Camshaft

a technology of camshafts and camshafts, applied in the direction of valve drives, valve details, valve arrangements, etc., can solve the problem of more complex keeping a plurality of function elements, and achieve the effect of simplifying production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

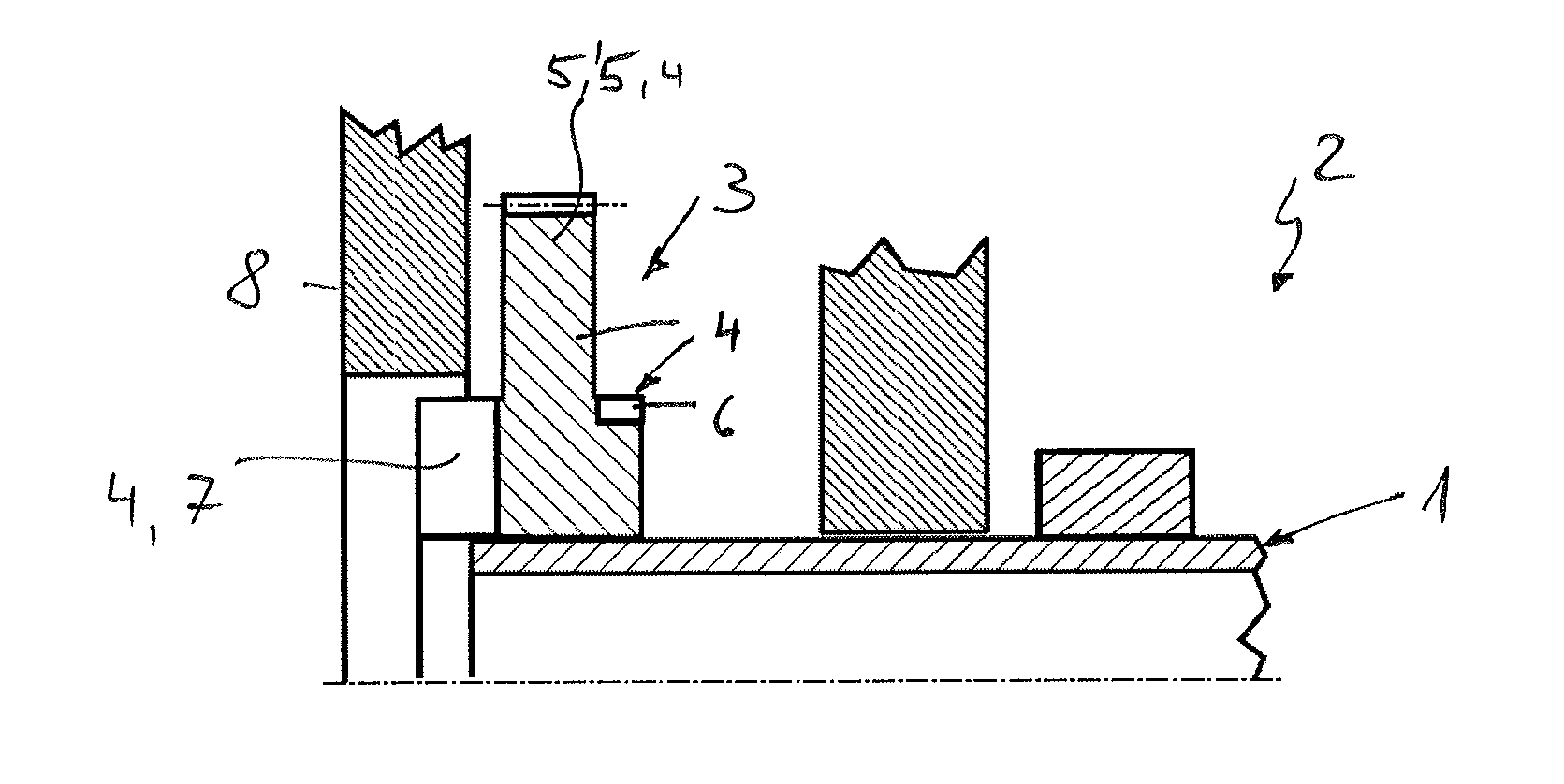

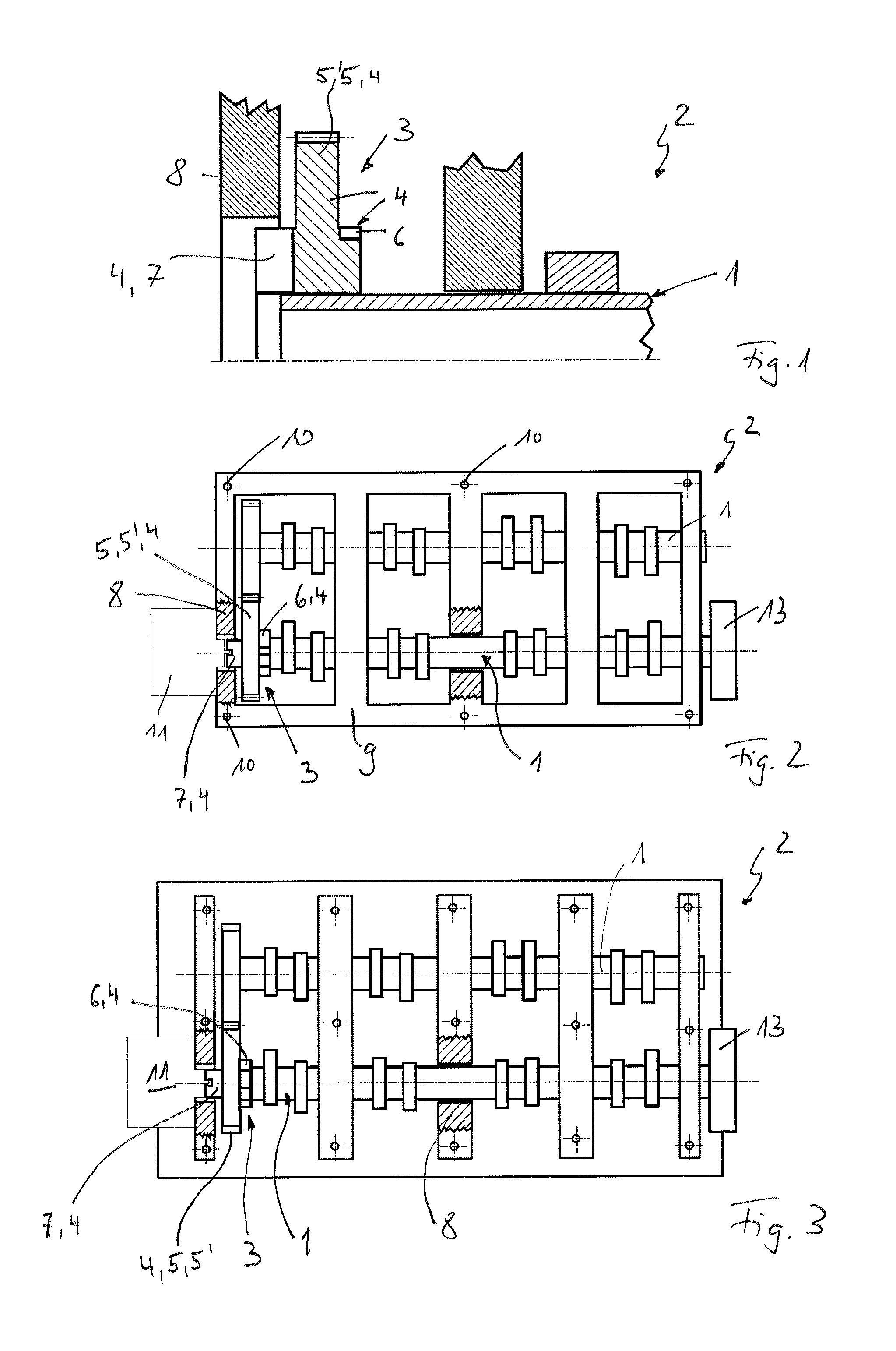

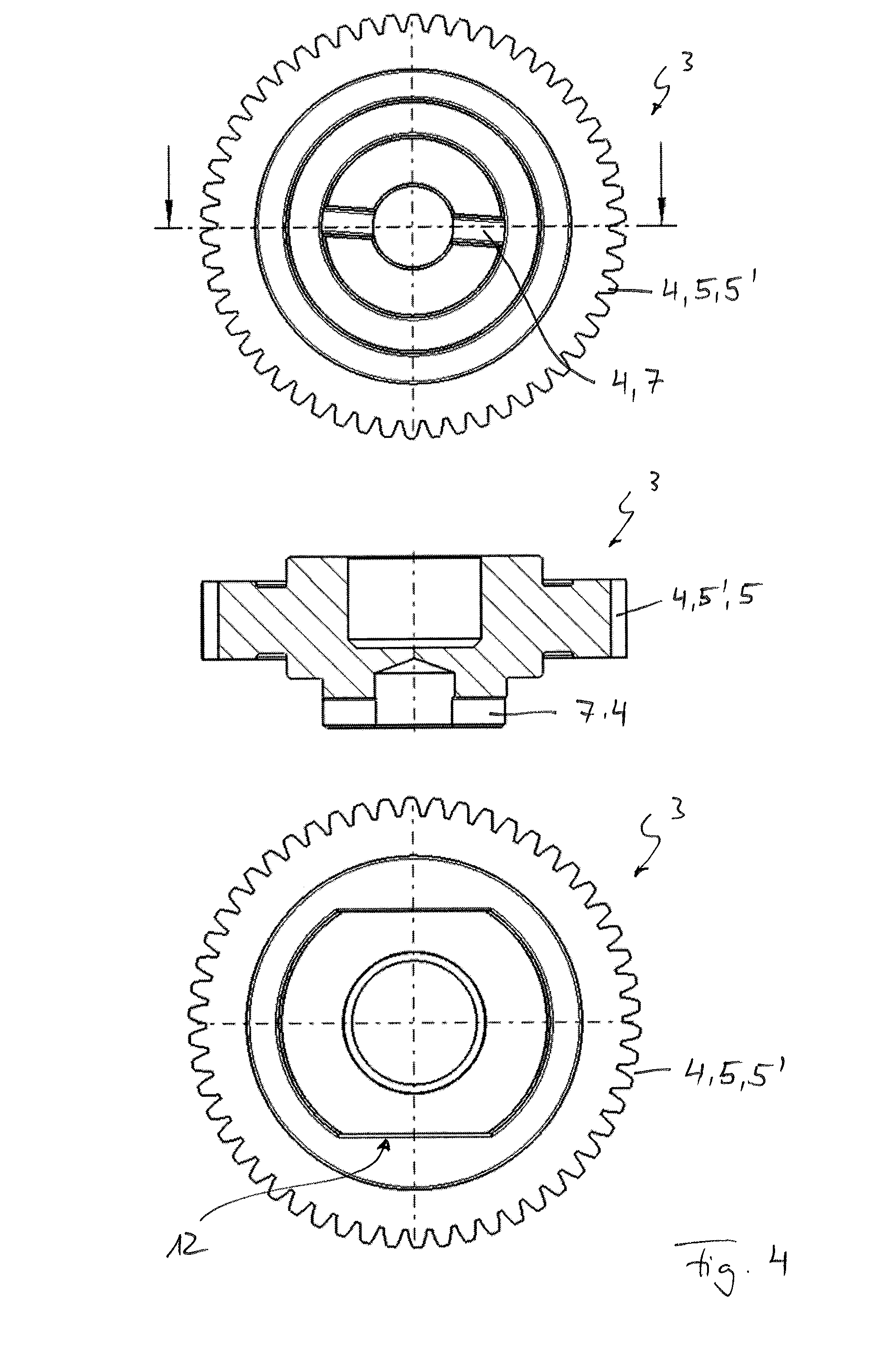

[0019]According to the FIGS. 1-3, a camshaft 1 of an internal combustion engine 2 according to the invention comprises at least one function device 3 that is connected to the camshaft 1 via a shaft-hub connection, in particular via a press fit connection, which is put together of at least two different function elements 4. The individual function elements 4 in this case fulfil different functions and are merely combined in the common function device 3 to simplify the assembly. At least one function element 4 in this case can for example be formed as a gear wheel 5, in particular as a coupling gear wheel, as a cam, as a pump actuating device, as an encoder wheel 6, as a belt pulley, as a coupling 7, in particular as an Oldham coupling, or as a chain wheel 5′. The function device 3 represented according to FIG. 1 thus has three function elements 4, namely the coupling 7, the chain wheel 5′ or gear wheel 5 as well as the encoder wheel 6. By combining a plurality of function elements 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com