Heat processing apparatus for workpiece

A technology for heat treatment devices and workpieces, applied in heat treatment furnaces, heat treatment equipment, quenching devices, etc., can solve the problems of low processing capacity, unbalanced processing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

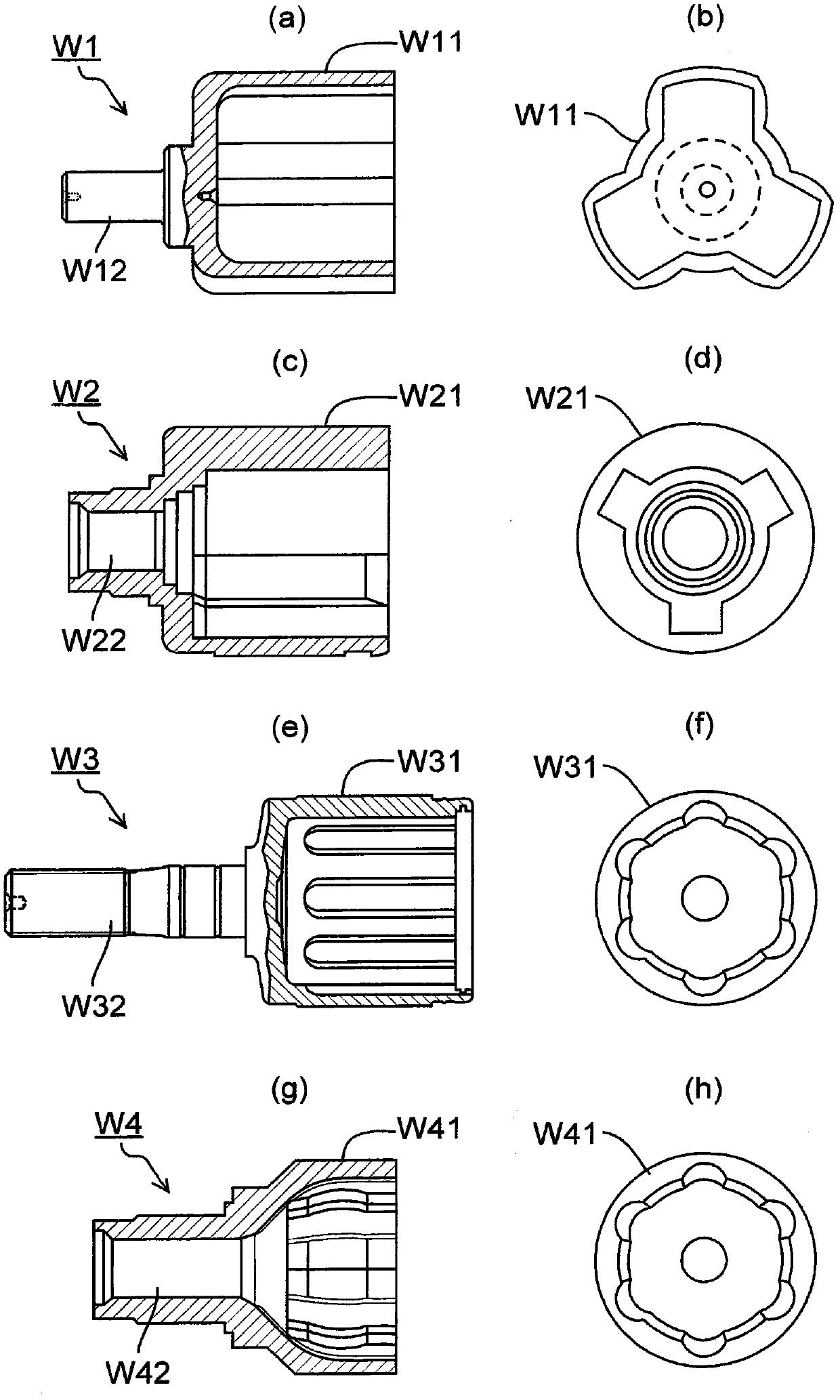

[0147] Heat treatment device 1 with figure 1 The four types of shells shown are the workpieces to be processed. The cup-shaped body is held downward to perform heat treatment on the inner surface of the cup-shaped body and the outer surface of the rod shaft or the inner surface of the cup-shaped body and the hole surface of the cylinder shaft, so the cup-shaped body is called the lower part of the workpiece, and the rod shaft is called the lower part of the workpiece. The upper part or the cylindrical shaft part is called the upper part of the workpiece.

[0148] overall composition

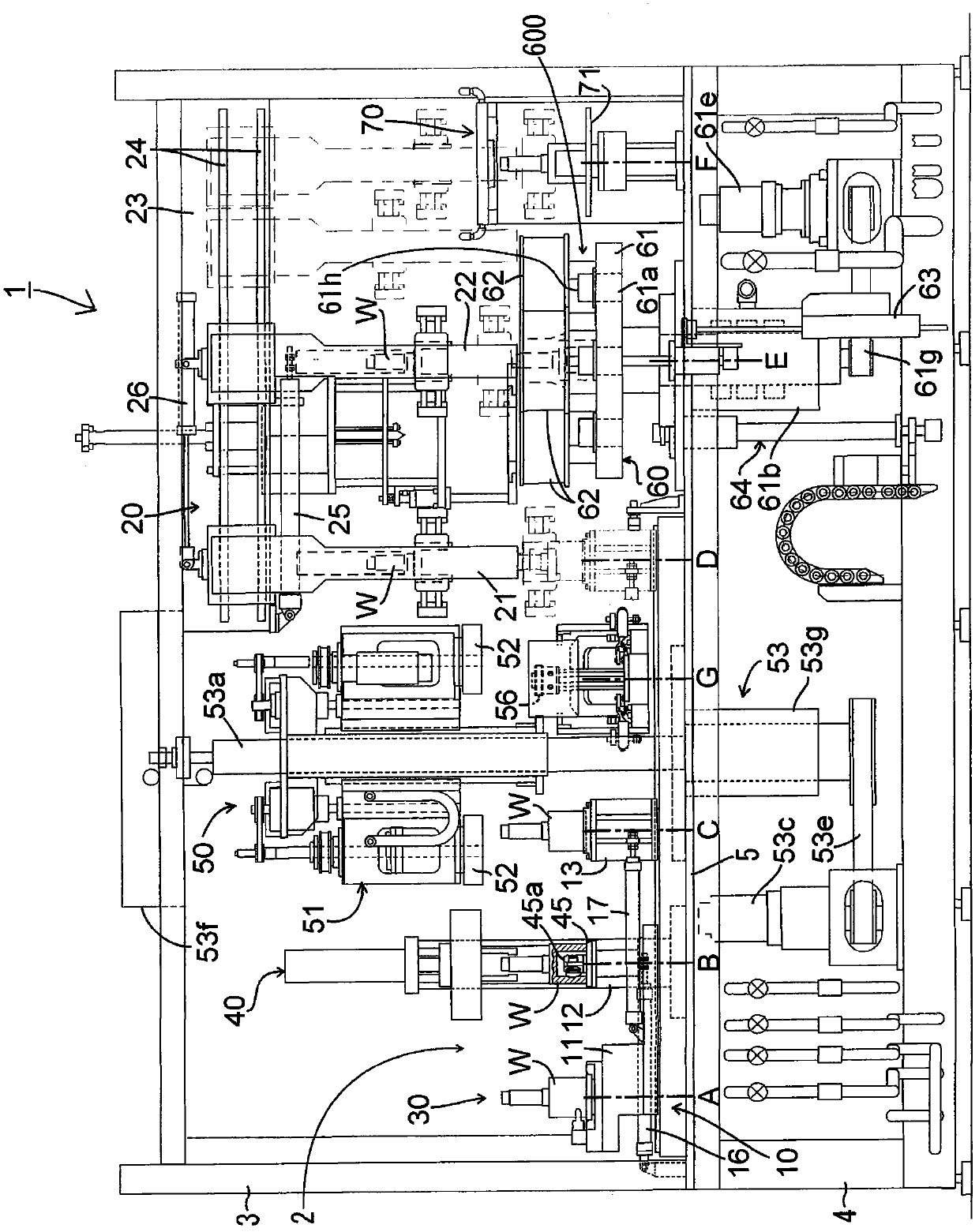

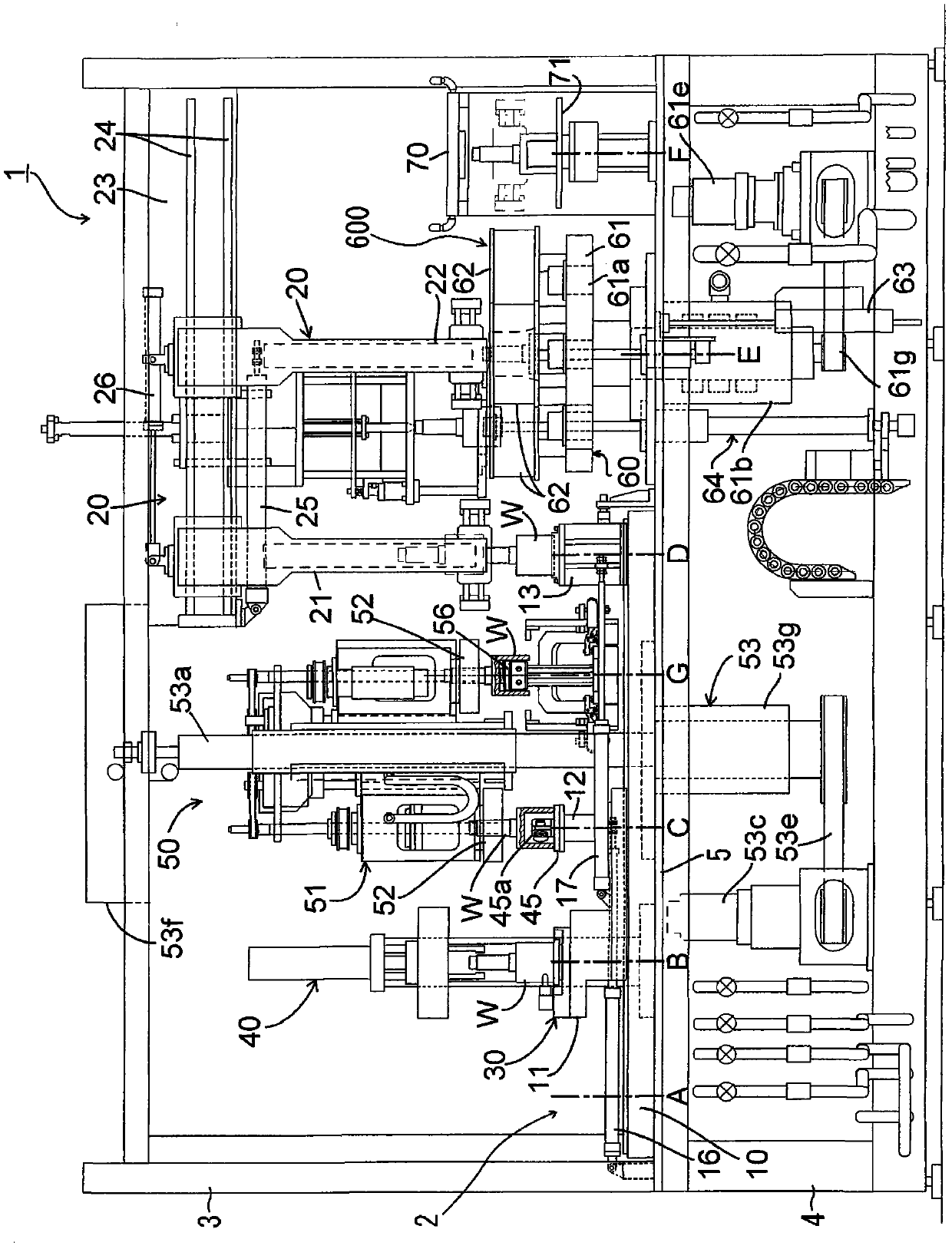

[0149] Such as figure 2 , image 3 , Figure 5 , Figure 6 As shown, the heat treatment apparatus 1 has a table-type conveying mechanism 10 at the front of the left side and a hanger-type conveying mechanism 20 at the front of the right, and conveys the workpiece W from left to right. The heat treatment device 1 includes: a provisional phase determination mechanism 30 for provisional pha...

no. 2 Embodiment approach

[0494] Figure 42 It is a thermal processing head of another embodiment, (a) is a perspective view seen from upper right, (b) is a perspective view seen from upper left, (c) is a top view which shows the connection with a power supply part.

[0495] The heat treatment head 301 of this embodiment includes: a heating coil 310 ; a powered terminal 320 disposed at one end of the heating coil 310 ; and another powered terminal 330 disposed at the other end of the heating coil 310 .

[0496] The heating coil 310 is produced by bending a copper hollow tube or the like. The shape of the heating coil 310 is determined by the shape of the workpiece and the area to be heat-treated, and is not limited to Figure 42 status shown. That is, part of the heating coil 310 has a shape that can approach a portion to be heated that is a portion to be heat-treated of a workpiece (not shown). By passing an alternating current through the portion of this shape, an eddy current is induced in the po...

no. 3 Embodiment approach

[0508] Figure 43 (a) is a perspective view seen from the upper right, (b) is a perspective view seen from the upper left, (c) is a top view which shows the connection with a power supply part, and shows the thermal processing head 301A of still another embodiment. The heat treatment head 301A includes a heating coil 310 and a pair of power supply terminals 320 and 330A. A terminal 320 to be fed is provided at one end of the heating coil 310 , and a terminal 330 to be fed is provided at the other end of the heating coil 310 .

[0509] The terminal 320 to be powered is configured in the same manner as in the other embodiment described above, and has a hollow portion 321 , a hole 322 , and a cooling water inlet 323 . The configuration of the terminal 330A to be fed is different from that of the terminal 330 of the first embodiment. Powered terminal 330 in the first embodiment has hollow portion 331 , hole 332 , and cooling water outlet 333 , but powered terminal 330A in this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com