Brake pad drilling mold

A technology for drilling dies and brake pads, which is used in drilling dies for workpieces, metal processing, etc., can solve the problems of low drilling precision, insufficient fixing of brake pads, and lack of limit and guide devices for punching devices. Achieve the effect of facilitating subsequent installation and use, reducing the displacement of the brake pads, and improving the drilling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

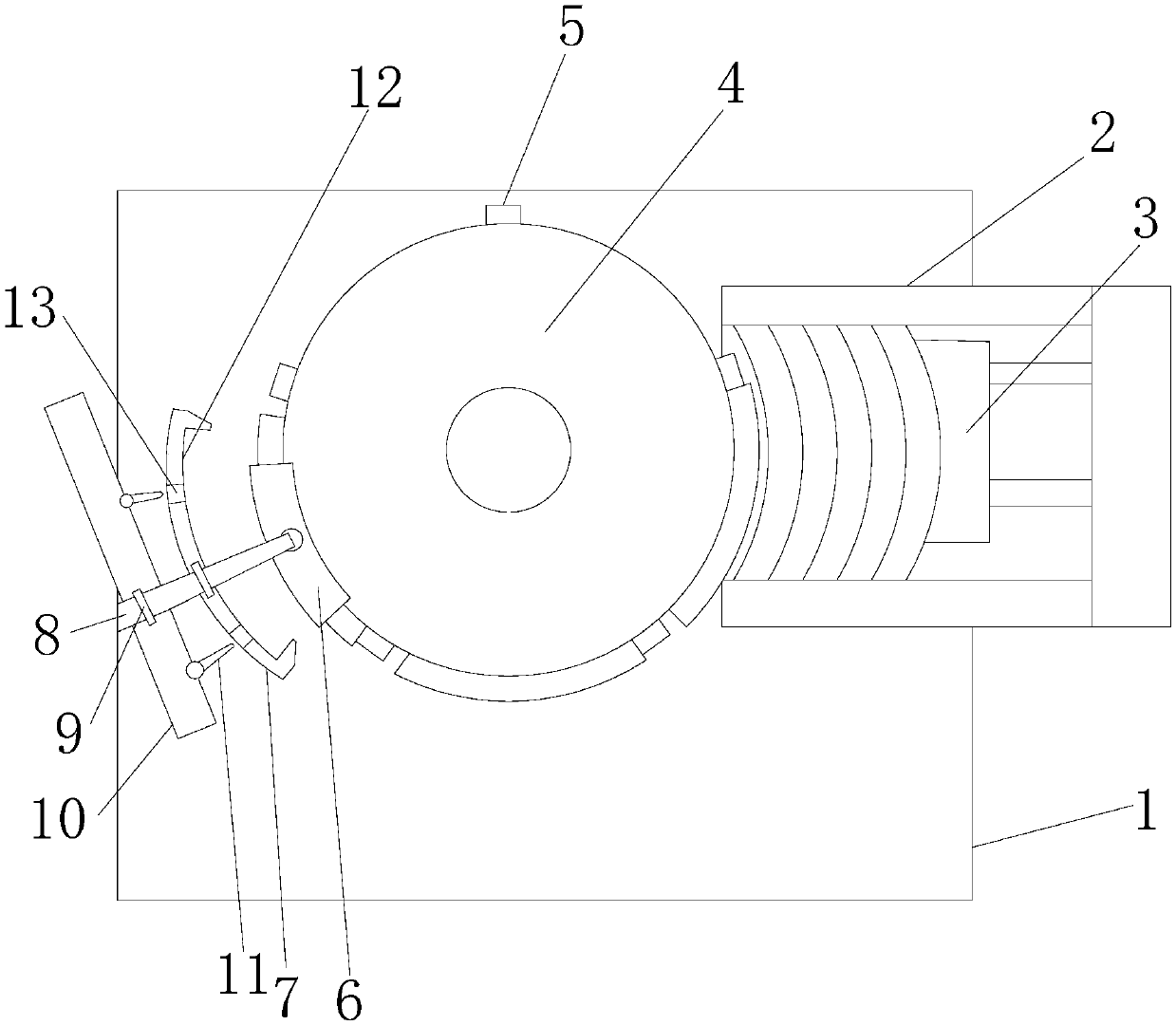

[0012] refer to figure 1 , a brake pad drilling mold of the present invention, comprising a base 1, a feeding trough 2, a pusher 3, a feeding turntable 4, a pushing protrusion 5, a pressing block 6, a limit card groove 7, a guide rail 8, an electric slide Block 9, movable substrate 10, drilling motor 11, the top of the base 1 is provided with a feeding chute 2, a pusher 3 is installed in the feeding chute 2, and a feeding turntable 4 is arranged on the left side of the feeding chute 2, so A plurality of pushing protrusions 5 are arranged on the feeding turntable 4, a pressing block 6 is arranged above the feeding turntable 4, and the pressing block 6 is installed below a guide rail 8, and the guide rail 8 is arranged on the left side of the feeding turntable 4 , the limit card slot 7 is installed on the guide rail 8 through the electric slider 9, the outer side of the limit card slot 7 is provided with a movable substrate 10, and the movable substrate 10 is provided with sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com