Fixing device for template of cast-in-place reinforced concrete column

A technology for fixing reinforced concrete columns and formwork, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and preparation of building components on site. Problems such as large material consumption and engineering quality accidents can be achieved to reduce engineering quality accidents, reduce template displacement, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

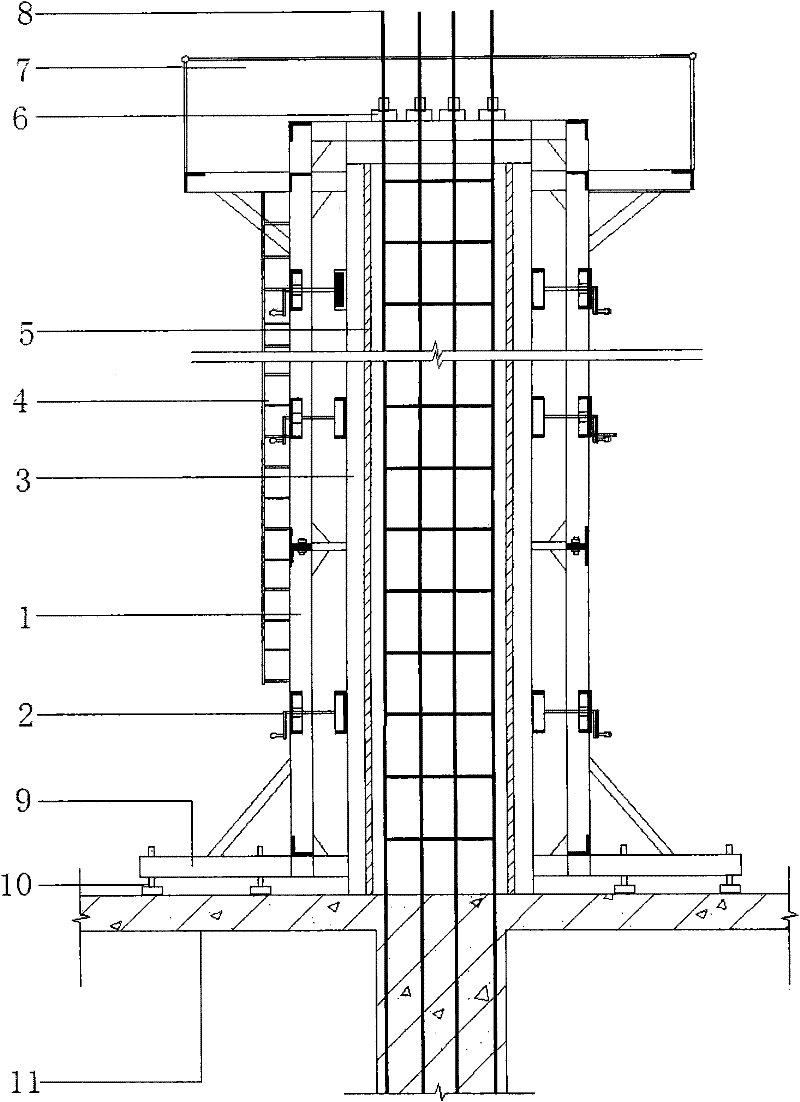

[0017] like figure 1 As shown, the formwork fixed outer support 1 is welded by section steel, the cross-sectional shape is square (not shown), the internal side length is greater than the maximum cross-sectional dimension of the column, and the height is greater than the pouring height of the column. It can be made in sections and heightened by bolt connection , The bottom outer bracket is provided with a widening base 9, the base 9 is provided with a leveling device 10, the middle outer bracket is provided with a ladder 2, and the upper outer bracket is provided with an operating platform 3.

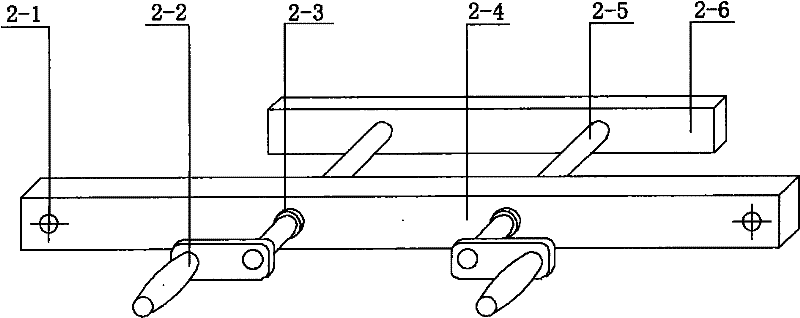

[0018] like figure 2 Shown, formwork pressing device is made up of horizontal bar 2-4, pressing screw nut 2-3, pressing screw mandrel 2-5, pressing rocking handle 2-2 and wooden square pressing plate 2-6. The horizontal bar 2-4 is made of section steel, fixed on the template fixing outer support 1 with the fixing bolt 2-1, two compression nuts 2-3 are welded with the horizontal bar 2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com