Machine and method for folding and adhesively bonding blanks for the production of folding boxes

A technology of cutting parts and folding boxes, which is applied in the direction of container manufacturing machinery, luggage manufacturing, rigid/semi-rigid container manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

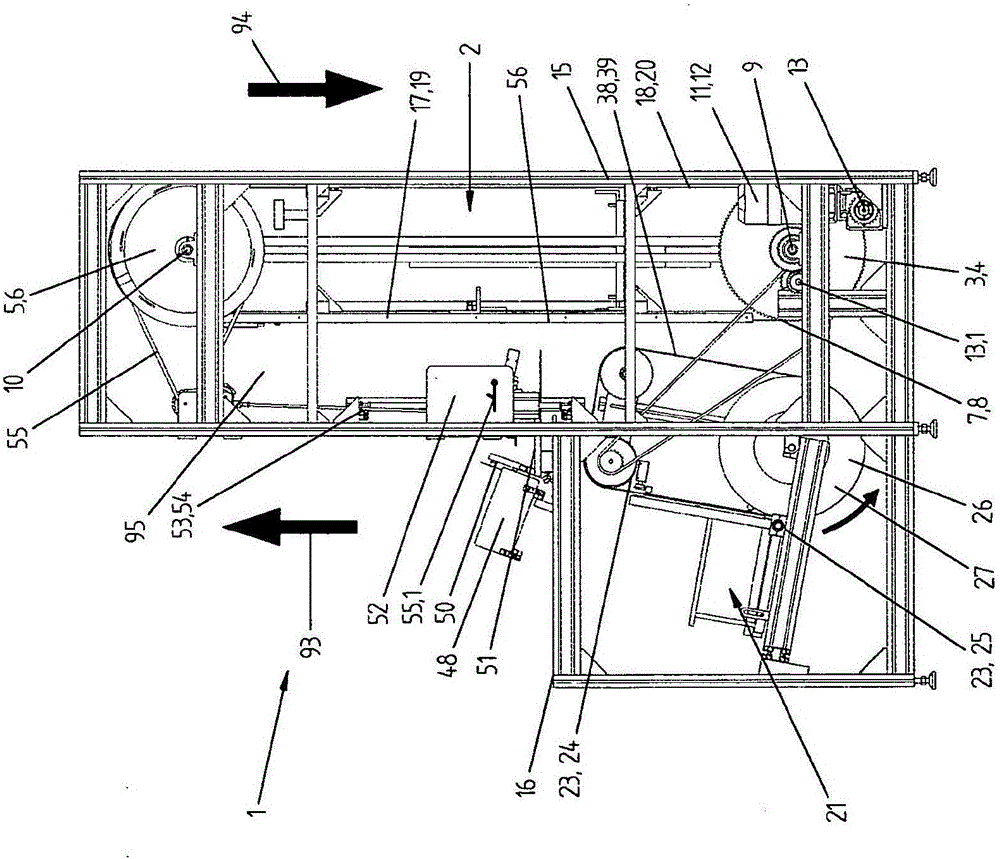

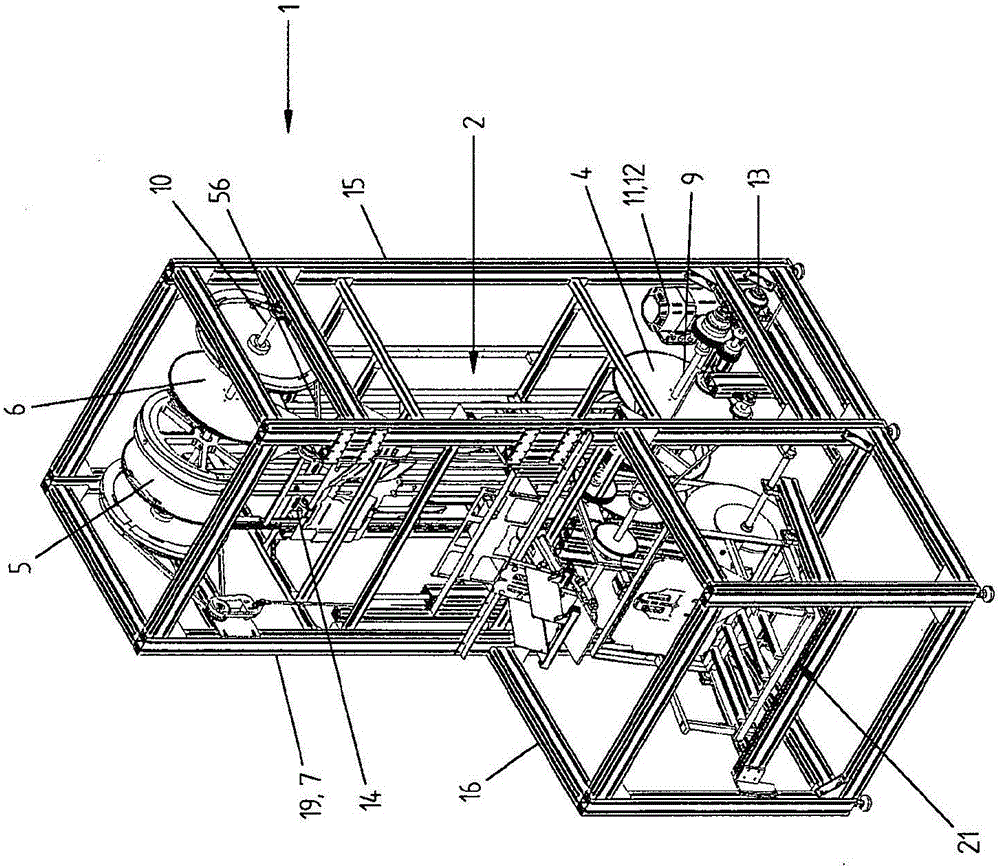

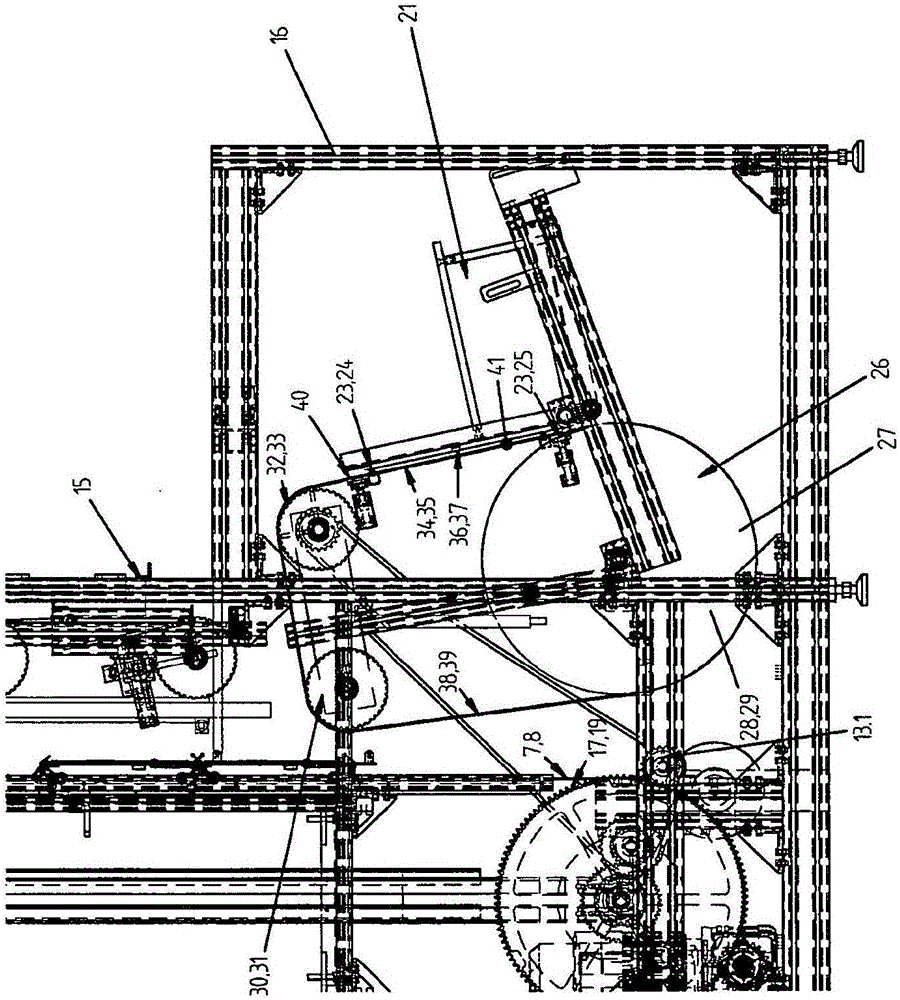

[0094] according to figure 1 and 2 , the machine 1 according to the invention comprises a transport system 2 with two parallel spaced apart lower deflection rollers 3, 4 and upper deflection rollers 5, 6 each, a pulling mechanism 7, 8 in said Steering rollers guide. The deflection rollers 3 to 5 are sprockets and the pulling means 7 , 8 are chains.

[0095] The deflection rollers 3 to 5 are supported on shafts 9 , 10 respectively.

[0096] A drive comprising an electric motor 12 and a transmission 13 drives the lower shaft 9 on which the two lower deflection rollers 3 , 4 are located.

[0097] The workpiece carriers 14 are fastened to the two pulling means 7 , 8 at a distance from one another. To this end, the pulling means 7 , 8 are each fixedly connected to the base part on which the workpiece carrier 14 is mounted. The base part is, for example, a crossbar fixedly connected to the two pulling mechanisms 7 , 8 . The workpiece carrier 14 can be removed from the base par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com