Method of forming score lines on blank, method of manufacturing package using same, and package

a technology of manufacturing method and score line, which is applied in the field of forming score lines on blanks, can solve the problems of warped blanks not being allowed to be supplied to packaging machines, swollen and distorted whole packages, and not being able to fit comfortably in the hand of users, etc., and achieves the effect of easy handling and easy forming score lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

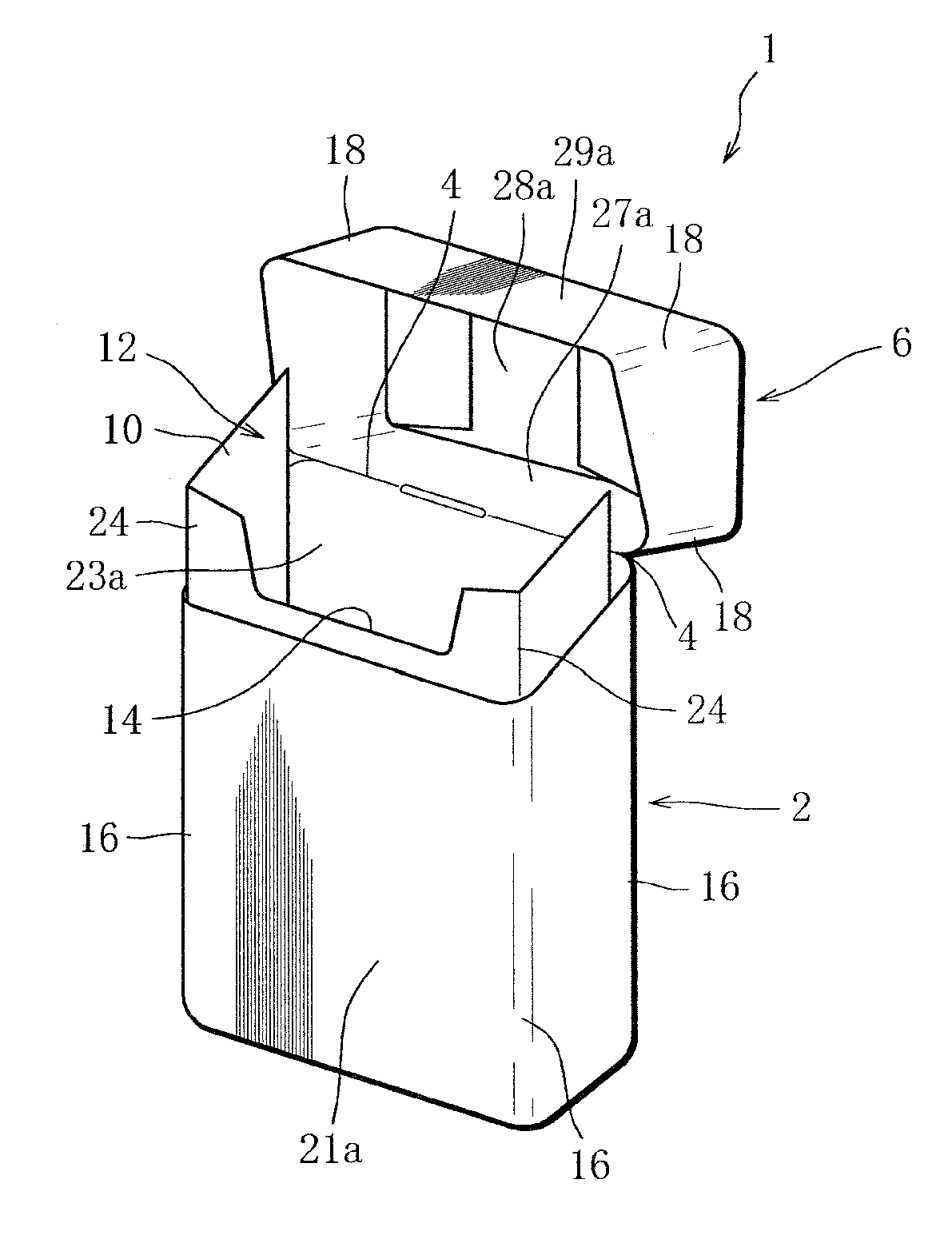

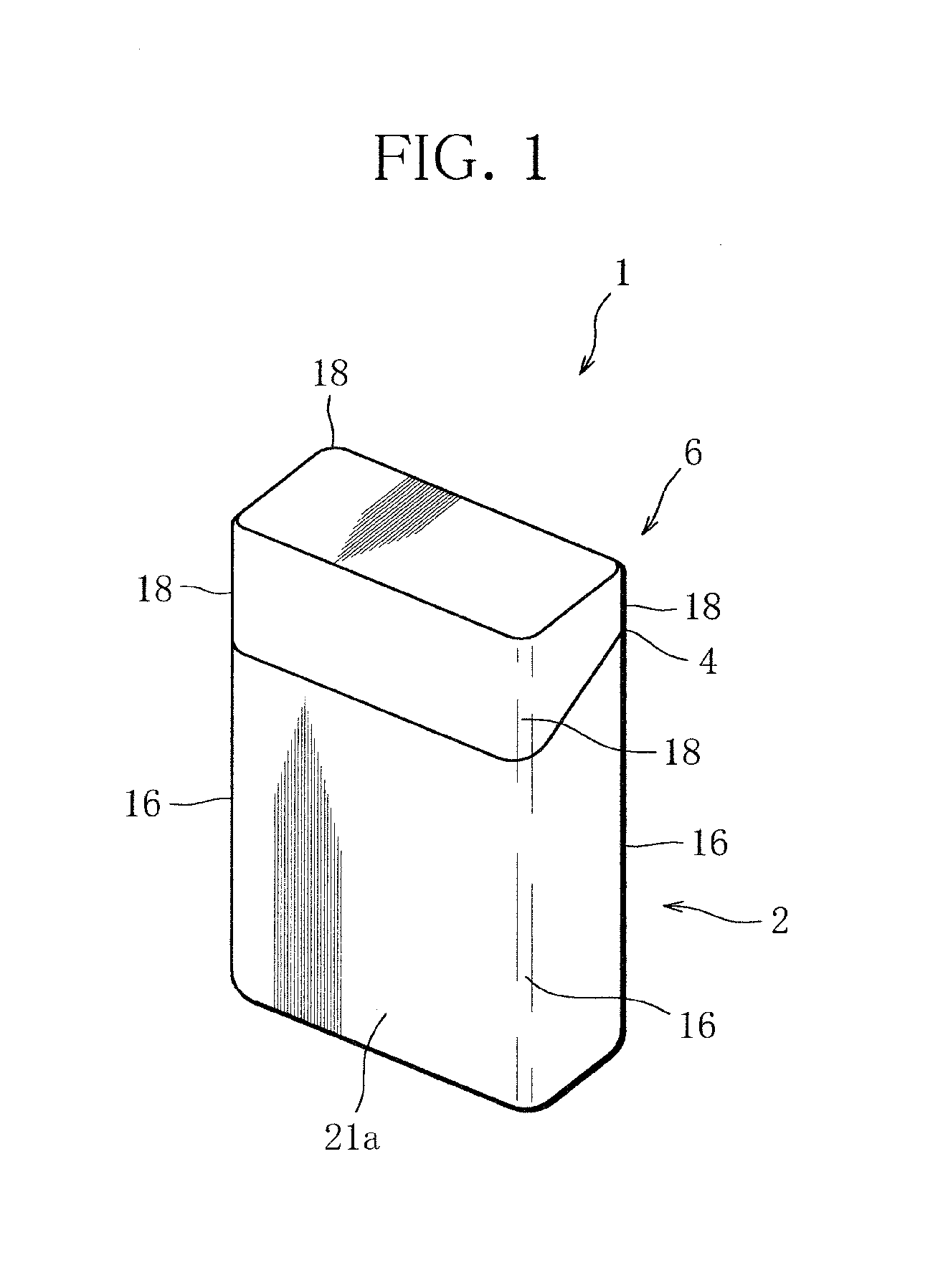

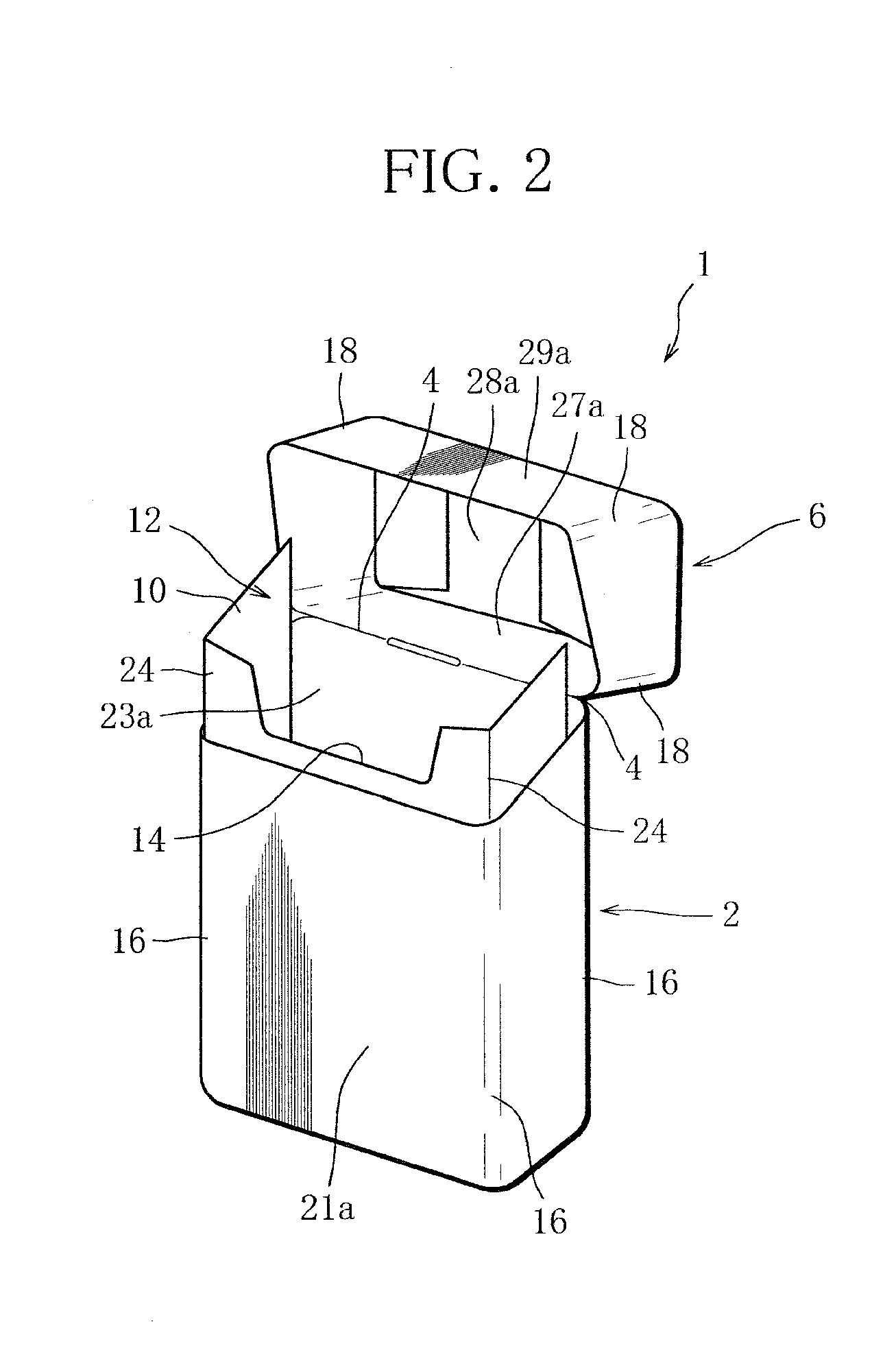

[0027]A cigarette package (box) 1 shown in FIG. 1 is, as a whole, cuboidal in shape and covered with a transparent film (not shown). The covering film has a tear tape. The package is partly exposed by opening the covering film along the tear tape. The cigarette package 1 includes a container 2. The container 2 is open at the top. The open top is closed with a lid 6. The lid 6 is connected to the rear top edge of the container which functions as a hinge 4. The lid is therefore able to be rotated on the hinge 4 to open or close the container. More specifically, as seen from FIG. 2, the container 2 has inclined top edges. The container 2 has further a U-shaped inner frame 10. The inner frame 10 is arranged to project from the top of the container 2 to define the top opening 12 of the container 2. The inner frame 10 has an access opening 14 in the front wall thereof. The access opening 14 has an approximately U shape.

[0028]The lid 6 is in the shape of a box whose bottom edges define an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com