Method for preparing low-cost oriented silicon steel by utilization of continuous annealing

A low-cost technology of grain-oriented silicon steel, applied in the field of preparing low-cost grain-oriented silicon steel by continuous annealing, can solve the problems of long secondary recrystallization annealing time, etc., and achieve the effect of shortening production time, shortening process flow, and improving final performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

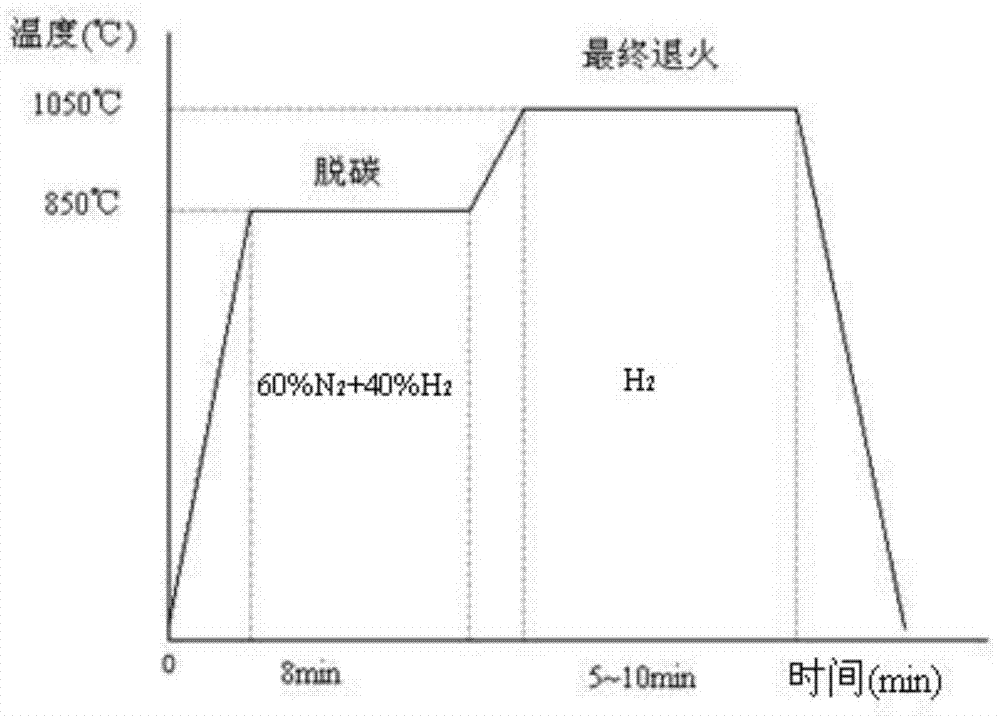

[0029] 1 process route

[0030] Smelting and continuous casting→hot rolling→primary cold rolling→intermediate annealing→secondary cold rolling→continuous annealing

[0031] 2 process parameters

[0032] 2.1 Smelting and continuous casting

[0033] The composition of the grain-oriented silicon steel obtained after smelting is shown in Table 2, and the original thickness of the slab is 30mm.

[0034] Table 2 Composition (wt%)

[0035] Si

C

mn

S

Al

3

0.05

0.05

0.02

0.017

[0036] 2.2 Hot rolling process

[0037] The original cast slab is kept at 1200°C for 30 minutes, and after heat treatment, it is hot-rolled five times to a hot-rolled plate with a thickness of 2mm.

[0038] 2.3 Primary cold rolling process

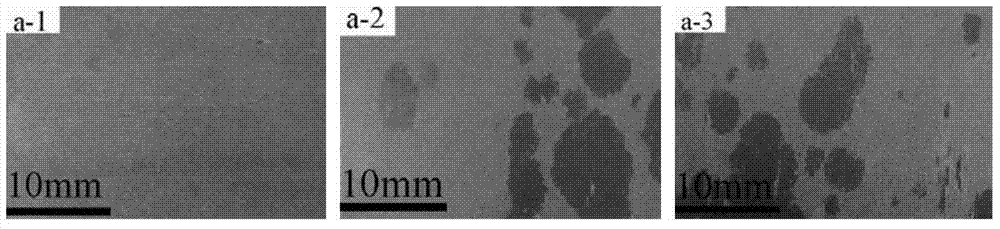

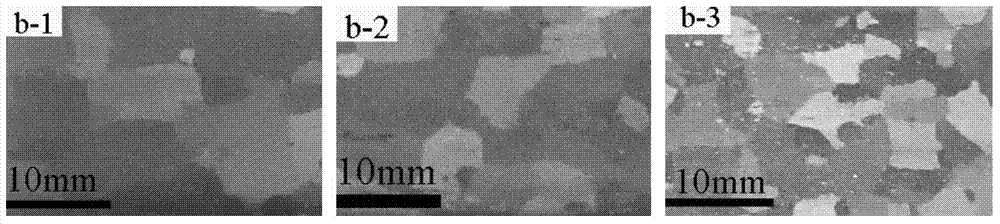

[0039] Preheating at 150°C for 10 minutes, the reduction rate of primary cold rolling is controlled to three parameters of 77.5%, 71.5%, and 64%. The thicknesses of the steel plates after one cold rolling are 0.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com