Method for manufacturing a cellulose product, cellulose product forming apparatus and cellulose product

A technology of cellulose fibers, forming equipment, applied in the direction of manufacturing tools, flat products, envelope/bag making machinery, etc., which can solve the problems of non-recyclability, no practical or industrial method invented, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Various aspects of the present disclosure will hereinafter be described to illustrate but not to limit the present disclosure, with reference to the accompanying drawings, wherein like reference numerals refer to like elements and variations of the described aspects are not limited to the specific illustrated embodiments, Rather, it is applicable to other variations of the present disclosure.

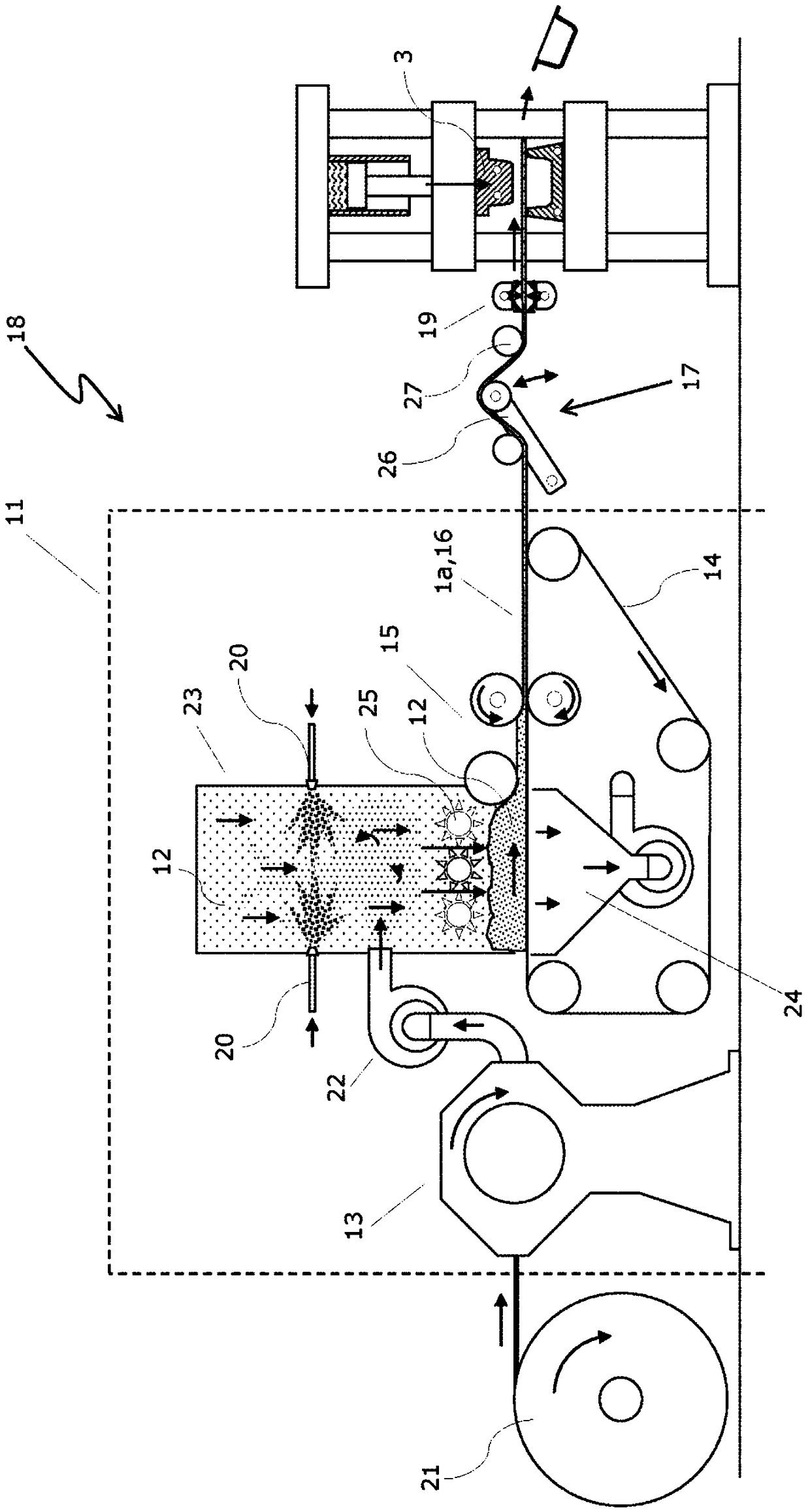

[0047] In this detailed description, a method of manufacturing a cellulose product, a cellulose product forming apparatus, and a cellulose product will be described.

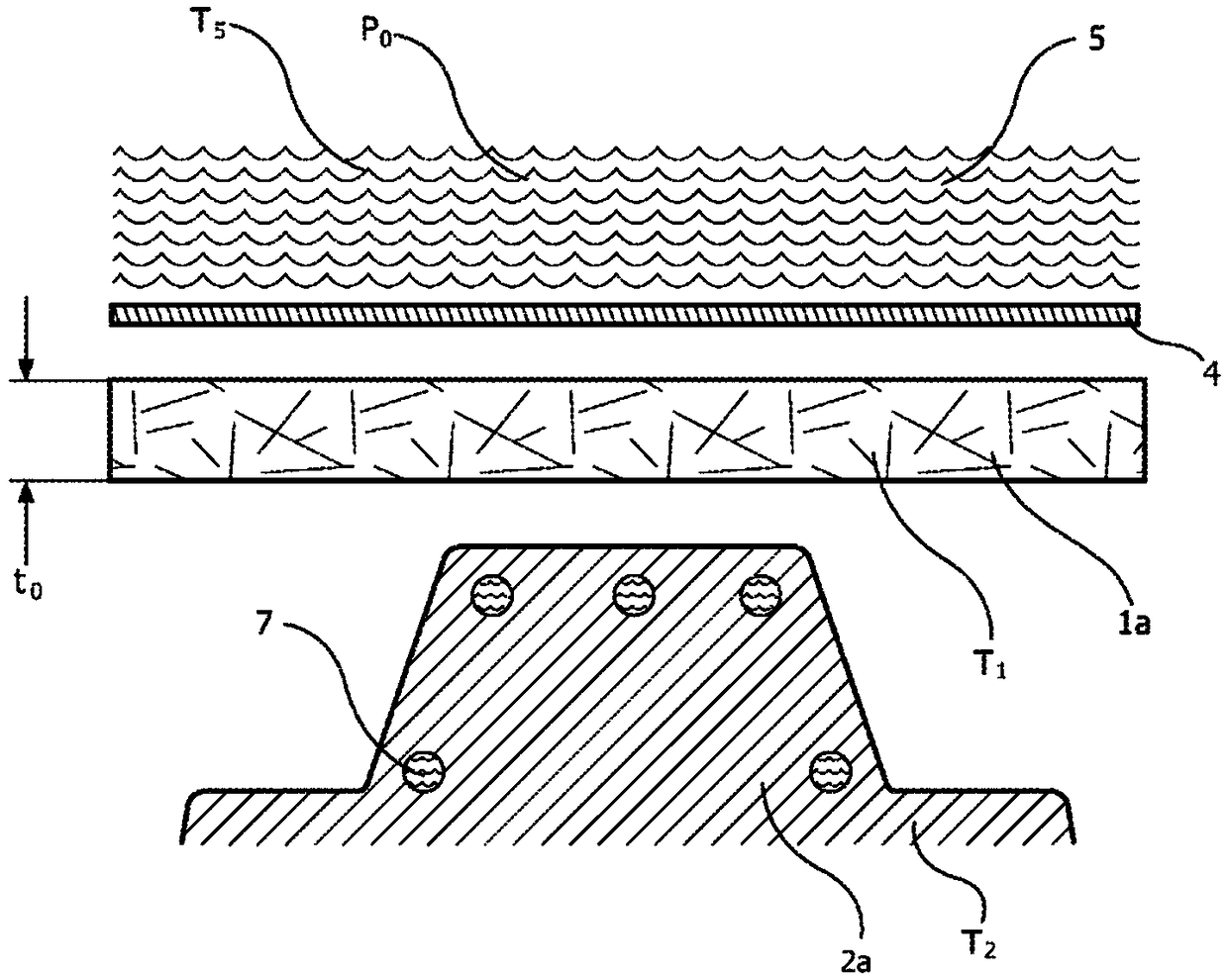

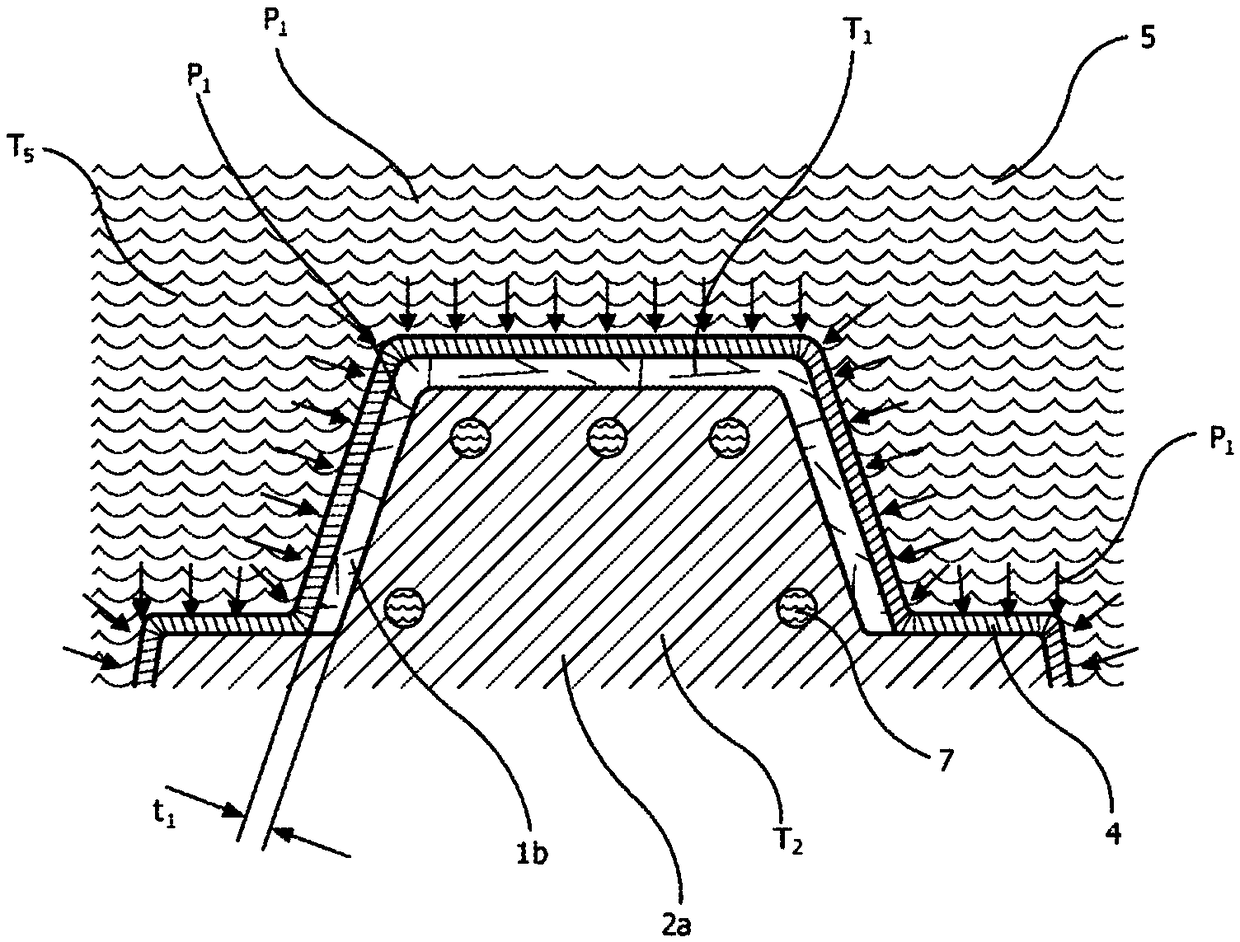

[0048] Various embodiments of sheets or blanks according to the present disclosure are discussed primarily with reference to a cellulosic blank placed in a flat shape for forming in a forming die. It should be noted that this in no way limits the scope of the invention, which also includes, for example, blanks preformed into three-dimensional objects.

[0049] For example, a blank may be presented to a forming die...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com