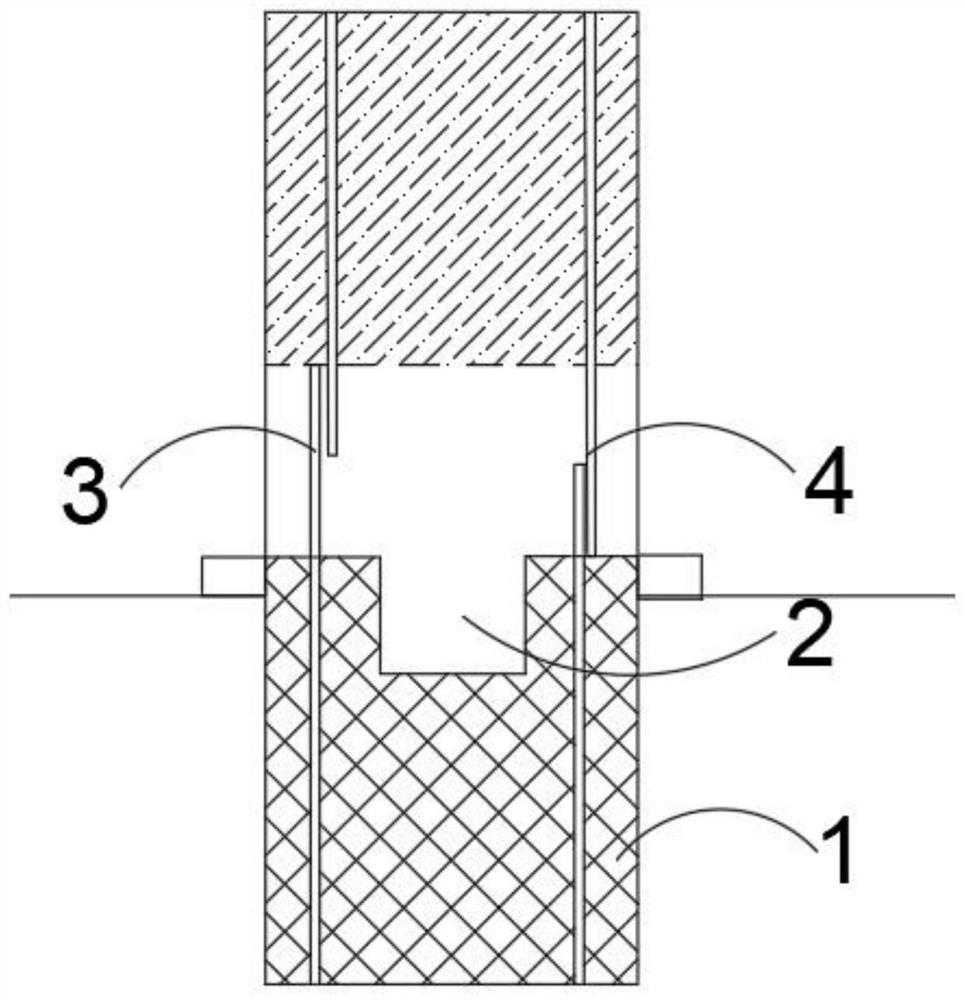

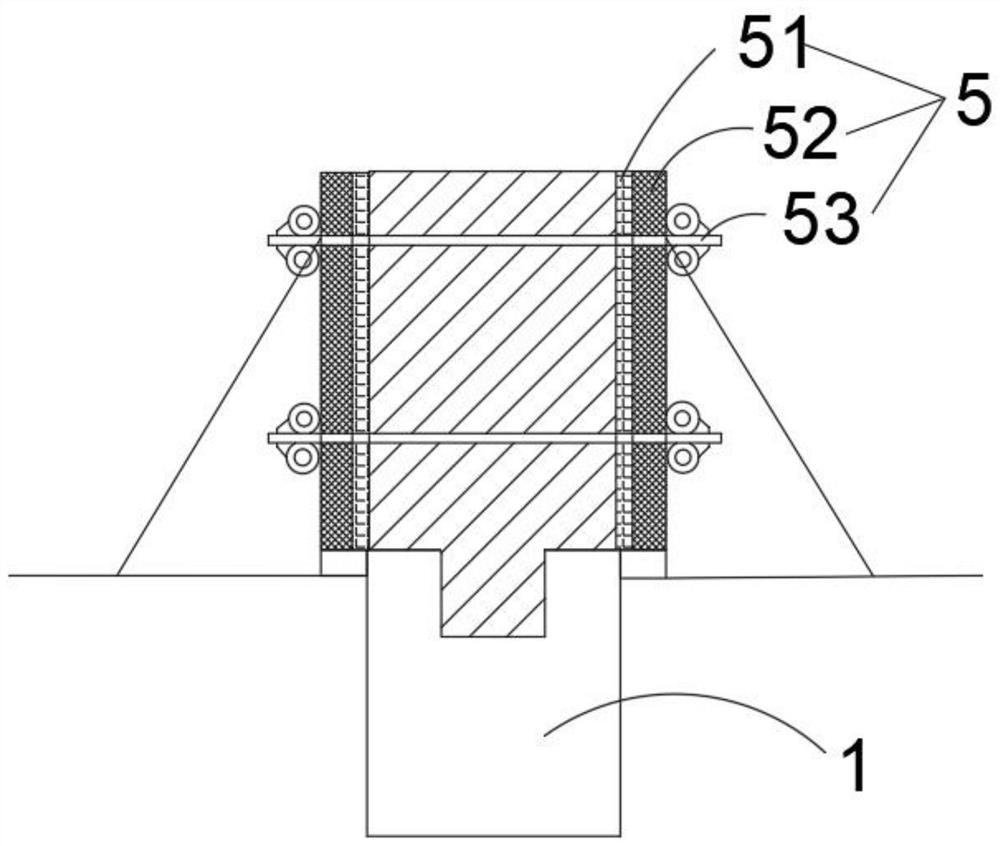

Novel sloping field constructional engineering pile construction method

A technology for construction engineering and construction methods, which is applied in construction, infrastructure engineering, sheet pile walls, etc., and can solve the problem of the quality pass rate of punching cast-in-place piles. The quality of the pile connection and the complex construction process of the punched cast-in-place pile foundation can achieve the effect of avoiding the overturning of the mechanical platform, avoiding environmental pollution and site occupation, and shortening the time for connecting up and down piles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Project Overview:

[0045] The construction area of the project is about 220195.22㎡, of which the 6-storey building area of B1 factory building is about 96354.5㎡; the 6-story building area of B2 factory building is about 93917.5㎡; ㎡; the construction area of the first floor of the S1 factory building is about 24462.04㎡; the construction area of the first basement and the first floor of the equipment room is about 2207㎡; the construction area of the first floor of the switch station is about 227.48㎡; ;

[0046] After adopting the new construction method of slope construction piles, the pile connection work can be carried out without earth backfilling, and the ground construction can be fully realized. The time for personnel to connect piles can be shortened by more than 75%. Compared with ordinary pipe piles, the pile connection time can be advanced The construction of the inserted pile project adopts a new construction method of slope construction engineeri...

Embodiment 2

[0052] Project Overview:

[0053] Building No. 5 of this project is 70.2m high, with 2 floors underground and 23 floors above ground, with a single-story building area of 563.64m 2 , with a total construction area of 13,000 m 2 , No. 6 residential building is 67.2m high, with 2 floors underground and 22 floors above ground, with a single floor area of 683.42m 2 , with a total construction area of 15,000 m 2 , Building No. 11 is a residential building with a height of 79.2m, 2 floors underground, 26 floors above ground, and a single-story building area of 789.2m 2 , with a total construction area of 20,500 m 2 , Building No. 12 is a residential building with a height of 9.10m, 0 floors underground, 2 floors above ground, and a single-story building area of 418.3m 2 , with a total construction area of 8,400 m 2 , Building No. 16 is 79.2m high, with 2 floors underground and 26 floors above ground, with a single-story building area of 794.04m 2 , with a tot...

Embodiment 3

[0060] Project Overview:

[0061] The total construction area of this project is 34302.7㎡, with a tower building of 22 floors, a podium building of 3 floors, and two underground floors. The height of the tower is 98.5 meters. The structural system of the tower is a shear wall structure, and the basement is a frame structure.

[0062] After adopting the new construction method of slope construction piles, the pile connection work can be carried out without earth backfilling, and the ground construction can be fully realized. The time for personnel to connect piles can be shortened by more than 75%. Compared with ordinary pipe piles, the pile connection time can be advanced The construction of the inserted pile project adopts a new construction method of slope construction engineering piles, and the benefits produced are as follows:

[0063] It takes an average of 4 days to construct a pile with punching cast-in-place piles, while the average construction period of a pile is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com