5G communication signal sensor machining equipment

A processing equipment and communication signal technology, which is applied in the field of 5G communication signal sensor processing equipment, can solve problems such as solder joint errors and inclinations of components, and achieve the effect of reducing displacement and increasing the supporting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

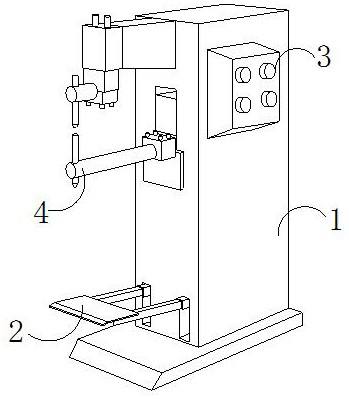

[0025] as attached figure 1 To attach Figure 5 Shown:

[0026] The present invention provides a 5G communication signal sensor processing equipment, the structure of which includes a body 1, a pedal 2, a controller 3, and a spot welding device 4. The pedal 2 is installed on the bottom of the front of the body 1, and the controller 3 is vertically installed on the The upper middle part of the right side of the body 1, and the spot welding device 4 is installed on the upper middle part of the front side of the body 1.

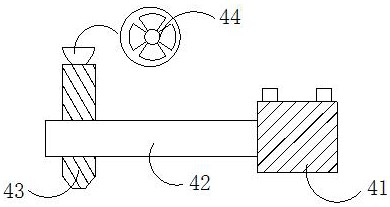

[0027] Described spot welding device 4 is provided with conductive box 41, current bar 42, electrode conduit 43, support mechanism 44, and described conductive box 41 is positioned at the right side of spot welding device 4, and described current bar 42 is connected with conductive box 41 left ends, The electrode conduit 43 vertically runs through the upper and lower surfaces of the left end of the current rod 42 , and the support mechanism 44 is vertically in...

Embodiment 2

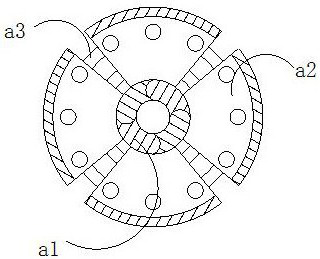

[0034] as attached Figure 6 To attach Figure 7 Shown:

[0035] Wherein, the exhaust hole d5 is provided with a support bar r1, a push spring r2, a limit plate r3, a push bar r4, and a blocking block r5. The support bar r1 is located on both sides of the exhaust hole d5, and the limit plate r3 The push spring r2 is installed on the top of the inner side of the support bar r1, and the blocking block r5 is installed between the inner side of the support bar r1 through the push bar r4. There are two limiting plates r3, which are symmetrically distributed on the left and right, which is beneficial to the limit The movable cooperation between the plate r3 and the two sides of the blocking block r5 is beneficial to limit the blocking block r5.

[0036] Wherein, the blocking block r5 is provided with a block body t1, a bearing t2, a matching block t3, an elastic strip t4, and a groove t5, the block body t1 is located in the middle of the blocking block r5, and the matching block t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com