Water-soluble micro-crosslinked copolymer, preparation and use thereof

A copolymer and micro-crosslinking technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of small pores that are easy to block oil reservoirs, the difficulty of conformational transformation, and the difficulty of crosslinking and crosslinking distribution. And other problems, to achieve excellent anti-aging properties, good viscosity and salt resistance, high solution viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

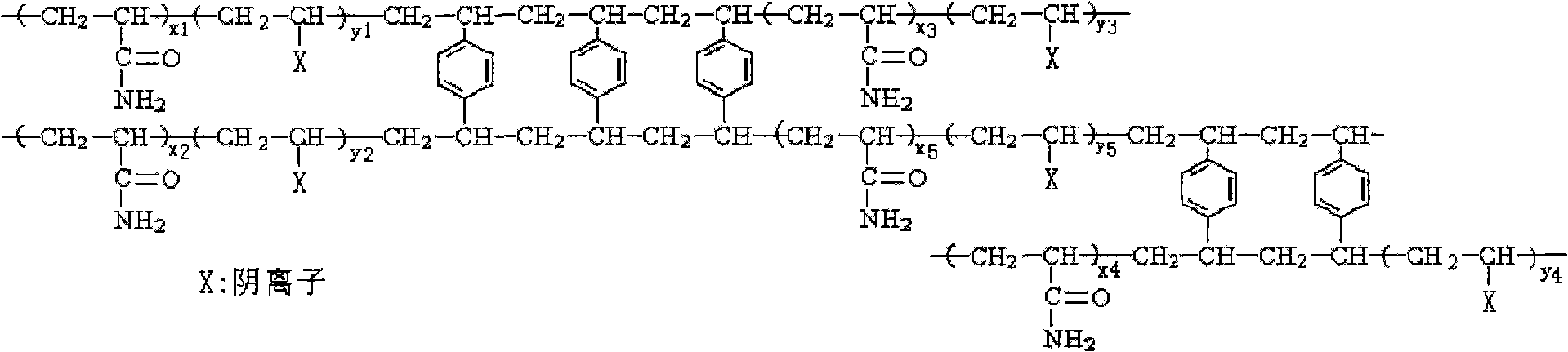

Method used

Image

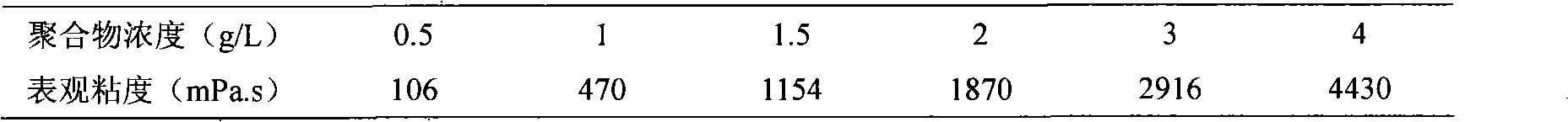

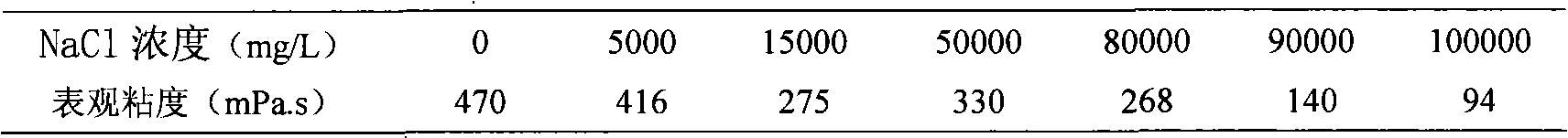

Examples

Embodiment 1

[0034] Dissolve 20.000 grams of acrylamide, 12.740 grams of acrylic acid, 5.620 grams of divinylbenzene and 45.16 grams of sodium lauryl sulfate in 785 ml of distilled water, add them to a three-necked reaction flask, adjust the pH of the solution to 6 with NaOH, and the reaction temperature is 40°C. Pass N 2 After 30 minutes, add 9.08 mL of 0.05 mol / L potassium persulfate initiator solution, react for 12 hours, and dilute the polymer with water to obtain a concentrated PADM solution.

Embodiment 2

[0036] Dissolve 20.000 grams of acrylamide, 8.260 grams of 2-acrylamido-2-methylpropanesulfonic acid, 3.012 grams of divinylbenzene and 29.420 grams of sodium lauryl sulfate in 510 milliliters of deionized water, adjust the pH with NaOH= 7. The reaction temperature is 50°C, and N is passed through 2 After 30 minutes, add 6.73 mL of 0.05 mol / L ammonium persulfate initiator solution, and react for 16 hours. The polymer was dissolved in water to obtain a PADM concentrated solution.

Embodiment 3

[0038] Dissolve 20.000 g of acrylamide, 4.250 g of 3-acrylamido-3-methylbutanoic acid, 2.170 g of divinylbenzene and 14.610 g of sodium lauryl sulfate in 305 ml of deionized water, and adjust the pH to 8 with NaOH , reaction temperature 45°C, pass N 2 After 30 minutes, add 1.08 mL of 0.05 mol / L potassium persulfate initiator solution, and react for 24 hours. The polymer was dissolved in water to obtain a PADM concentrated solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com