Short arc type flash lamp with both ends sealed

A flash lamp and sealing type technology, which is applied in the direction of discharge lamps, gas discharge lamps, parts of gas discharge lamps, etc., can solve problems such as the inability to obtain assembly structures, and achieve the effects of reducing risks and improving pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

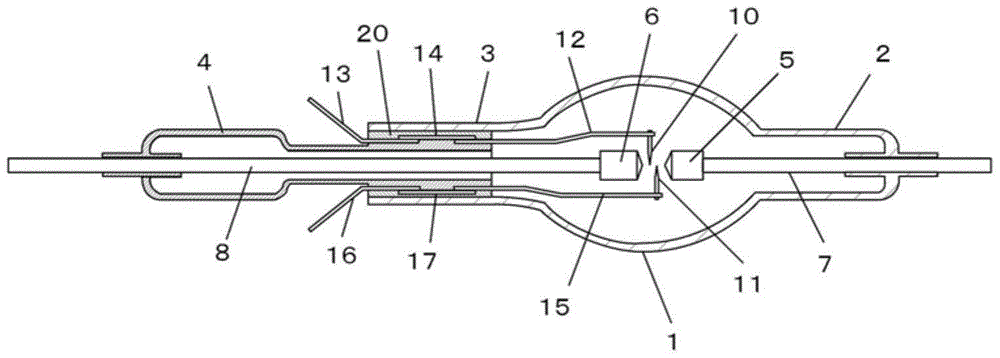

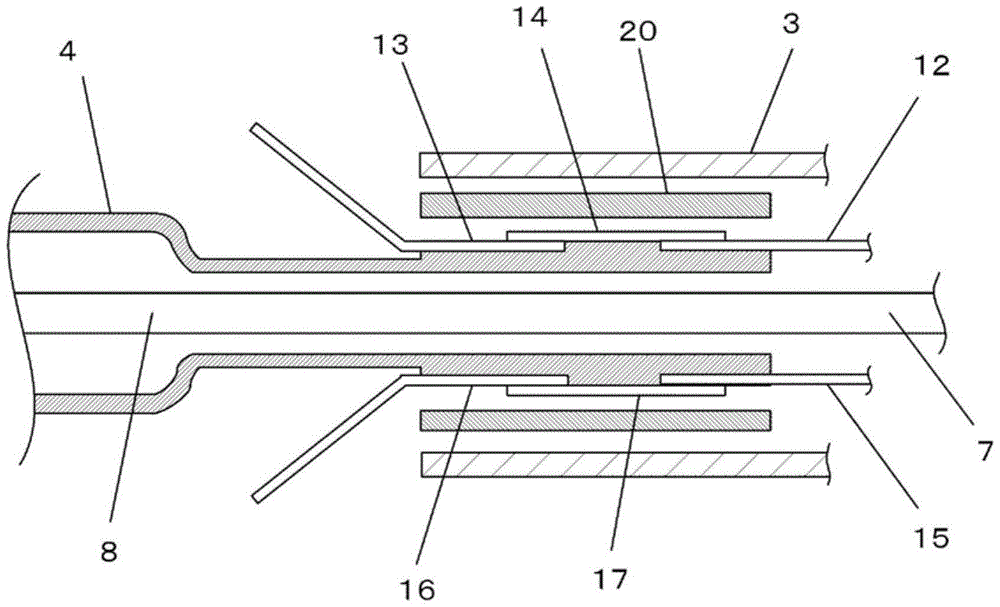

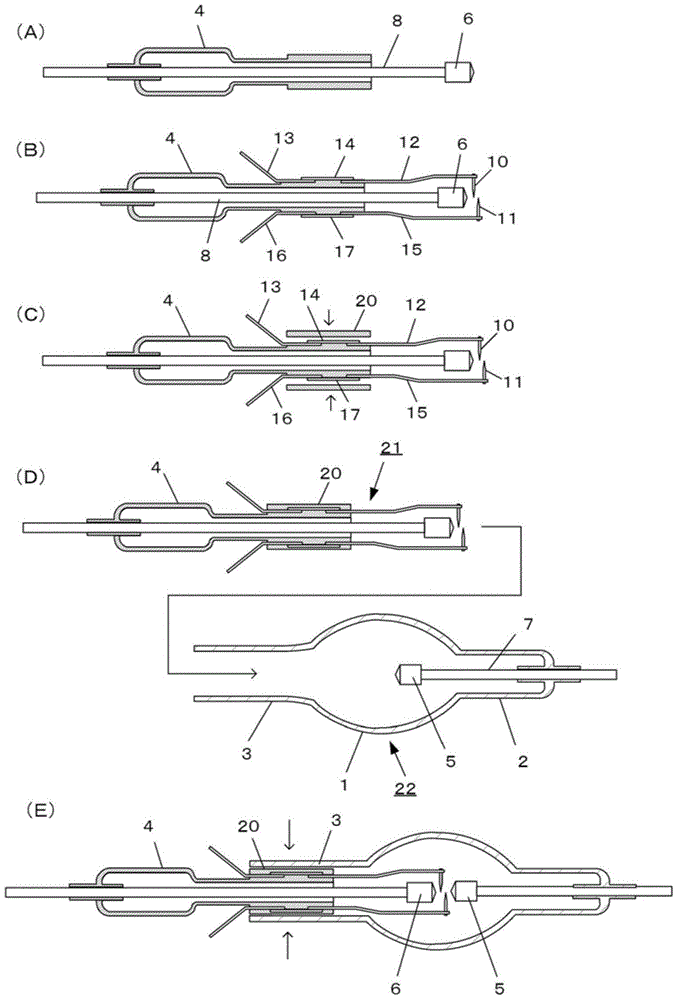

[0045] figure 1 It is a sectional view of the whole of the two-ends-sealed short-arc flash lamp with the lamp cap fixed in the present invention, figure 2 yes figure 1 The exploded and enlarged cross-sectional view of the main part.

[0046] This short-arc flashlight is a so-called sealed-end type, and its basic structure and Figure 4 The conventional example shown is the same. That is, it has, for example, an ellipse-shaped arc tube 1 forming a light-emitting space, a first sealing tube 2 connected to one end of the arc tube 1 and extending outward along the tube axis direction, and the other end connected to the arc tube 1. The second sealing tube 3 extending outward along the tube axis direction at one end is inserted into the second sealing tube 3 with the glass tube 4 for sealing, and both are welded in the overlapping region.

[0047] A pair of first main electrodes 5 and second main electrodes 6 are arranged to face each other in the arc tube 1 . The core wire 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com