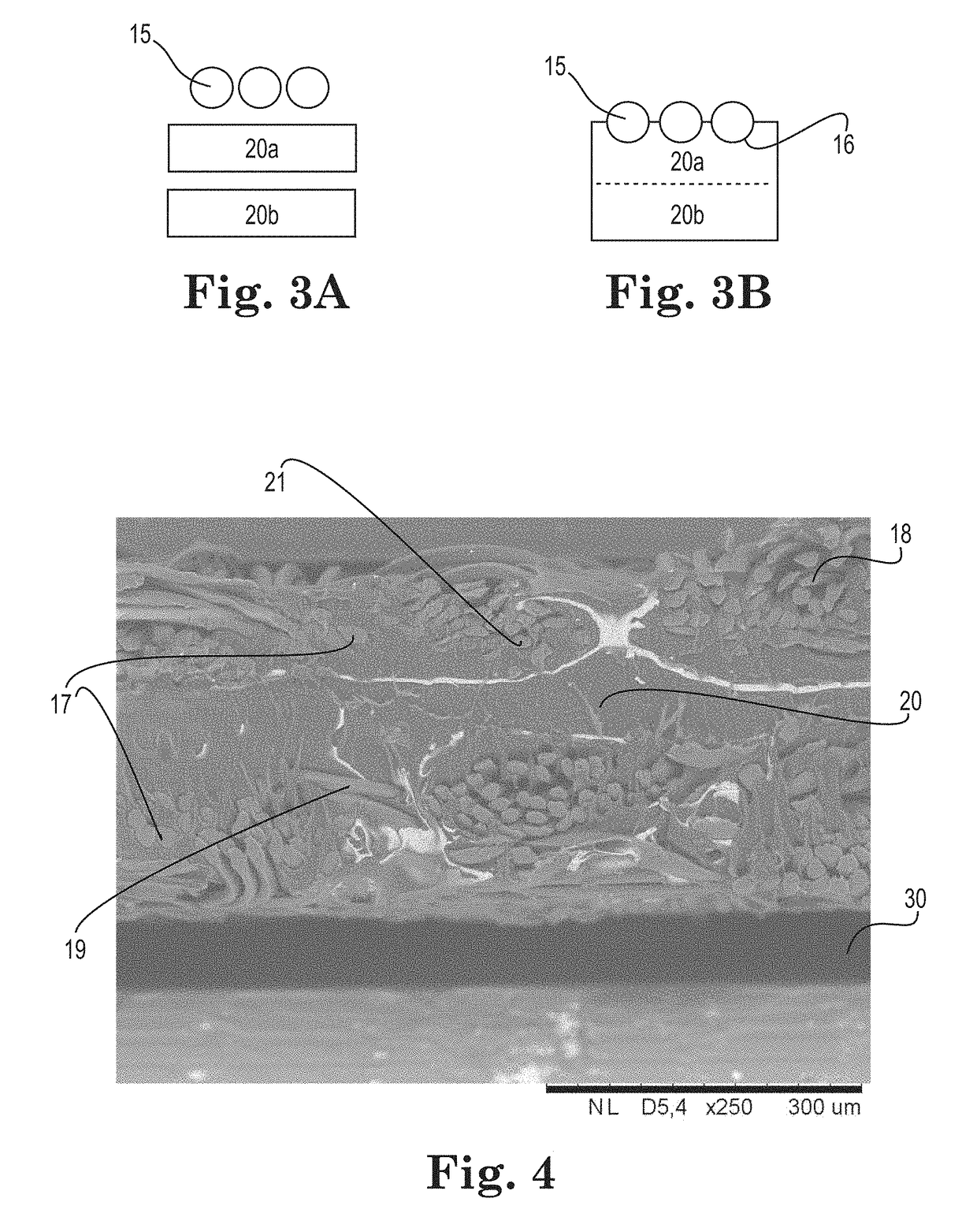

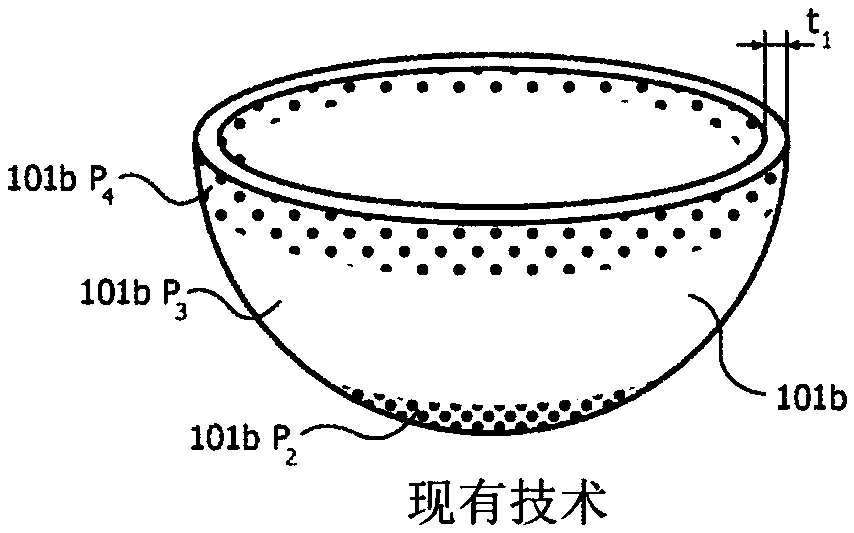

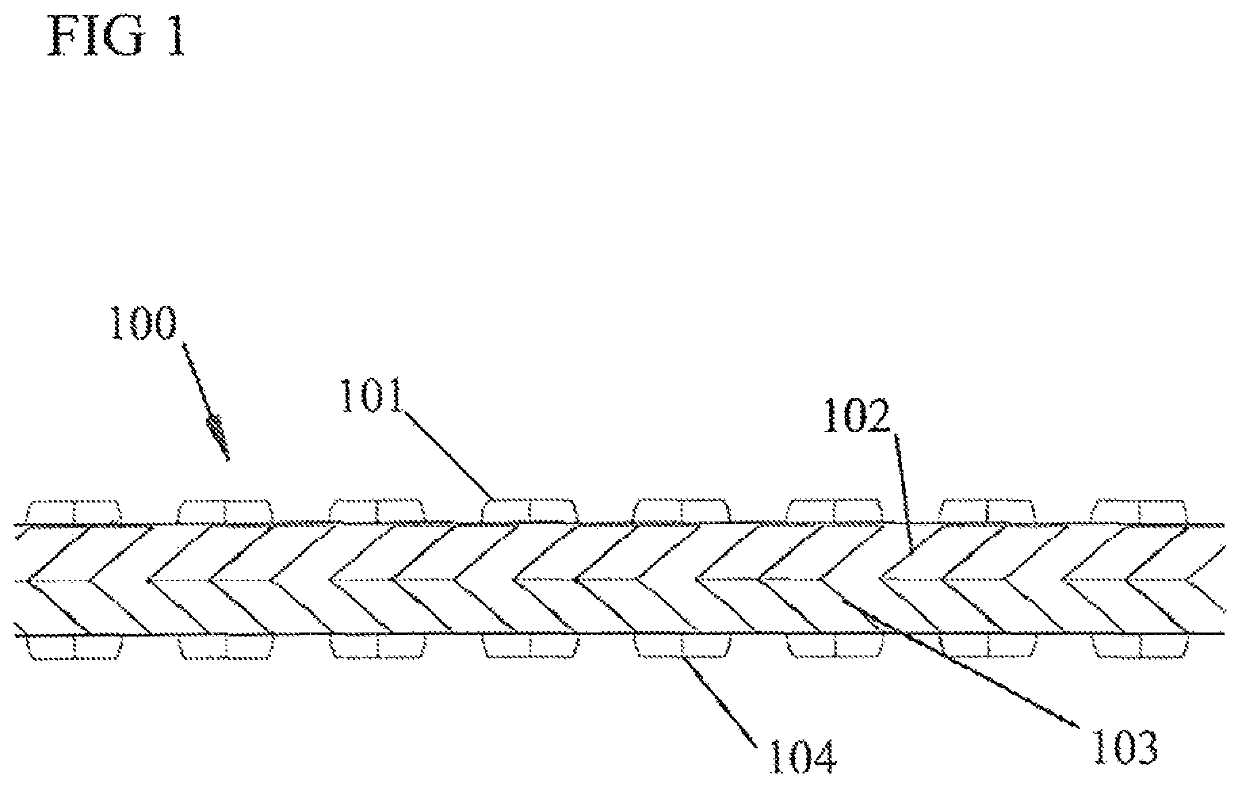

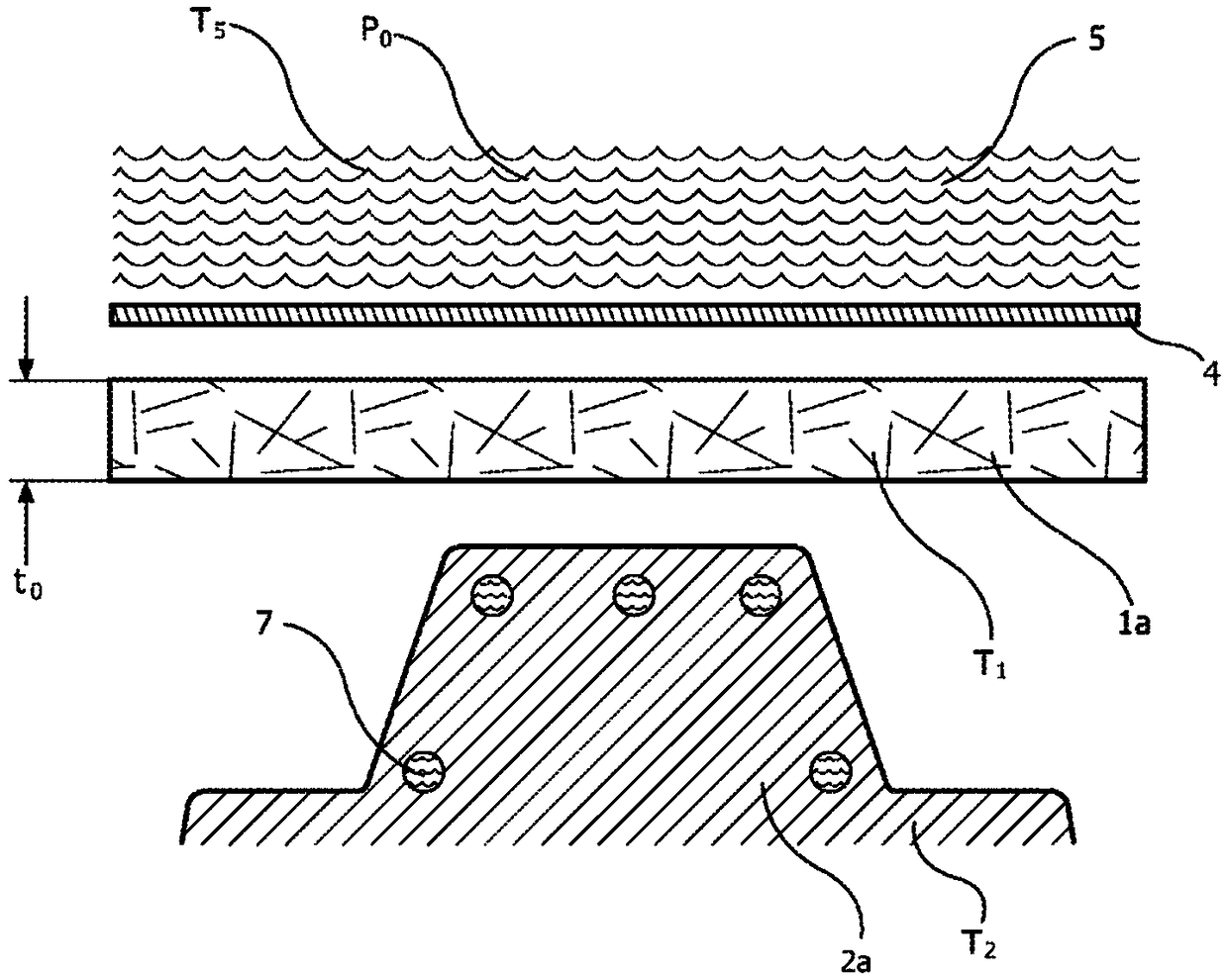

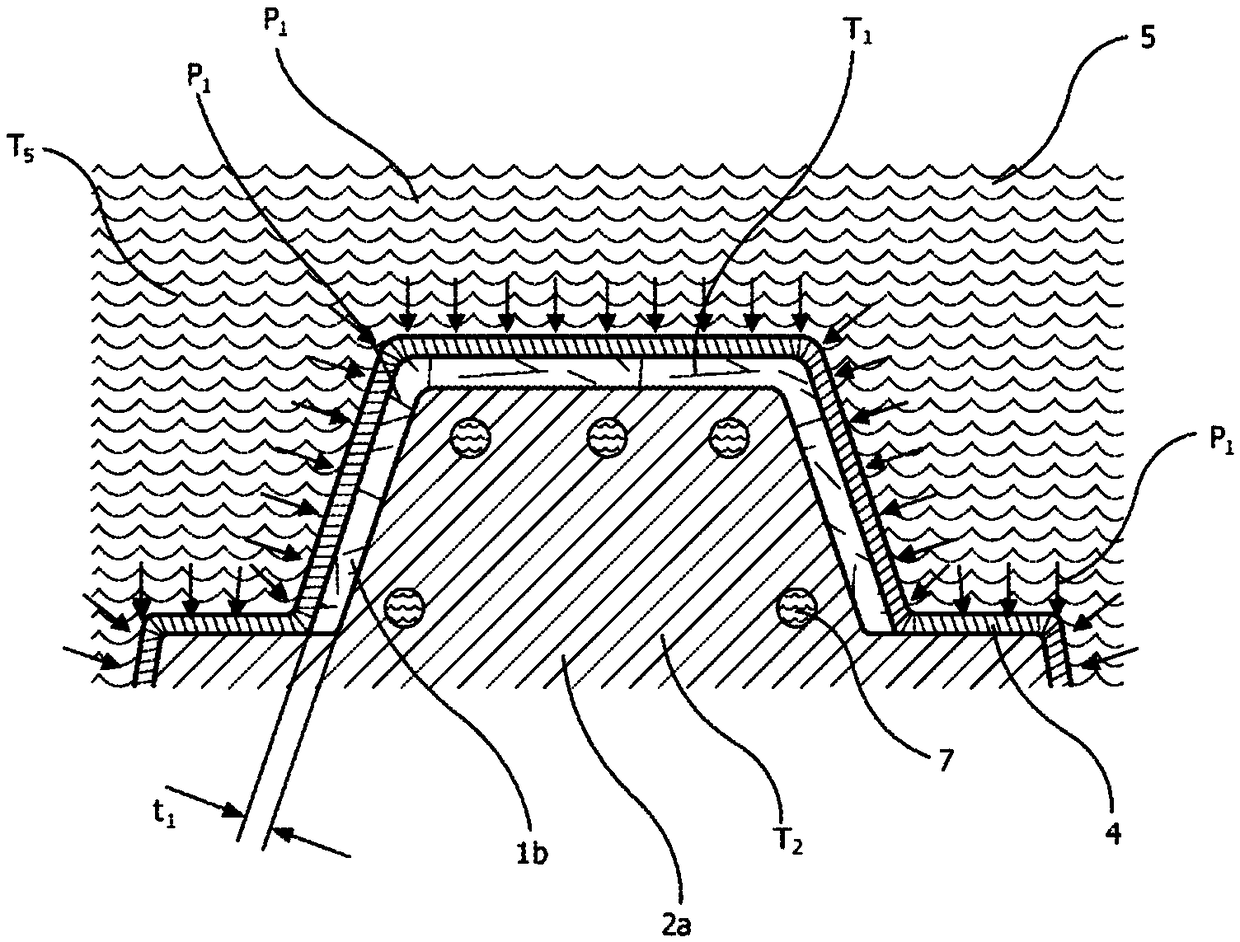

Comfort layer for a collecting bag

ActiveUS20150133881A1Increase resistanceImproved visualBag making operationsPaper-makingFiberEngineering

A collecting bag for human body wastes having a barrier film (20a, 20b) covered by a comfort layer (15) attached to the barrier film in an attachment zone wherein the comfort layer is a textile material that is attached to said barrier film in one or more zones of attachment such that not all of the fibre filaments of the textile material in the attachment zone(s) are embedded in the barrier film material.

Owner:COLOPLAST AS

Filter bag and method for the production thereof

ActiveUS20070175190A1Easily fitted into vacuum cleanLow flexural strengthCombination devicesAuxillary pretreatmentFolded formEngineering

Described is a filter bag for a vacuum cleaner which may include a tubular bag with a closed free end area and an opposed, at least partially closed area as well as with a retaining plate. The bag is made from a bag material having at least one non-woven layer, and the at least partially closed area is folded forming a bottomplies of the bag material which lie the one above the other are formed in areas, and is at least partially closed by a weld seam extending centrally in the bottom, the plies of the bag material which lie the one above the other being at least partially connected to one another.

Owner:EUROLIFTERS HLDG NV

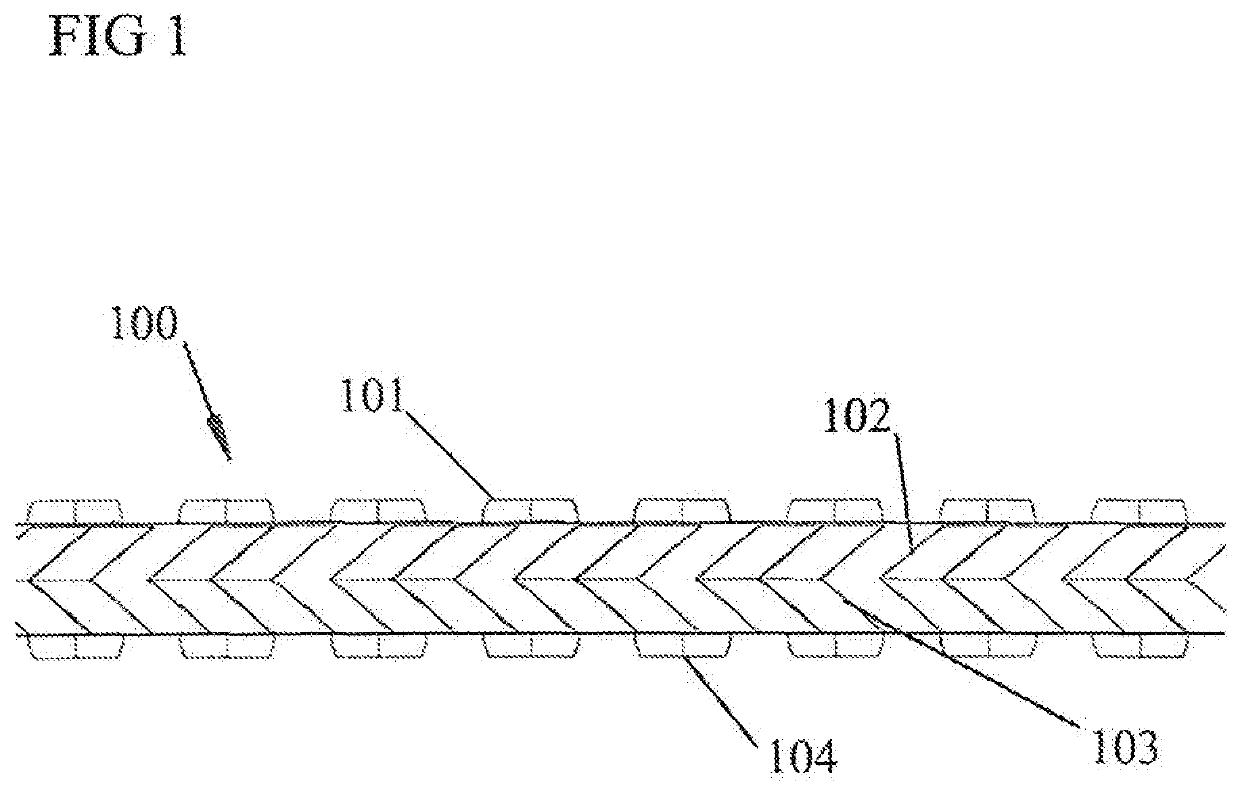

Protective Products Such as Envelopes Having a Unique Combination of Interior Padding of Expanded Slit Sheet Paper and Exterior Lining of Embossed Paper

ActiveUS20200039720A1Improve rigidityAvoid deformationMechanical working/deformationWrappersStructural engineeringPaper sheet

A protective product, such as, e.g., an envelope or pouch, is provided that includes at least one expanded slit paper sheet in an expanded state, and an embossed paper sheet facing the expanded slit paper sheet and fixed to the expanded slit paper sheet along at least a portion of a length in an expansion direction of the expanded slit sheet paper. In the preferred embodiments, the embossed paper sheet has a plurality of embossings that increase the rigidity of the embossed paper sheet, thereby inhibiting deformation of the embossed paper sheet that is fixed to the expanded slit sheet paper.

Owner:HEXCELPACK LLC

Method for making a multicompartment thermoplastic bag

A method of making a multicompartment reclosable thermoplastic bag having at least two compartments is disclosed. Each compartment has a top, a bottom, two side edges, and two opposing sidewalls joined at the side edges and the bottom. Each compartment has a closure across the top thereof, which are arranged back-to-back and aligned. The compartments are attached together proximate the tops of the compartments, and the bottoms of the compartments are free from being attached to each other. Processes for making such bags from one or more webs are also disclosed.

Owner:SC JOHNSON & SON INC

Comfort layer for a collecting bag

ActiveUS10045878B2Increase resistanceImproved visual and tactile characteristicBag making operationsPaper-makingFiberEngineering

A collecting bag for human body wastes having a barrier film (20a, 20b) covered by a comfort layer (15) attached to the barrier film in an attachment zone wherein the comfort layer is a textile material that is attached to said barrier film in one or more zones of attachment such that not all of the fiber filaments of the textile material in the attachment zone(s) are embedded in the barrier film material.

Owner:COLOPLAST AS

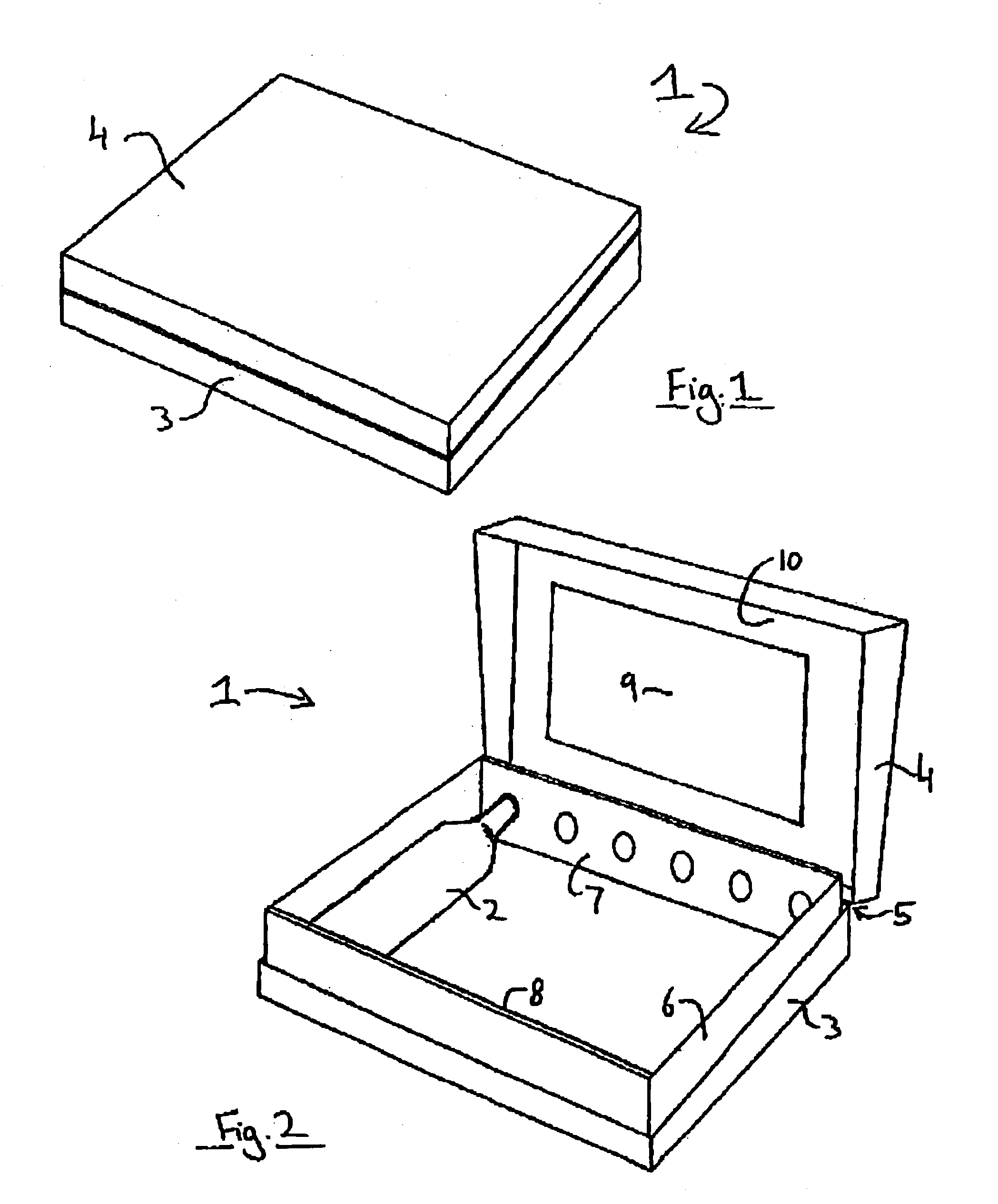

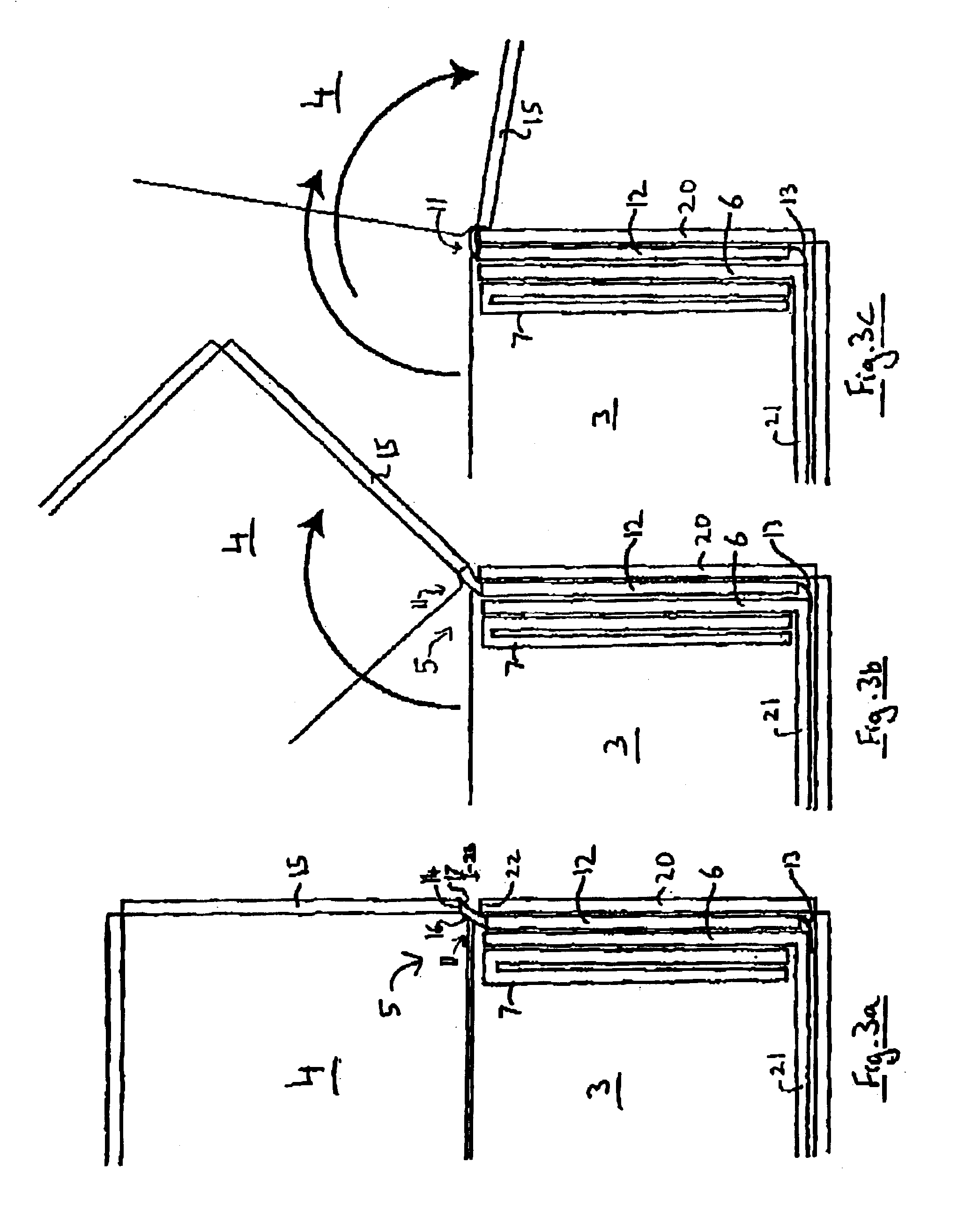

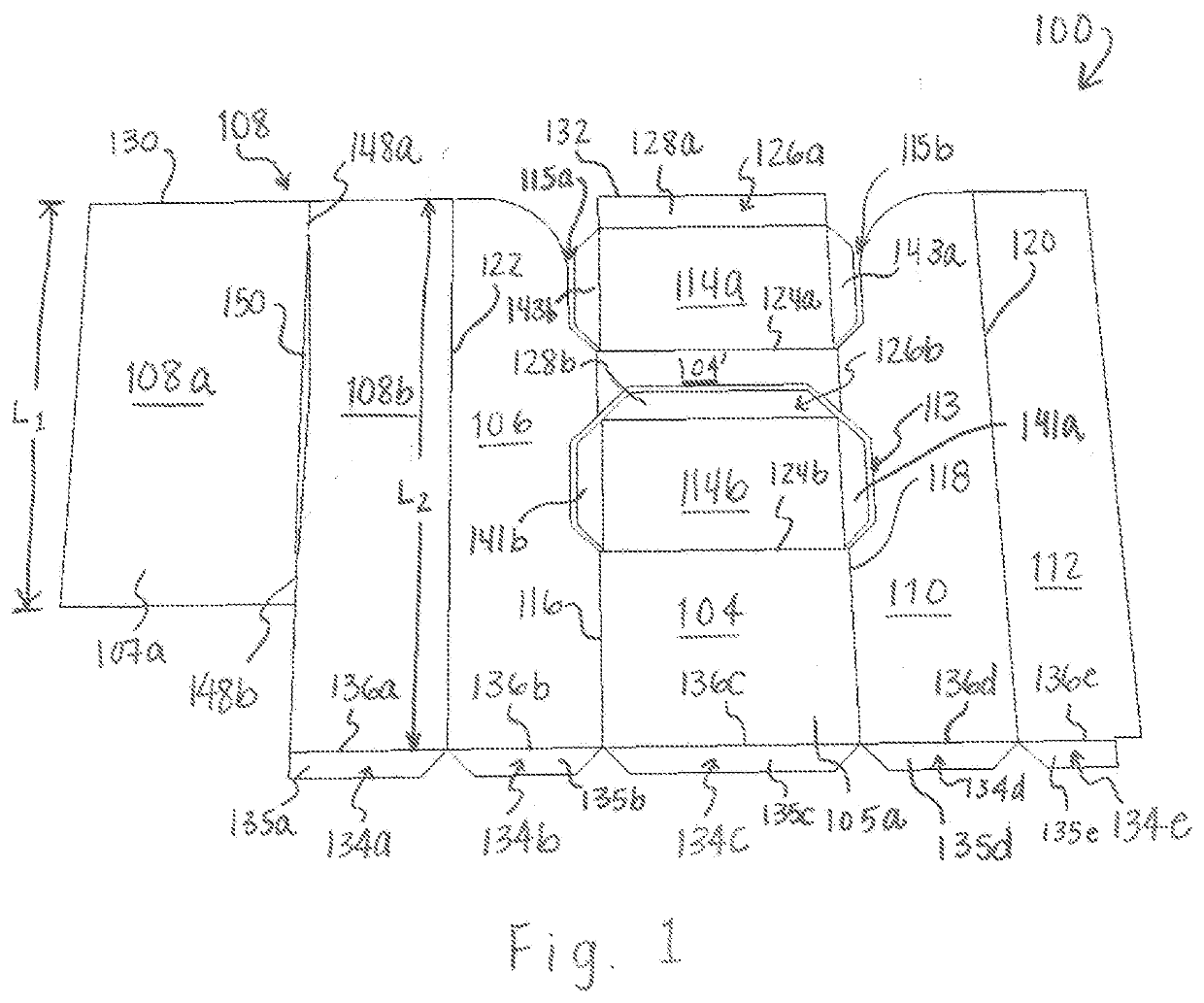

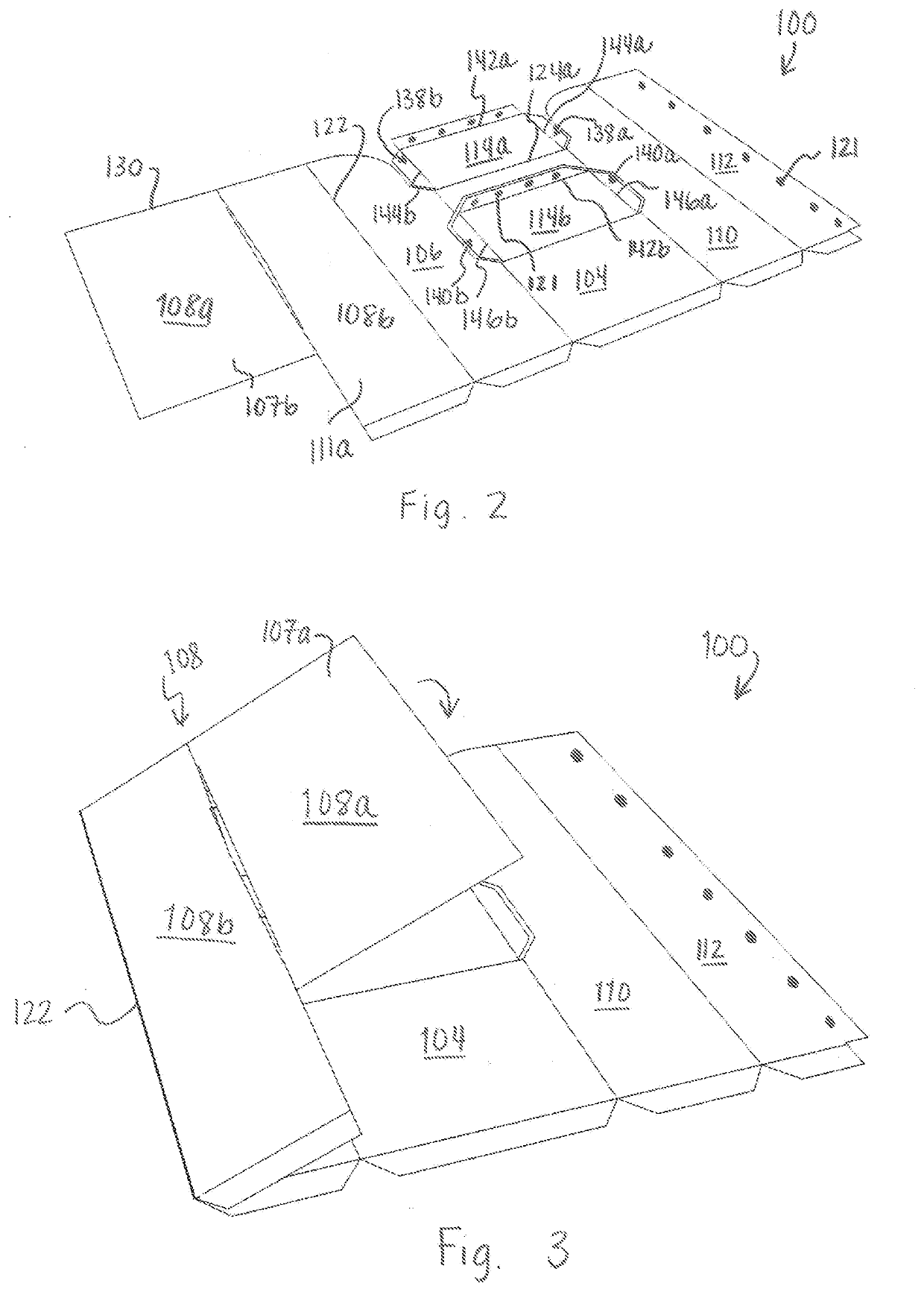

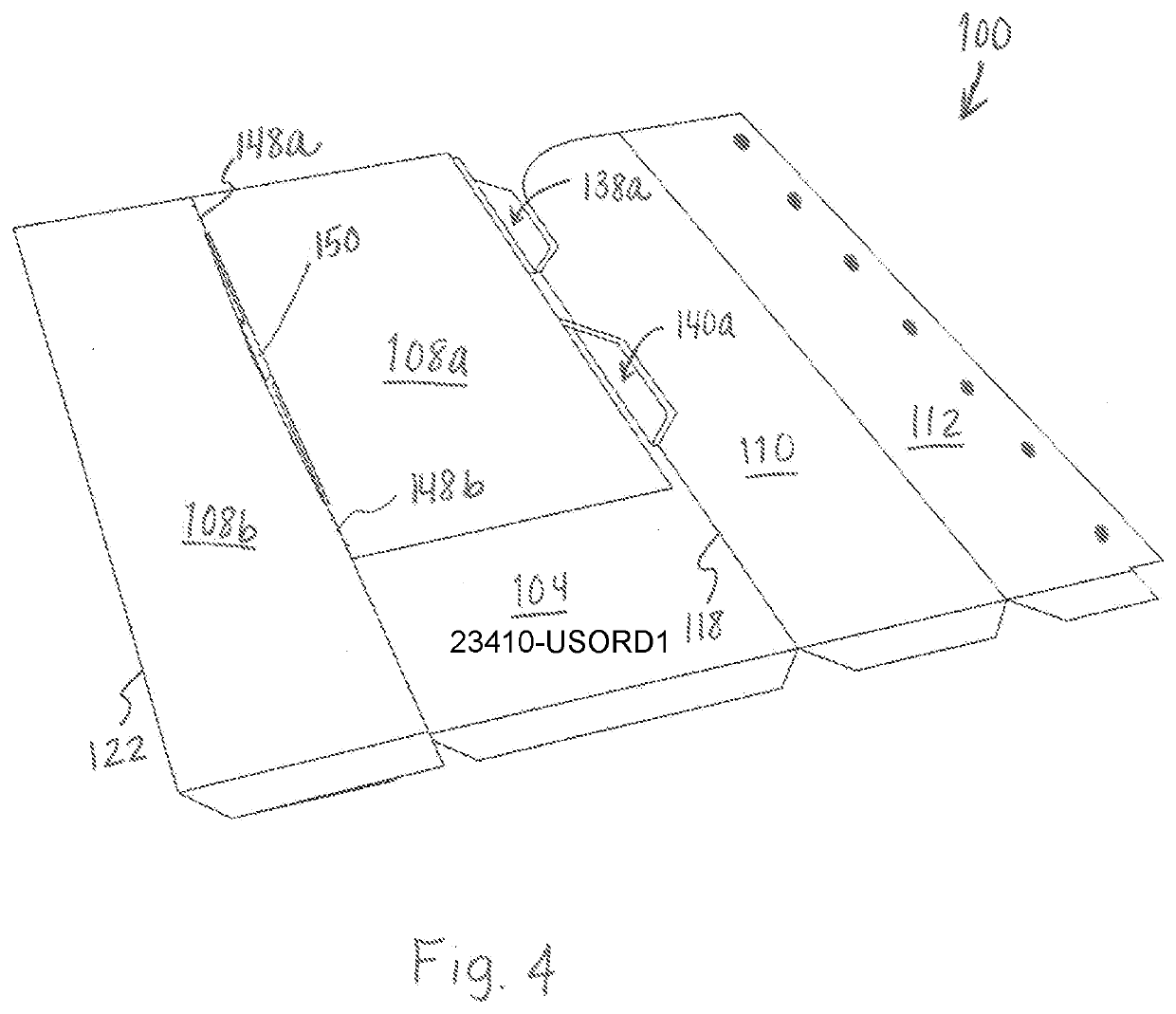

Display box having a hinge including a flexible and rigid portion

InactiveUS6910584B2Mechanical working/deformationBoxes/cartons making machineryEngineeringMechanical engineering

Owner:HENDERSON MCPHERSON

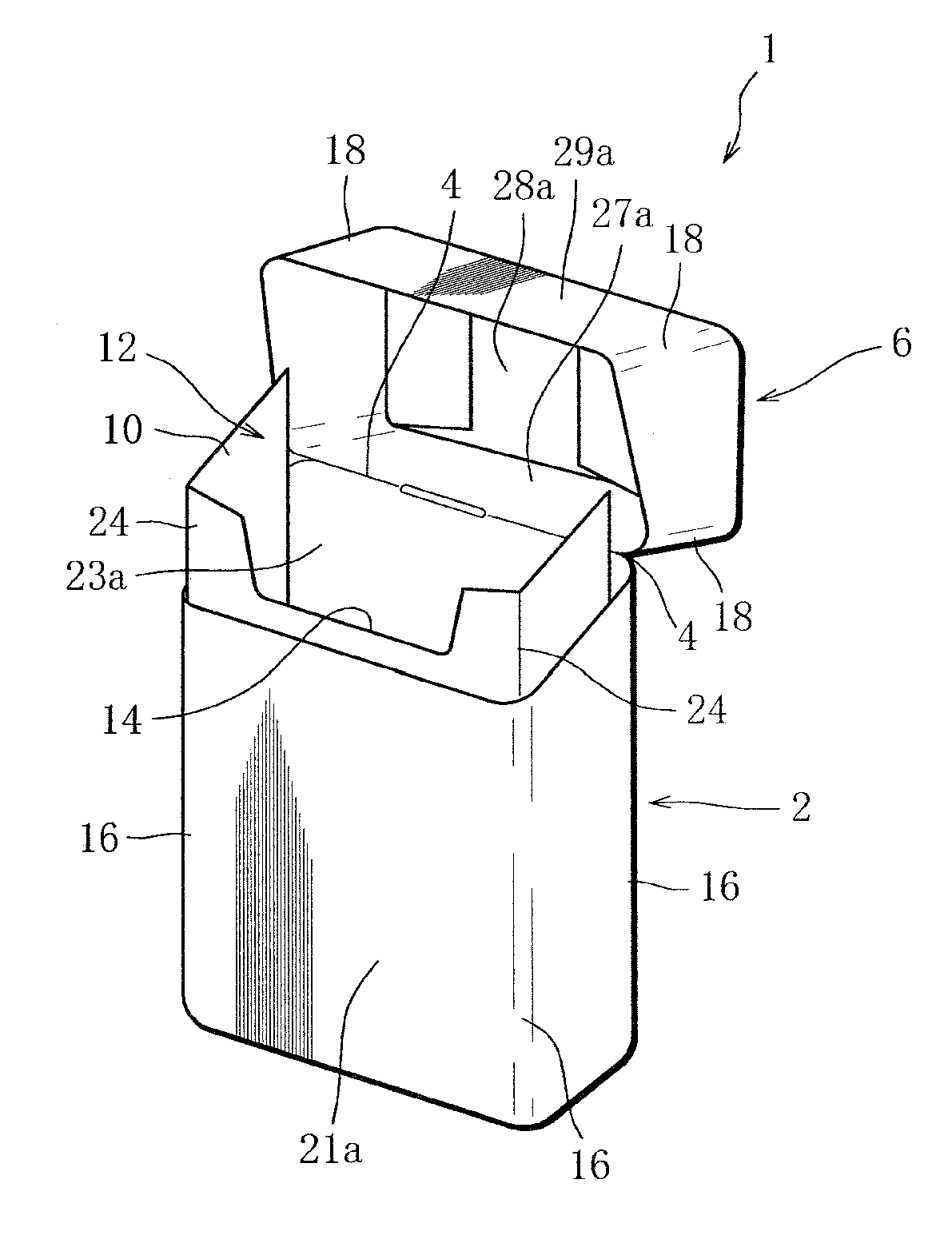

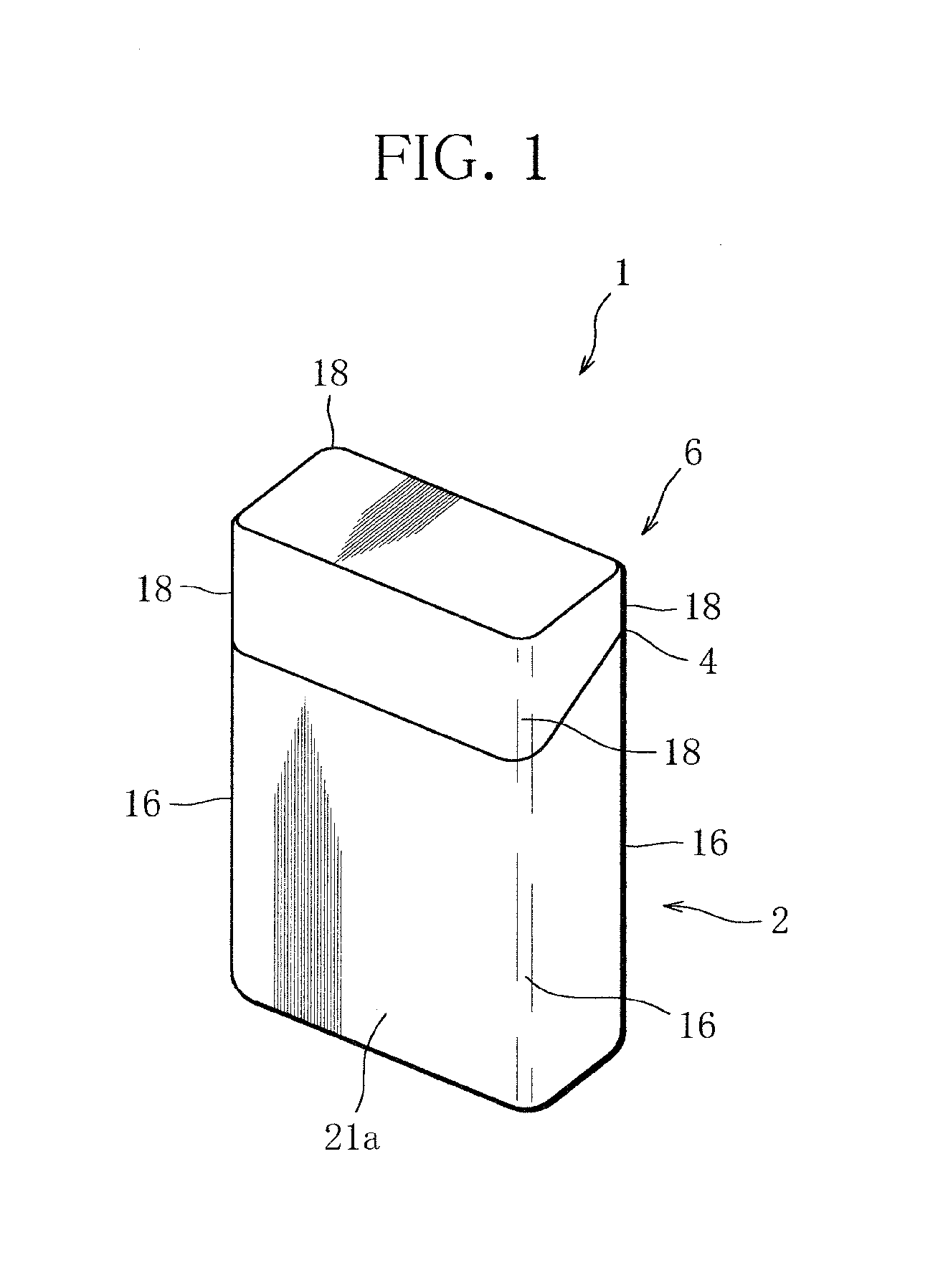

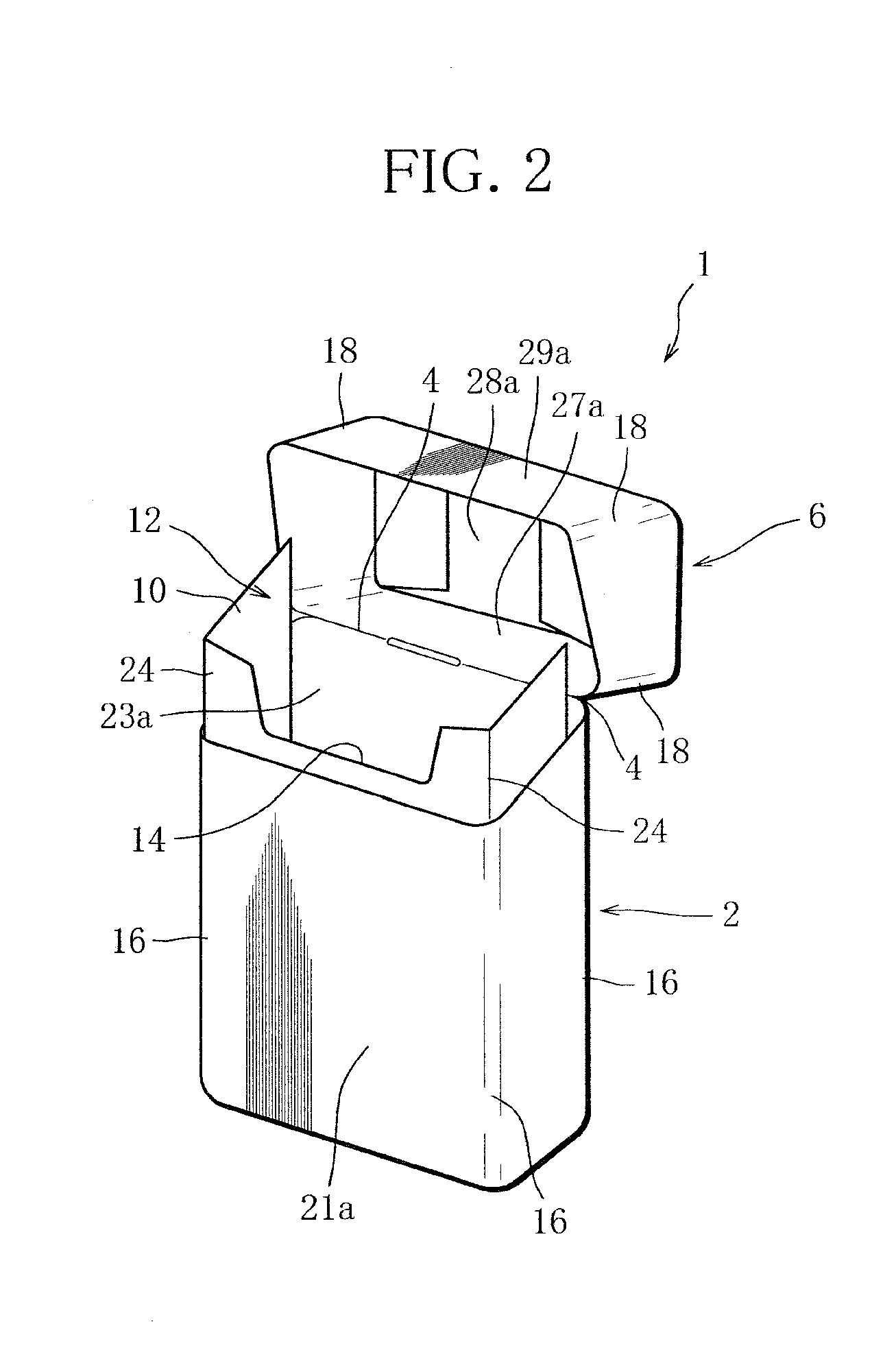

Method of forming score lines on blank, method of manufacturing package using same, and package

InactiveUS20130341380A1Easy to handleWell formedEnvelopes/bags making machineryPaper-makingEngineeringPackaging machine

A blank forming step for forming a sheet-shaped resin blank able to be formed into a box by folding and bending, and a score line forming step of forming score lines in score line forming areas of the blank which are to be bent to form outer edges of the box, to extend in the direction in which the outer edges should extend. In the score line forming step, the score lines are formed in a manner causing grooves to be produced on the back side of each score line forming area, along the score lines, through plastic deformation. The blank therefore does not undergo tensile stress pulling on the blank to either side of each groove, and thus, does not undergo warping as a whole. The blank thus retains its sheet shape and can be steadily supplied to a packaging machine.

Owner:JAPAN TOBACCO INC

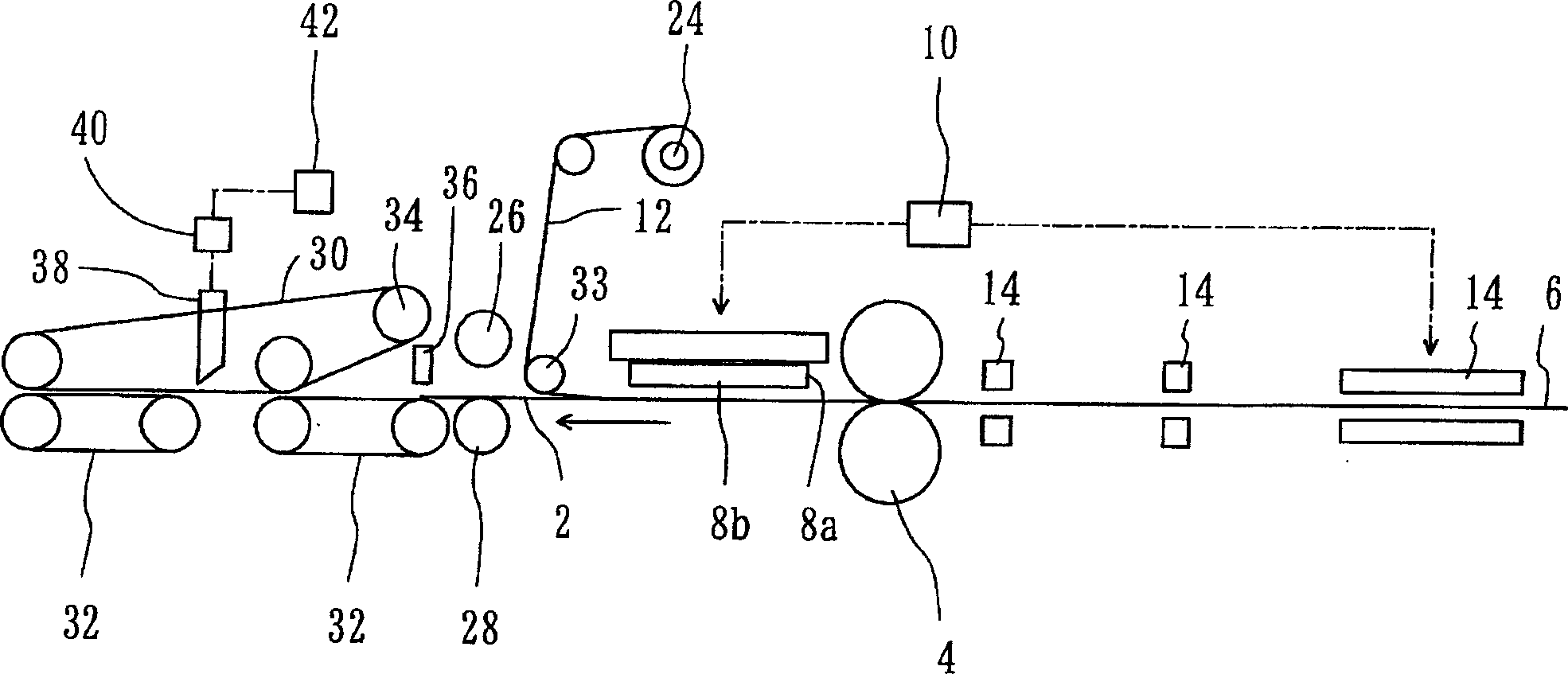

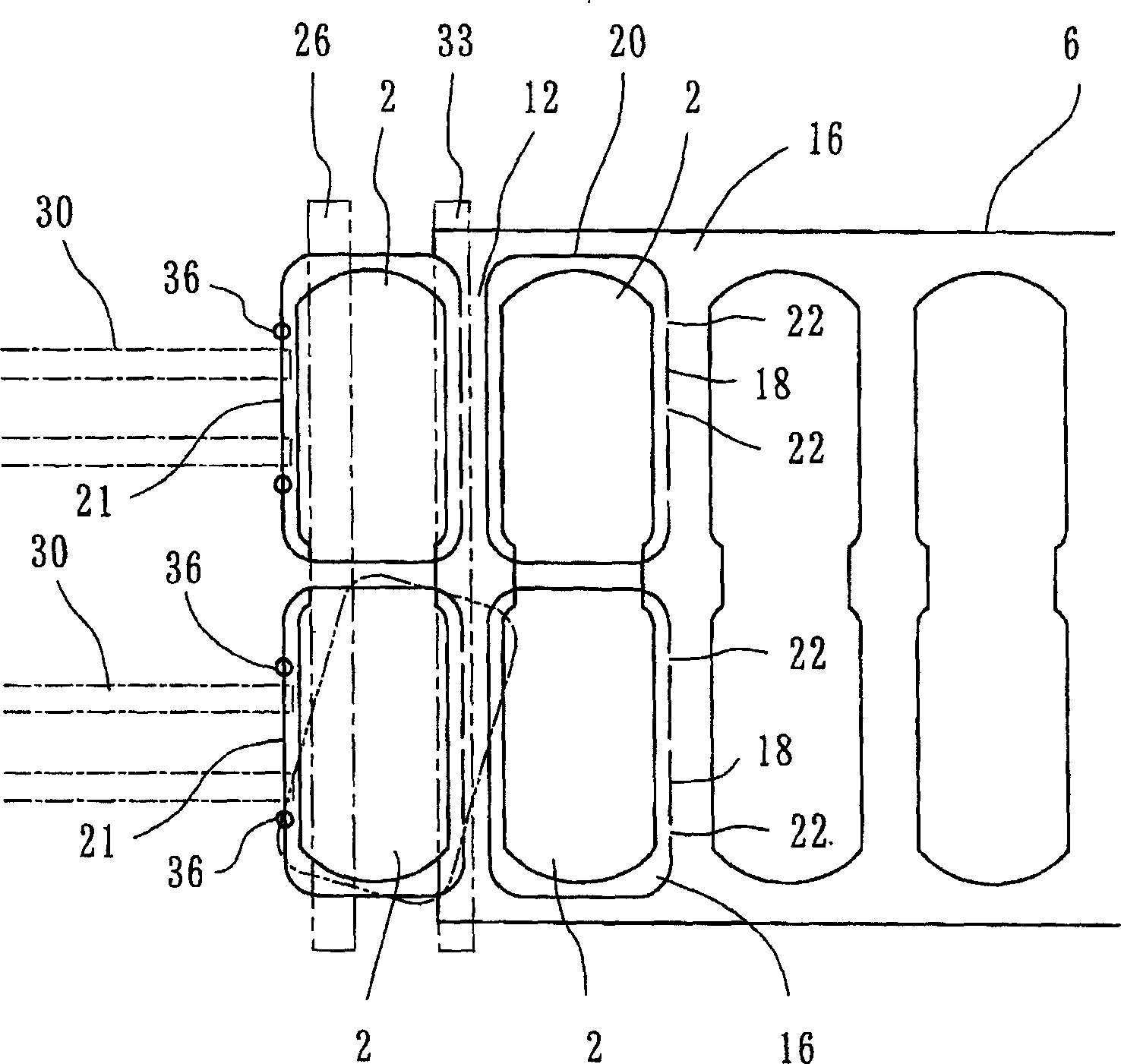

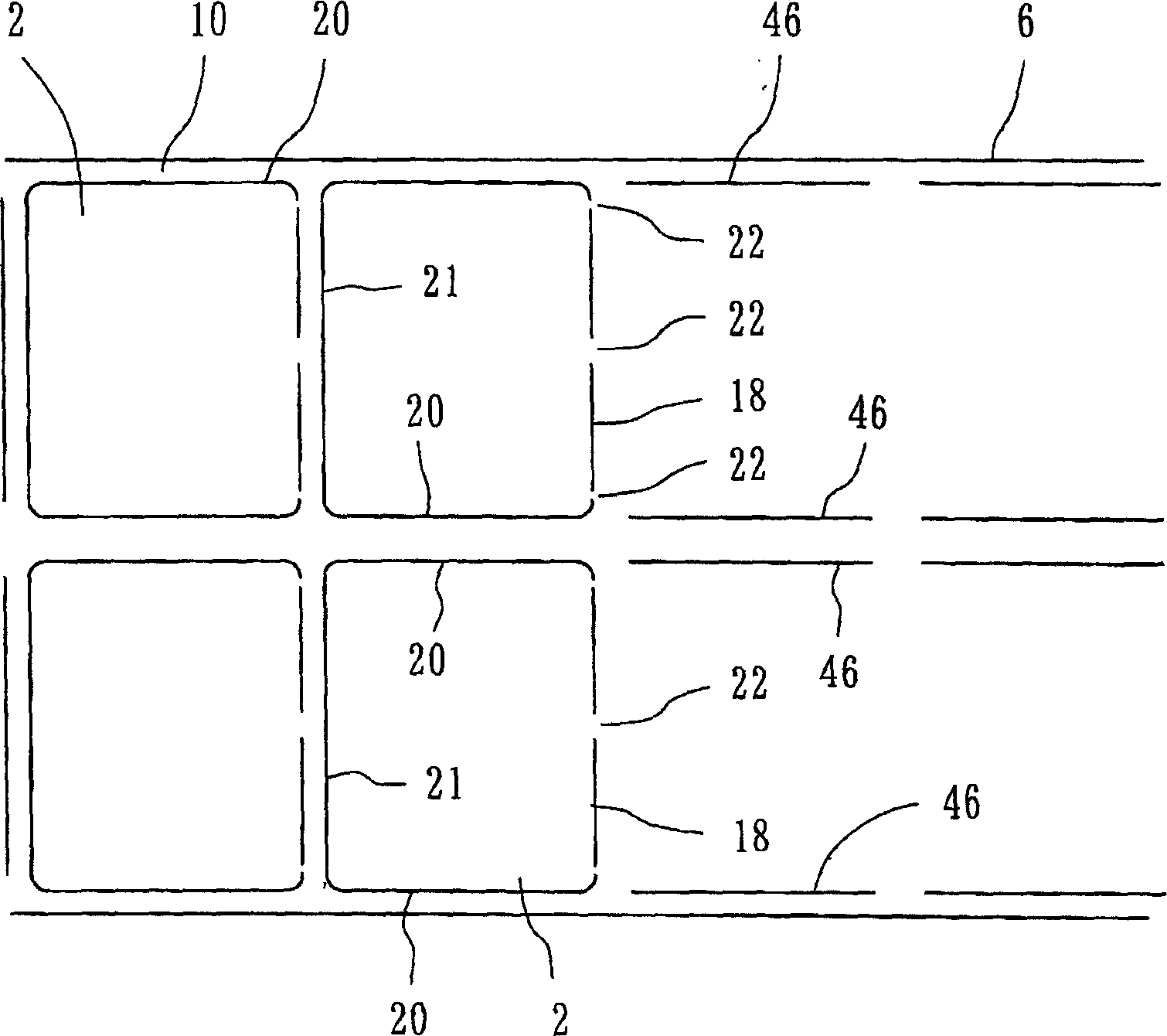

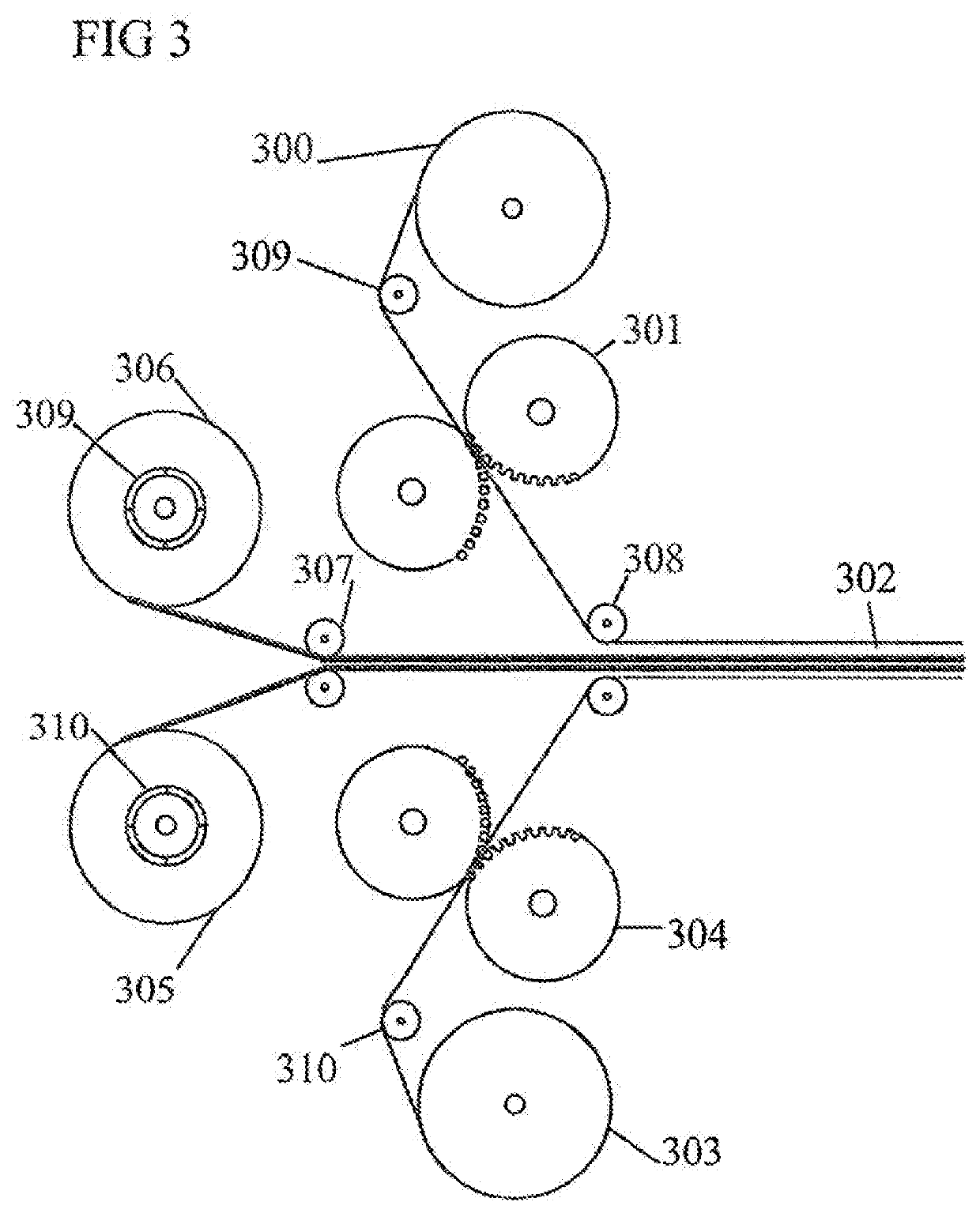

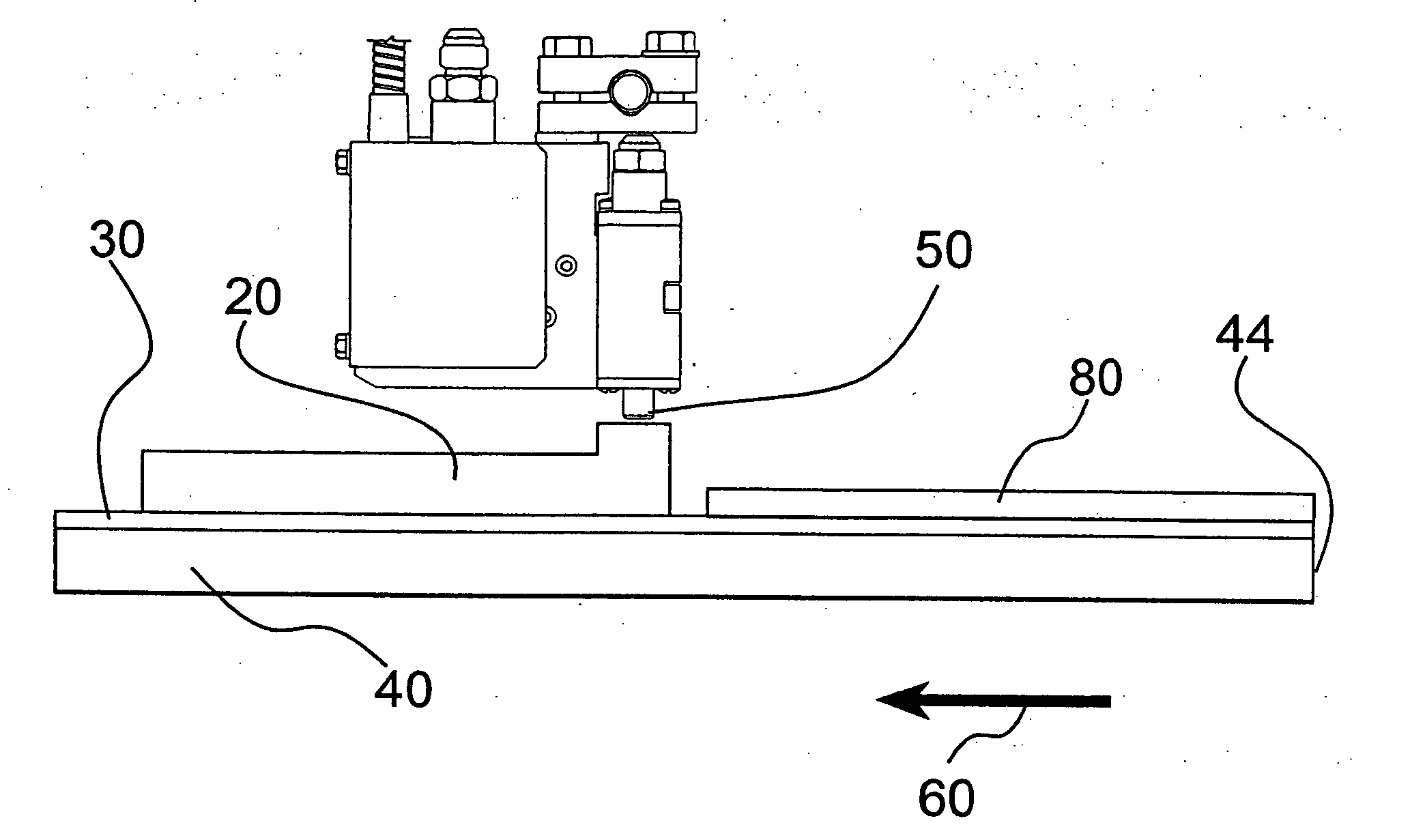

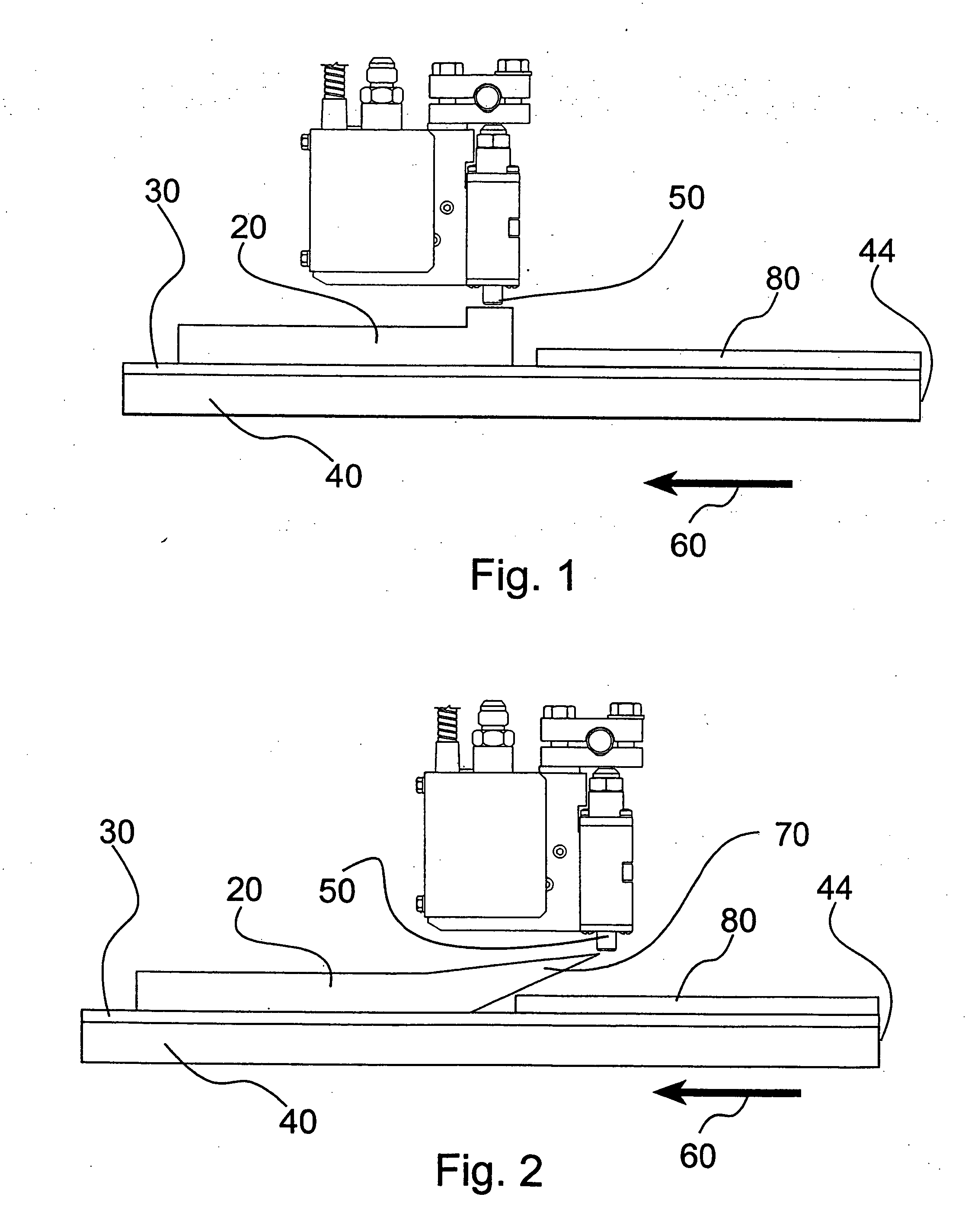

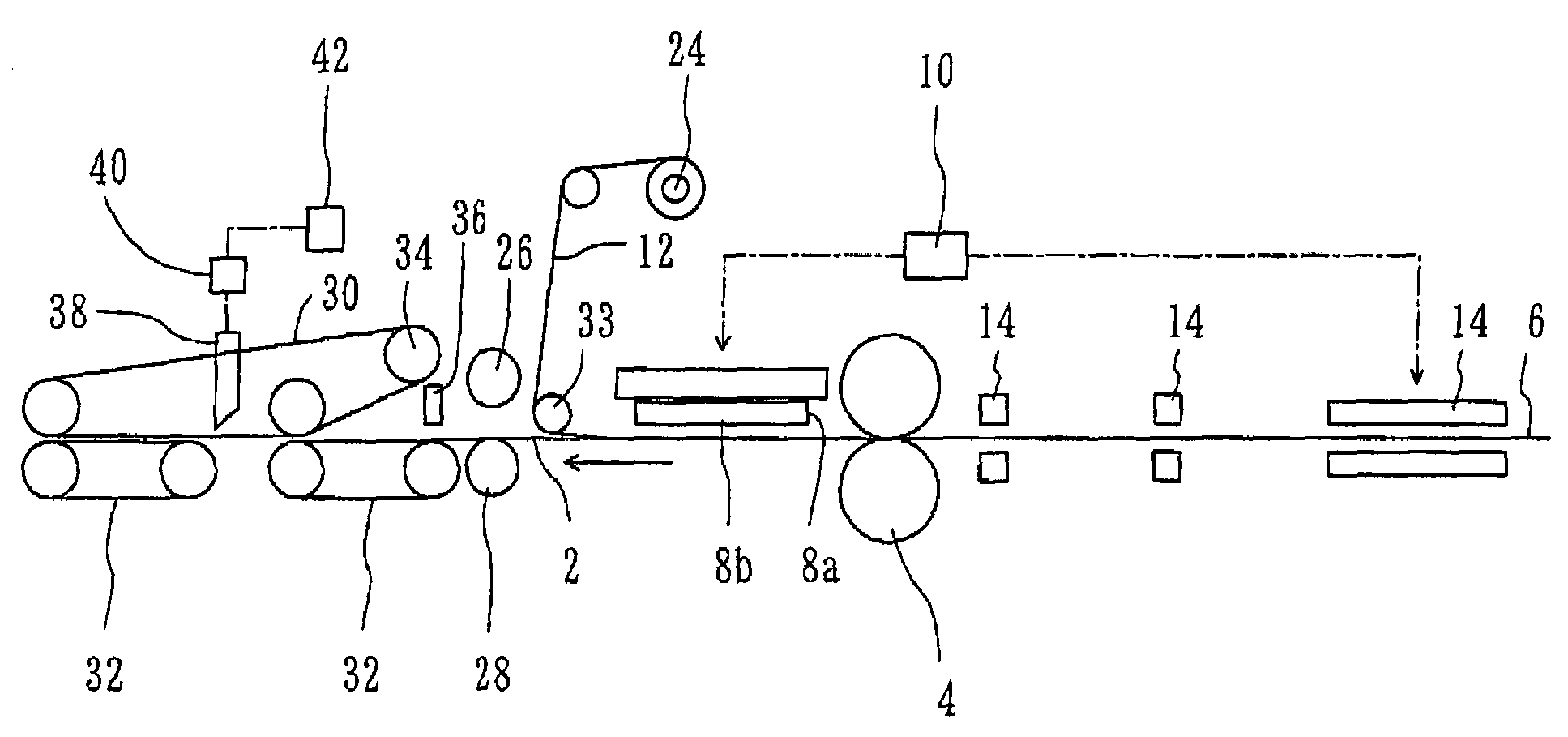

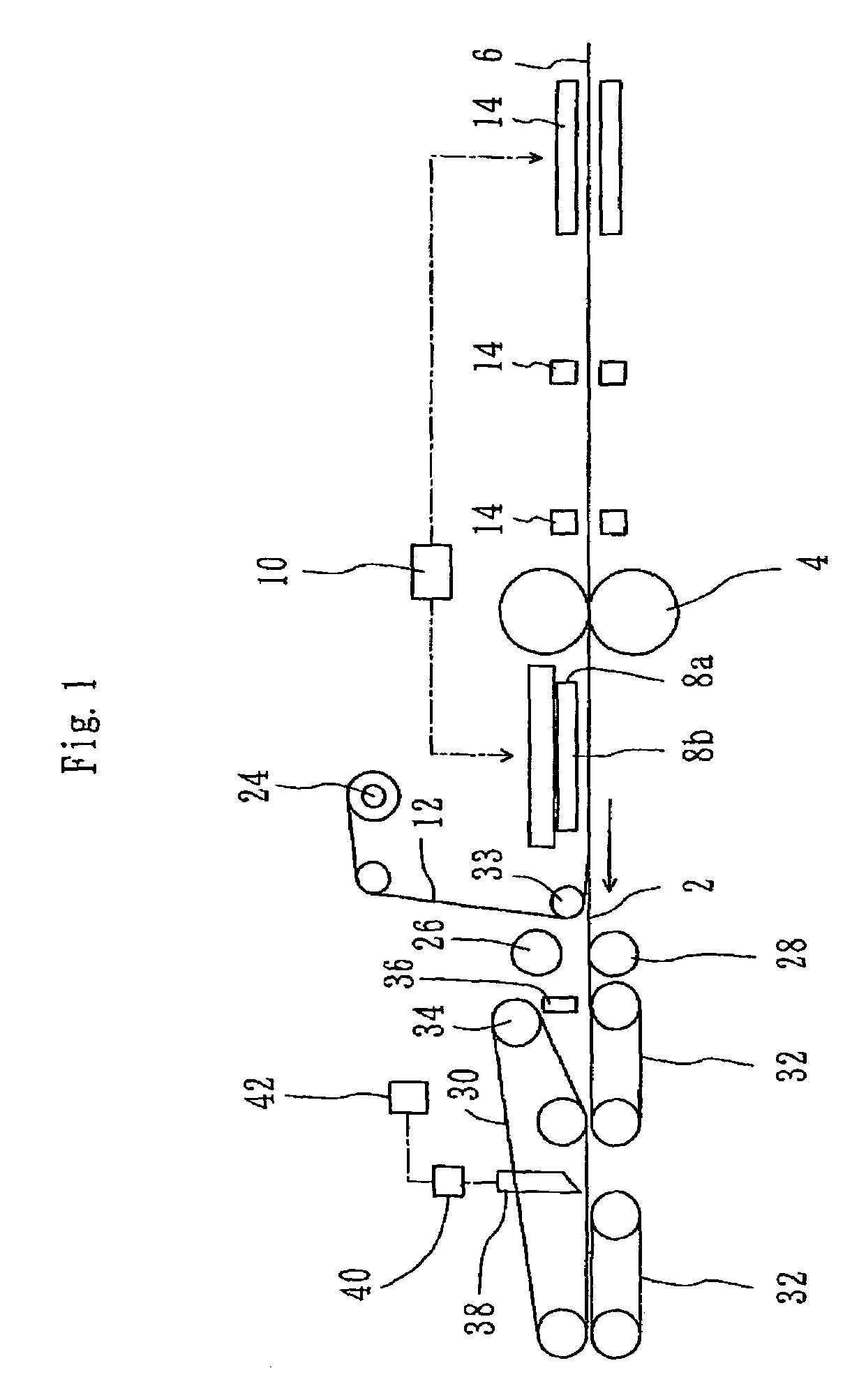

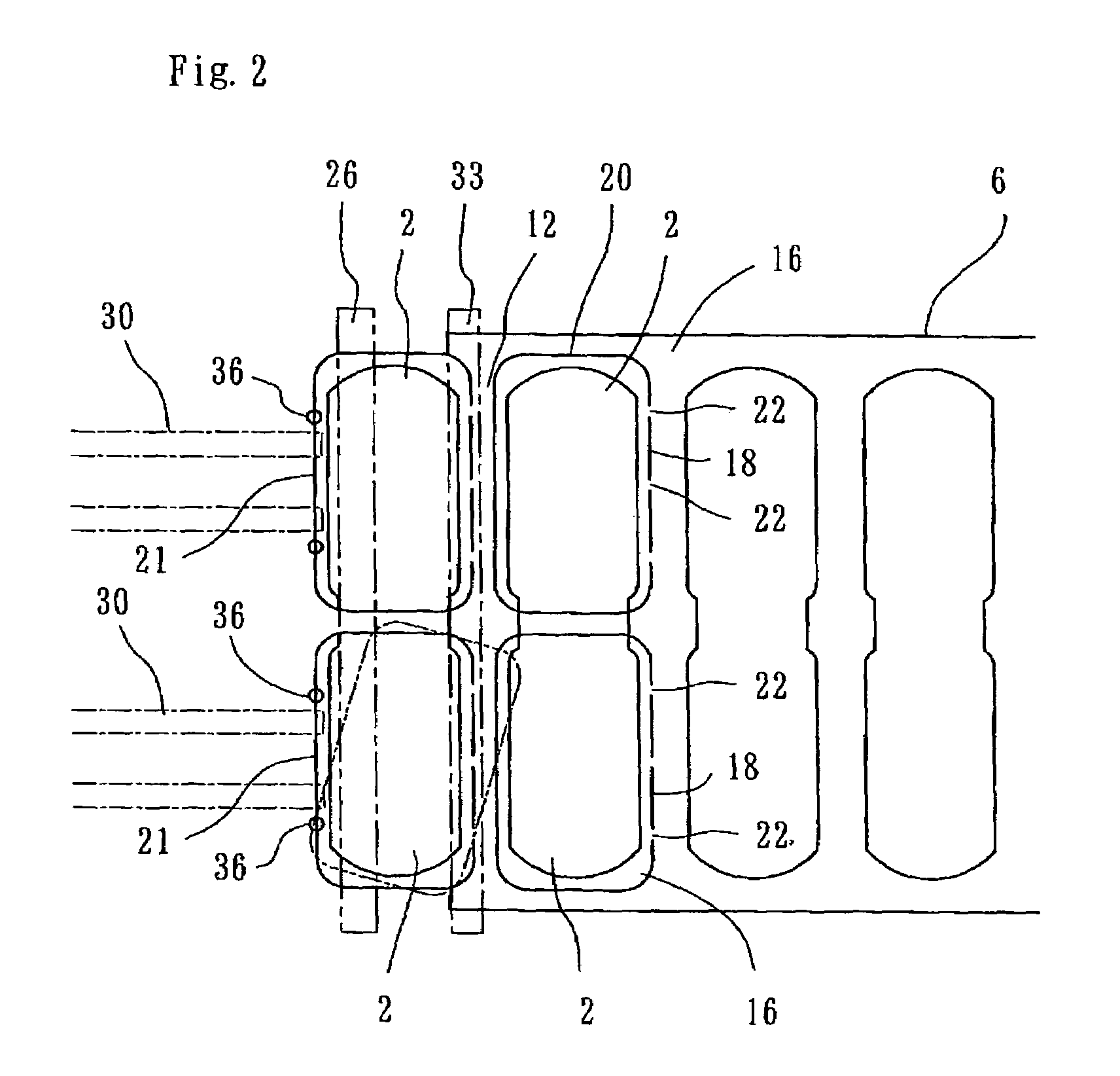

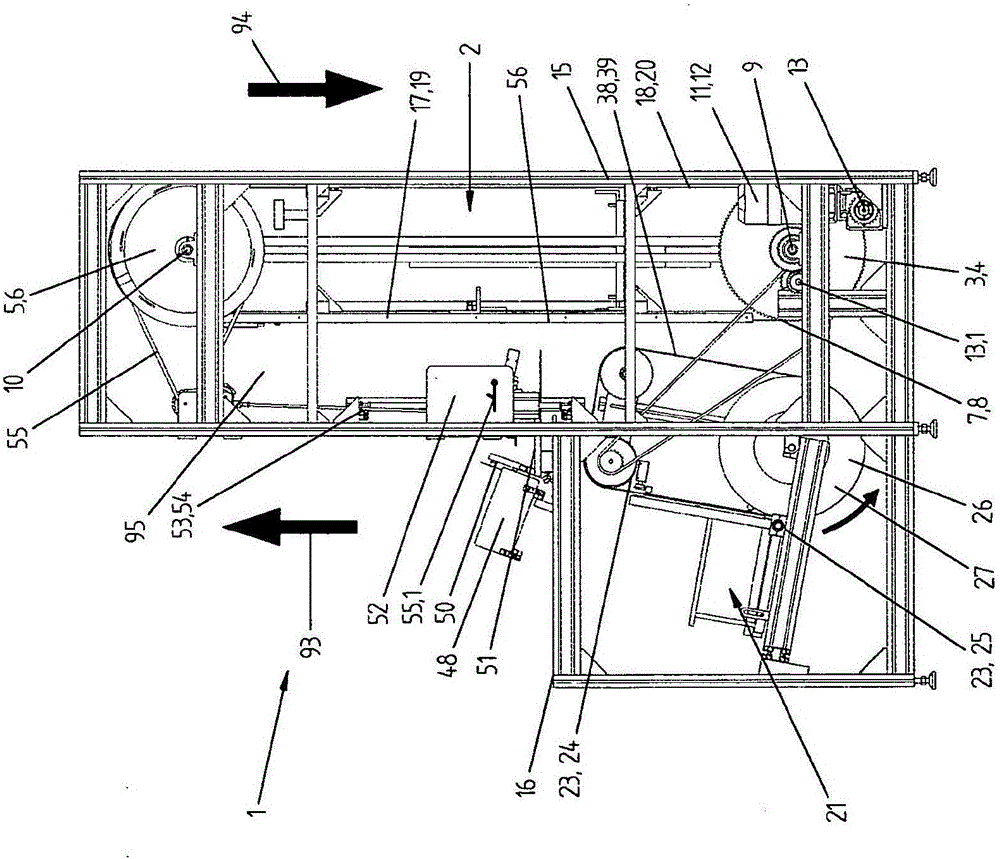

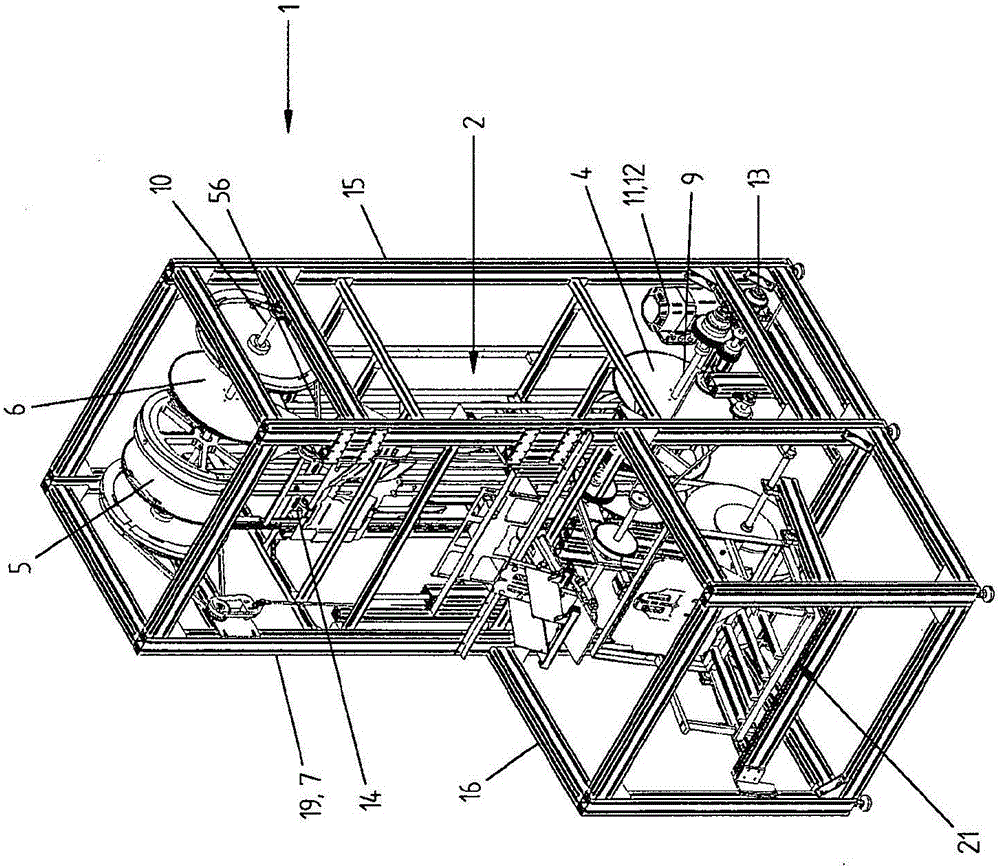

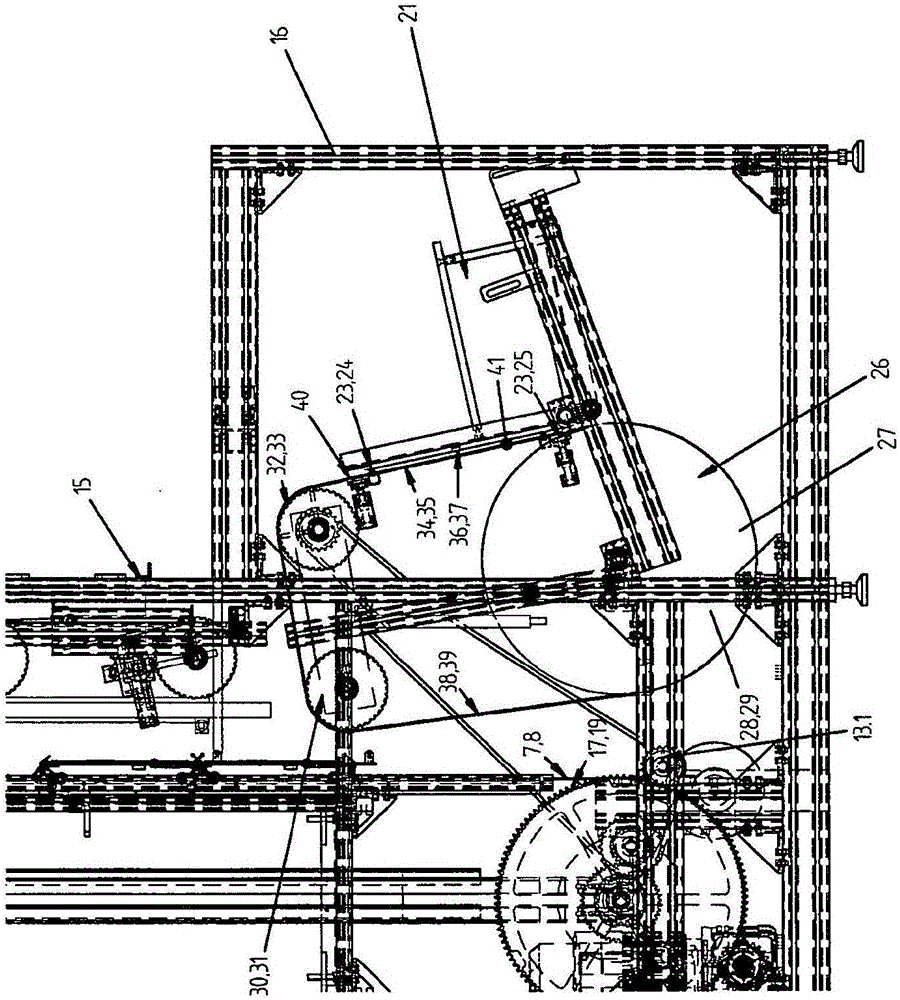

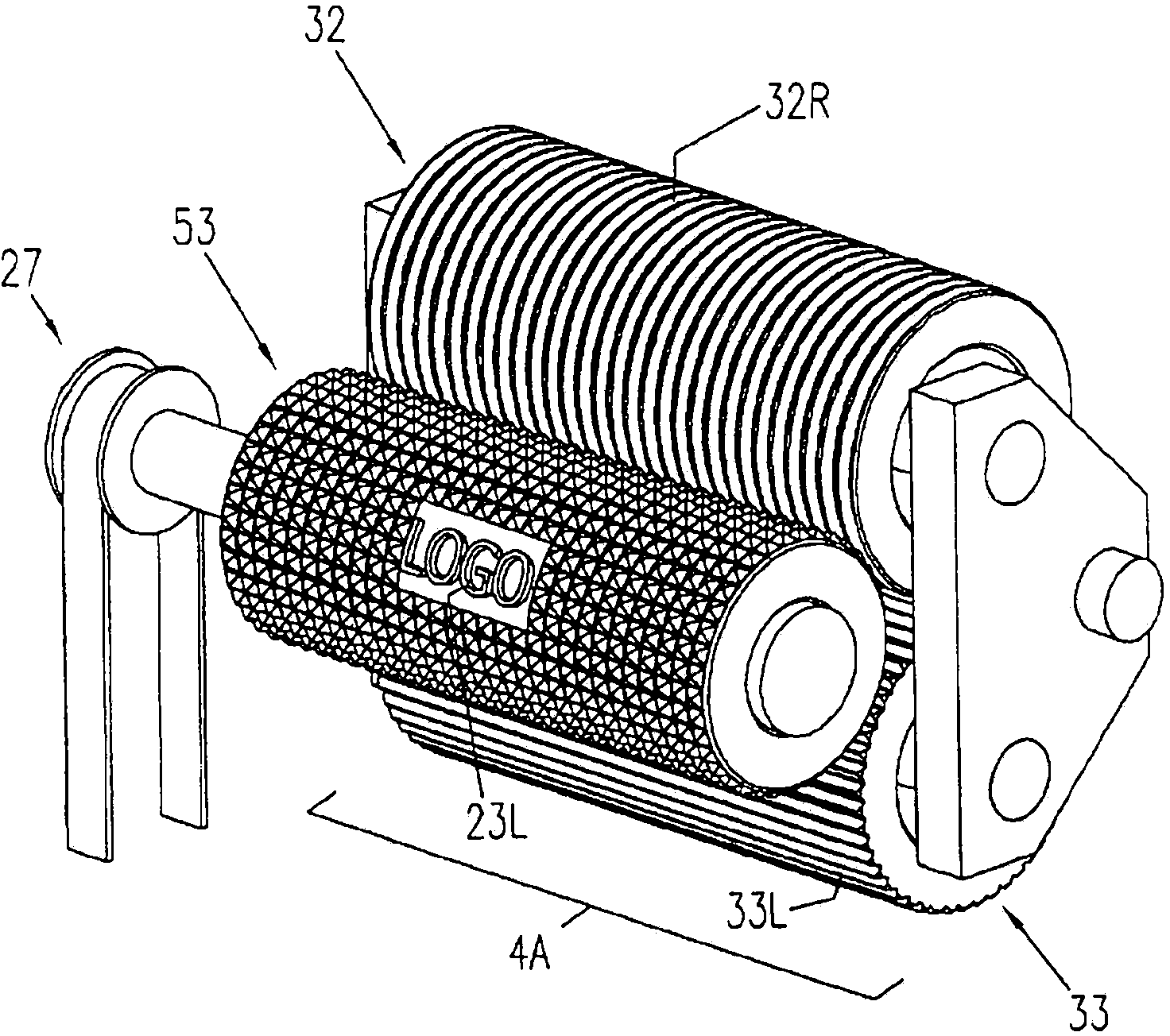

Plastic bag making apparatus

ActiveUS7044184B2Convenient treatmentEnvelopes/bags making machineryMechanical working/deformationEngineeringPlastic film

An apparatus is arranged to successively make plastic bags each of which has a shape of circumference. The apparatus comprises web feeding means by which a web material is intermittently fed for a length along a longitudinal feeding path. The web material comprises two or more layers of plastic film. Web cutting means is disposed along the feeding path. The web cutting means has a shape corresponding completely or incompletely to the shape of circumference of plastic bag so that the web material can be cut into the shape of circumference of plastic bag by the web cutting means whenever the web material is intermittently fed and temporarily stopped, to successively make the plastic bags with a waste kept continuous. The web cutting means comprises partially cutting means. The plastic bag has an upstream edge along which the web material is partially cut by the partially cutting means so that the plastic bag can be kept connected with the waste at the upstream edge of plastic bag. Drawing means is disposed downstream of the cutting means. The waste is diverged from the plastic bag, directed to and drawn by the drawing means after the web material is cut. Discharge means is disposed downstream of the cutting means. The plastic bag is directed to the discharge means without the waste. The plastic bag is then pulled by the discharge means to be torn from the waste at the upstream edge of plastic bag. The plastic bag is then discharged by the discharge means.

Owner:TOTANI CORP (JP)

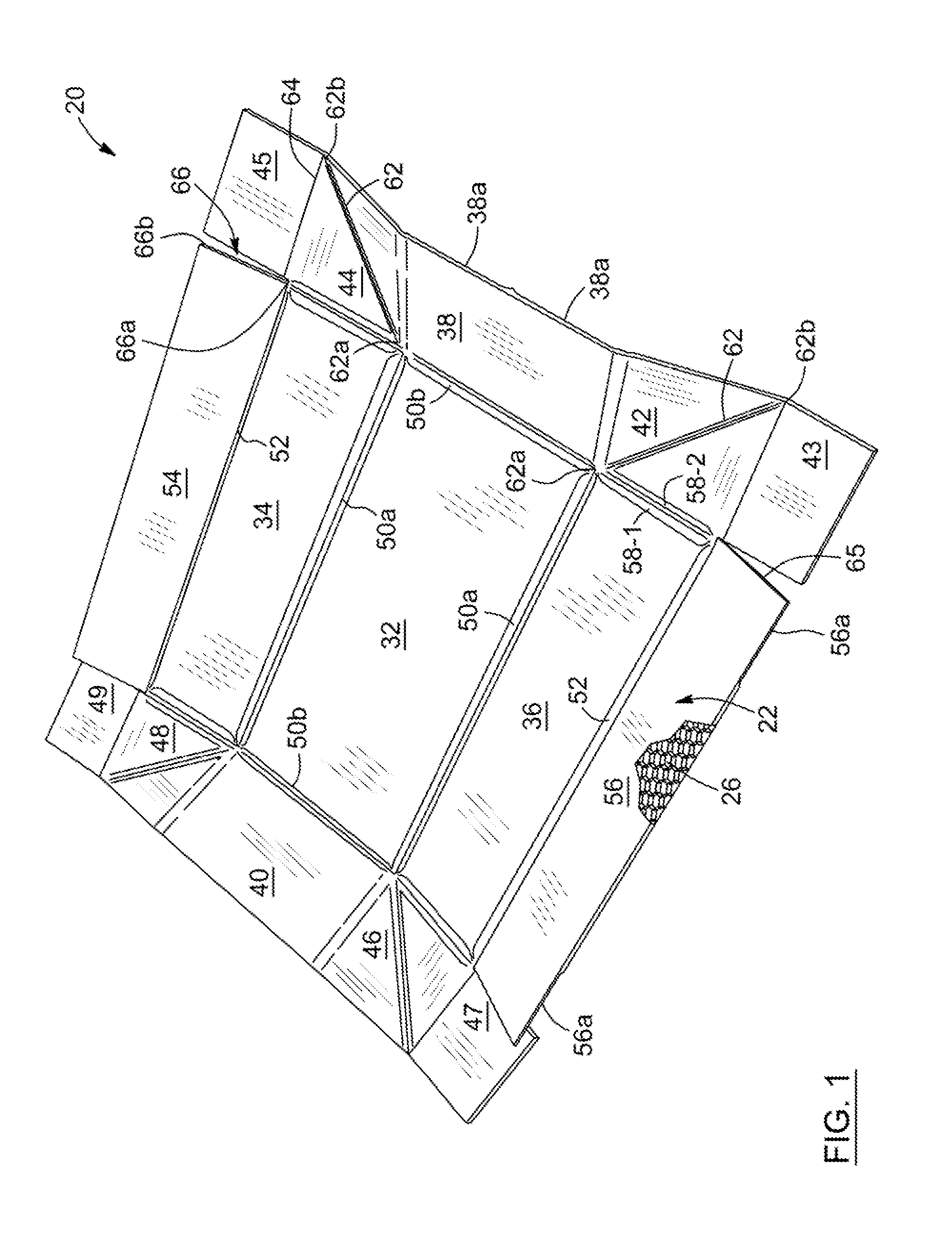

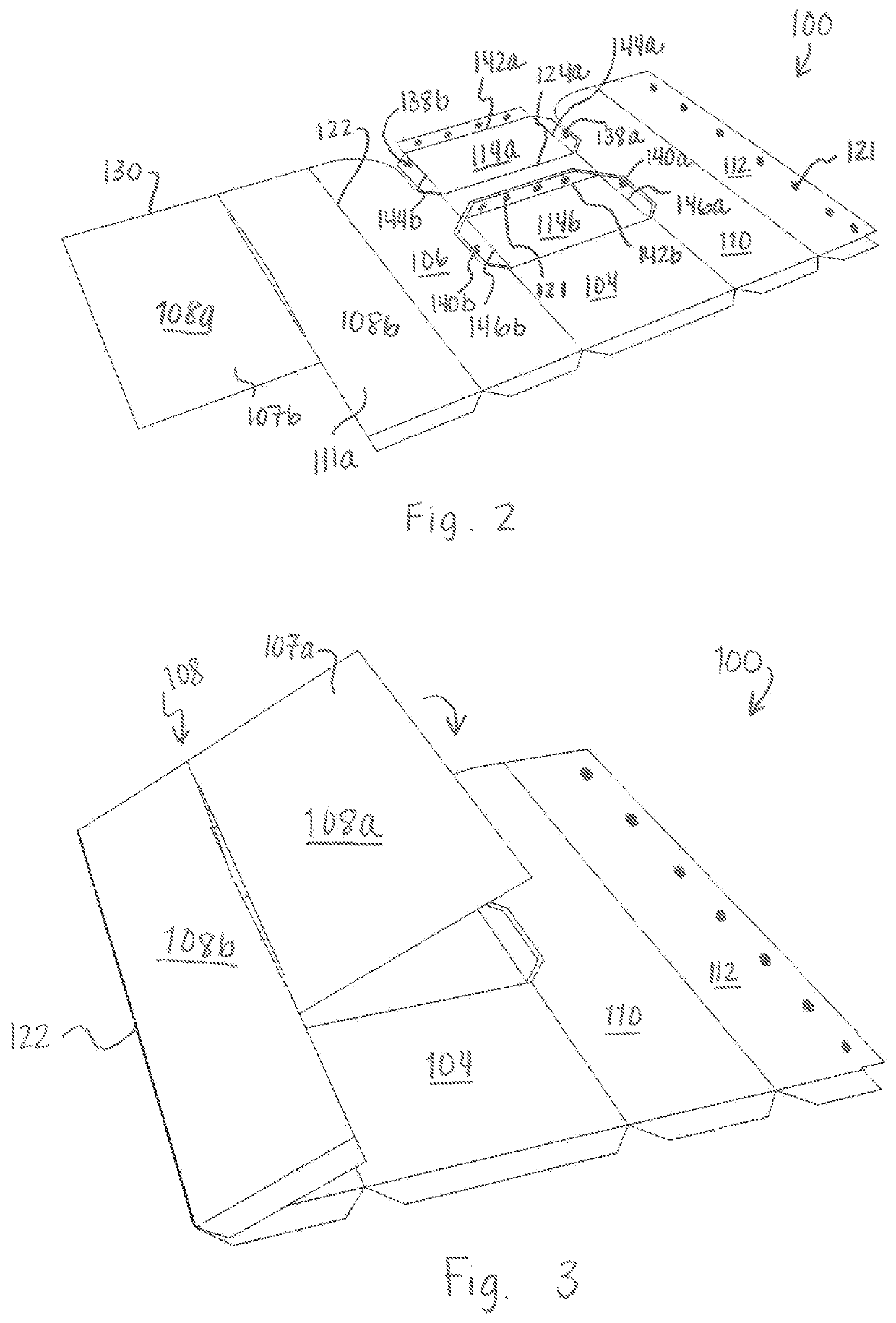

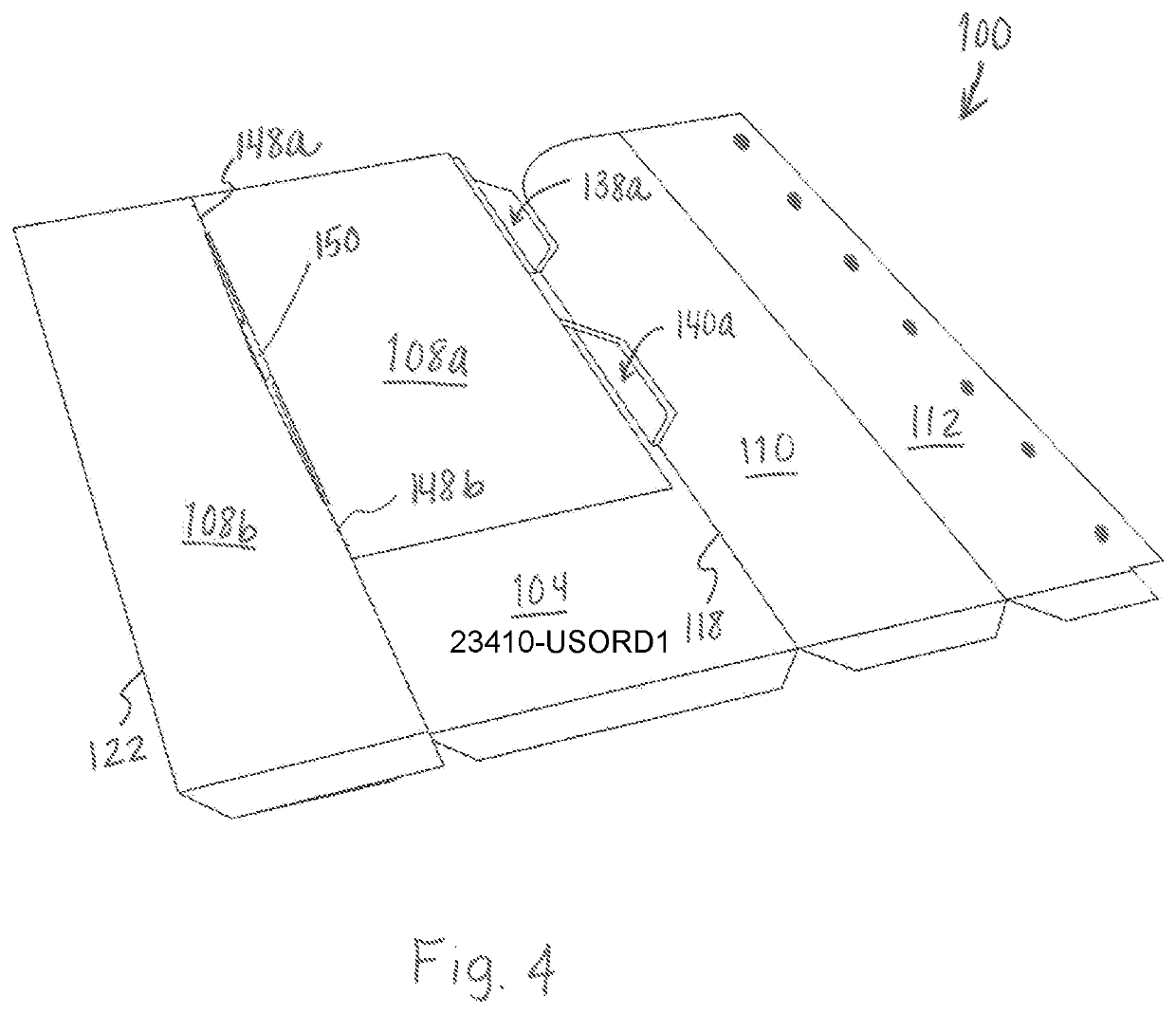

Display hutch

A container includes a plurality of panels connected together at fold lines configured for extending at least partially around an interior space. The panels include a front panel, a first side panel, a back panel and a second side panel. The back panel includes a first back portion and a second back portion. At least one of the first back portion or the second back portion is free from openings. A shelf panel is foldably connected to the front panel. The first back portion is adhered to the shelf panel.

Owner:WESTROCK SHARED SERVICES LLC

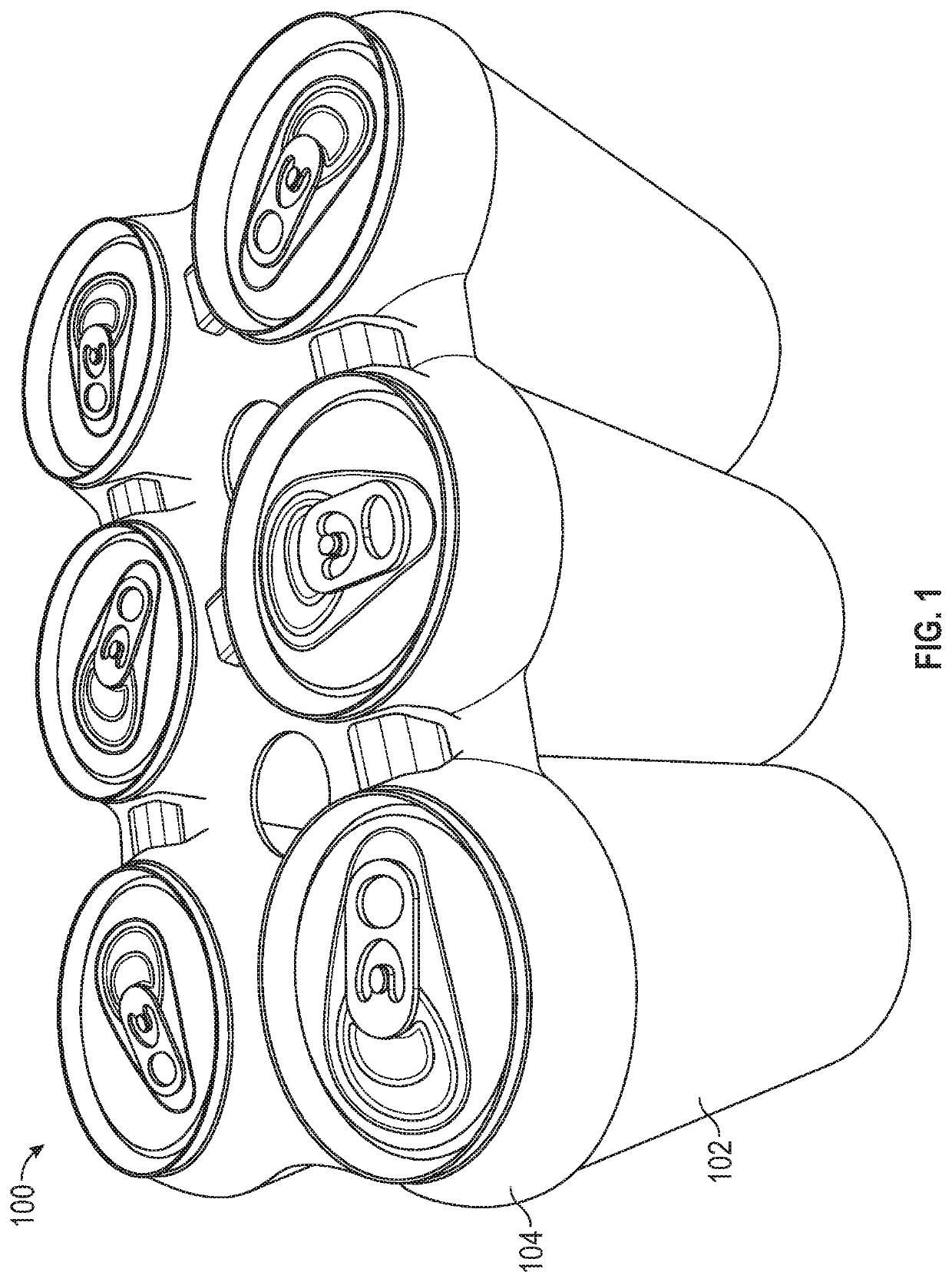

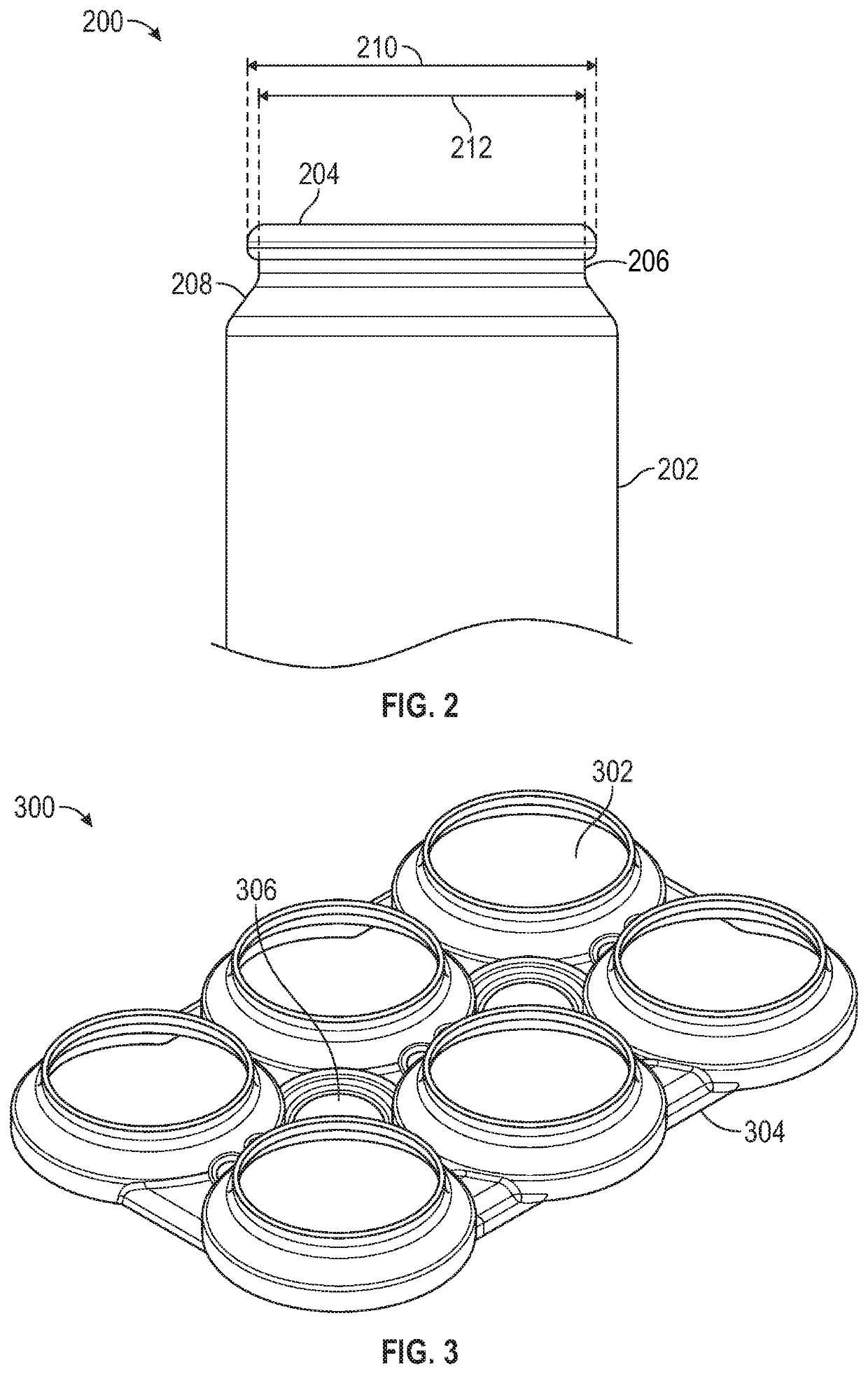

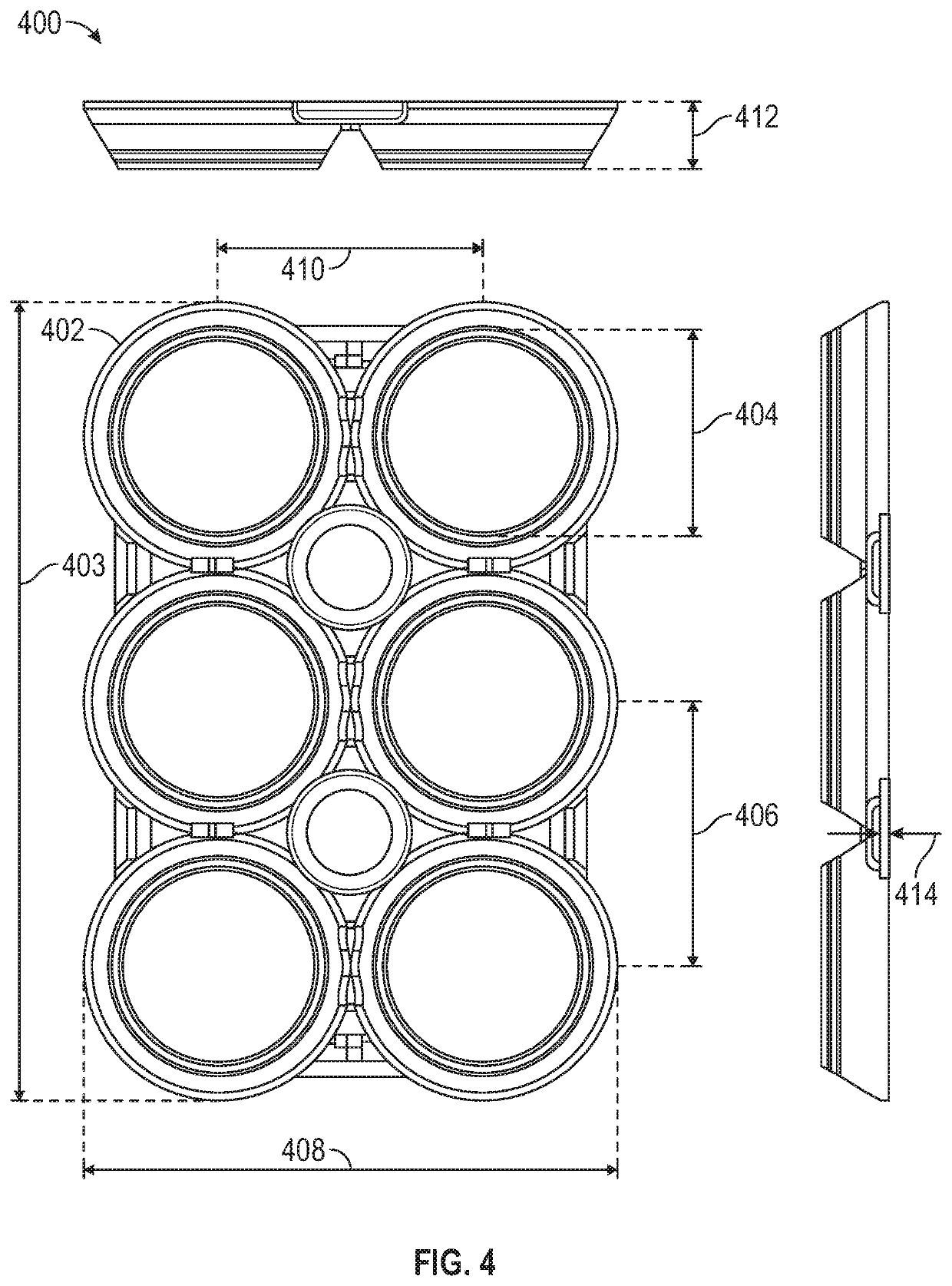

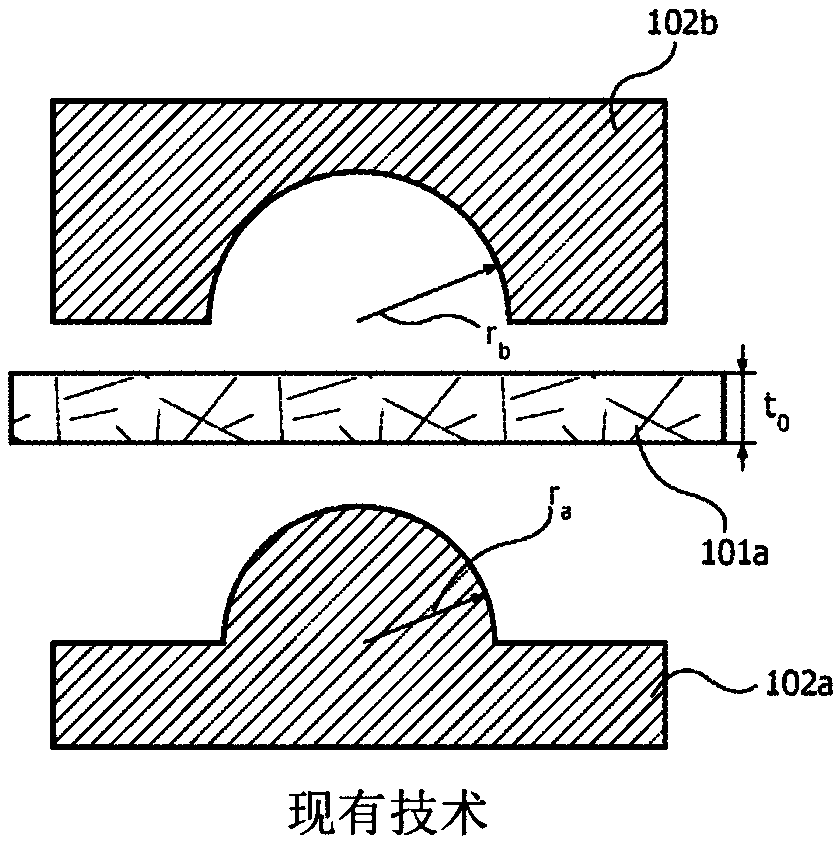

Methods and Apparatus For High-Strength Fiber-Based Beverage Holders

PendingUS20210039856A1Reduce weightShorten cycle timePaper/cardboard articlesWater-repelling agents additionFiberEngineering

Methods and apparatus for vacuum forming a beverage carrier yoke are described. The yoke comprises a number (e.g., four or six) collars interconnected by a web, and each collar exhibits dimensions—including a nominal diameter and a substantially uniform thickness—selected to improve strength and increase comfort. The yoke is produced using a slurry comprising a moisture barrier and a fiber base.

Owner:FOOTPRINT INT LLC

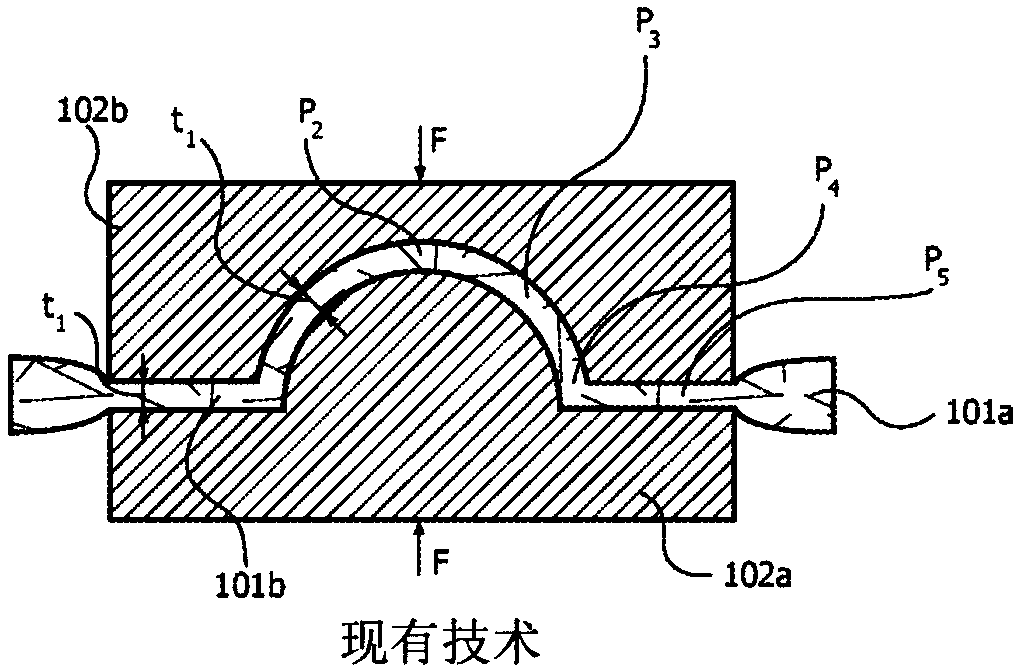

Method for manufacturing cellulose product by pressure moulding apparatus, pressure moulding apparatus and cellulose product

The present invention relates to a method of manufacturing a cellulose product having a flat or non-flat product shape by a pressure moulding apparatus comprising a forming mould. The forming mould has a forming surface defining the product shape, The method comprises the steps of: arranging a cellulose blank containing less than 45 weight percent water in the forming mould; heating the celluloseblank to a forming temperature in the range of 100 to 200 degrees centigrade; and pressing the cellulose blank by means of the forming mould with a forming pressure acting on the cellulose blank across the forming surface, the forming pressure being in the range of MPa to 100 MPa.

Owner:PULPAC AB

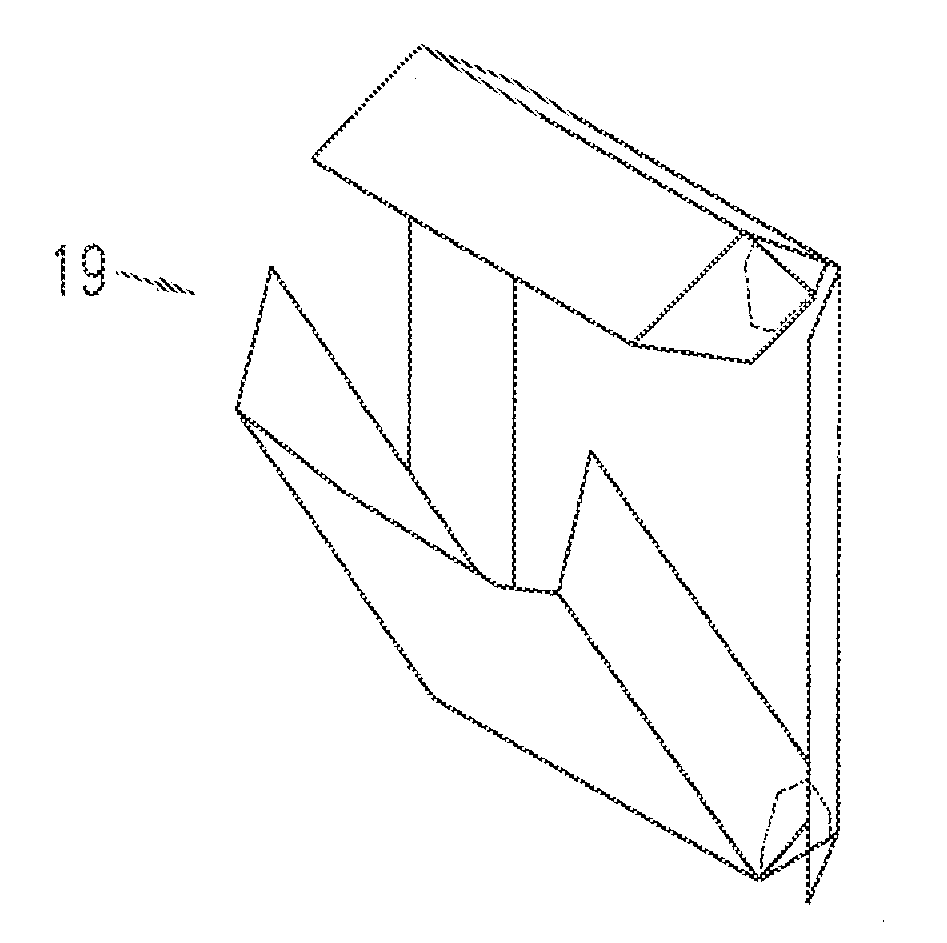

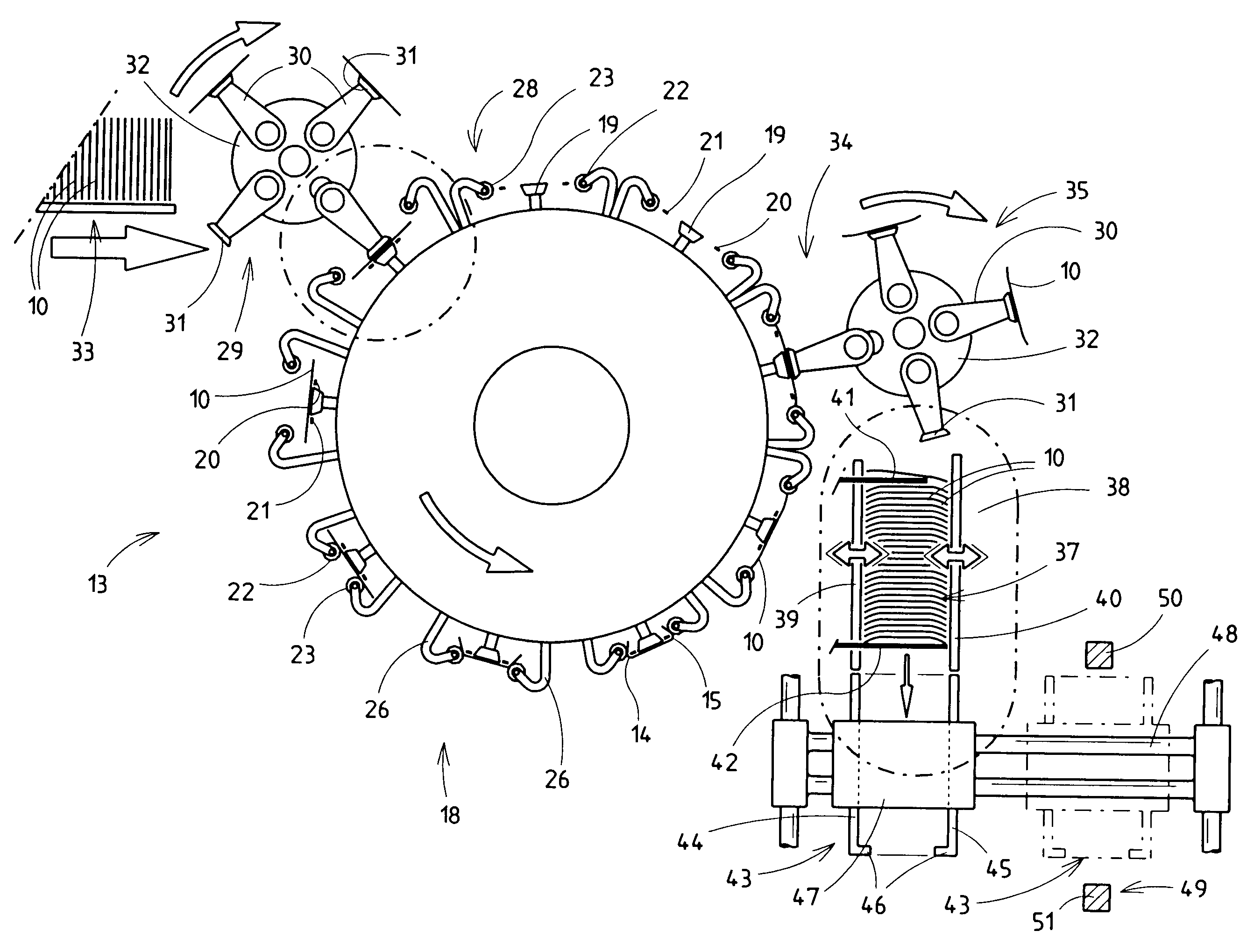

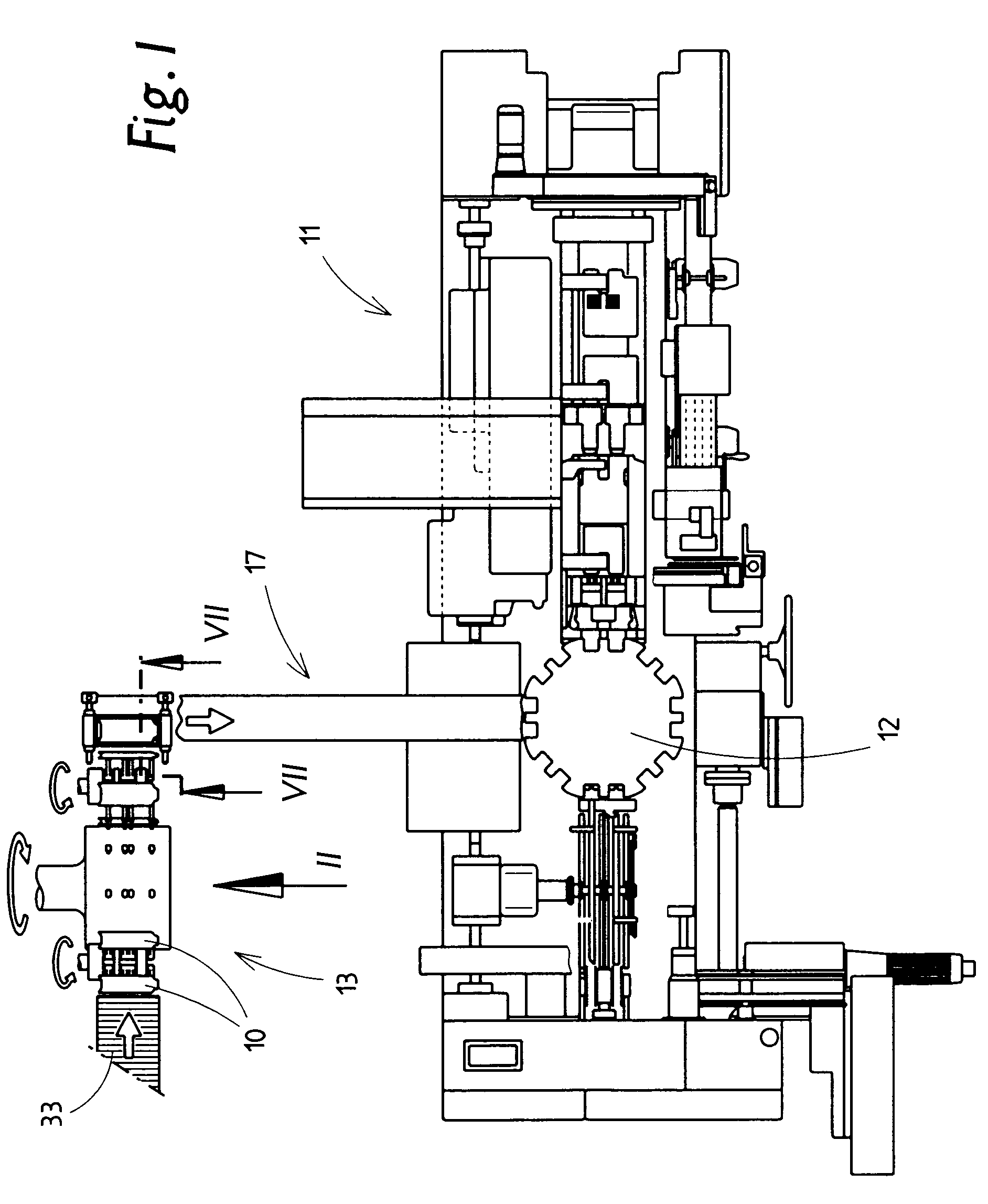

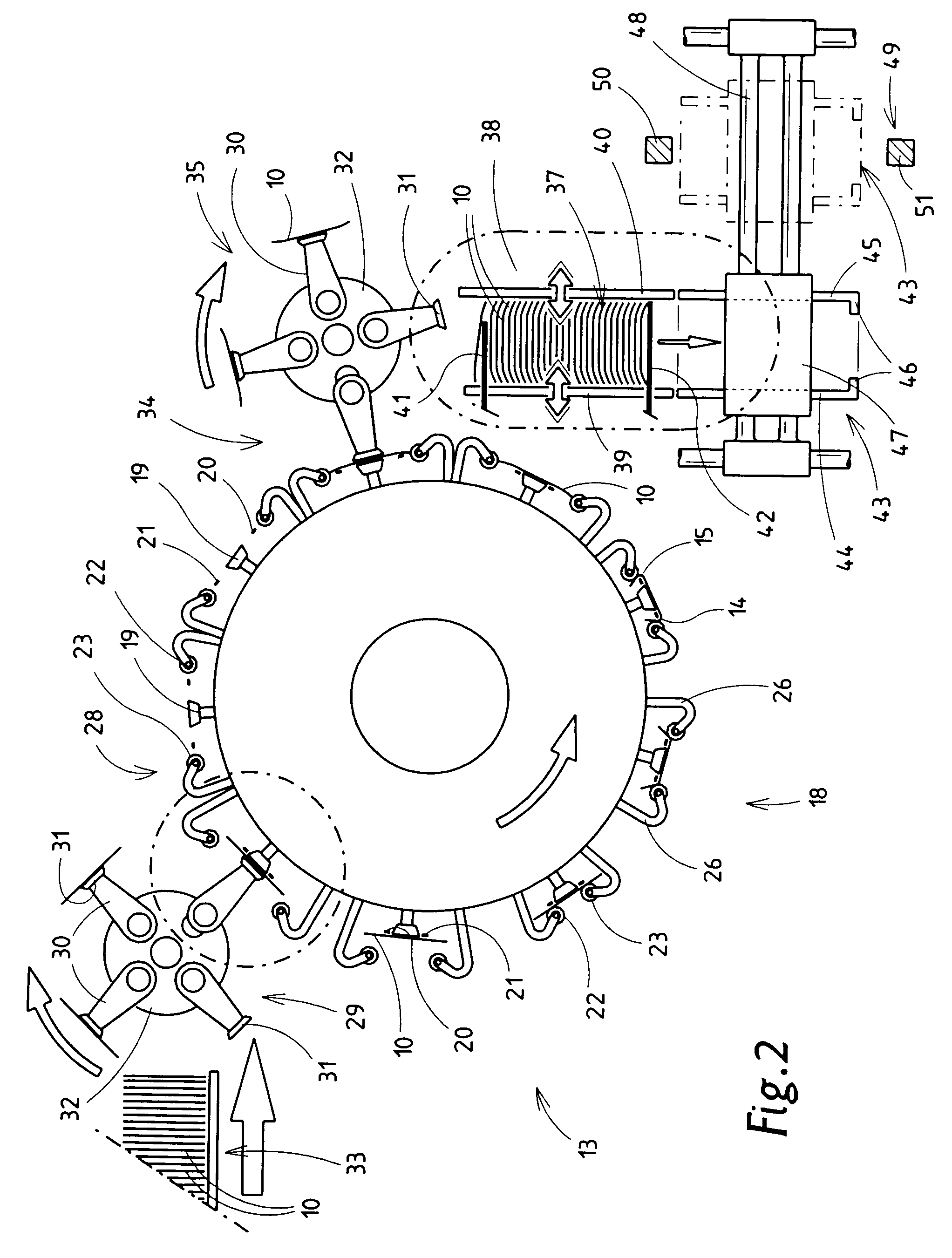

Process for producing hinge-lid boxes

InactiveUS7001320B1Improve output performanceQuality improvementMechanical working/deformationBoxes/cartons making machineryStructural engineeringMechanical engineering

In the production of (cigarette) packs of the hinge-lid-box type with round edges, preliminary deformation of blanks (10) is desirable for producing hinge-lid boxes of satisfactory quality. The preliminary deformation of the round edges takes place in the region of a rounding turret (18) during transportation of the blanks (10). The latter are deformed back into an essentially planar starting position upon leaving the rounding turret (18) and thereafter.

Owner:FOCKE & CO (GMBH & CO KG)

Machine and method for folding and adhesively bonding blanks for the production of folding boxes

Owner:KRONES AG

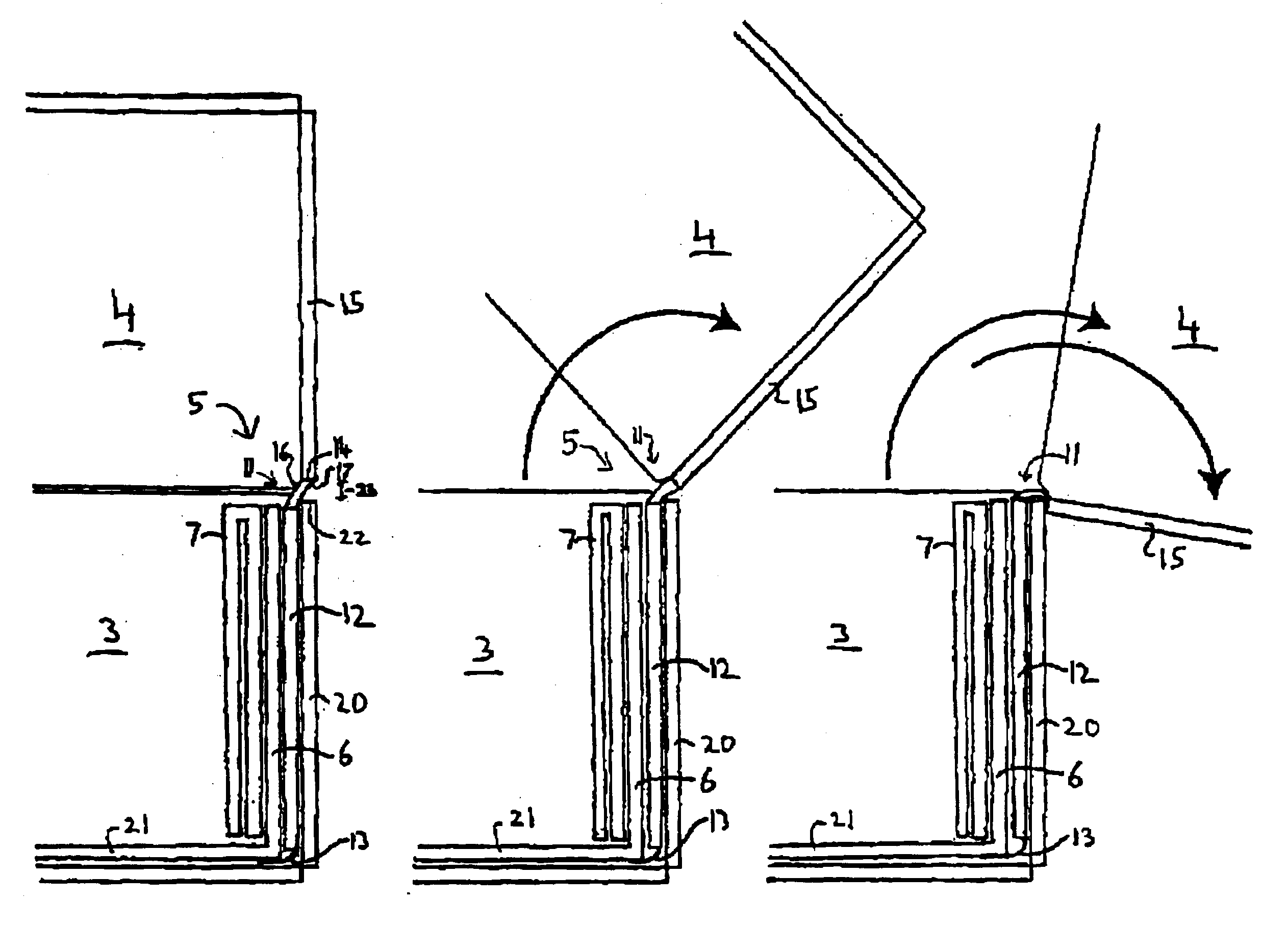

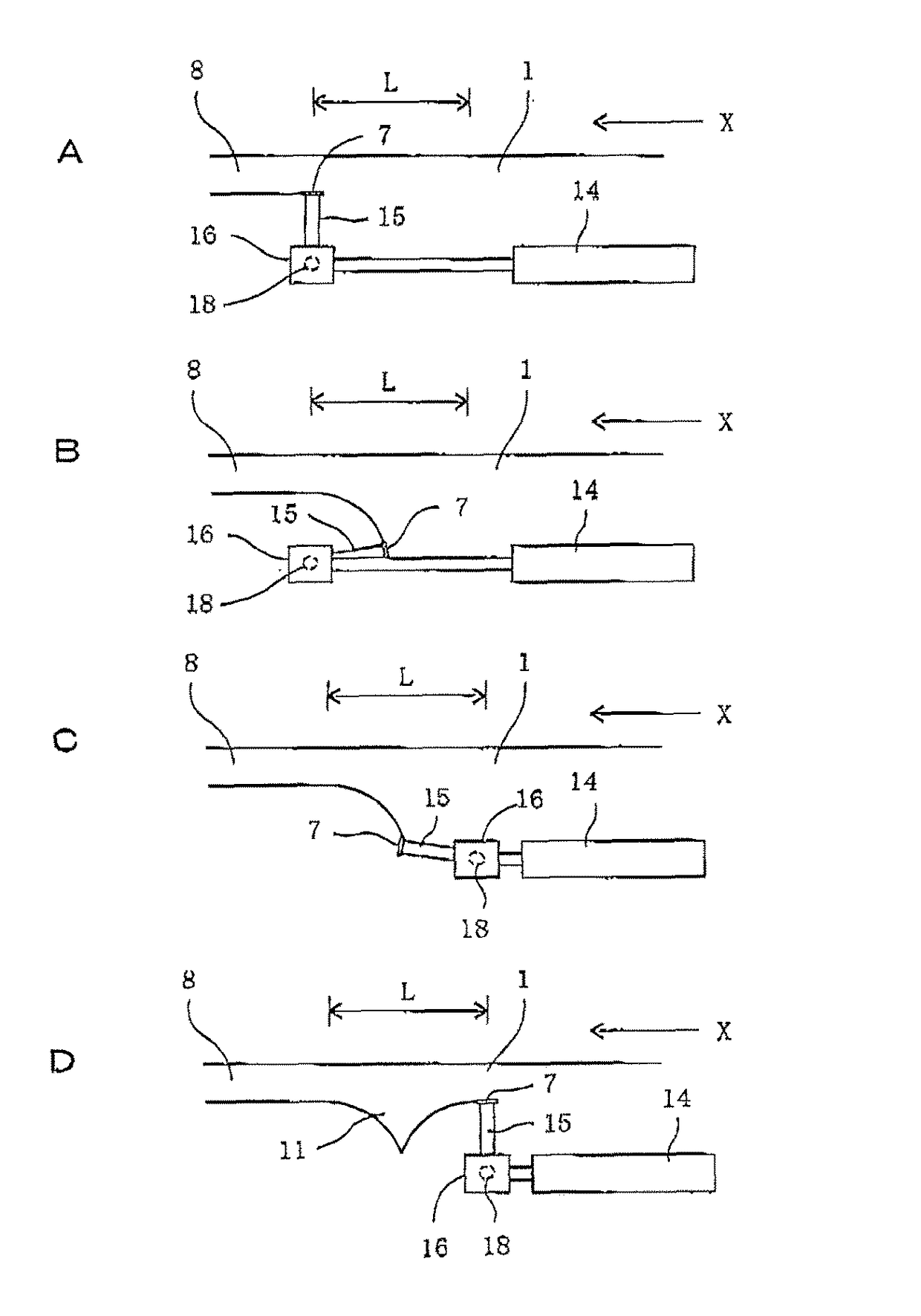

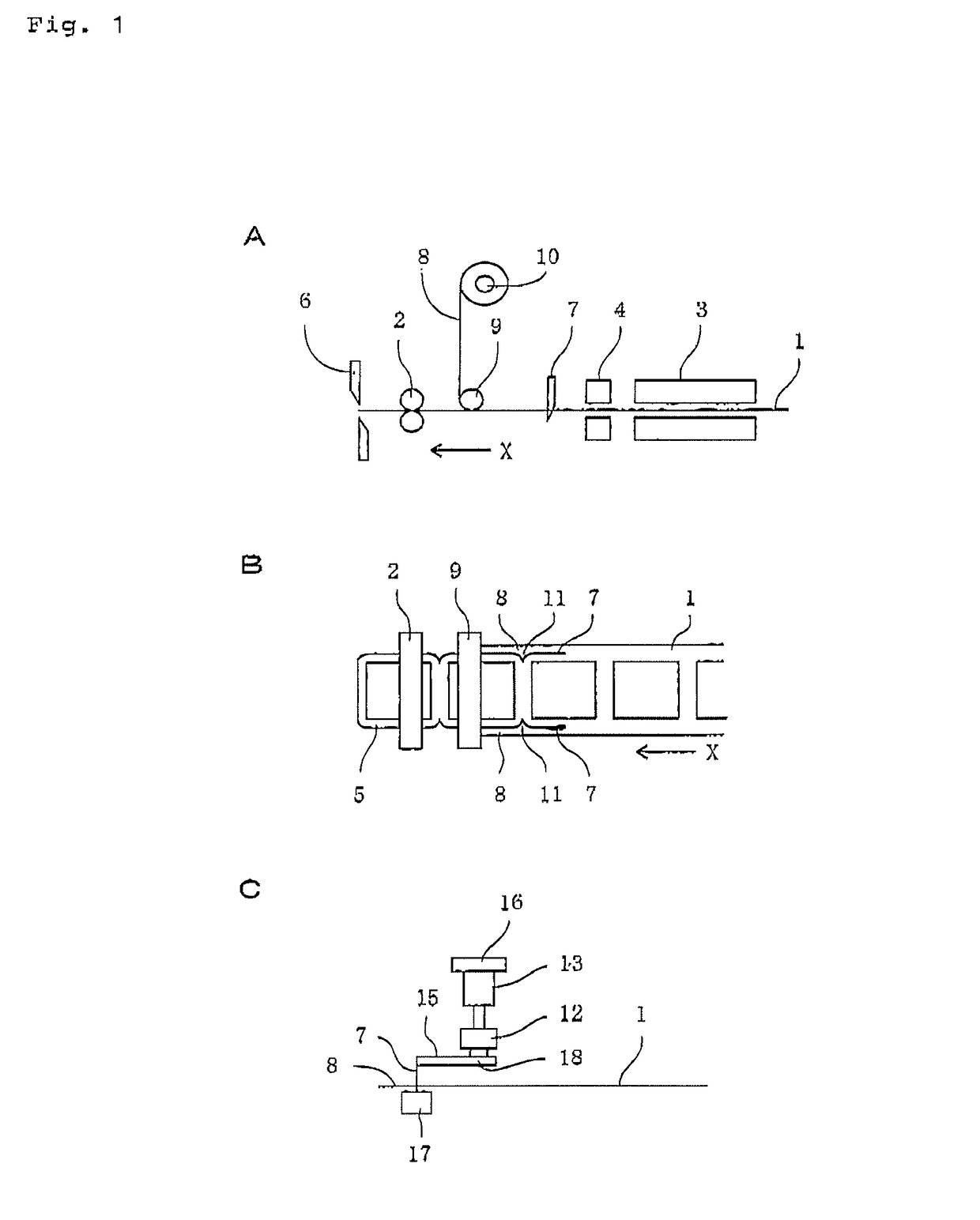

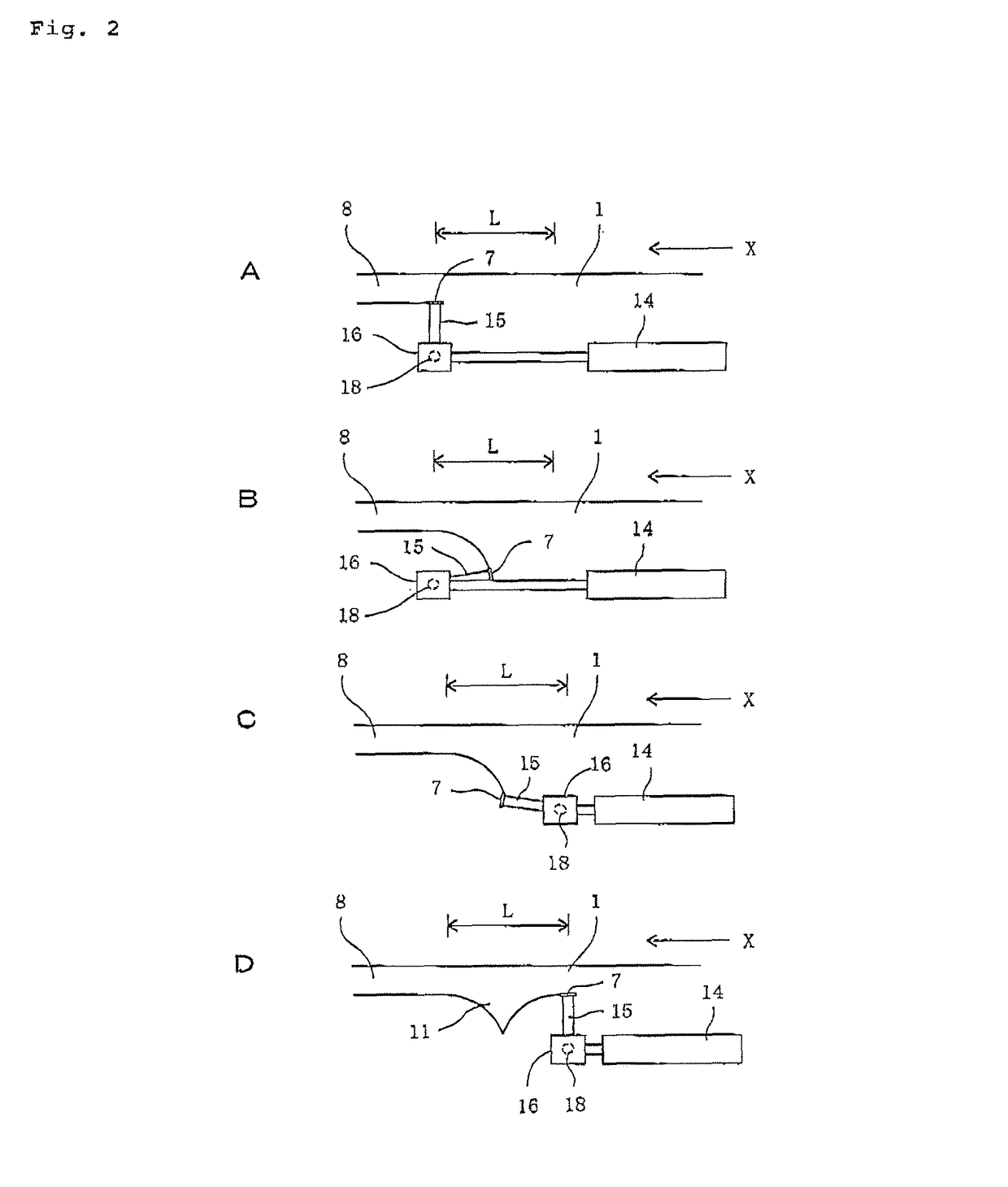

Plastic bag making apparatus

Upon cutting a corner of a plastic bag, the cut-out portion is prevented from attaching to the plastic bag. A plastic film (1) is trimmed by a trimming cutter (7) to form a selvage (8). Every time that the plastic film (1) is intermittently fed, the trimming cutter (7) is moved by a trimming cutter moving mechanism, so that a corner of the plastic bag is cut by the trimming cutter (7) and the cut-out portion (11) is continued from the selvage (8).

Owner:TOTANI CORP (JP)

Method and device for producing a package for smoking articles

ActiveCN103492169ARational productionEnvelopes/bags making machineryMechanical working/deformationCardboardMetal foil

The method involves forming an outer layer that accommodates bar-shaped smoking articles and holds a package together. A printed or plain foil strip (3) is embossed and / or provided with creasing breaks in a process cycle (P) of a packaging machine (7), where the foil strip is suitable for the outer layer. The strip is cut, and the resulting blank (19) is folded around the articles in the packaging machine. The outer layer is made of a light material e.g. paper, thin cardboard, hybrid foils, multi-layer coated foils of different materials or paper- and plastic foils or metal foil. An independent claim is also included for a device for producing a package for rod-shaped smoking articles.

Owner:BOEGLL GRAVURES SA

Protective products such as envelopes having a unique combination of interior padding of expanded slit sheet paper and exterior lining of embossed paper

ActiveUS10981712B2Costlier to manufactureLow costWrappersMechanical working/deformationMaterials sciencePaper sheet

A protective product, such as, e.g., an envelope or pouch, is provided that includes at least one expanded slit paper sheet in an expanded state, and an embossed paper sheet facing the expanded slit paper sheet and fixed to the expanded slit paper sheet along at least a portion of a length in an expansion direction of the expanded slit sheet paper. In the preferred embodiments, the embossed paper sheet has a plurality of embossings that increase the rigidity of the embossed paper sheet, thereby inhibiting deformation of the embossed paper sheet that is fixed to the expanded slit sheet paper.

Owner:HEXCELPACK LLC

Method for manufacturing a cellulose product, cellulose product forming apparatus and cellulose product

A method for manufacturing a cellulose product, comprising the steps: dry forming a cellulose blank in a dry forming unit; arranging the cellulose blank in a forming mould; heating the cellulose blankto a forming temperature in the range of 100 DEG C to 200 DEG C; and pressing the cellulose blank in the forming mould with a forming pressure of at least 1 MPa.

Owner:PULPAC AB

Display hutch

A container includes a plurality of panels connected together at fold lines configured for extending at least partially around an interior space. The panels include a front panel, a first side panel, a back panel and a second side panel. The back panel includes a first back portion and a second back portion. At least one of the first back portion or the second back portion is free from openings. A shelf panel is foldably connected to the front panel. The first back portion is adhered to the shelf panel.

Owner:WESTROCK SHARED SERVICES LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com