Oblique pole type motor Hall installation structure

A technology of installation structure and sloping pole, applied in the direction of electromechanical devices, structural connections, electrical components, etc., can solve the problems of difficult control of the external angle calculation and adjustment of the Hall, unstable motor motion, accurate positioning and fixation of the Hall, etc. Achieve the effect of improving motor motion stability, reducing motor cost, and accurate positioning and fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to the accompanying drawings and specific embodiments.

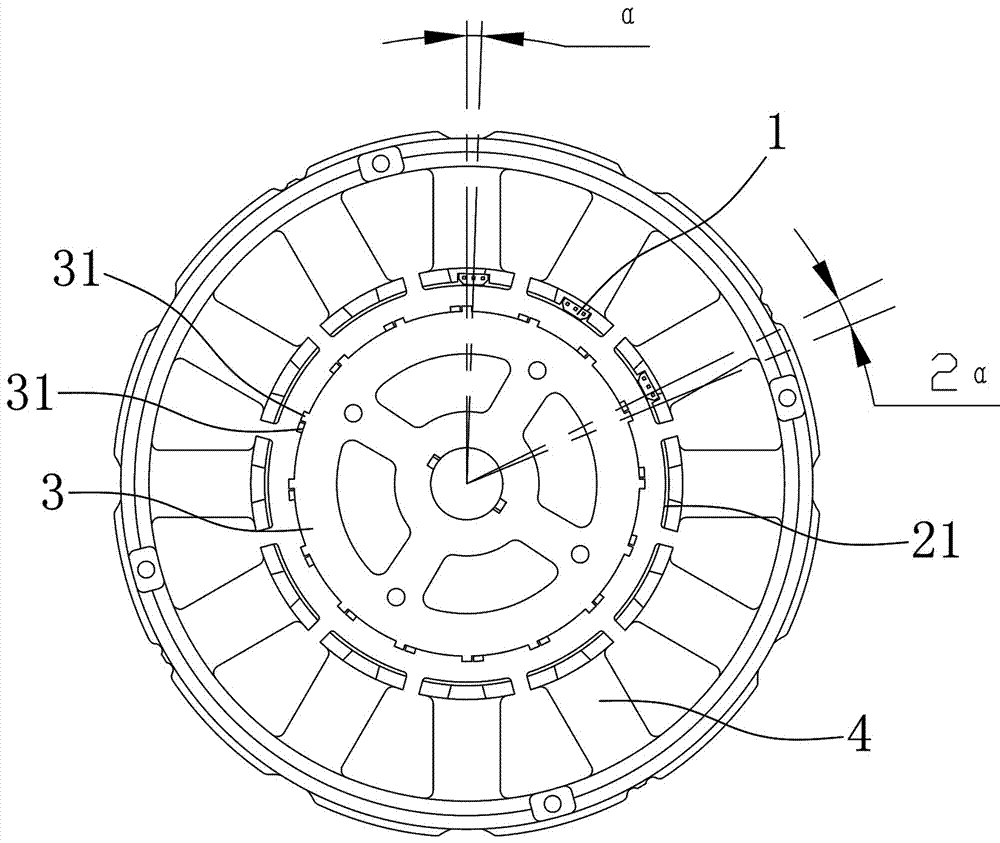

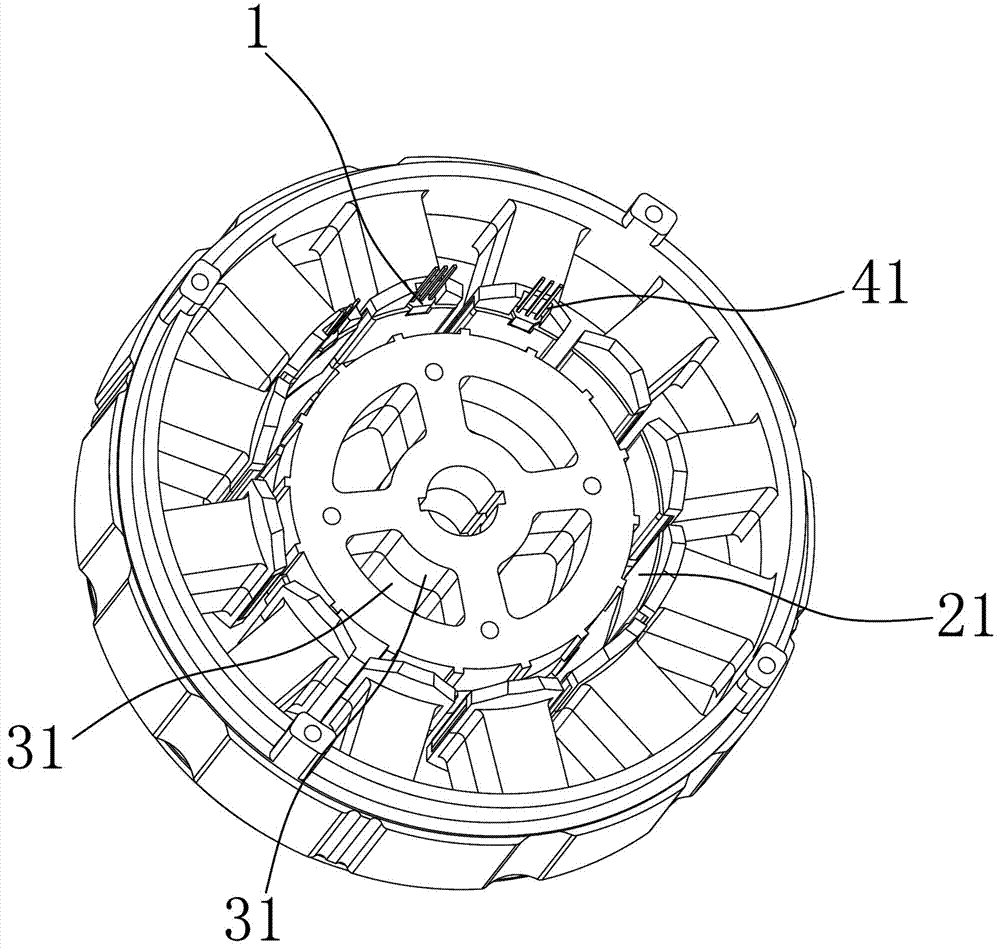

[0013] Depend on figure 1 , figure 2 As shown in the present invention, a hall installation structure of a slanted-pole motor is provided. The hall 1 is fixed on the stator, and the stator is provided with a rotor 3. The rotor 3 is composed of two rotor units 31, and the adjacent rotor units 31 are opposite to each other. Deflection, the inner edge of the tooth portion 21 of the stator is formed with an accommodating groove for accommodating the Hall 1, the Hall housing of the Hall 1 is located in the accommodating groove, and the Hall pins of the Hall 1 extend along the parallel line of the rotor shaft, The center of the accommodating slot deviates from the center of the stator tooth portion where the accommodating slot is located, the relative deflection angle of the adjacent rotor units 31 is 2α, and the relative deflection angle between the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com