Patents

Literature

31results about How to "Reduce displacement phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

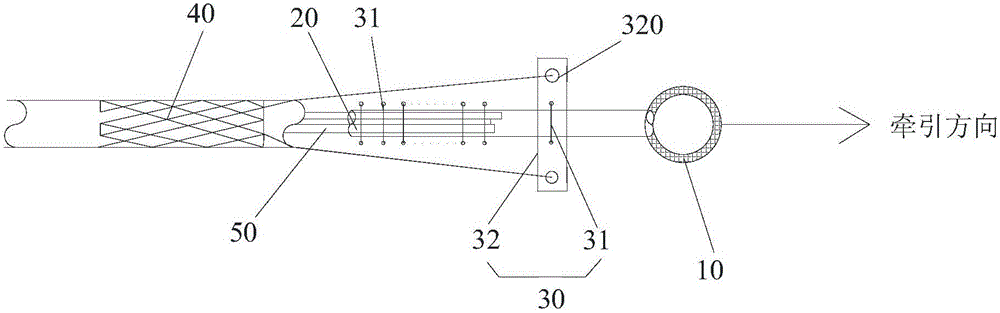

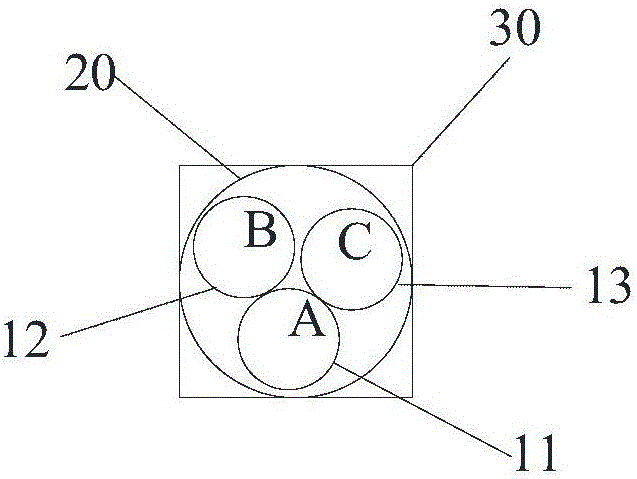

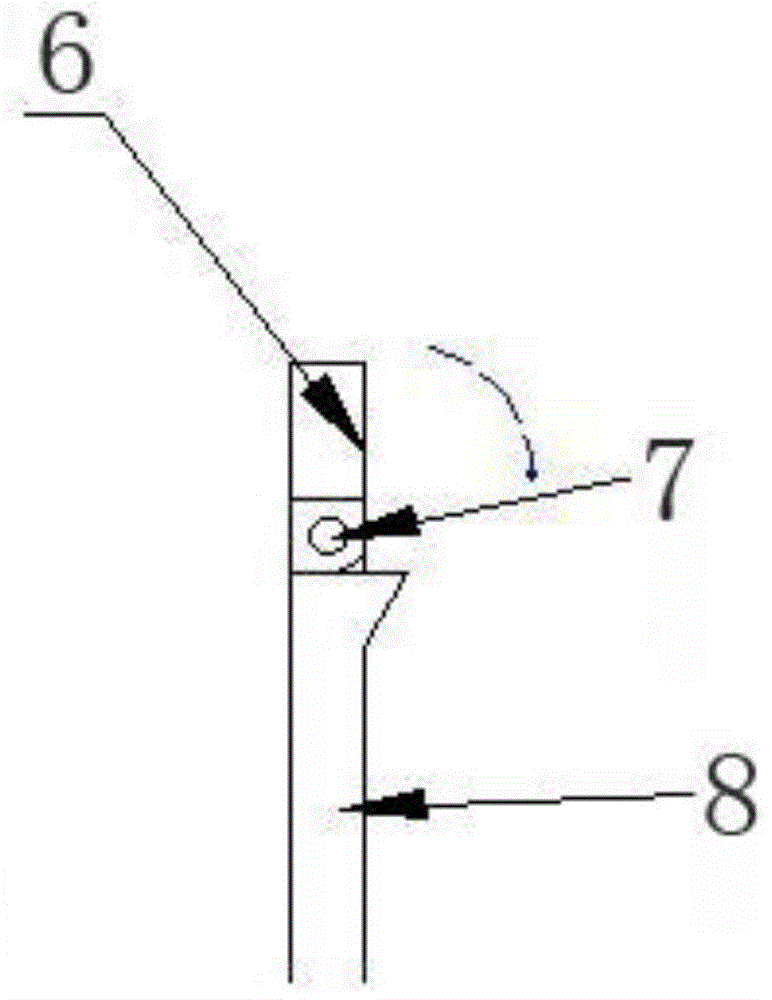

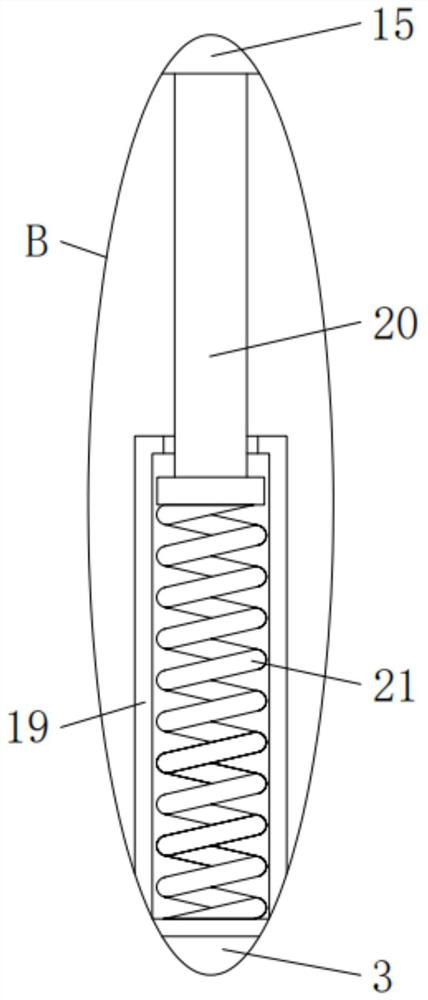

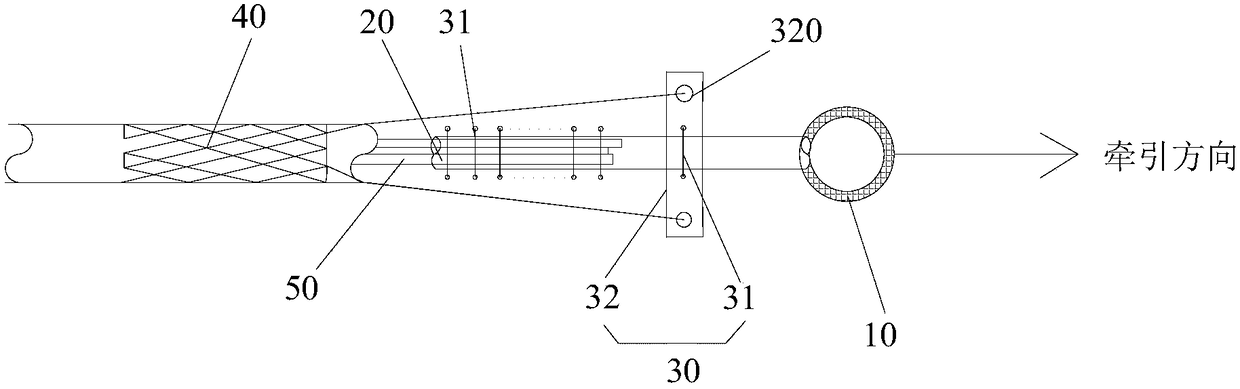

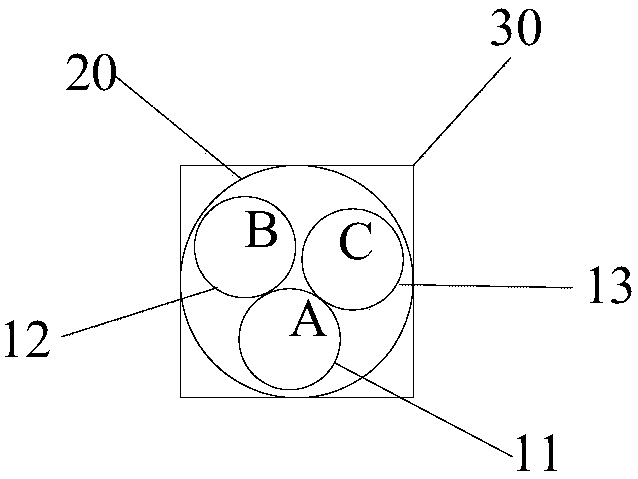

Cable traction assembly and method of preventing cable stretching

ActiveCN105914662AAvoid safety hazardsAvoid stretchingApparatus for joining/termination cablesApparatus for laying cablesMechanical engineeringTractive effort

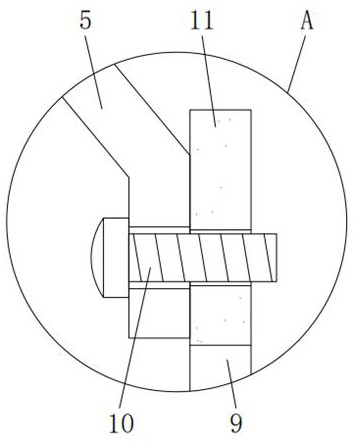

The invention provides a cable traction assembly and a method of preventing cable stretching. The cable traction assembly comprises a traction part; and a pipe body part, wherein one end of the pipe body part is in connection with the traction part, and the other end of the pipe body part is arranged on a wire part to prevent the wire part from being stretched in a laying process, thereby solving the problem that in the prior art, cables are easy to stretch in a laying process. The pipe body part is arranged on the wire part, allowing the pipe body and the wire part to be meanwhile under the tractive effort in the traction process of the wire part; according to the pipe body part, the wire part provided with the pipe body part and a cable over sheath are meanwhile dragged, thereby reducing expansion or displacement between the wire part and the cable over sheath, guaranteeing lead integrity, and effectively avoiding potential safety hazards caused by stretching cables in a laying process.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

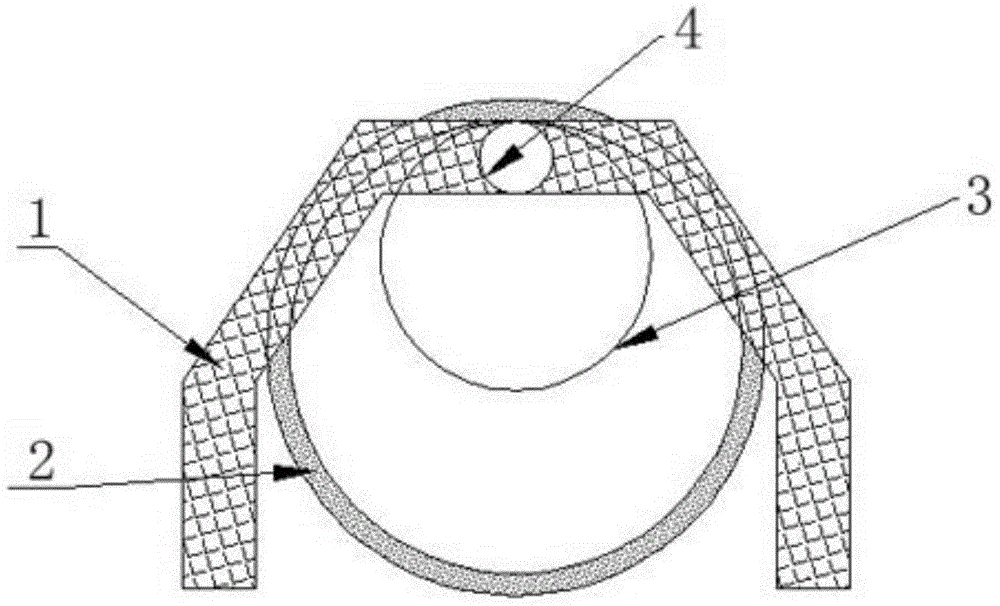

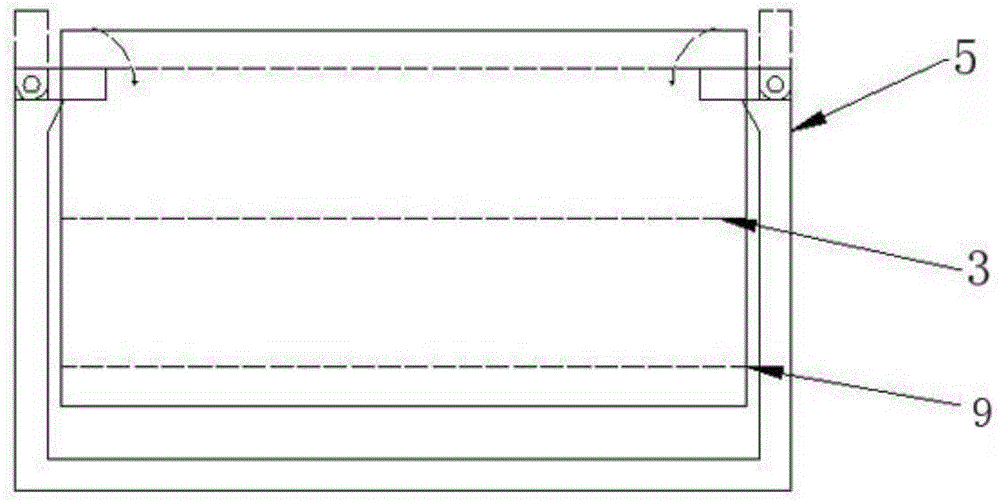

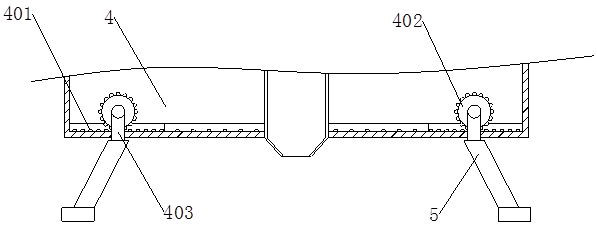

Novel suspended roller forming reinforced concrete drainage pipe maintenance structure and maintenance method thereof

ActiveCN104924448AReduce slumpIncrease the compression areaCeramic shaping apparatusReinforced concreteRebar

The invention discloses a novel suspended roller forming reinforced concrete drainage pipe maintenance structure and a maintenance method thereof. The maintenance structure comprises a reinforced concrete drainage pipe steel mold, a steel cylinder and a movable support used for static stop after a suspended roller is formed, wherein the steel cylinder is arranged in the reinforced concrete drainage pipe steel mold, and the two ends of the steel cylinder stretch out. The maintenance method includes the steps that firstly, before the suspended roller is formed, a suspended roller shaft is sleeved with the steel cylinder, and the steel cylinder replaces the suspended roller shaft to roll the inner wall of the reinforced concrete drainage pipe steel mold; secondly, after a pipe body is formed, the static stop process is omitted, the reinforced concrete drainage pipe steel mold and the steel cylinder are directly lifted off a suspended roller machine, the steel cylinder serves as the support to be hung for maintenance, and the steel cylinder is suspended on the movable support. The concrete slump value is effectively reduced, the suspended roller can be immediately away from the suspended roller shaft after being formed, static stop is not needed, the displacement phenomenon caused by the gravity effect of top end concrete before the top end concrete is in a condensation state can be effectively reduced, and production quality is guaranteed while production efficiency is improved.

Owner:SICHUAN CHINA STRUCTURE RESIDENTIAL IND

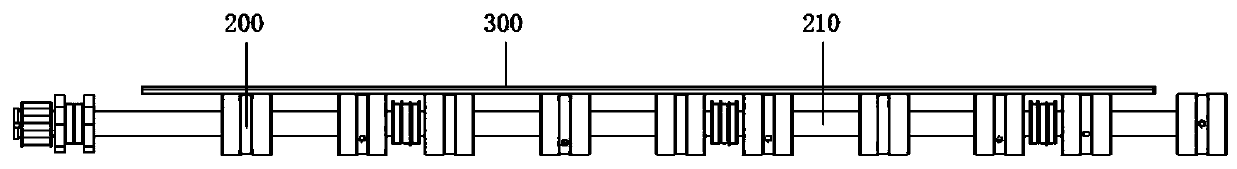

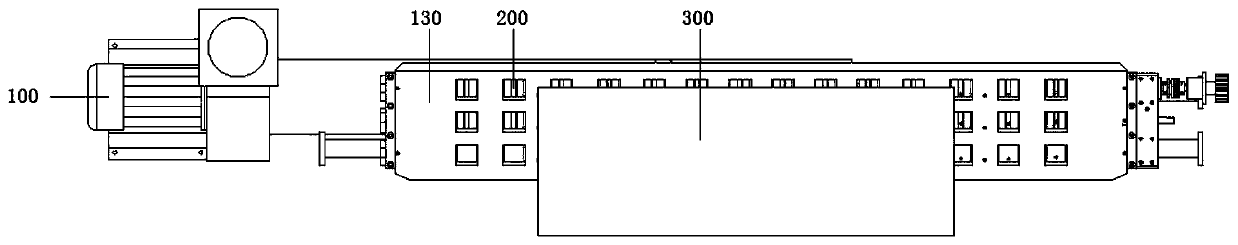

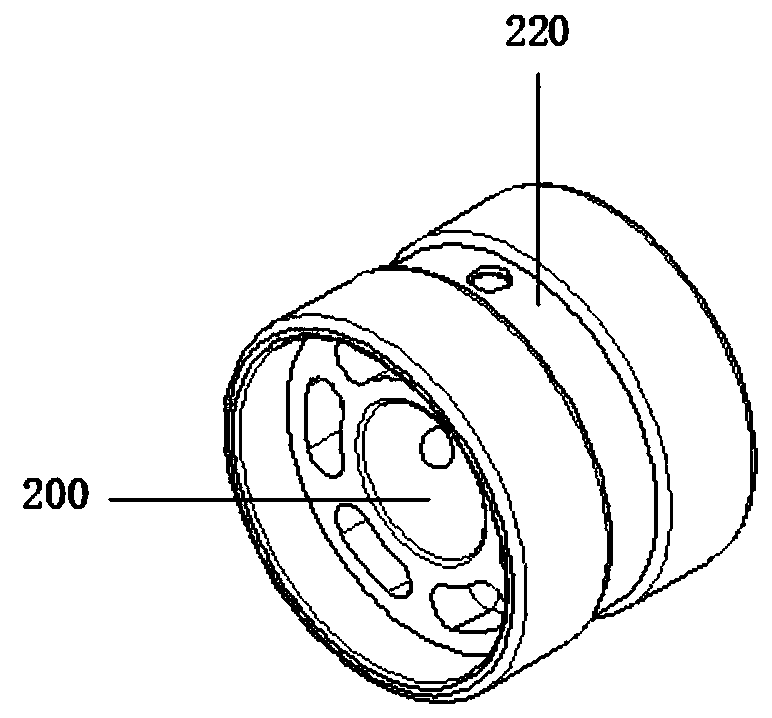

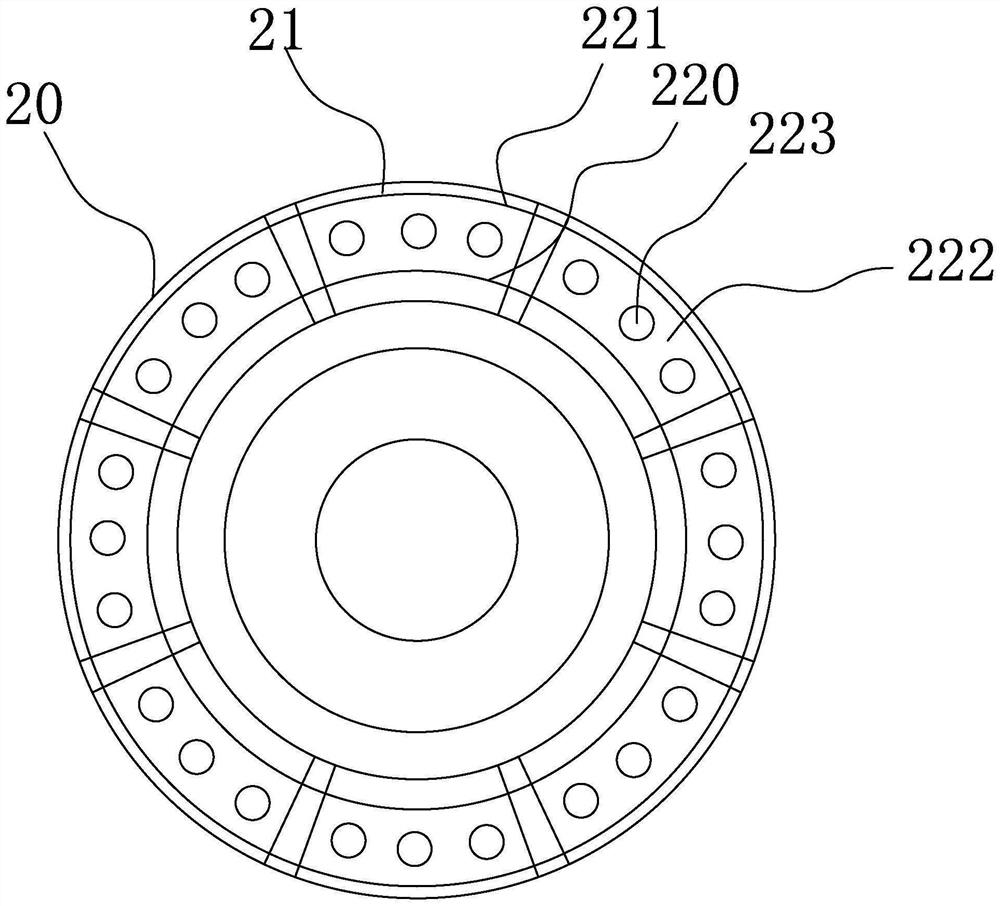

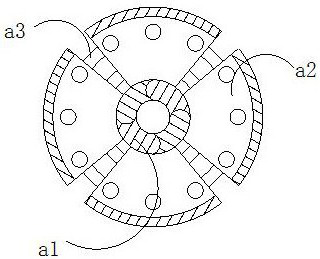

Ceramic wheel for printing

PendingCN110356098AIncrease frictionReduce displacement phenomenonPlate printingRotary pressesPaperboardEngineering

The invention belongs to the technical field of printing equipment, and particularly relates to a ceramic wheel for printing. The ceramic wheel for printing comprises a fan and a printing ceramic wheel body, wherein an air outlet of the fan is connected with an air pipe; the end part of the air pipe is connected with a distribution air pipe; the top of the distribution air pipe is provided with anegative pressure air box; the printing ceramic wheel body is arranged on the negative pressure air box; the printing ceramic wheel body comprises a connecting shaft rod and an air suction groove; andthe connecting shaft rod penetrates through the negative pressure air box. According to the ceramic wheel for printing, the friction force between the printing ceramic wheel body and a production paperboard is enhanced through the grinding structure of the surface of the printing ceramic wheel body; meanwhile, the air pressure is generated through the work of the fan, and the air pressure is increased to the maximum through the matching of the air pipe, a connecting pipe and a ventilation pipe; and the air suction groove arranged on the printing ceramic wheel is matched with the negative pressure generated by the negative pressure air box, so that the adsorption force and the transmission friction force between the printing ceramic wheel body and the paperboard are increased, the frequency that the paperboard is displaced in the transmission process is reduced, the printing quality is guaranteed, and the practicability of the ceramic wheel for printing is increased.

Owner:广东拓品智能机械科技有限公司

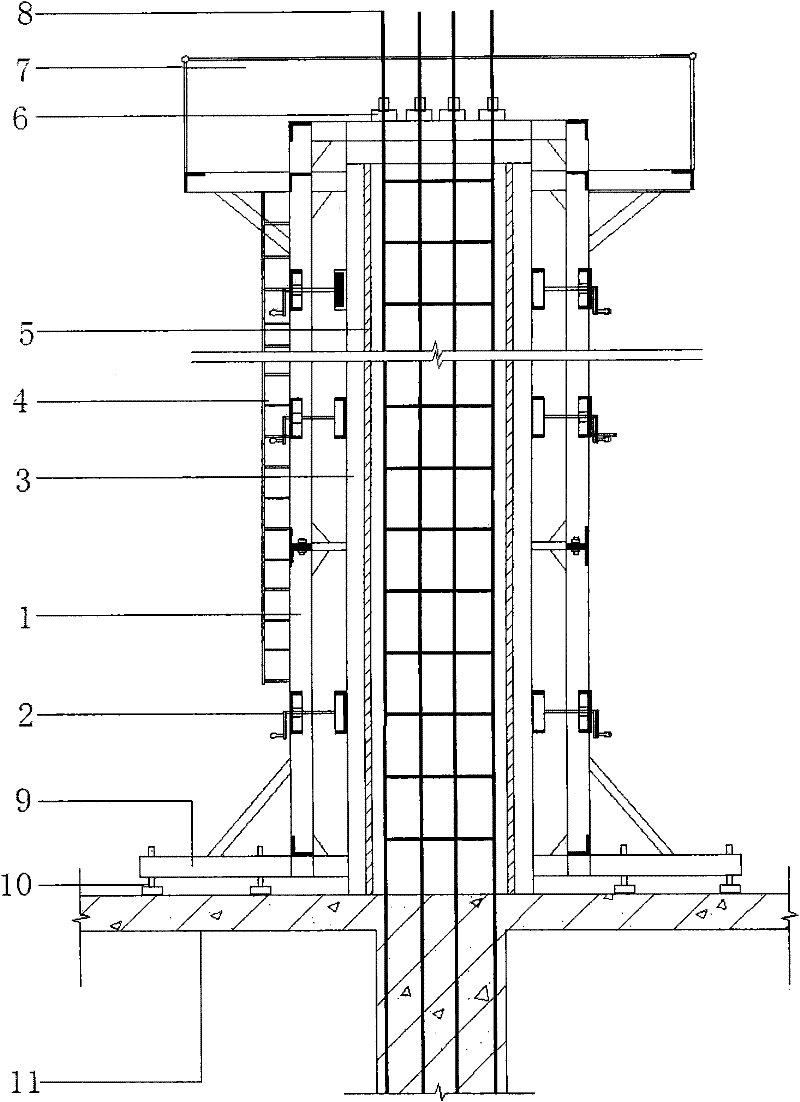

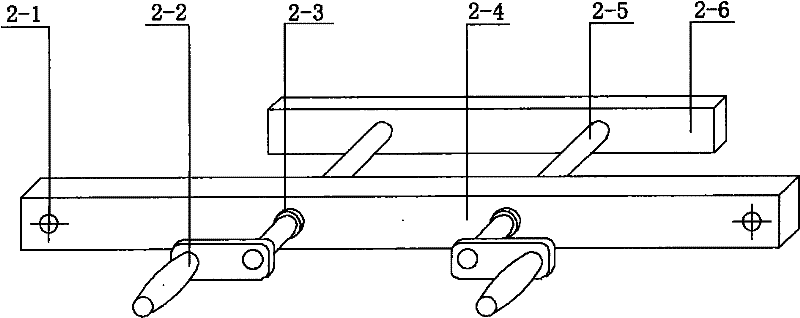

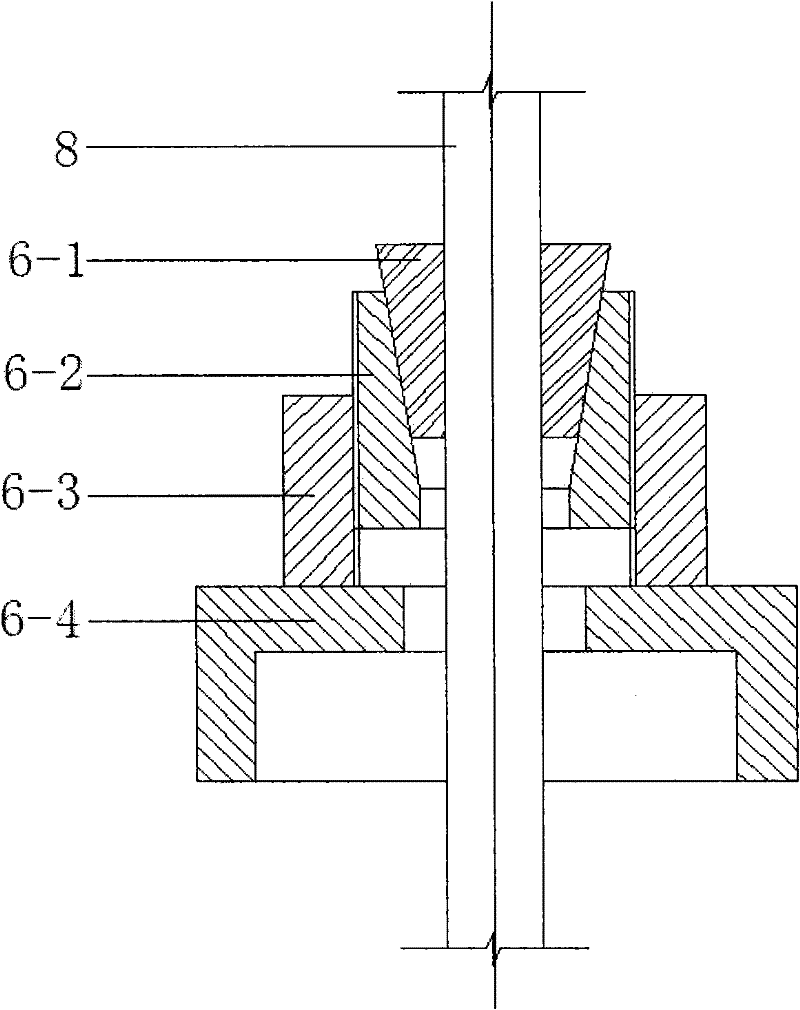

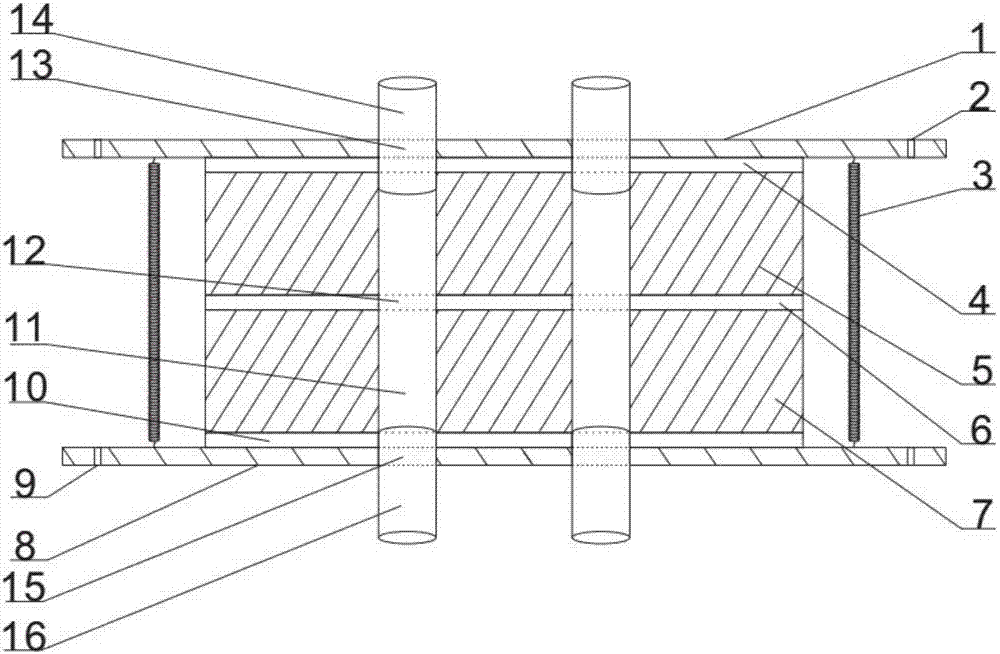

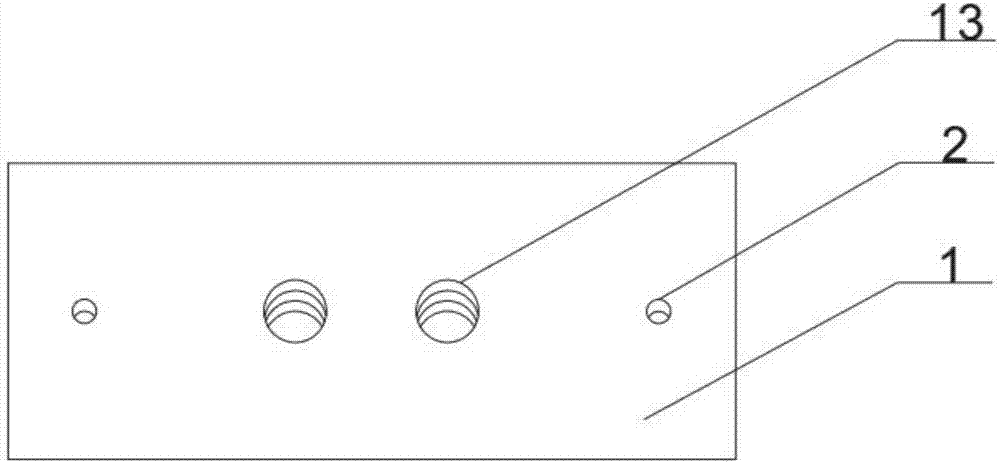

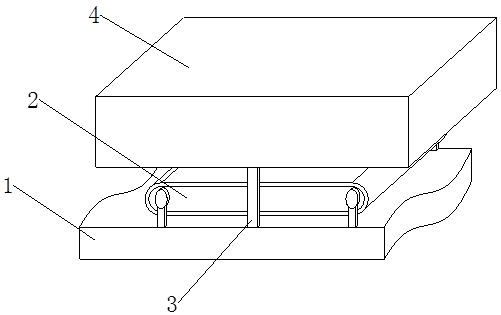

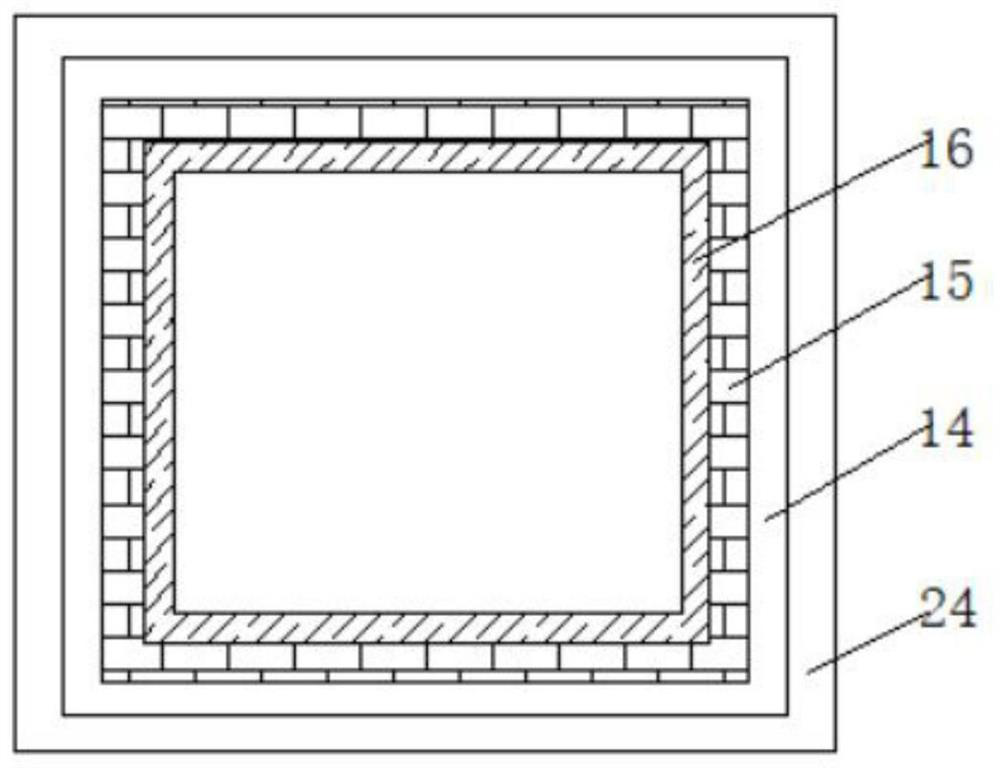

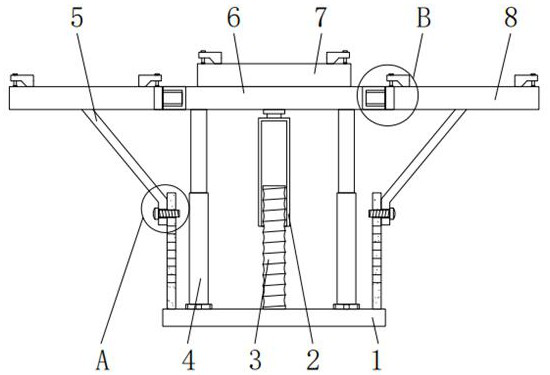

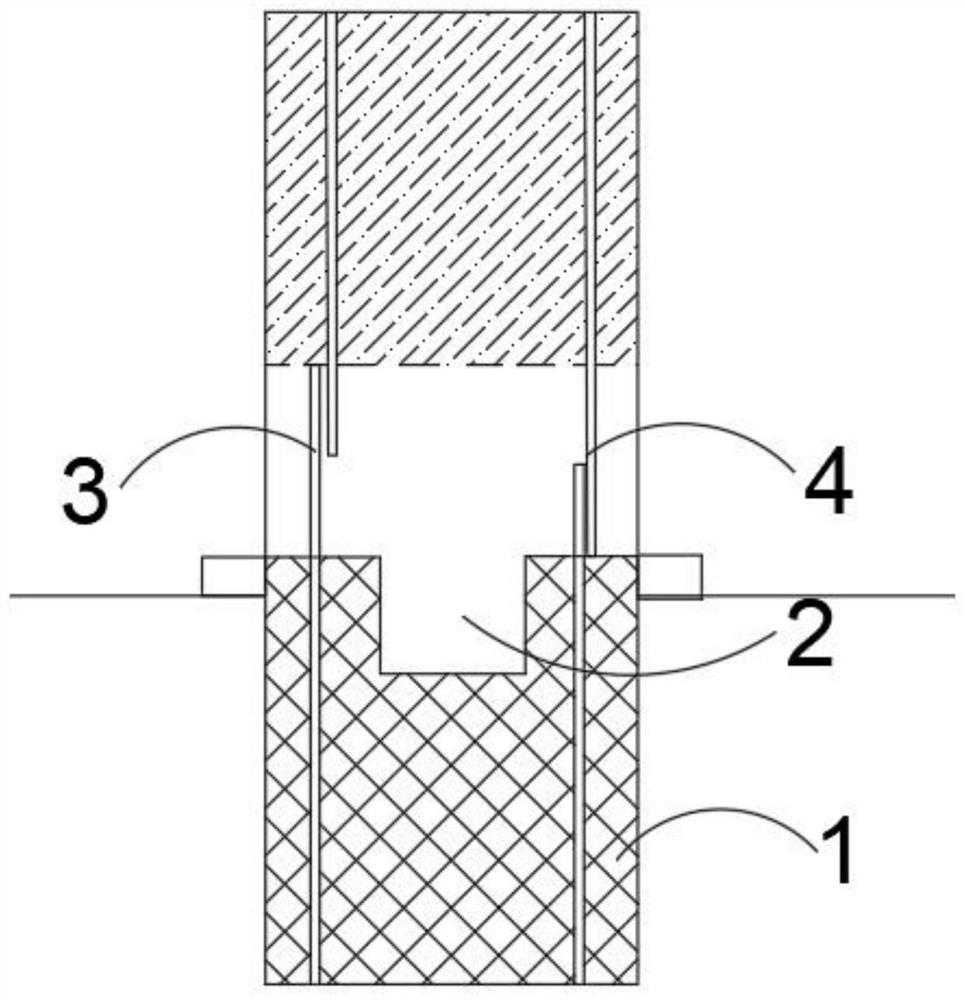

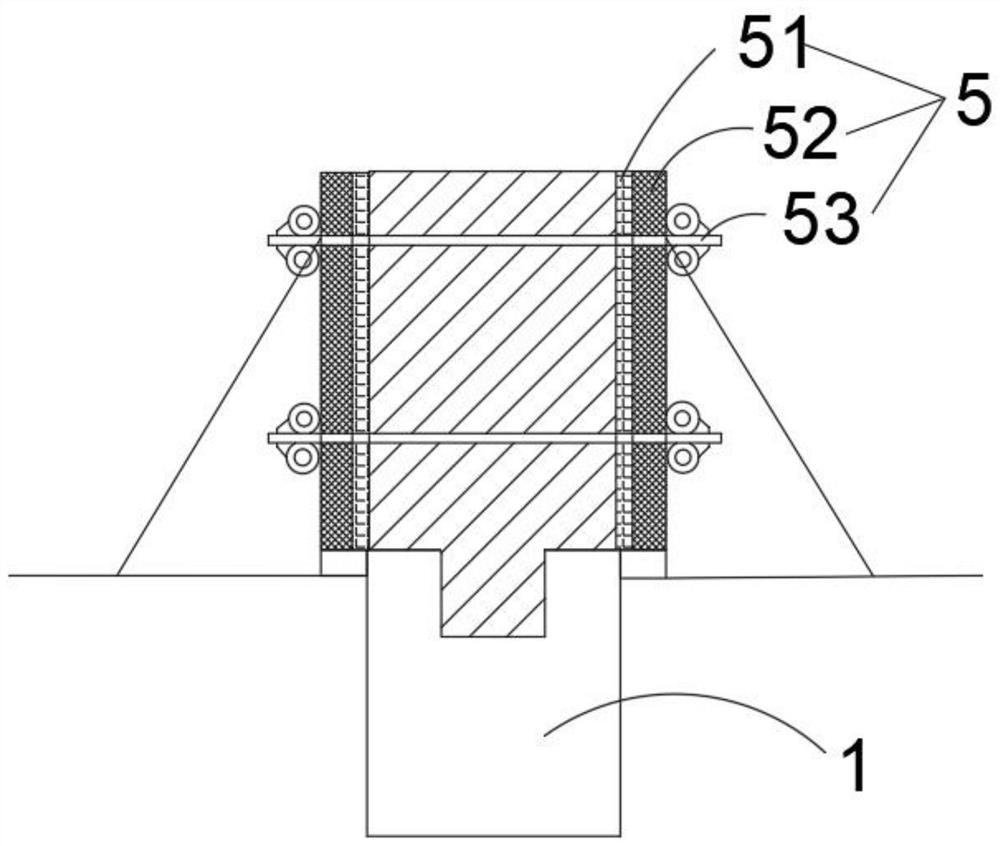

Fixing device for template of cast-in-place reinforced concrete column

InactiveCN102127966BReduce displacement phenomenonSimple structureForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksReinforced concrete columnArchitectural engineering

The invention discloses a fixing device for a template of a cast-in-place reinforced concrete column. The fixing device consists of a template fixing external frame, a template compacting device and a column angle steel bar self-anchoring device, wherein the template fixing external frame is welded by a profile steel, the height of the template fixing external frame is higher than the casting height of the column, the template fixing external frame can be manufactured in a segmenting way, the template fixing external frame is connected with a plurality of screw bolts to be heightened, the bottom external frame is provided with a widened base, the base is provided with a leveling device, the middle external frame is provided with a crawling ladder, and the upper external frame is provided with an operating platform; the template compacting device comprises a horizontal crossbeam and a wood beam press board rod, a compacting screw rod is connected with a wood beam press board rod by a compacting screw nut arranged on the surface of the horizontal crossbeam, one end of the compacting screw rod is provided with a compacting crank, and the two transverse ends of the horizontal crossbeam is respectively provided with a fixed screw bolt; and the column angle steel bar self-anchoring device consists of a jacking crossbeam, a jacking screw nut, a jacking sleeve and a fastening clampingpiece. The device is simple in structure and convenient to operate, so that the movement of the template during casting can be effectively reduced, and the happening of the engineering quality accidents can be reduced.

Owner:SUQIAN HUAXIA CONSTR GROUP ENG +1

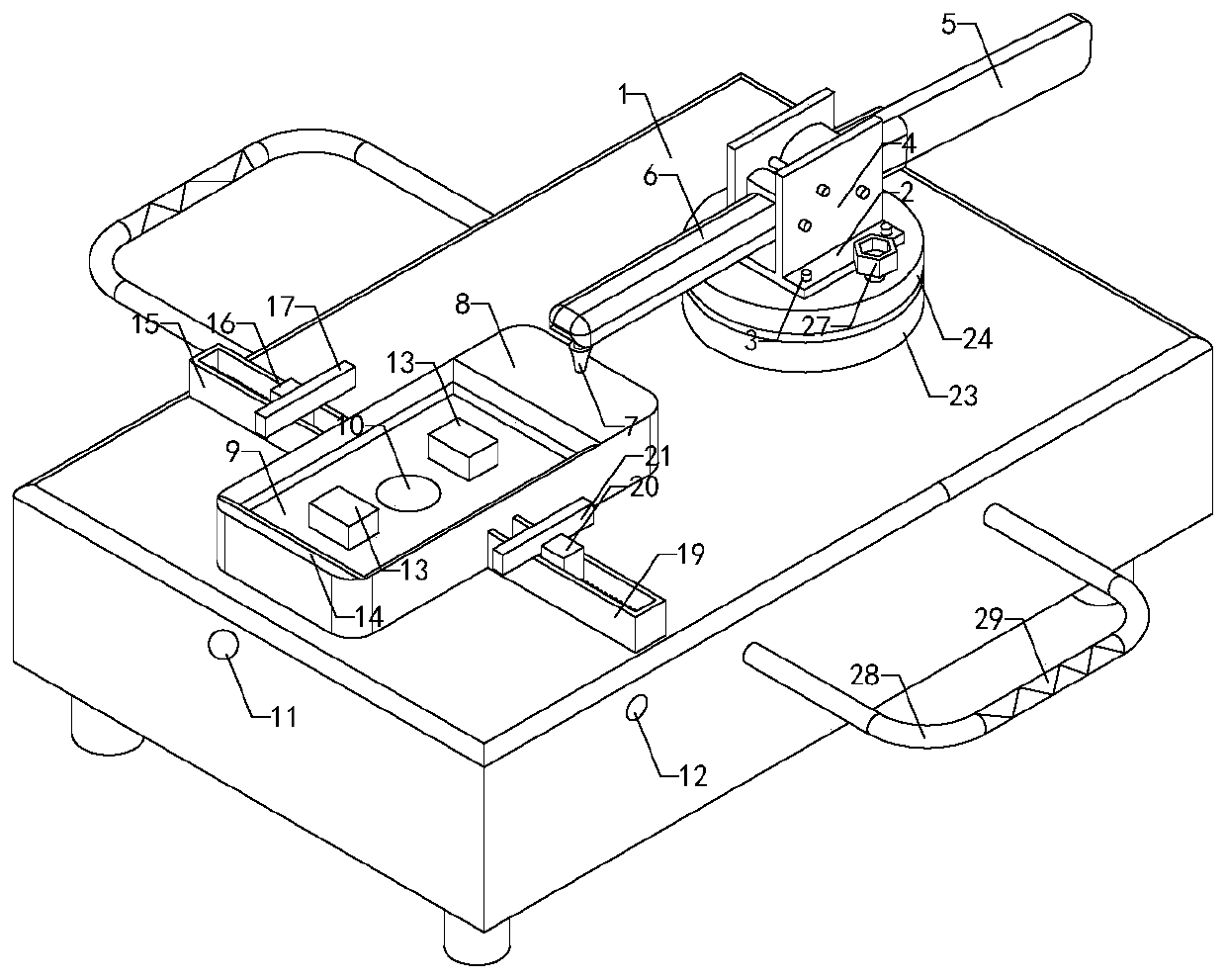

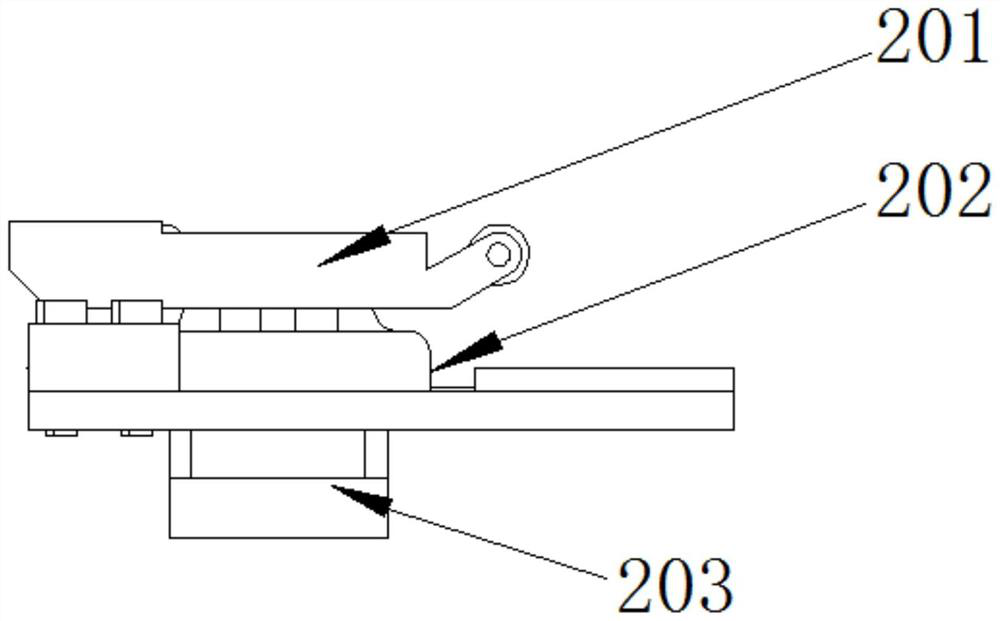

Fixing clamp for touch screen processing

InactiveCN110625539AReduce displacement phenomenonImprove the stability of useWork holdersEngineeringHinge point

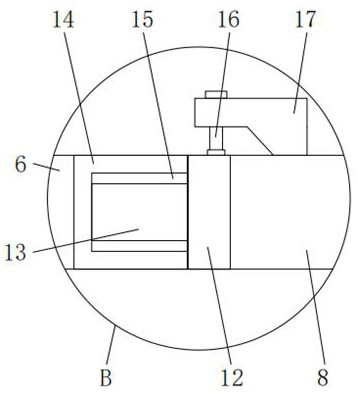

The invention relates to the technical field of electronic processing equipment, in particular to a fixing clamp for touch screen processing. The fixing clamp firmly adsorbs a workpiece, reduces the displacement phenomenon of the workpiece and improves the use stability. Firstly, the upper end of a workbench is wiped, the workpiece is placed at the upper end of the workbench, a pressing handle ispressed, the pressing handle drives a pressing rod to press down through a hinged point until a dead point clamping device is pressed to a dead point position, and the workpiece is pressed by the pressing rod through a rubber pressing head. The fixing clamp further comprises a vacuum workbench, a vacuum adsorption groove, a vacuum adsorption hole, an air exhaust hole, a rubber cushion block and asealing ring, the vacuum workbench is arranged in the middle of the upper end of the workbench, the upper end of the vacuum workbench is provided with the vacuum adsorption groove, the center of the upper end of the vacuum adsorption groove is provided with the vacuum adsorption hole, the upper end of the vacuum adsorption groove is provided with the rubber cushion block, the sealing ring is installed on the edge of the vacuum adsorption groove, the front end of the workbench is provided with the air exhaust hole, and the air exhaust hole communicates with the vacuum adsorption hole.

Owner:JIANGSU DIJIA ELECTRONICS CO LTD

Production process of PTFE aramid fiber composite high-temperature-resistant needled filter bag

PendingCN114290788AImprove high temperature resistanceHigh filtration precisionLamination ancillary operationsControlling laminationComplex filterAramid

The invention discloses a production process of a PTFE aramid fiber composite high-temperature-resistant needled filter bag, and aims to provide a production process of a needled filter bag with a formed filter material being good in high-temperature-resistant effect, strong in integrity and good in filtering effect, the key points of the technical scheme are as follows: PTFE short fibers and aramid fibers are selected, the mixing ratio of the PTFE short fibers to the aramid fibers is 50: 50, and the PTFE short fibers and the aramid fibers are mixed uniformly; the PTFE short fibers and the aramid fibers are uniformly mixed, the PTFE filament base cloth is selected as the reinforcing base cloth as a main material, and the PTFE short fibers and the aramid fibers are mixed, so that the characteristics of the PTFE short fibers and the aramid fibers are exerted, the overall high temperature resistance of the needled filter bag is improved, the filter precision is high, and the needled filter bag adapts to complex filter working conditions; the invention is suitable for the technical field of filter bag production.

Owner:ZHEJIANG HEADING ENVIRNMENT TECH CO LTD

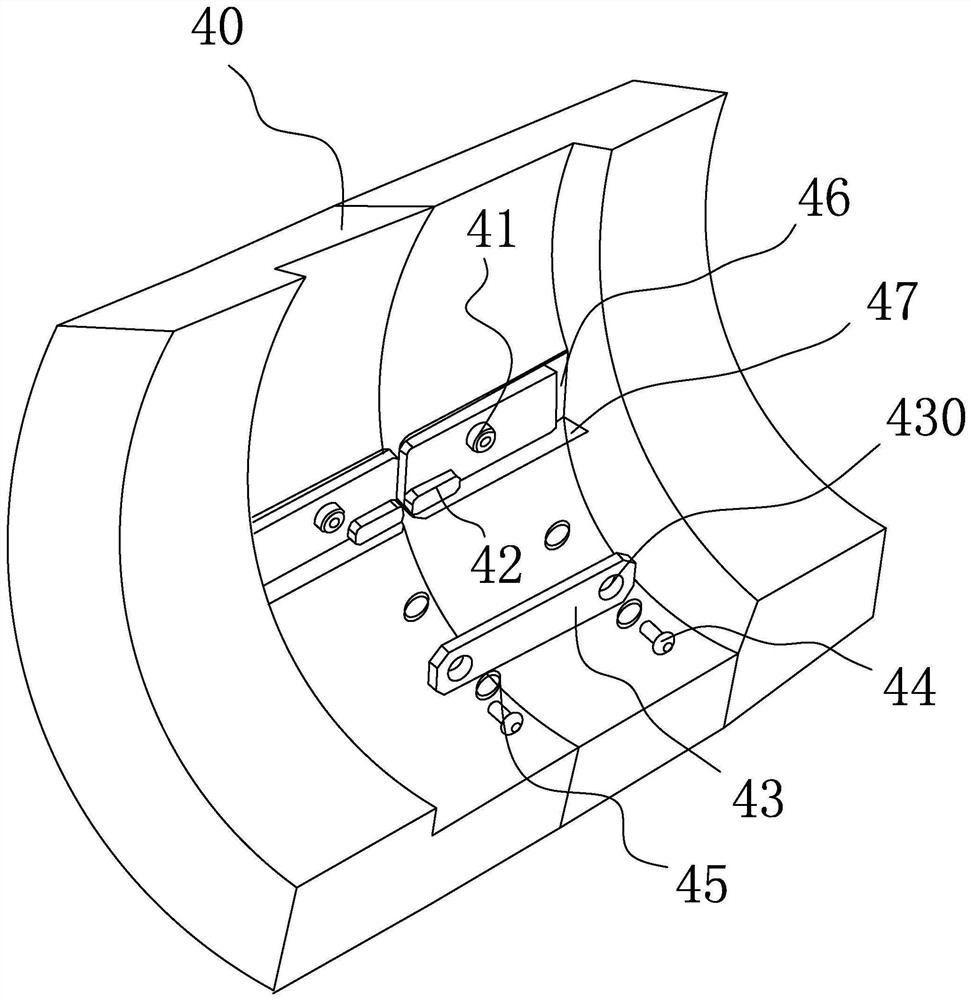

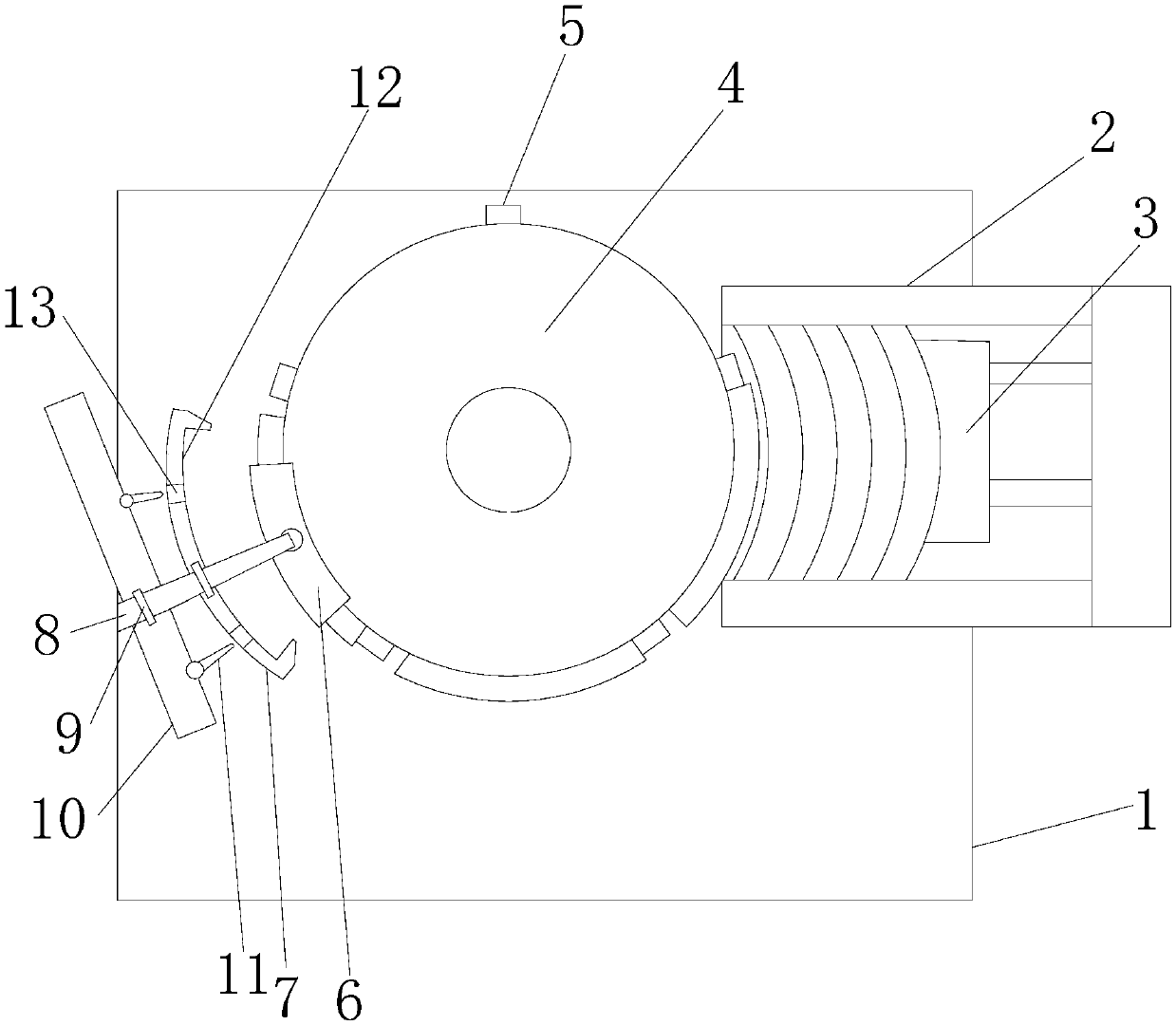

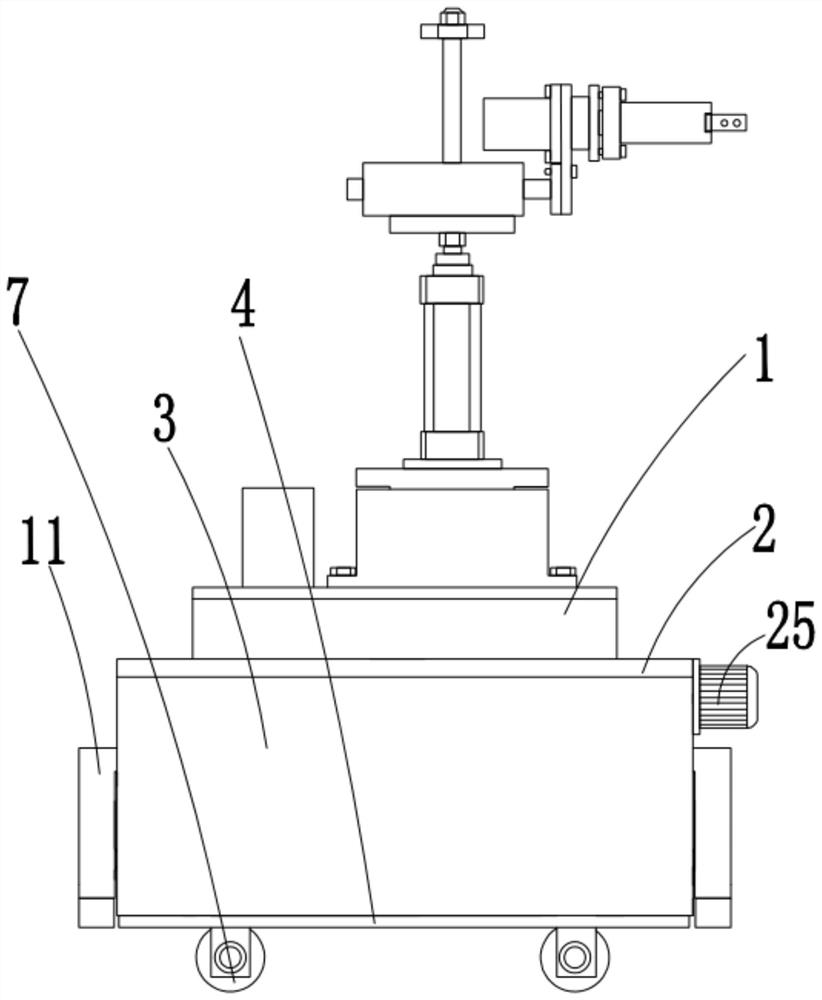

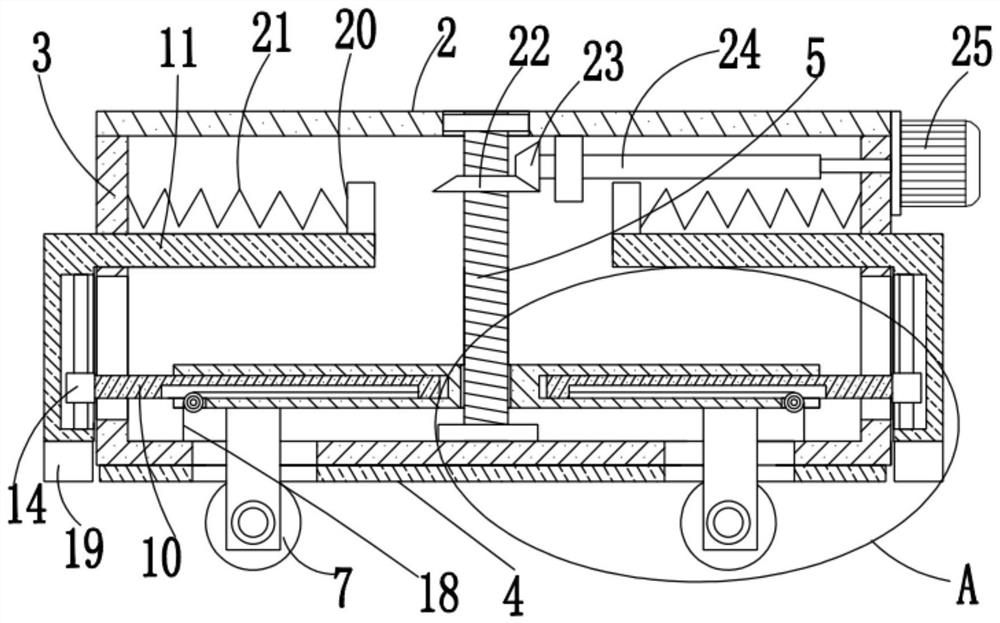

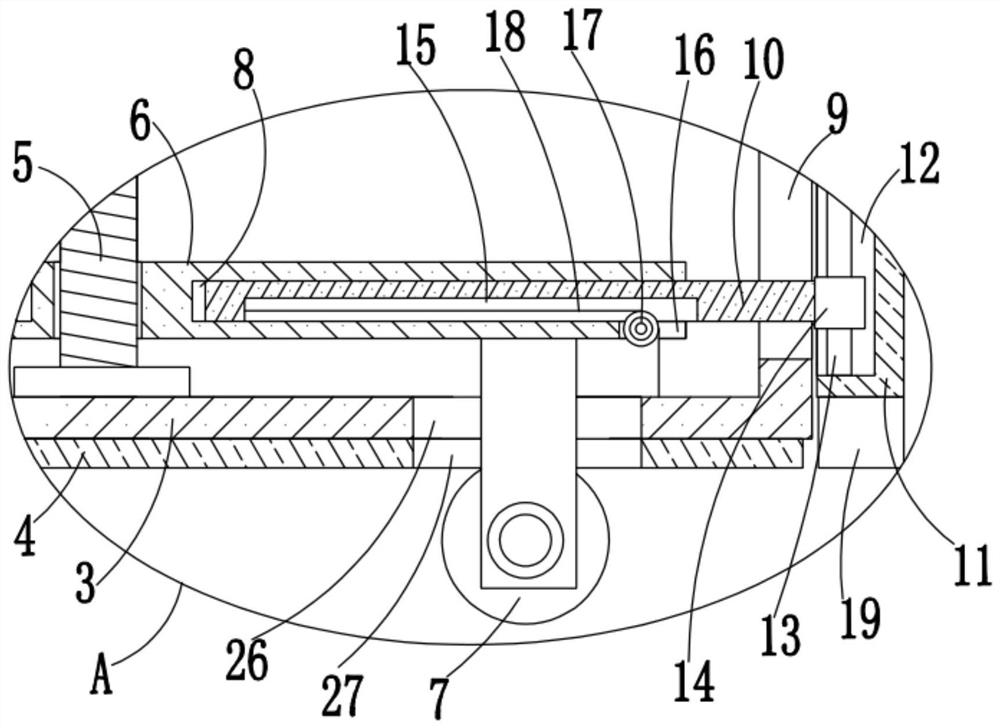

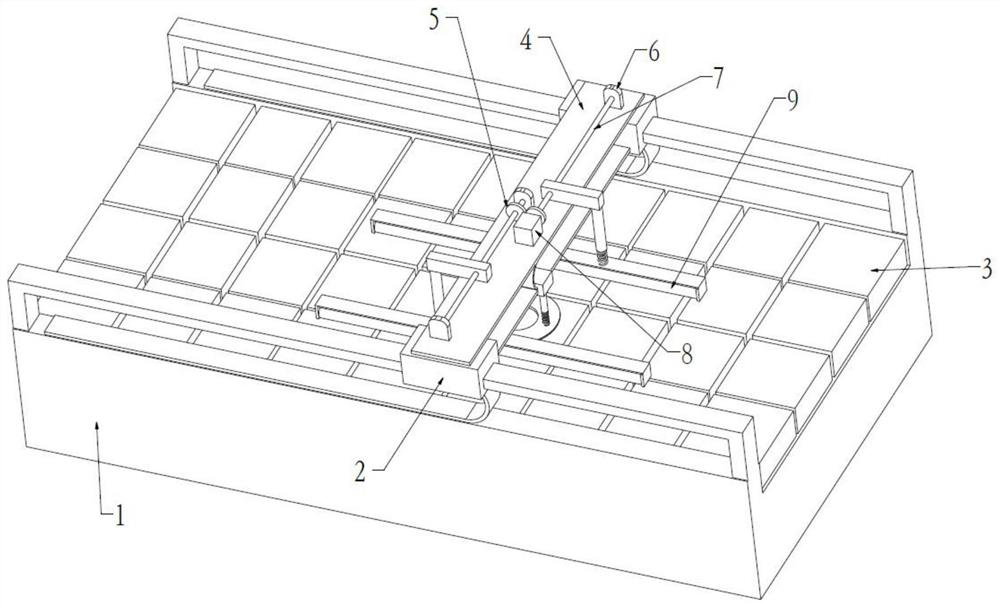

Brake pad drilling mold

InactiveCN107838480APrecise positioning and fixingReduce displacement phenomenonMetal working apparatusDrill jigsPunchingEngineering

The invention discloses a brake pad drilling mold, which comprises a base, a feeding trough, a pusher, a feeding turntable, a pushing protrusion, a pressing block, a limit card slot, a guide rail, an electric slider, a movable base plate, and a drilling hole. motor. The invention enables precise positioning and fixing of the brake pad during drilling, effectively reduces the displacement of the brake pad during the drilling process, improves the drilling precision, and facilitates the subsequent installation and use of the brake pad.

Owner:杨利人

Production and maintenance method for prestressed spun concrete square pile

InactiveCN104552597AReduce desolderingReduce displacement phenomenonCeramic shaping apparatusBasementPre stress

The invention discloses a production and maintenance method for a prestressed spun concrete square pile. The production and maintenance method comprises the following steps: producing a reinforced cage; mounting the reinforced cage and performing mechanical material distribution; performing die assembly to realize the great improvement of concrete compaction and finally form a spun square pile; carrying out steam maintenance; pretreating raw materials in a centrifugal die, wherein the pretreatment step consists of a raw material pre-mixing pretreatment and raw material post-mixing pretreatment. According to the production and maintenance method for prestressed spun concrete square pile, the antiseptic performance of the spun square pile can be enhanced, so that the production and maintenance method is worthy of popularization and use in malloseismic regions and building foundations of highrise buildings and large-area basements.

Owner:NANTONG ZHONGJI PILE

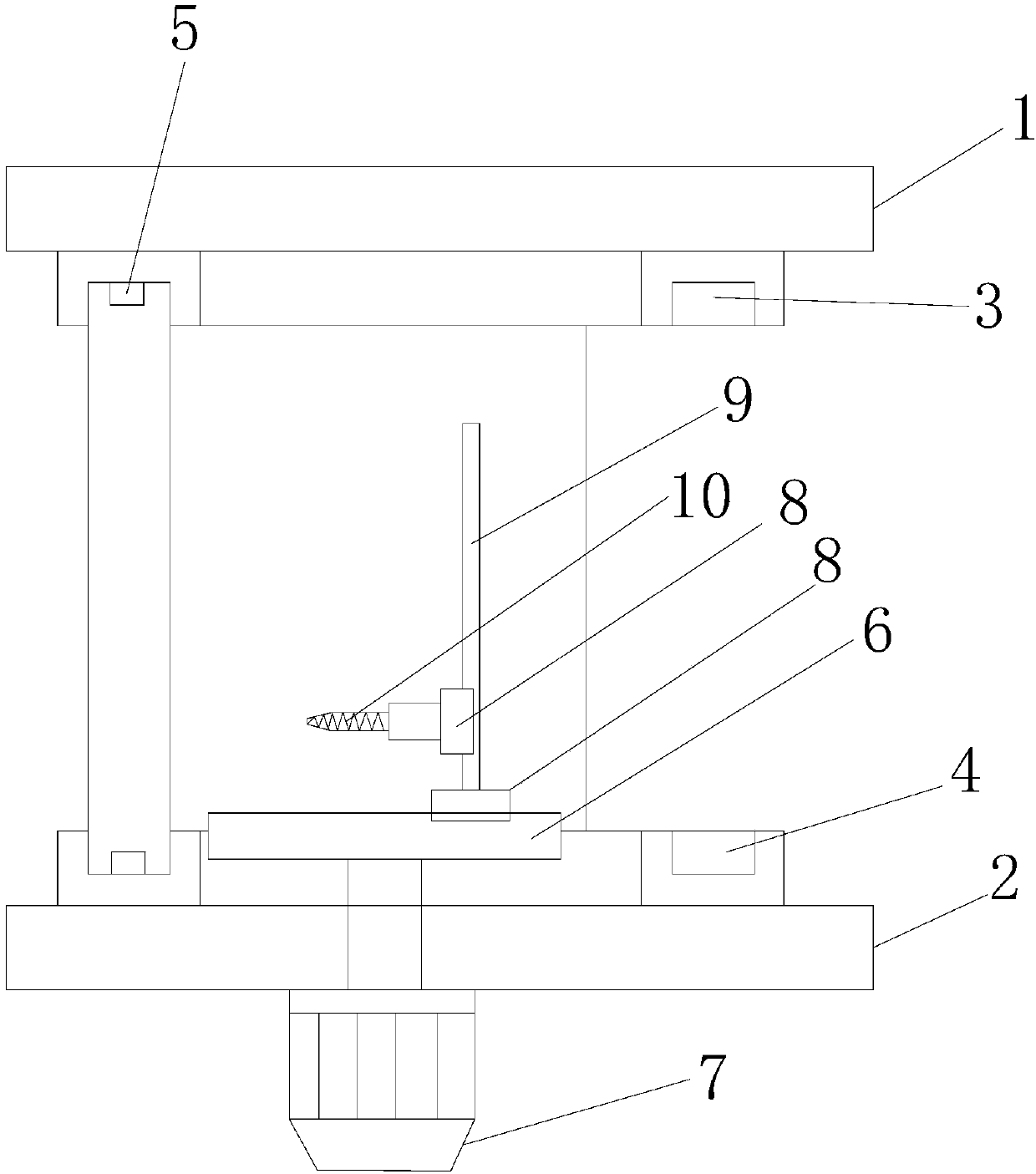

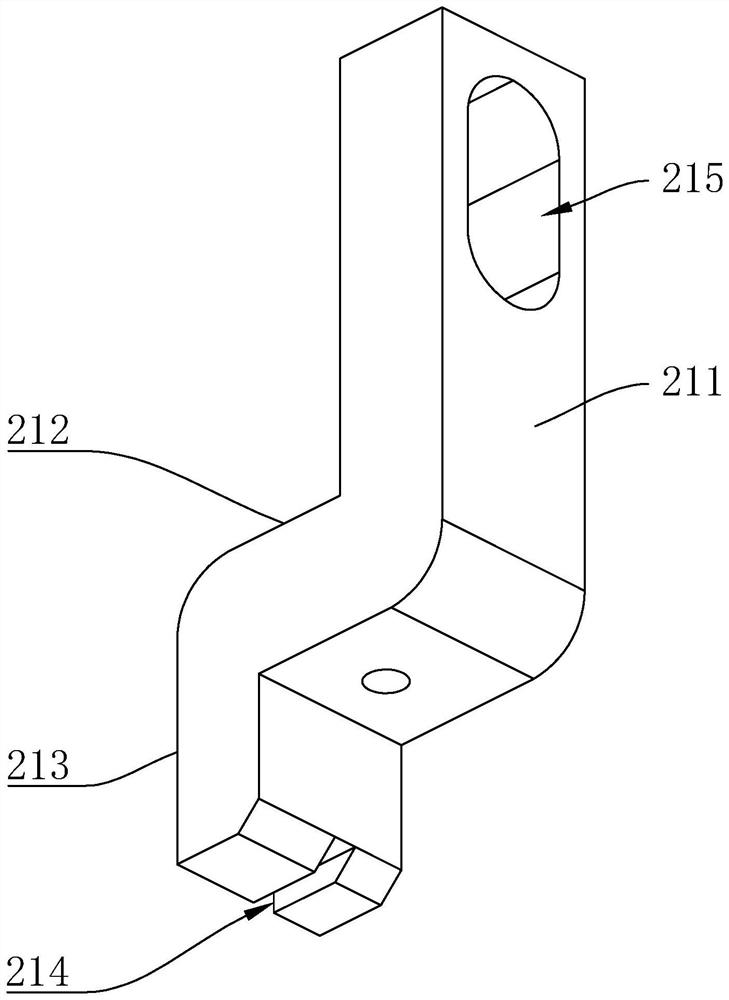

Workpiece fixture

InactiveCN103958099BAvoid damageReduce displacement phenomenonChucksPositioning apparatusEngineeringMachining

The invention relates to a workpiece fixing device. Specifically, by improving the position fixing structure of the workpiece, it can not only prevent the damage of the workpiece during the position fixing process, but also accurately maintain the gap between the processing point of the workpiece and the processing tool. The concentric line of the machine can prevent poor processing and realize rapid and reliable position setting of the workpiece.

Owner:辛光子

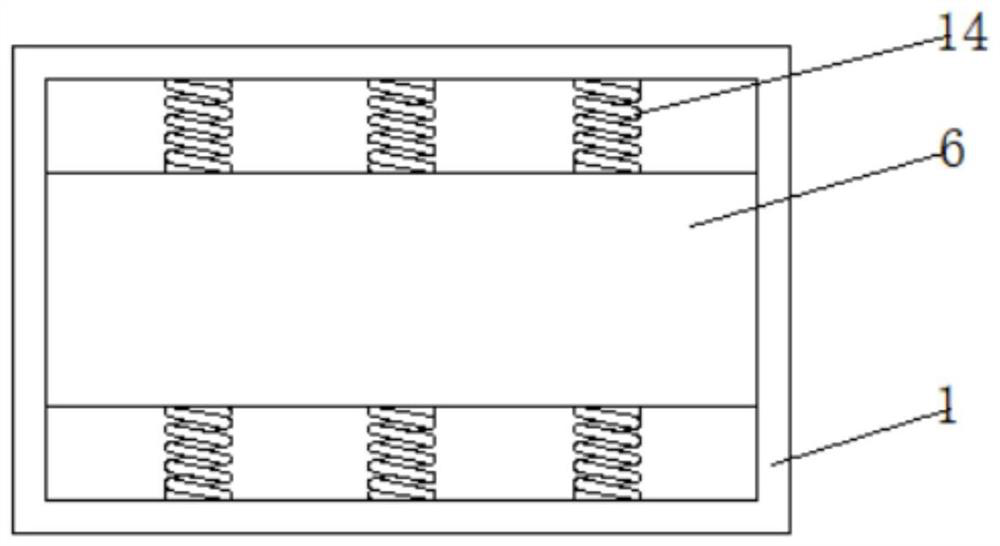

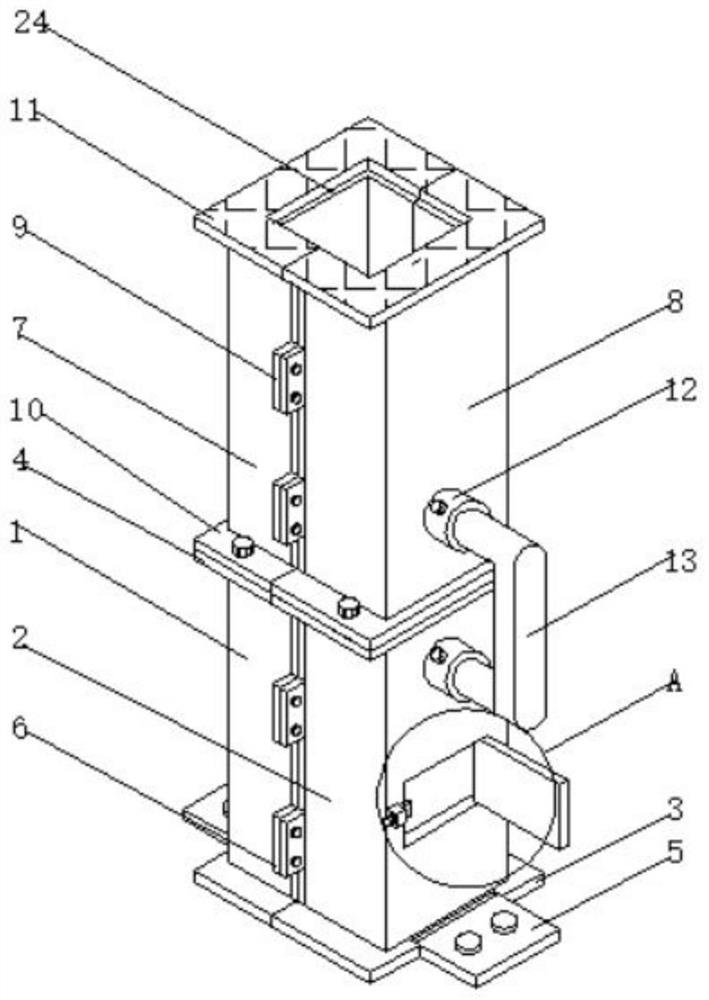

Elevator damping device

InactiveCN107140507AImprove buffering effectImprove shock absorptionHigh internal friction springsBuilding liftsEngineeringMechanical engineering

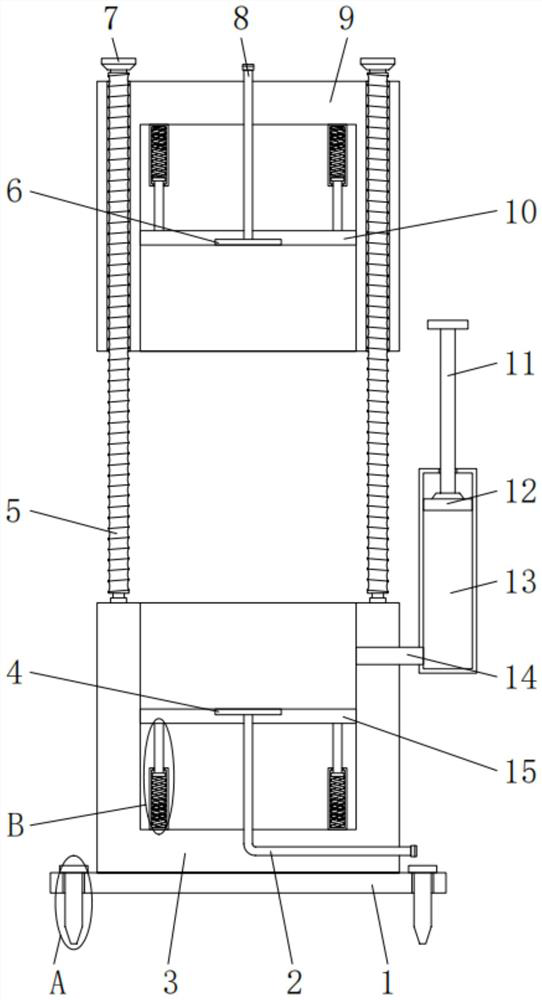

The invention provides an elevator damping device which comprises base plates and rubber bodies. The base plates comprise the upper base plate and the lower base plate. The rubber bodies comprise the first rubber body and the second rubber body. A first bonding layer and a second bonding layer are arranged between the rubber bodies and the base plates. A second bonding layer is arranged between the first rubber body and the second rubber body. The first rubber body and the second rubber body are provided with through holes in the longitudinal direction correspondingly. The through hole in the first rubber body communicates with the through hole in the second rubber body. The first bonding layer, the second bonding layer and the third bonding layer are provided with bonding layer through holes correspondingly. The upper base plate and the lower base plate are arranged in an up-down symmetrical mode. The two ends of the upper base plate and the two ends of the lower base plate are provided with penetrating holes correspondingly. A spring is arranged between the upper base plate and the lower base plate. The upper base plate is provided with an upper base plate through hole. The lower base plate is provided with a lower base plate through hole. An upper double-screw bolt is arranged in the upper base plate through hole, and a lower double-screw bolt is arranged in the lower base plate through hole. The elevator damping device has the advantages of being good in damping effect, good in limiting function, good in firmness performance, resistant to abrasion, long in service life and the like.

Owner:NANTONG XING HUA DA GAO IND CO LTD

Brake pad fixing inner drilling die

InactiveCN107824839AReduce brake pad displacementImprove drilling accuracyWork benchesPortable drilling machinesPuncturingEngineering

The invention discloses a fixed internal drilling mold for a brake pad, which comprises an upper fixed mold, a lower fixed mold, an upper fixed guide groove, a lower fixed guide groove, a limit bump, a horizontal guide rail, a rotating motor, an electric slider, a vertical Guide rail, electric drill. The invention enables the brake pads to be drilled under the condition that the brake pads are firmly fixed, reduces the displacement of the brake pads during the drilling process, improves the drilling precision, and facilitates the subsequent installation and use of the brake pads.

Owner:杨利人

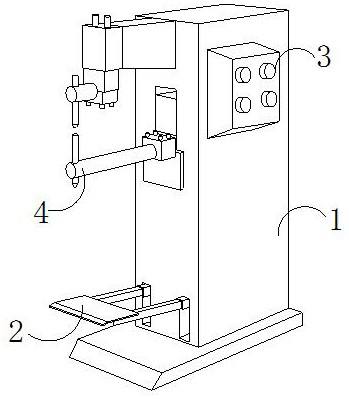

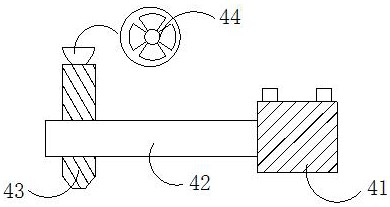

5G communication signal sensor machining equipment

InactiveCN112427789AIncrease the support areaReduce displacement phenomenonWelding/soldering/cutting articlesMetal working apparatusEngineeringMachine

The invention discloses a 5G communication signal sensor machining equipment which structurally comprises a machine body, a pedal, a controller and a spot welding device, the pedal is installed at thebottom of the front face of the machine body, the controller is vertically installed on the middle upper portion of the right side of the machine body, the spot welding device is installed on the middle upper portion of the front face of the machine body, and when the gravity at the two ends of a component is different, the position of the component is inclined, a supporting mechanism is movablymatched with the component, so that the supporting area of the component is increased, the component is limited, the displacement phenomenon of the component in the spot welding process is reduced, spot welding connection of the component of the sensor is facilitated, and when exhaust holes are in an unblocked state, external airflow easily flows back into a deformation plate, stop blocks in the exhaust holes move along with flowing of the airflow, the stop blocks are clamped in the exhaust holes, airflow blocking at the bottom of a bottom plate is facilitated, proper gas density in the deformation plate can be maintained, and the component can be tightly sucked to the top of a pressing plate.

Owner:广州比美强机械技术开发有限公司

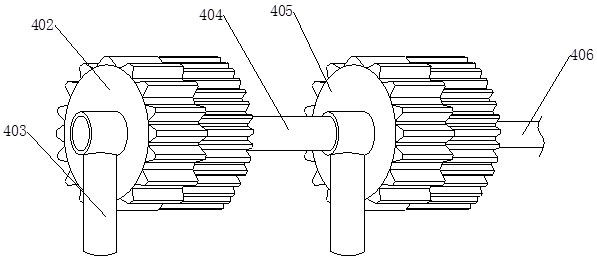

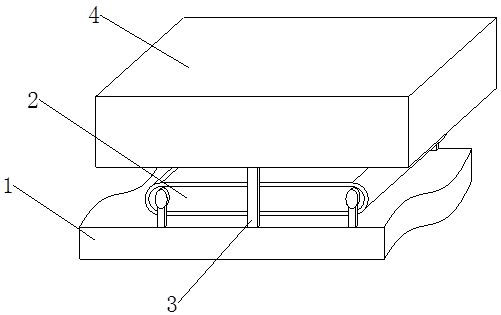

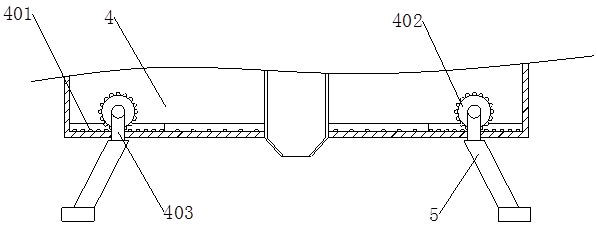

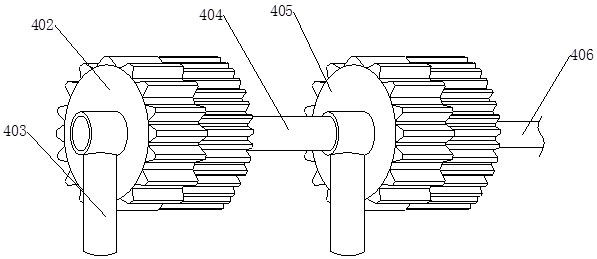

Coating equipment applied to high-performance electricity-resistant coating of metal product

ActiveCN113275160AEasy to processIncrease horizontal distanceSpraying apparatusElectric machineGear wheel

The invention provides coating equipment applied to high-performance electricity-resistant coating of a metal product. The coating equipment comprises a base, a conveying belt and a supporting column. Fixing plates, a driven gear and a driving gear are installed, the two fixing plates form a splayed shape, when the metal product is machined, one motor rotates clockwise, the other motor rotates anticlockwise, the driven gear and the driving gear on the two sides are driven to move along a first sliding rail to a third sliding rail, when the driven gear and the driving gear rotate, the ends, away from a fixing rod, of connecting rods are perpendicular to the ground through a bearing under the gravity action of the connecting rods and the fixing plates, and the horizontal distance between the two connecting rods is gradually decreased, so that the distance between the connecting plates at the bottom ends of the two fixing plates is gradually decreased; and the connecting plates approach the metal product in the moving process until the side faces of the two connecting plates make contact with the metal product, so that the metal product is fixed, and machining of the metal product is facilitated.

Owner:南通安泰新材料科技有限公司

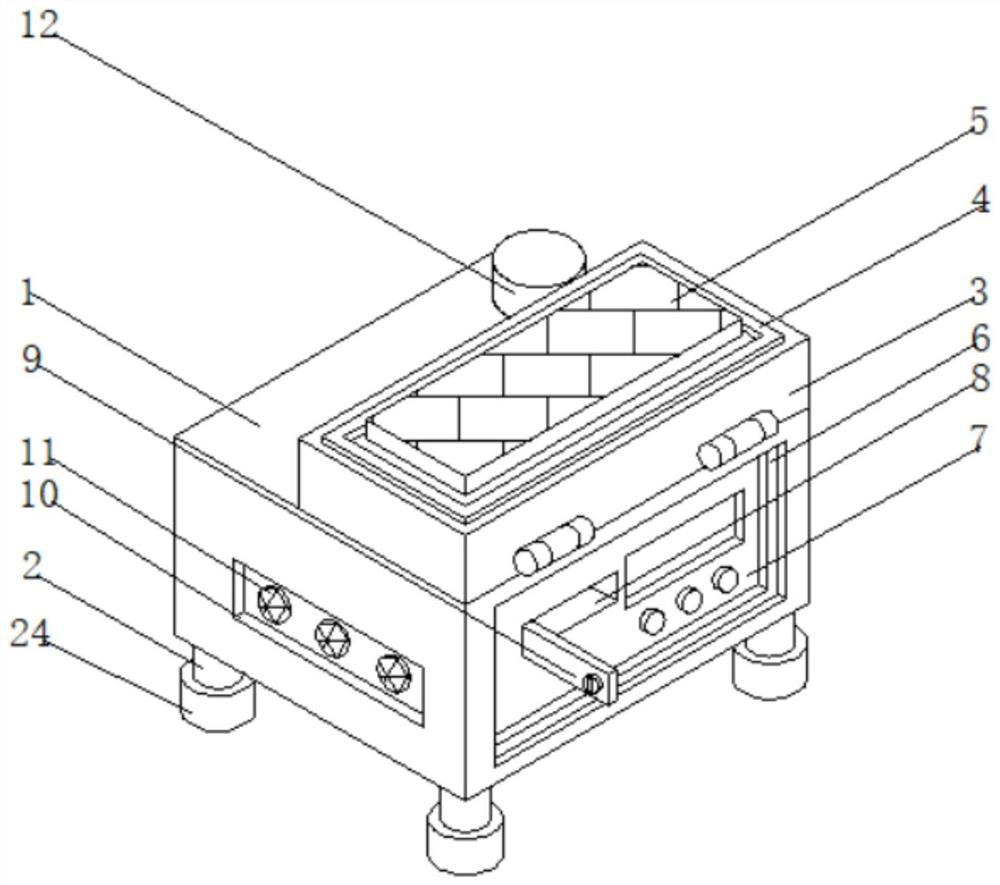

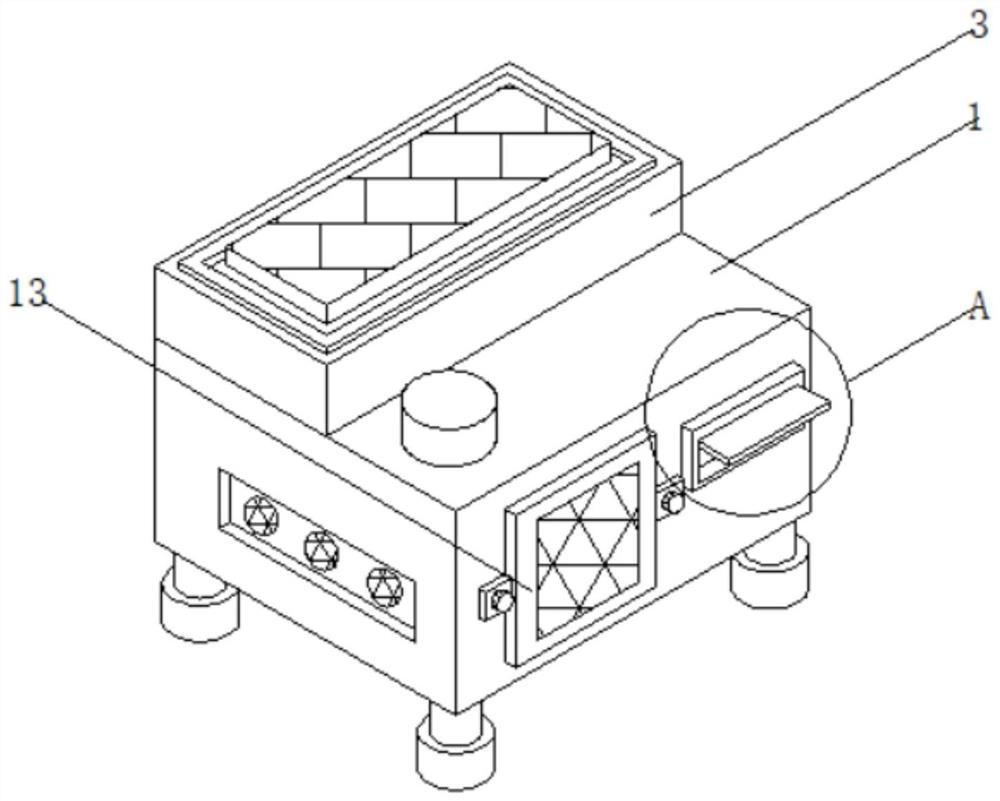

Remote service management system for mechanical equipment

PendingCN114071970AReduce displacement phenomenonEffective protectionThermometer detailsCasings/cabinets/drawers detailsStructural engineeringMechanical equipment

A remote service management system for mechanical equipment disclosed by the present invention comprises a box body. Supporting legs are fixedly connected to four corners of the lower surface of the box body, protective sleeves are fixedly connected to the bottom ends of the four supporting legs, and a sealing cover is movably connected to the front side surface of the box body. A sealing ring is fixedly connected to the upper surface of the sealing cover, a first protection pad is fixedly connected to the position, located on the inner side of the sealing ring, of the upper surface of the sealing cover, a protection box is fixedly connected to the inner side of the box body, and a signal box is fixedly connected to the inner side of the protection box. When the box body is collided and toppled over, the first spring is compressed through the protection box so that the first spring is in a compressed state, an impact force can be buffered, the signal box is effectively protected, the situation that the signal box is broken and the service life is shortened due to the fact that the box body is collided and the signal box is collided is avoided, and therefore the practicability is improved.

Owner:谢明亮

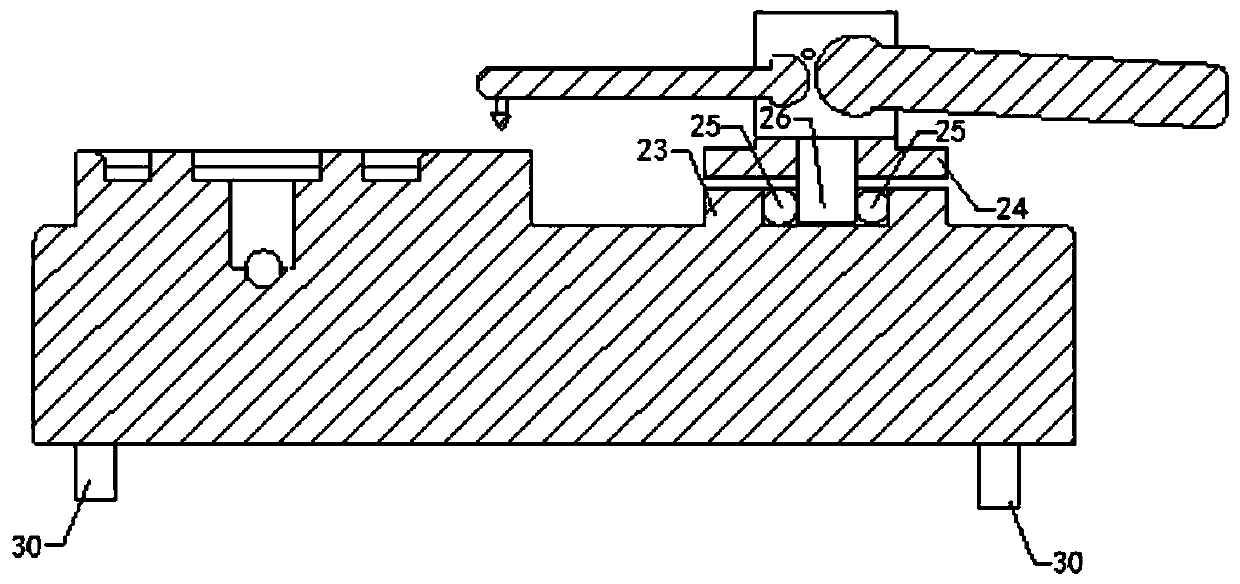

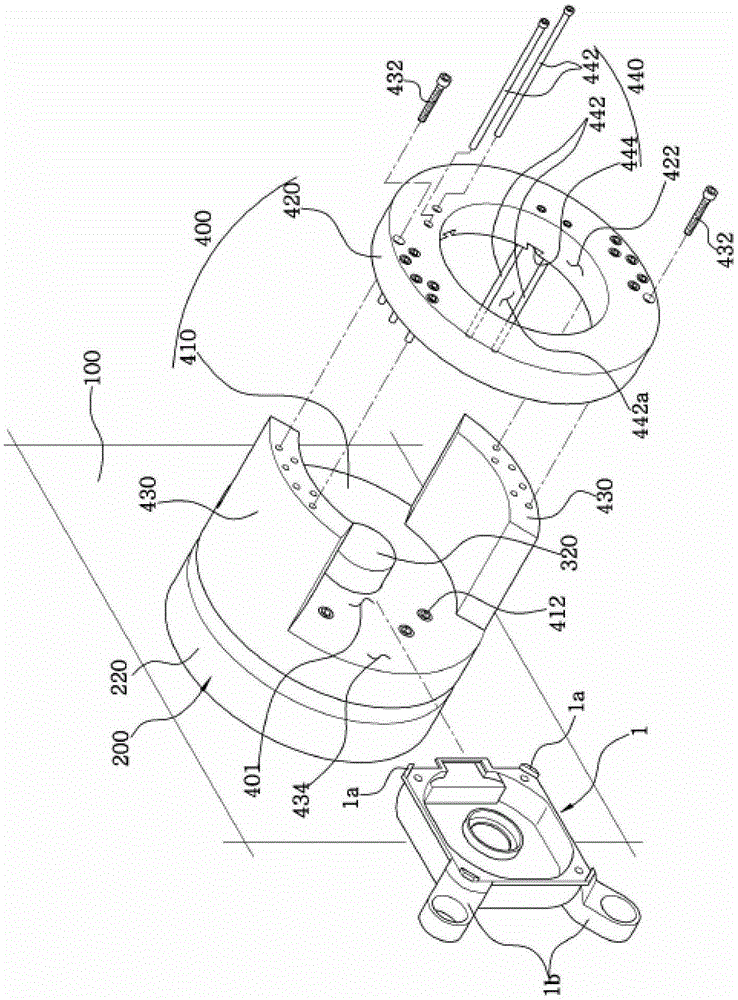

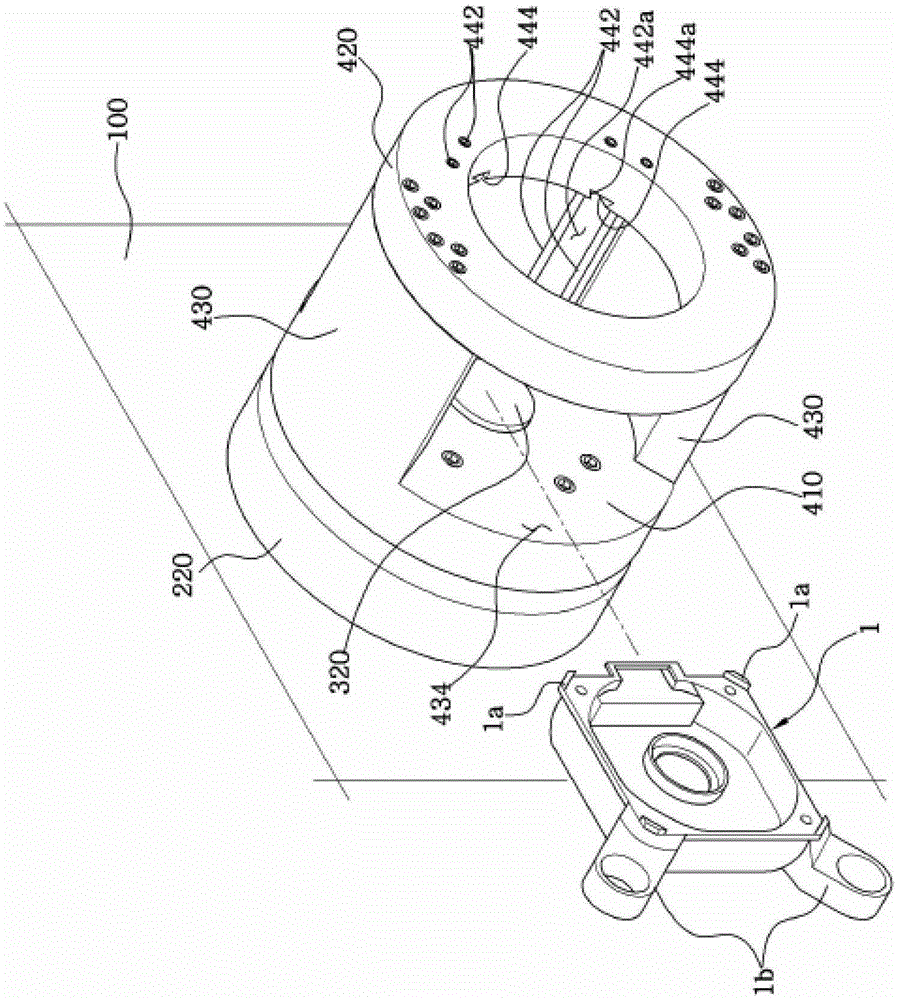

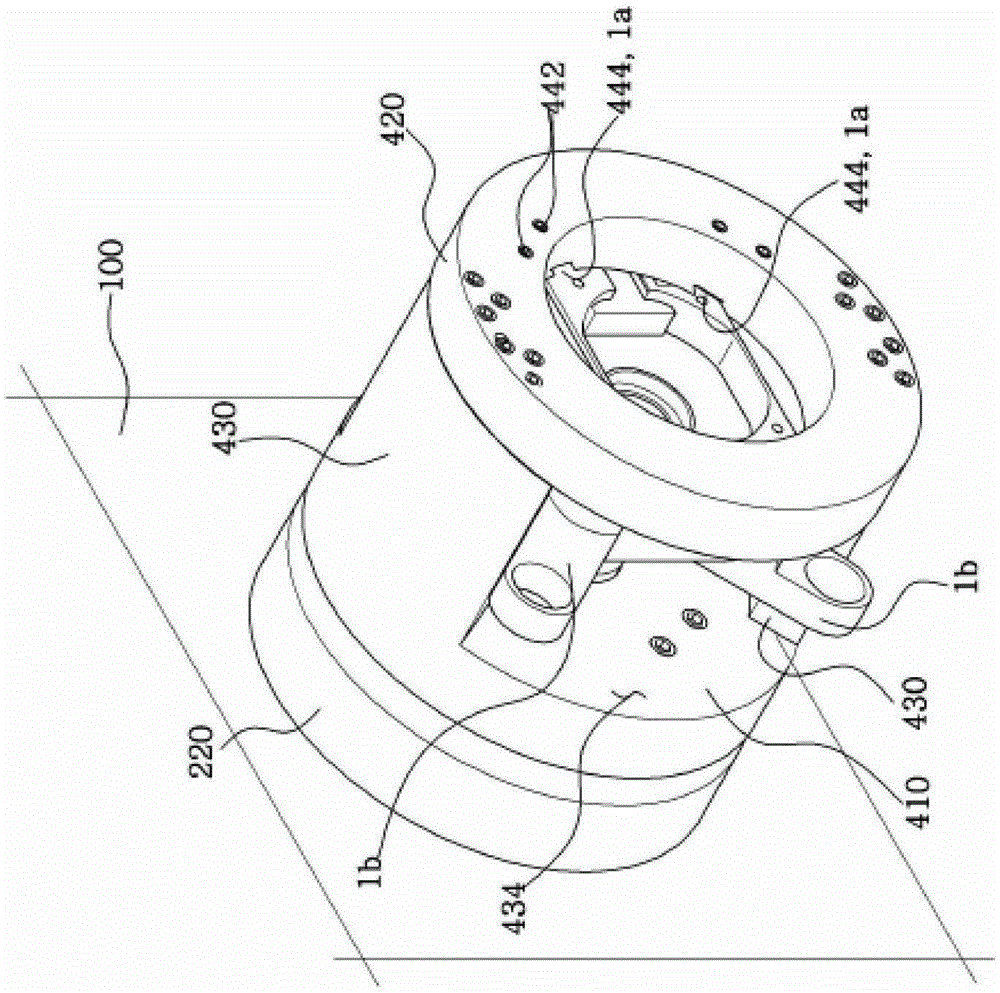

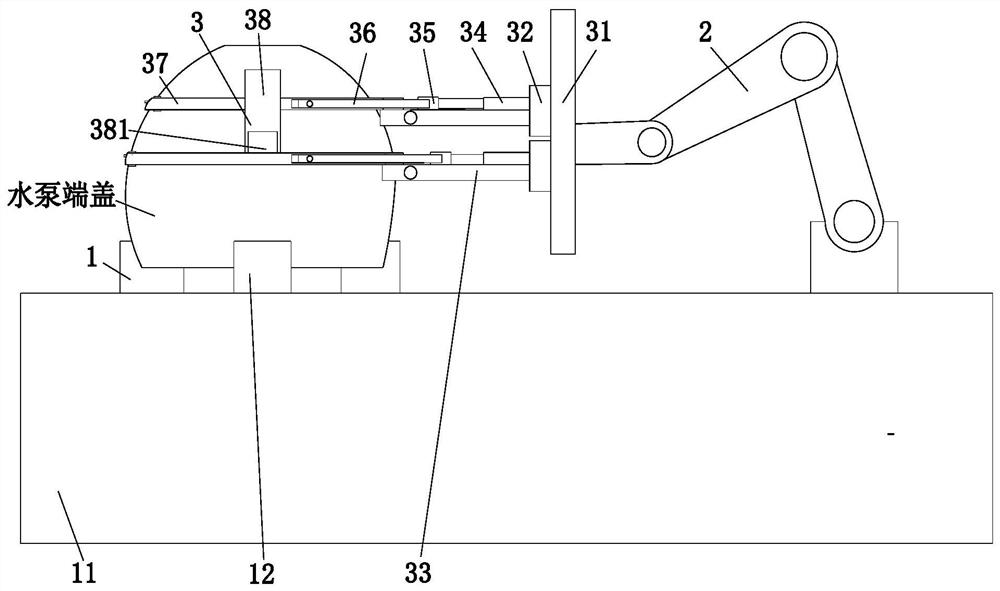

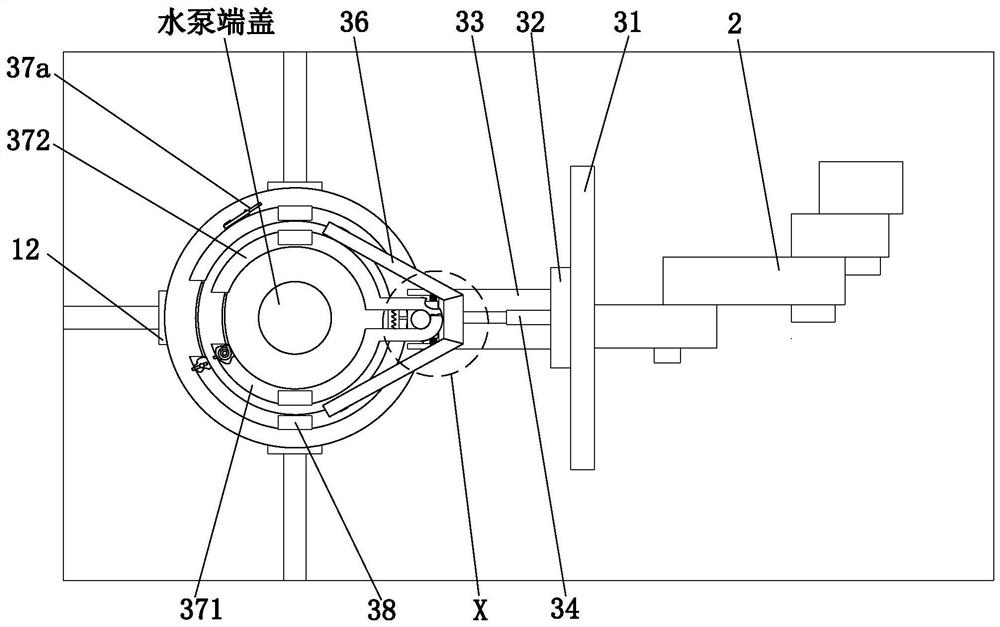

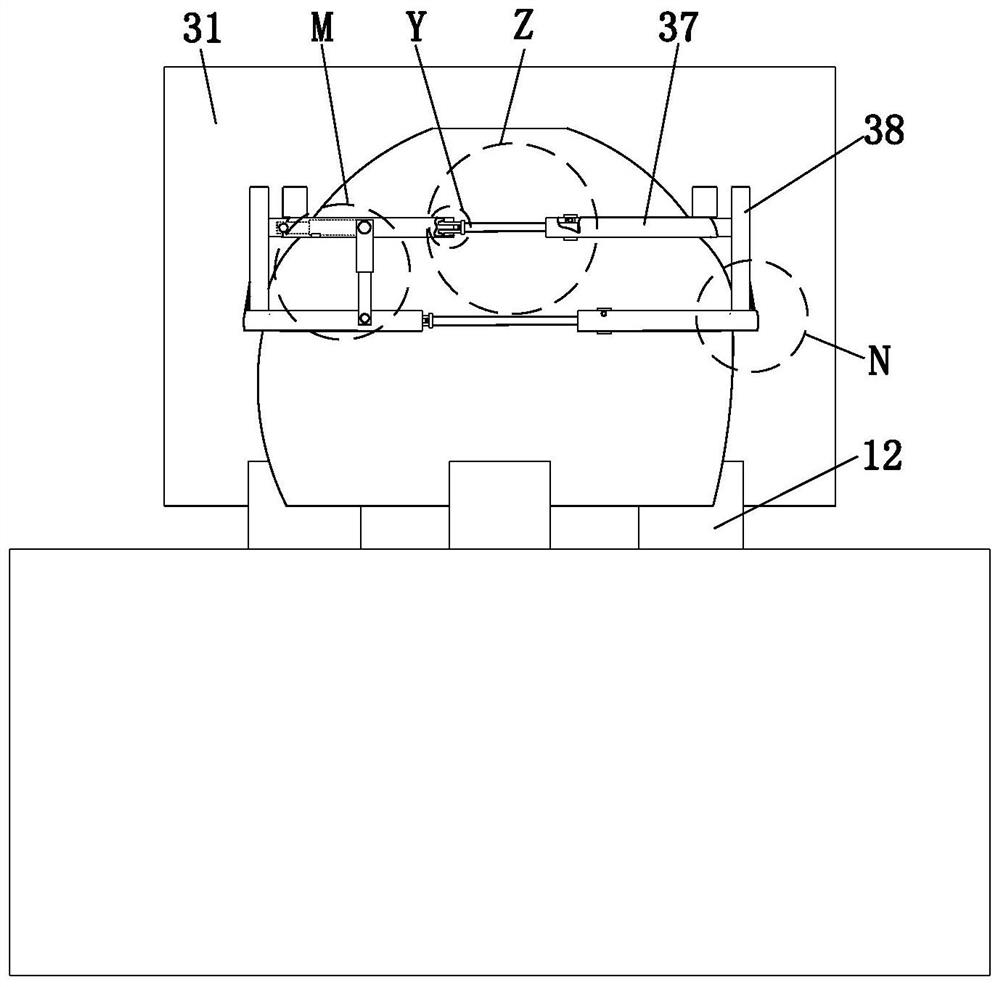

A drilling and positioning tool for the peripheral surface of the water pump end cover

ActiveCN110497226BIncrease profitAct as a guide limitPositioning apparatusMetal-working holdersClassical mechanicsStructural engineering

The invention relates to a drilling and positioning tool for the circumferential surface of a water pump end cover, which includes a clamping device, an electric mechanical arm and a positioning device. The upper end of the clamping device is equipped with an electric mechanical arm, and the left end of the electric mechanical There is a positioning device, and the positioning device is located above the clamping device. The present invention can solve the problem that the drill bit is prone to deflection and slippage when drilling the peripheral surface of the water pump end cover directly with the drill bit. If the drill bit is not rigid enough, it is easy to drill into the end cover of the water pump due to the deflection of the drill bit, resulting in the phenomenon of chipping or breaking of the drill bit, and it is also easy to cause Damage to the surface of the pump cover.

Owner:浙江青霄科技股份有限公司

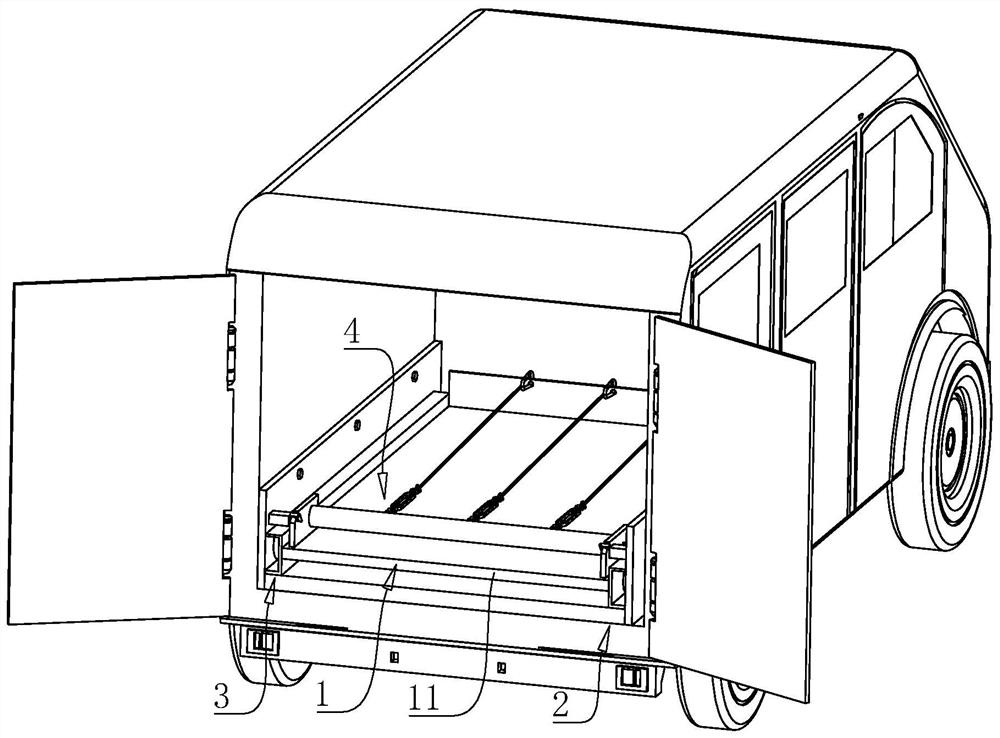

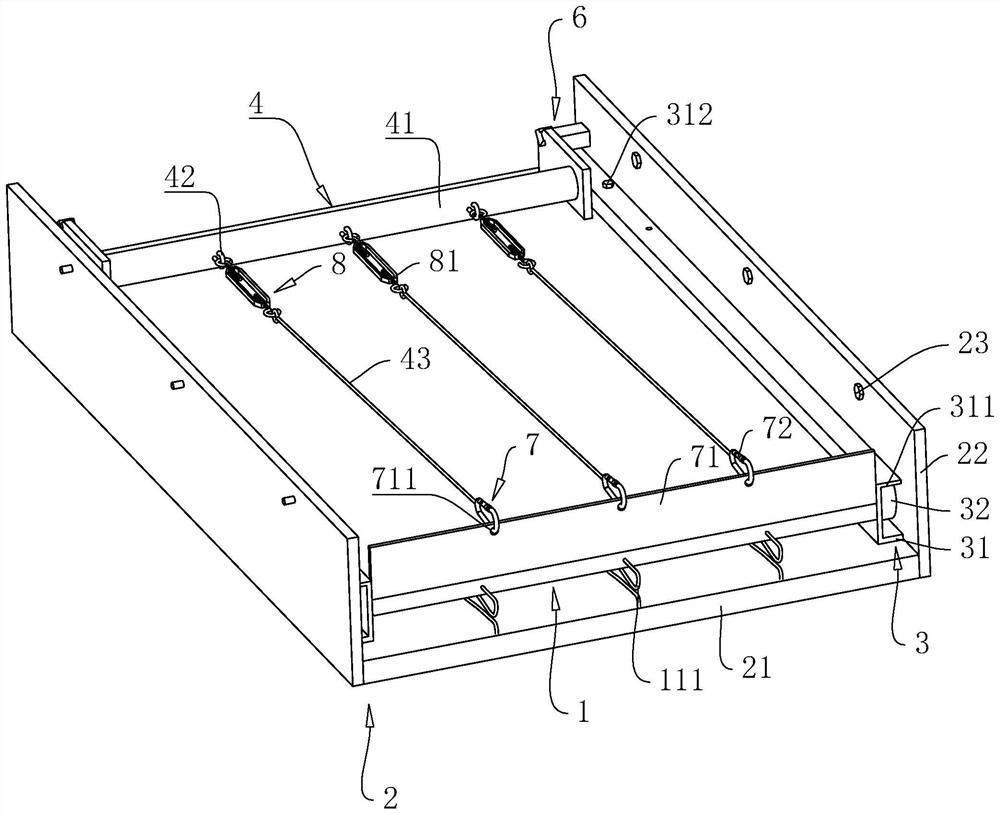

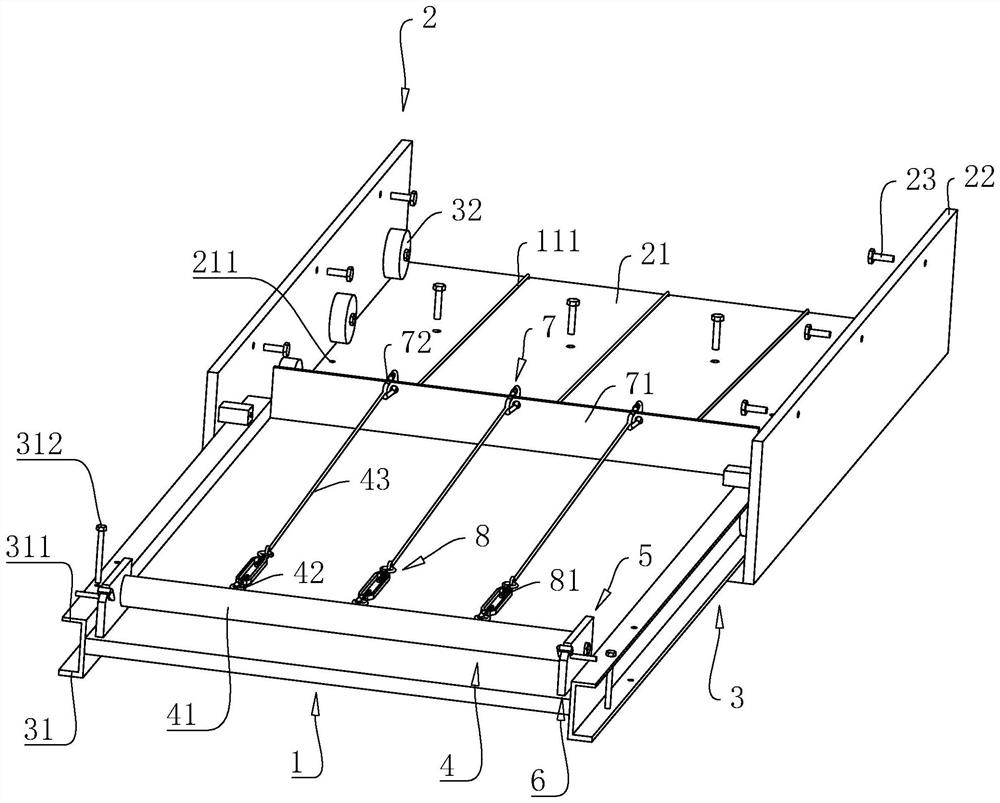

Cargo loading and unloading integrated equipment and application thereof

PendingCN114013358AReduce the difficulty of uninstallationShorten unloading timeLoading/unloading vehicle arrangmentTransportation itemsStructural engineeringTruck

The invention relates to cargo loading and unloading integrated equipment and application thereof, and relates to the technical field of cargo carrying equipment. The cargo loading and unloading integrated equipment comprises a loading device and a fixing device, the loading device is used for loading cargo, and the fixing device is used for installing the loading device; wherein the fixing device comprises a bottom supporting plate, two supporting plates and a plurality of fixing bolts, the two supporting plates are arranged on the two opposite sides of the bottom supporting plate, and the fixing bolts are used for fixing the bottom supporting plate and the supporting plates to a carrier for installing the fixing device; the object carrying device comprises an object carrying plate, and the object carrying plate is arranged on the supporting plate in a sliding mode through a sliding mechanism; and the cargo loading and unloading integrated equipment is used for loading and unloading cargoes on an airplane or a train or a truck. The device has the effects that the loading stability and the transportation stability of cargo are guaranteed, and the cargo unloading efficiency of unloading personnel is improved.

Owner:苏州亿源精密模具有限公司

Construction site concrete multi-layer pouring frame and construction method

InactiveCN113374248AImprove sealingImprove appearance qualityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksArchitectural engineeringSupport plane

The invention discloses a construction site concrete multi-layer pouring frame and a construction method. The construction site concrete multi-layer pouring frame comprises a first formwork, a second formwork, a third formwork and a fourth formwork, wherein the inner side surfaces of the first formwork, the second formwork, the third formwork and the fourth formwork are fixedly connected with protective layers, first bottom plates are fixedly connected to the lower surface of the first formwork and the lower surface of the second formwork correspondingly, first grooves are formed in the surfaces of the two first bottom plates correspondingly, and mounting plates are movably connected to the inner sides of the two first grooves correspondingly. According to the construction site concrete multi-layer pouring frame, the fourth formwork and the second formwork can be connected through a supporting frame, stability is improved, a user loosens fourth fastening bolts to detach the supporting frame, operation is easy and convenient, the detaching work efficiency is improved, the sealing performance between two first top plates and two second bottom plates can be improved through sealing gaskets, when concrete is poured, the situation that the concrete is leaked is avoided, the quality of the concrete is reduced, so that the practicability is improved.

Owner:CHINA MCC17 GRP

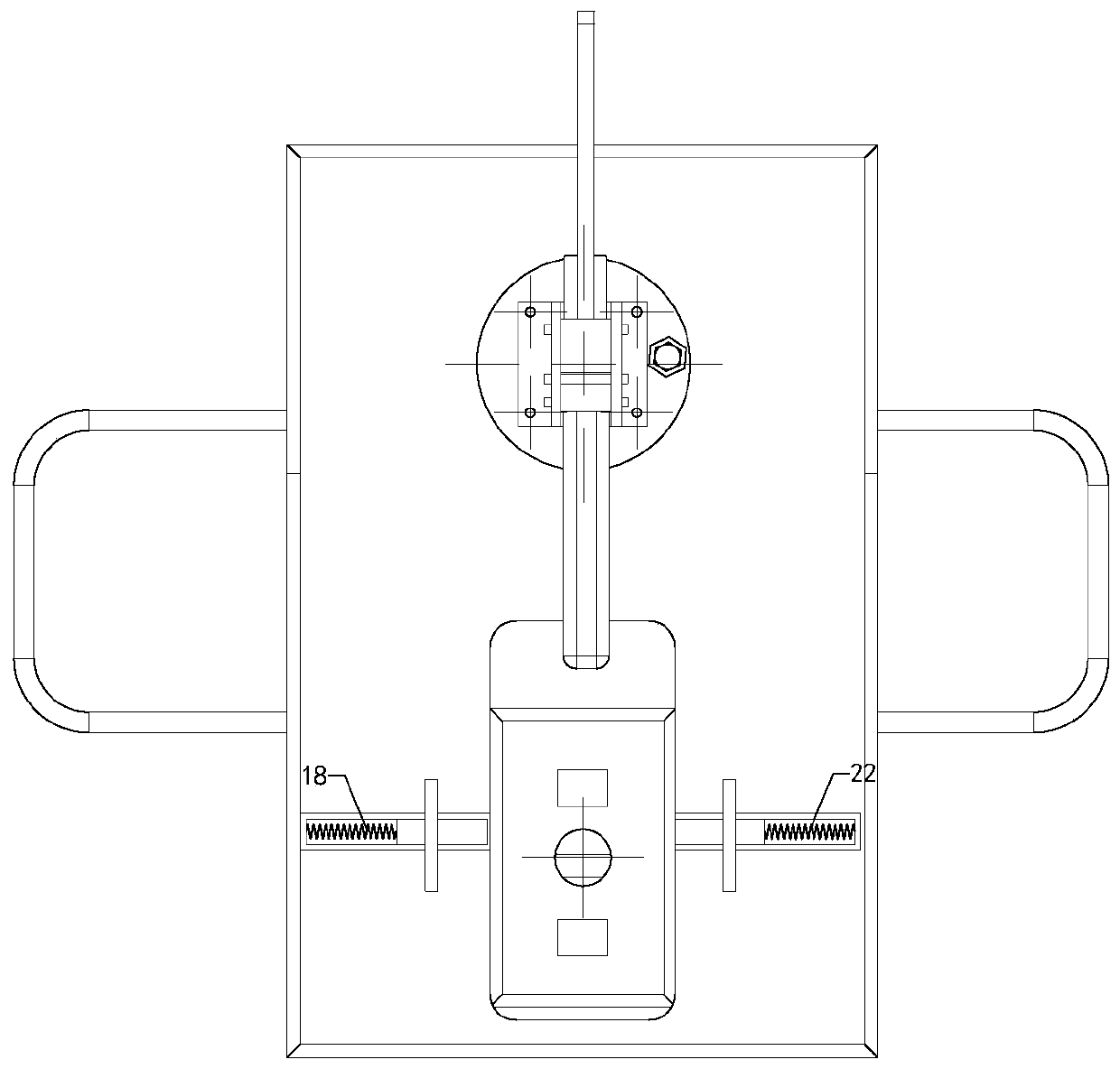

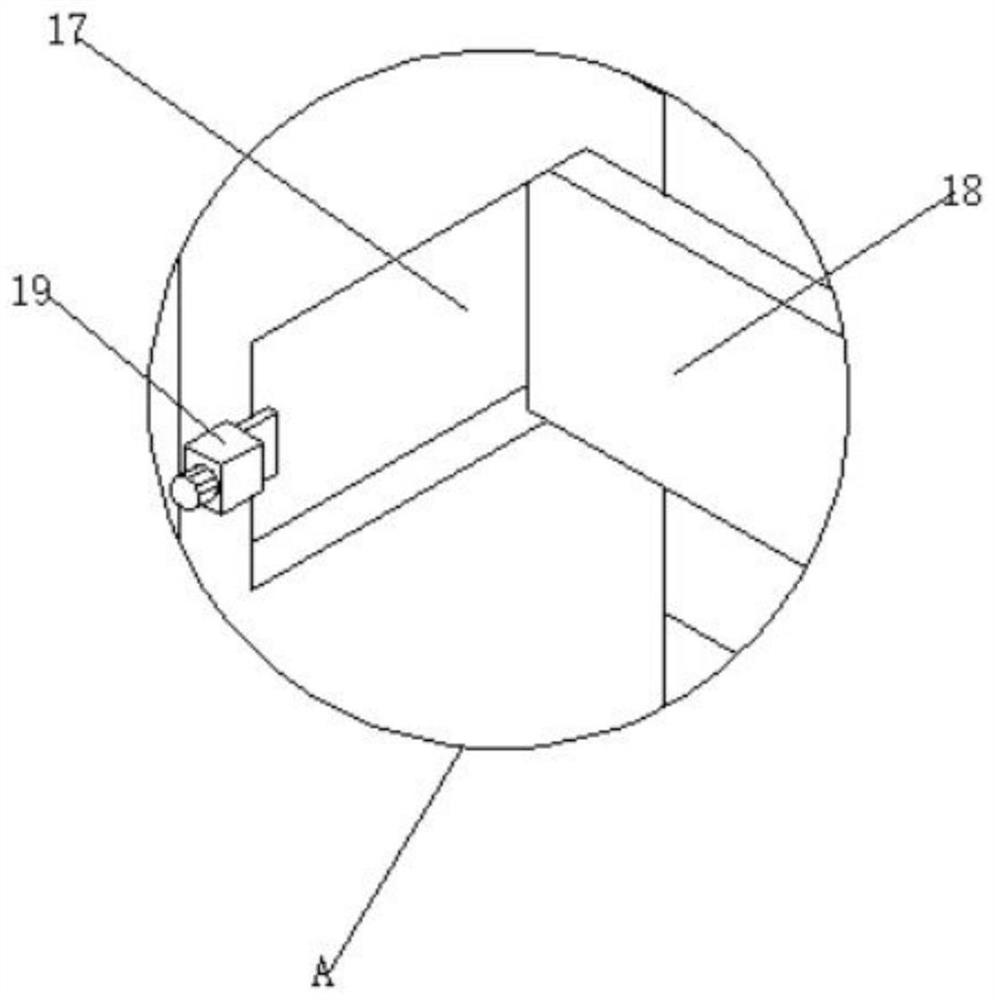

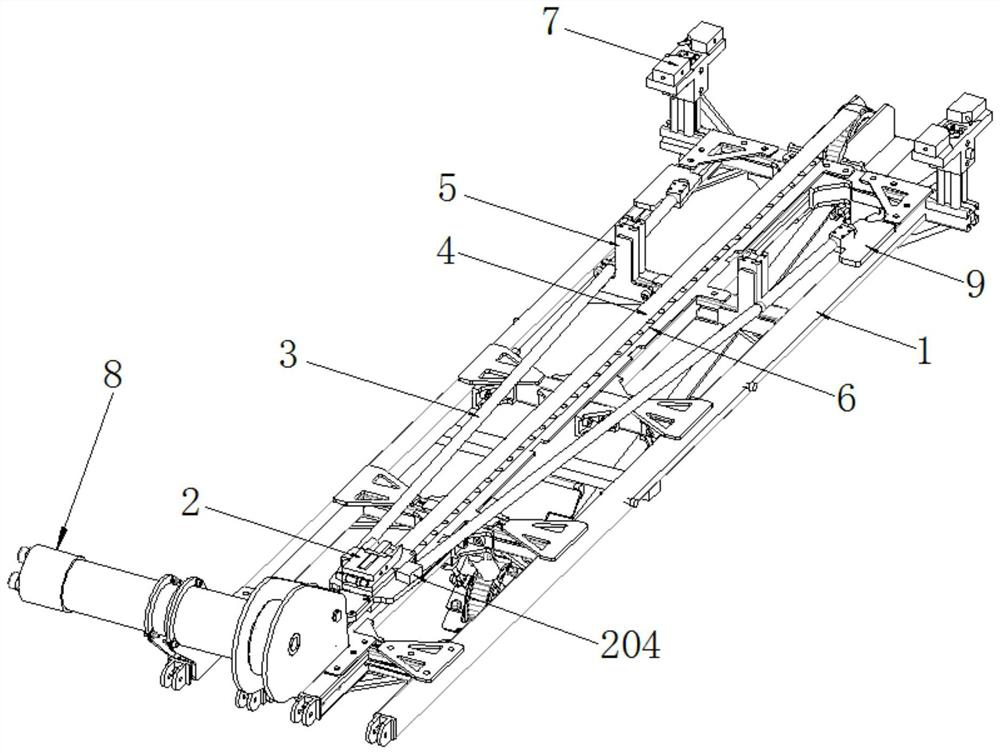

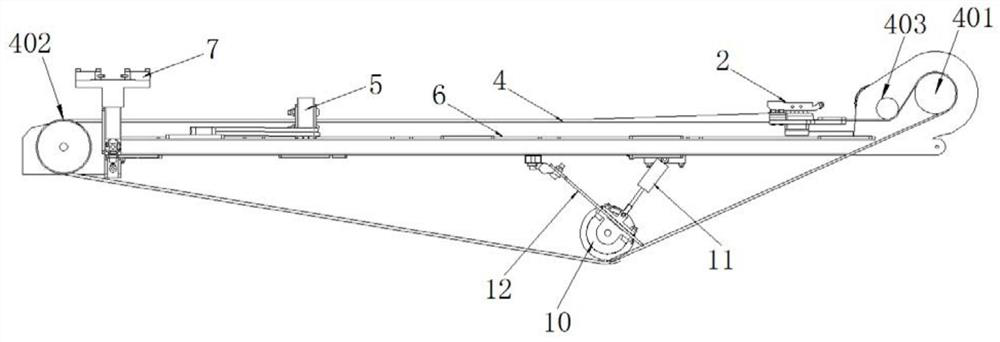

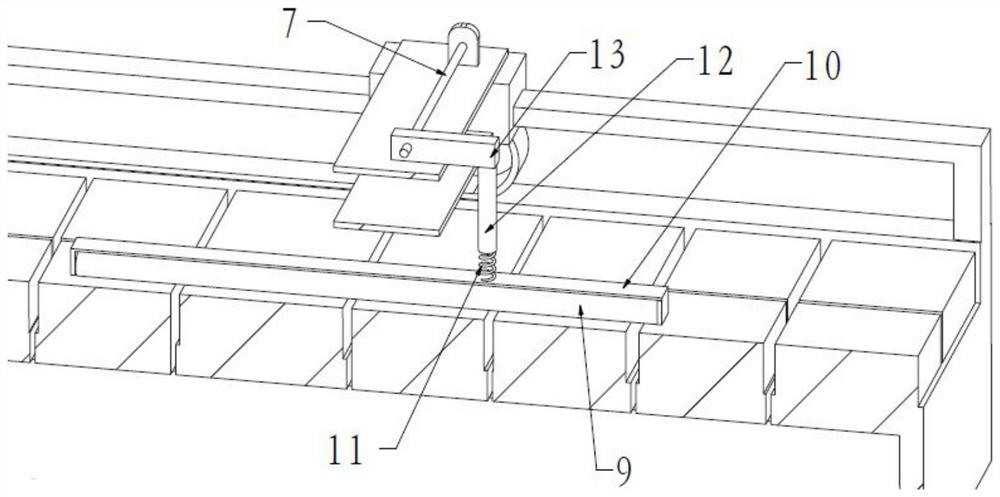

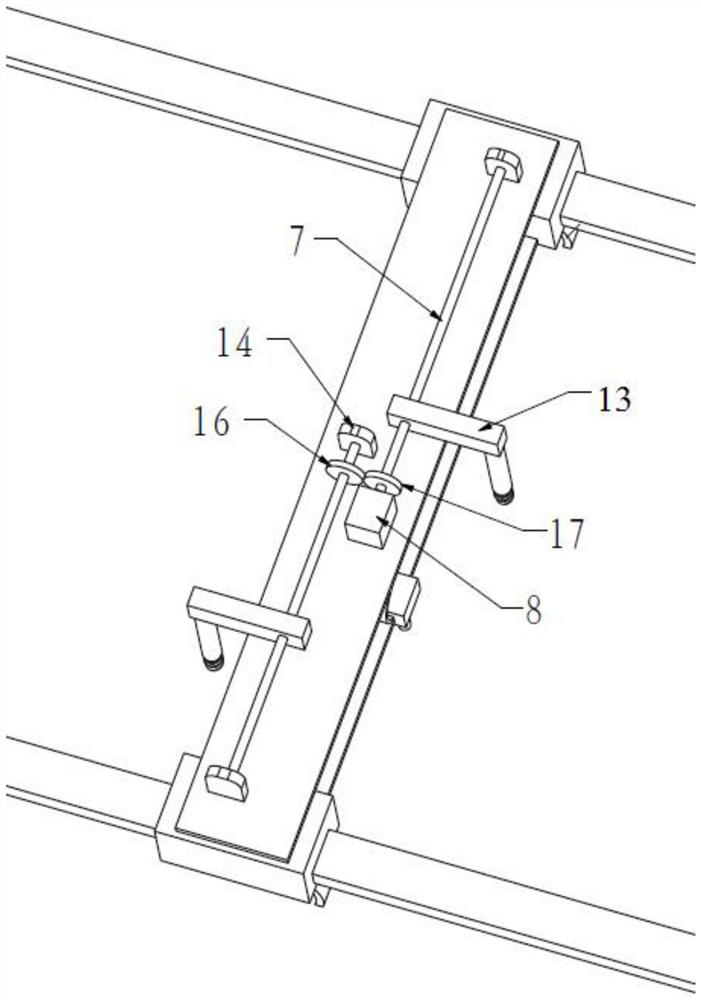

Launching device based on synchronous belt

PendingCN112937898ASimple device structureEasy to operateLaunching/towing gearDevices using time traversedBrushless motorsDrive wheel

The transmitting device comprises a frame, the synchronous belt, a driving wheel, a driven wheel, a direct current brushless motor, a guide rail and a sliding block type support, the driving wheel and the driven wheel are installed at the rear end and the front end of the frame respectively, the driving wheel is connected with a power output shaft of the direct current brushless motor, and the guide rail is connected with the sliding block type support. The two ends of the synchronous belt are connected with the driving wheel and the driven wheel respectively, and the guide rail is installed on the frame and located under the launching section of the synchronous belt. An edge pressing wheel is arranged at the rear end of the frame and is tightly pressed on the synchronous belt, so that the transmitting section of the synchronous belt is parallel to the guide rail; the sliding block type support is fixed to the transmitting section of the synchronous belt, and the lower end of the sliding block type support is in sliding connection with the guide rail. The sliding block type support of the launching device is connected with the synchronous belt, the edge pressing wheel is tightly pressed on the synchronous belt to enable the launching section of the synchronous belt to be parallel to the guide rail, the edge pressing wheel enables the synchronous belt to operate more stably, and therefore the unmanned aerial vehicle is stably launched through the sliding block support, and the device is simple in structure, easy to control and low in manufacturing cost.

Owner:SOUTH CHINA UNIV OF TECH +1

An industrial robot for gear processing

ActiveCN111660276BIncrease the support areaImprove stabilityProgramme-controlled manipulatorGear wheelControl engineering

The invention discloses an industrial robot for gear processing, which comprises a main body of the industrial robot. The bottom of the main body of the industrial robot is provided with a synchronous storage mechanism for rollers and a horizontal expansion and stability mechanism matched with the synchronous storage mechanism for the rollers. The roller synchronous storage mechanism includes a base plate fixedly connected to the bottom of the main body of the industrial robot, and the bottom of the base plate is fixedly connected with a rectangular box with an opening at the top, and the bottom of the rectangular box is glued and fixed with a non-slip rubber pad. The invention is reasonable in design, easy to move, easy to store the four traveling wheels synchronously, and convenient to increase the support area in contact with the ground in the lateral direction while storing the traveling wheels, so as to further improve the stability of placement and effectively reduce the Mis-touching or displacement caused by vibration can also prevent the traveling wheels from being stressed for a long time, so as to improve their service life and be beneficial to use.

Owner:山东国众机械科技有限公司

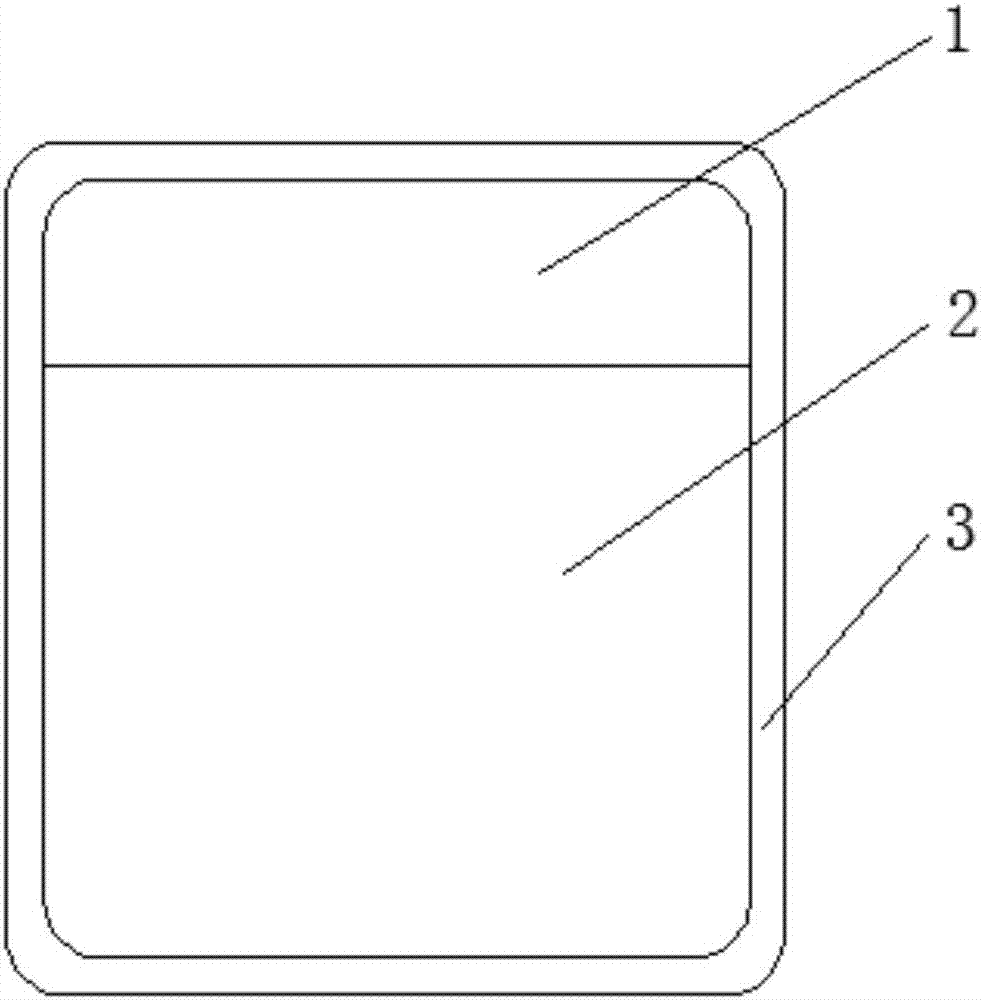

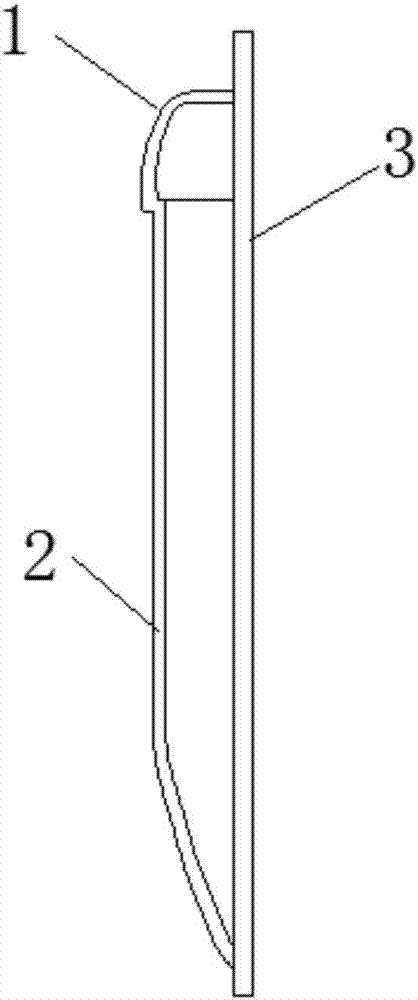

Close-fitting pocket

InactiveCN107259681ASimple structureReduce displacement phenomenonProtective garmentSpecial outerwear garmentsEngineeringViscosity

The invention discloses a close-fitting pocket, comprising a pocket upper cover, a pocket main body and a pocket backing, the upper end of the pocket main body is provided with a pocket upper cover, and the back of the pocket main body is provided with a pocket backing; the close-fitting pocket structure It is simple, made of materials with friction and viscosity, which reduces the displacement phenomenon during use, and has good and convenient use.

Owner:梁梅

A kind of production and maintenance method of prestressed concrete hollow square pile

InactiveCN104552597BReduce desolderingReduce displacement phenomenonCeramic shaping apparatusBasementPre stress

Owner:NANTONG ZHONGJI PILE

Spliced type solar cell mounting rack

PendingCN113300667AImprove convenienceImprove stabilityPhotovoltaic supportsSolar heating energyEngineeringSolar battery

A spliced solar cell mounting rack disclosed by the present invention comprises a bottom plate, a table body, a first placement frame, a second placement frame and vertical plates, the table body is arranged above the bottom plate, the vertical plates are fixed at the corner positions of the top end of the bottom plate, telescopic rods are mounted at the top end of the bottom plate on one sides of the vertical plates, and the top ends of the telescopic rods are fixedly connected with the bottom end of the table body. A spiral column is fixed to the center of the top end of the bottom plate, a spiral barrel is in threaded connection with the outer wall of one end of the spiral barrel, the top end of the spiral barrel is rotationally connected with the bottom end of the table body, a first placement frame is arranged at the center of the top end of the table body, and second placement frames are installed on the outer walls of the two sides of the table body correspondingly. Inclined rods are arranged at the two ends of the bottom of the second containing frame, and the outer walls of the ends, away from the second containing frame, of the inclined rods make contact with the outer walls of the vertical plates. According to the mounting rack, the convenience of the mounting rack in use is improved, the application range of the mounting rack is widened, and the stability of the mounting rack in use is improved.

Owner:TSINGHUA UNIV +1

Testing device for cylindrical lithium ion battery

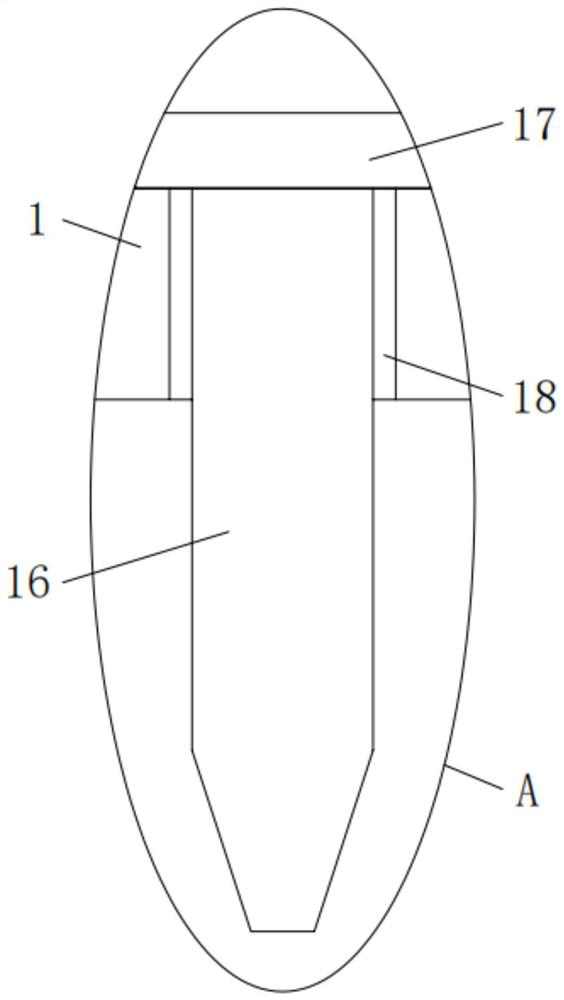

PendingCN113589176AImprove detection accuracyImprove stabilityElectrical testingMaterial strength using tensile/compressive forcesPhysicsElectrical battery

Disclosed is a testing device for a cylindrical lithium ion battery. The testing device comprises a bottom plate, a lower storage frame, an upper storage frame, an upper connecting plate and a lower connecting plate. The lower storage frame is arranged in the center of the top end of the bottom plate, the lower connecting plate is arranged in the center of the interior of the lower storage frame, a lower electric connector is arranged in the center of the top of the lower connecting plate, a first electricity leading wire is arranged at the center of the bottom of the lower electric connector, the end, away from the lower electric connector, of the first electricity leading wire extends to the outside of the lower storage frame, the upper storage frame is arranged above the lower storage frame, the upper connecting plate is arranged at the center of the interior of the upper storage frame, an upper electric connector is arranged at the center of the bottom of the upper connecting plate, and a second electricity leading wire is arranged in the center of the top of the upper electric connector. According to the invention, the detection precision of the testing device in use is improved, the stability of the testing device in use is improved, and the application range of the testing device is widened.

Owner:DONGGUAN LILONG BATTERY TECH CO LTD

Cable pulling assembly and method for preventing cable stretching

ActiveCN105914662BAvoid safety hazardsAvoid stretchingApparatus for joining/termination cablesApparatus for laying cablesEngineeringMechanical engineering

The invention provides a cable traction assembly and a method of preventing cable stretching. The cable traction assembly comprises a traction part; and a pipe body part, wherein one end of the pipe body part is in connection with the traction part, and the other end of the pipe body part is arranged on a wire part to prevent the wire part from being stretched in a laying process, thereby solving the problem that in the prior art, cables are easy to stretch in a laying process. The pipe body part is arranged on the wire part, allowing the pipe body and the wire part to be meanwhile under the tractive effort in the traction process of the wire part; according to the pipe body part, the wire part provided with the pipe body part and a cable over sheath are meanwhile dragged, thereby reducing expansion or displacement between the wire part and the cable over sheath, guaranteeing lead integrity, and effectively avoiding potential safety hazards caused by stretching cables in a laying process.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

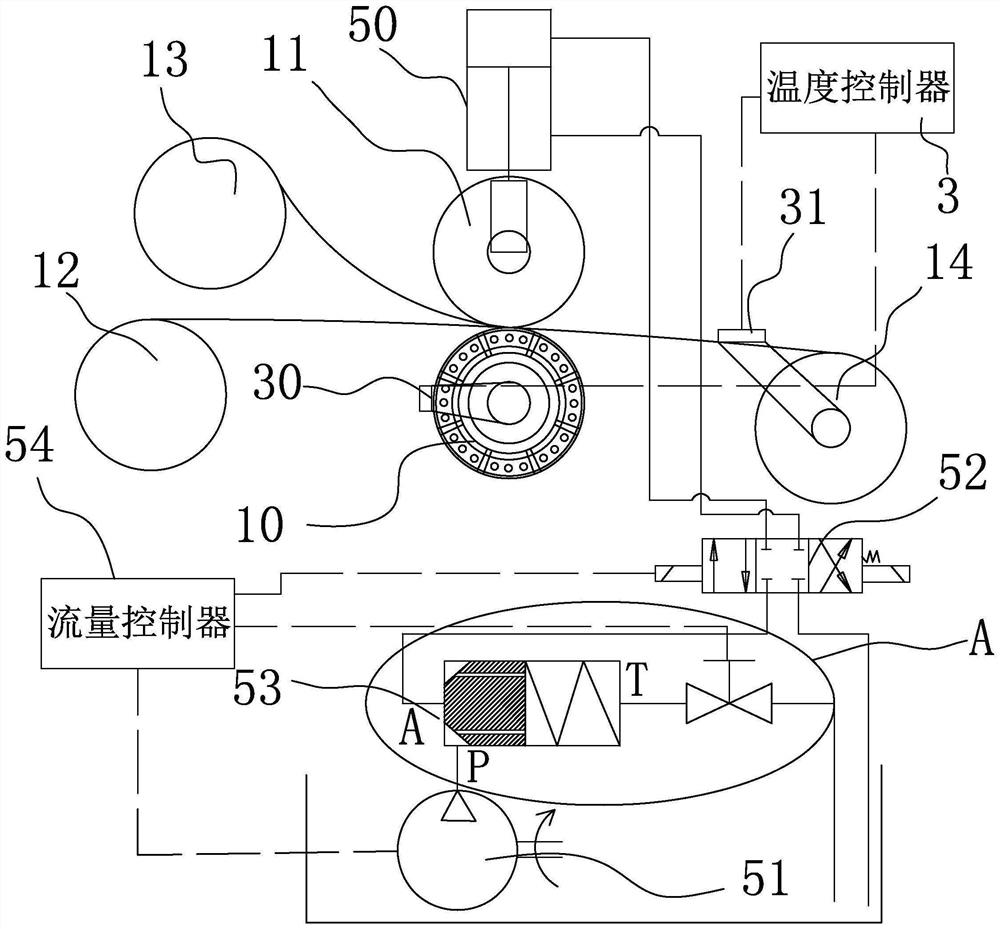

Cloth cutting device for garment processing

InactiveCN113882135AReduce displacement phenomenonReduce wrinklesSevering textilesMetal working apparatusBristleElectric machinery

The invention discloses a cloth cutting device for garment processing, and belongs to the technical field of garment processing. The cloth cutting device for garment processing comprises a workbench; bristle bricks are laid on the workbench in an array mode; the workbench is provided with vacuumizing through holes; the vacuumizing through holes are connected with vacuum branch pipes; the vacuum branch pipes are converged and communicated with a vacuumizing pipe; the vacuumizing pipe is connected with a vacuum pump; a telescopic cutter is movably arranged above the workbench; the telescopic cutter is driven by a linear motor assembly to move; a material pressing piece which synchronously moves is arranged on an outer ring of the telescopic cutter; material pressing rollers are movably arranged on the two sides of the telescopic cutter; and the material pressing rollers are driven by a lead screw transmission assembly to move.

Owner:会同县峰铧轩服装有限责任公司

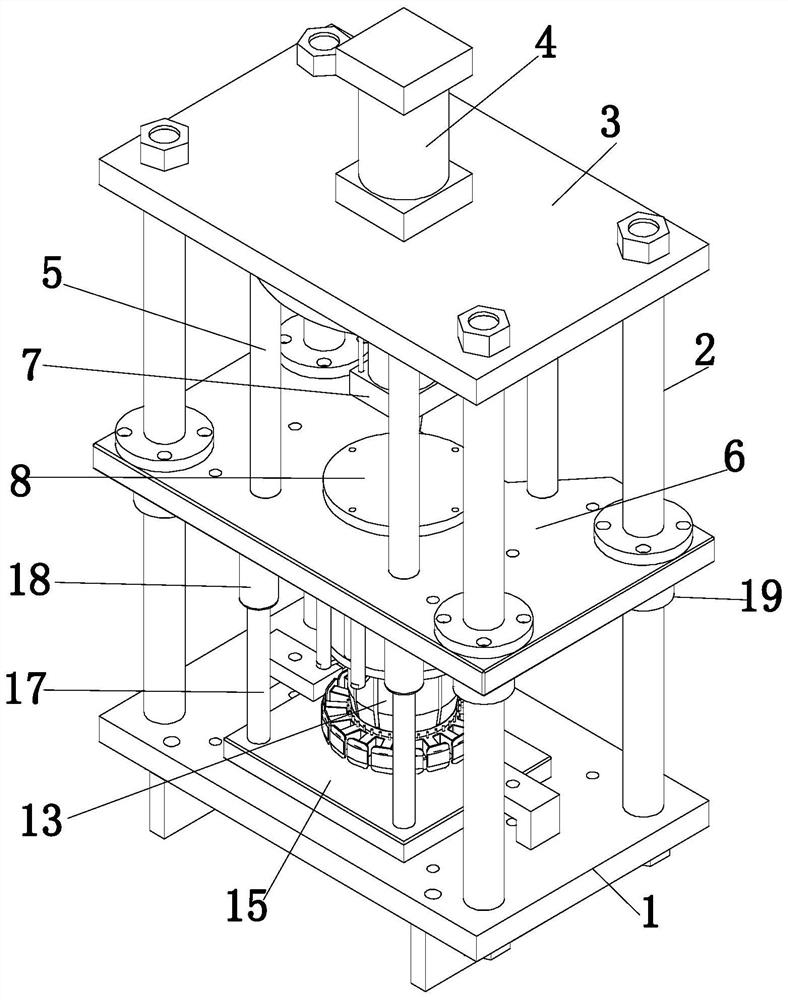

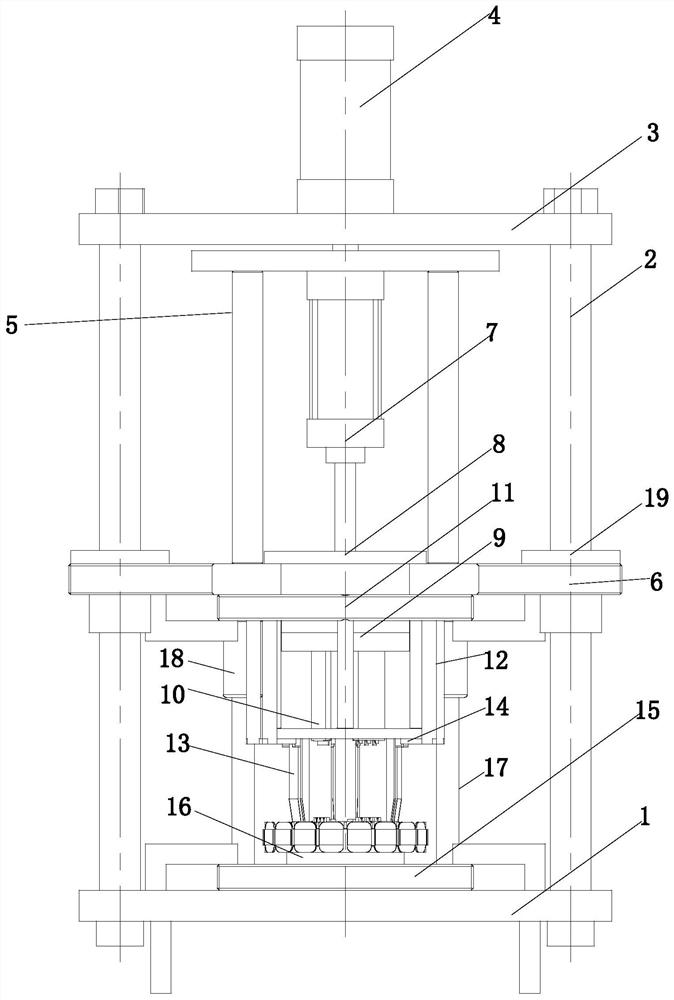

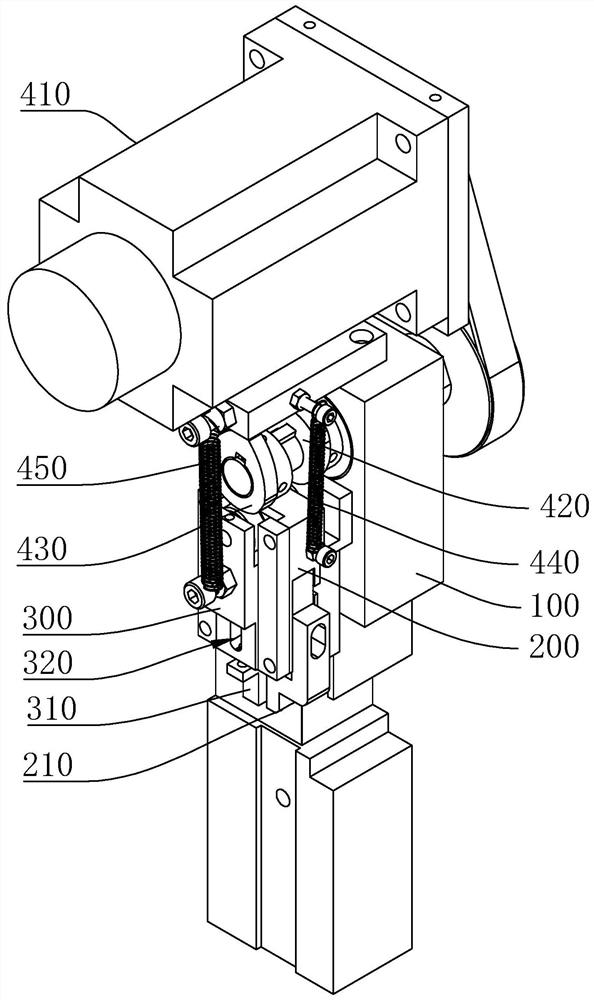

Stator wire ingot wiring crimping equipment

InactiveCN112350530ASimple structureEasy to operateManufacturing dynamo-electric machinesStatorKnife blades

The invention discloses stator wire ingot wiring crimping equipment which comprises a base, a guide column arranged above the base, a top plate arranged at the upper end of the guide column, a top aircylinder arranged above the top plate, a bearing frame arranged at the output end of the top air cylinder and located below the top plate, a middle sliding plate arranged at the lower end of the bearing frame in a sleeving mode, and a cutting air cylinder arranged on the bearing frame. A base plate is arranged at the output end of the cutting air cylinder, a fixing plate is arranged below the base plate, and a blade set is arranged below the fixing plate; the equipment also comprises a chess frame top plate fixed below the middle sliding plate, a supporting rod set located on the outer side of a cutter set is arranged below the chess frame top plate, a pressing ring matched with the cutter set is arranged below the supporting rod set, and a thread shifting rod set located on the outer side of the supporting rod set is further arranged below the chess frame top plate; a chess frame bottom plate is arranged on the upper surface of the base, and a thread spindle limiting seat is arrangedin the middle of the chess frame bottom plate. The equipment has the characteristics that the working efficiency can be effectively improved, and the displacement phenomenon of thread ends is reduced.

Owner:HUZHOU YUEQIU MOTOR

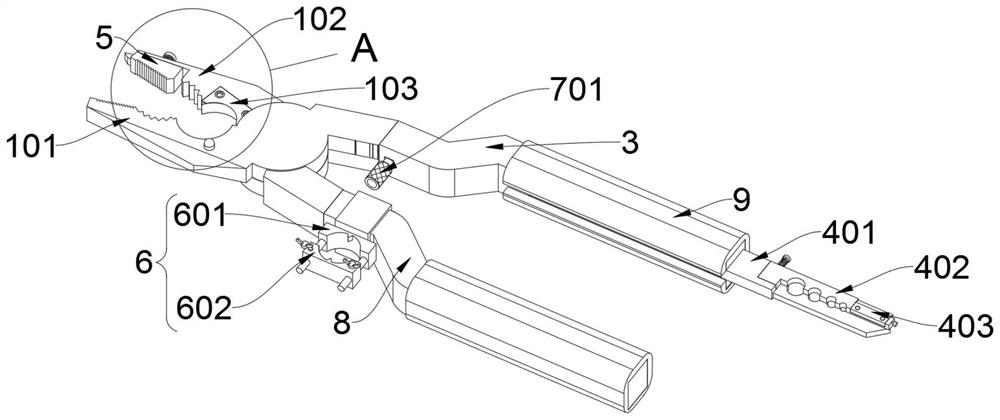

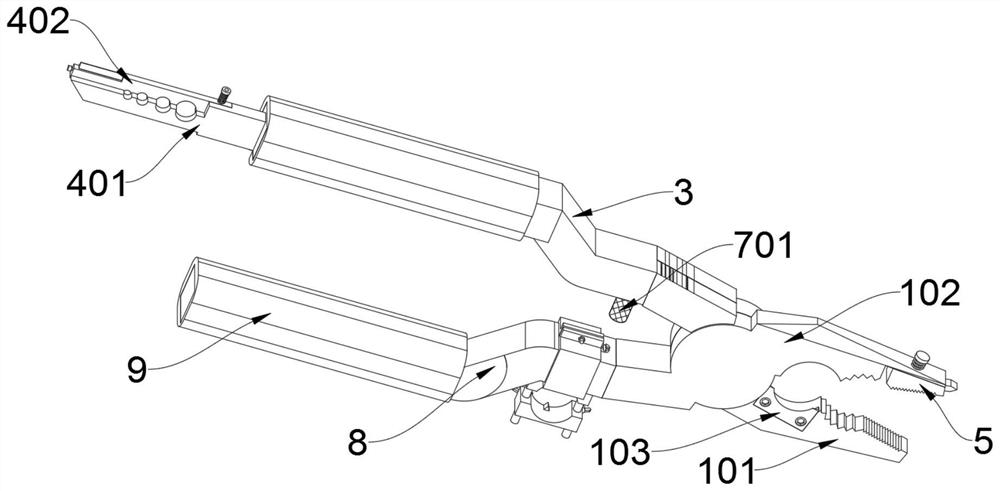

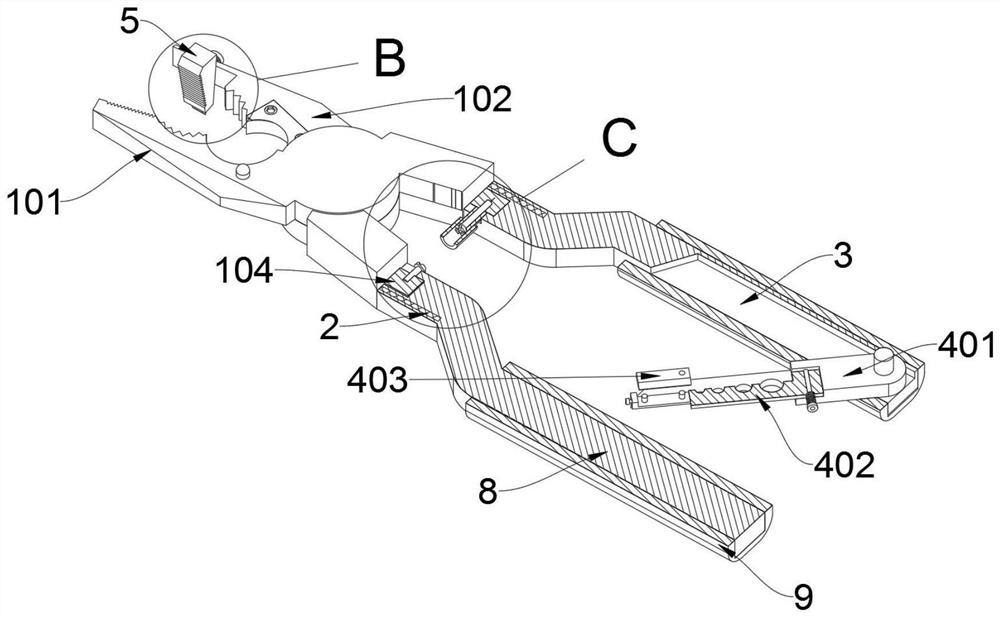

Multifunctional wire clipper structure based on communication

InactiveCN113681476AEasy to placeReduce displacement phenomenonPliersApparatus for removing/armouring cablesBolt cutterKnife blades

The invention provides a multifunctional wire clipper structure based on communication, belongs to the technical field of electric power communication, and solves the problem that a wire clipper is relatively single in use structure. The multifunctional wire clipper structure comprises a wire clipping mechanism; A cutting mechanism is mounted on the wire clipping mechanism, and a connecting block B is mounted between the wire clipping mechanism and an insulating handle A; and two reinforcing blocks which are of a rectangular structure are respectively arranged inside the insulating handle A and an insulating handle B, and the reinforcing blocks are of the rectangular structure. A movable clipper head A and a movable clipper head B are provided with grooves which are of an arc structure; the arc grooves are convenient to place a cable so as to reduce the displacement phenomenon of the cable in the cutting process; a mounting groove which is of a rectangular structure is formed on the basis of the arc grooves; the mounting groove is convenient to mount blades A; the blades A are provided with the semicircular cutting edge; and two blades A rub each other to cut off the cable.

Owner:马元中

Novel sloping field constructional engineering pile construction method

InactiveCN112211194AImprove bearing capacityThe cost is lower than that of perforated pilesFoundation repairBulkheads/pilesSlag (welding)Butt joint

The invention discloses a novel sloping field constructional engineering pile construction method. The method comprises the steps that the specific position of an original punched cast-in-place pile is explored through ultrasonic waves, and a pile head of the original punched cast-in-place pile is excavated through a small excavator or manual earth excavation; after the pile head of the original punched cast-in-place pile is excavated, concrete of the pile head of the original punched cast-in-place pile is broken and chiseled through a cannon machine, the center of the pile head of the original punched cast-in-place pile is chiseled away, a groove is chiseled out, and the groove is 300 mm in length, 300 mm in width and 300 mm in depth; butt joint pile main reinforcements and original punched cast-in-place pile main reinforcements are in lap joint in a double-face welding manner, welding slag is removed in time after welding, then the butt joint pile main reinforcements are hooped, andthe diameter and the distance of stirrups of the butt joint pile main reinforcements are the same as those of the original punched cast-in-place pile main reinforcements; and by the adoption of the novel sloping field constructional engineering pile construction method, ground operation can be achieved in engineering pile splicing construction, pile splicing construction is convenient and rapid through ground operation, the quality level is improved, safety risks are reduced, meanwhile, the stress area of a pile foundation is increased, the stress performance of the pile foundation is improved, and the service life is prolonged.

Owner:CHINA CONSTR FOURTH ENG DIV

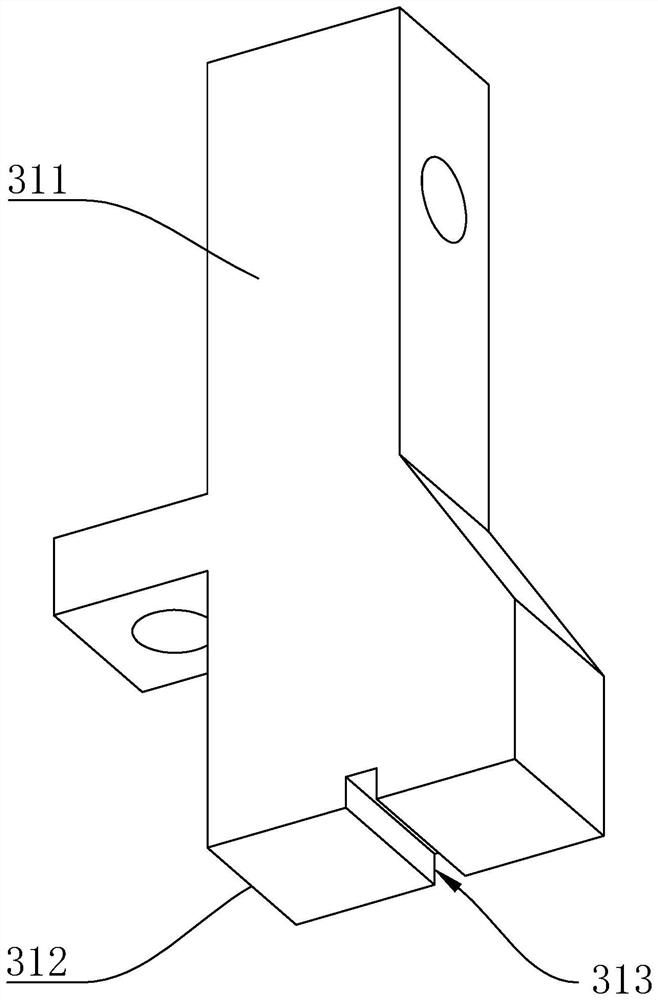

Zipper square block bolt pressing mechanism and zipper square block bolt machine

PendingCN114794680AImprove assembly qualityReduce product defect rateSlide fastenersStructural engineeringMechanical engineering

The invention discloses a zipper square block bolt pressing mechanism and a zipper square block bolt machine. The zipper square block bolt pressing mechanism comprises a mounting seat, a bolt pressing mechanism and a bolt pressing mechanism, the lifting driving mechanism is connected to the mounting seat, and the lifting driving mechanism is provided with a first movable end and a second movable end which can move up and down respectively; the first sliding block is connected to the mounting base in a sliding mode, the first movable end can drive the first sliding block to move in the vertical direction, and a positioning block is arranged on the bottom side of the first sliding block; the second sliding block is connected to the first sliding block in a sliding mode, the second movable end can drive the second sliding block to move in the vertical direction, and a stamping block is arranged on the bottom side of the second sliding block. Cloth strips are pressed and positioned firstly, then square blocks or plug pins are pressed and fixed to the cloth strips, the product assembling quality is greatly improved, and the production efficiency is improved. The phenomenon that the cloth strips are displaced when the square blocks or the bolts are pressed and fixed is reduced, and the reject ratio of products is reduced.

Owner:佛山市恩锌科技有限公司

Coating equipment for high-performance resistive coating applied to metal products

ActiveCN113275160BEasy to processIncrease horizontal distanceSpraying apparatusGear wheelElectric machinery

The invention provides a high-performance resistive coating coating equipment applied to metal products, including a base, a conveyor belt and a support column. The invention is equipped with a fixed plate, a driven gear and a driving gear, and the two fixed plates form a figure-eight , when processing metal products, two motors rotate clockwise and counterclockwise, driving the driven gear and driving gear on both sides to move along the slide rail to the slide rail three, and the driven gear and driving gear are moving When rotating, the connecting rod and the fixed plate are under the action of gravity, and the end of the connecting rod away from the fixed rod is perpendicular to the bottom surface through the bearing, and the horizontal distance between the two connecting rods gradually decreases so that the connecting plate at the bottom of the two fixed plates The distance between them gradually decreases, and the connecting plates move closer to the metal product until the sides of the two connecting plates are in contact with the metal product, thereby fixing the metal product and facilitating the processing of the metal product.

Owner:南通拓创光电材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com