An industrial robot for gear processing

A technology of industrial robots and gears, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of low processing precision, low processing efficiency, inconvenient portability, etc., to increase the support area, improve stability, and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

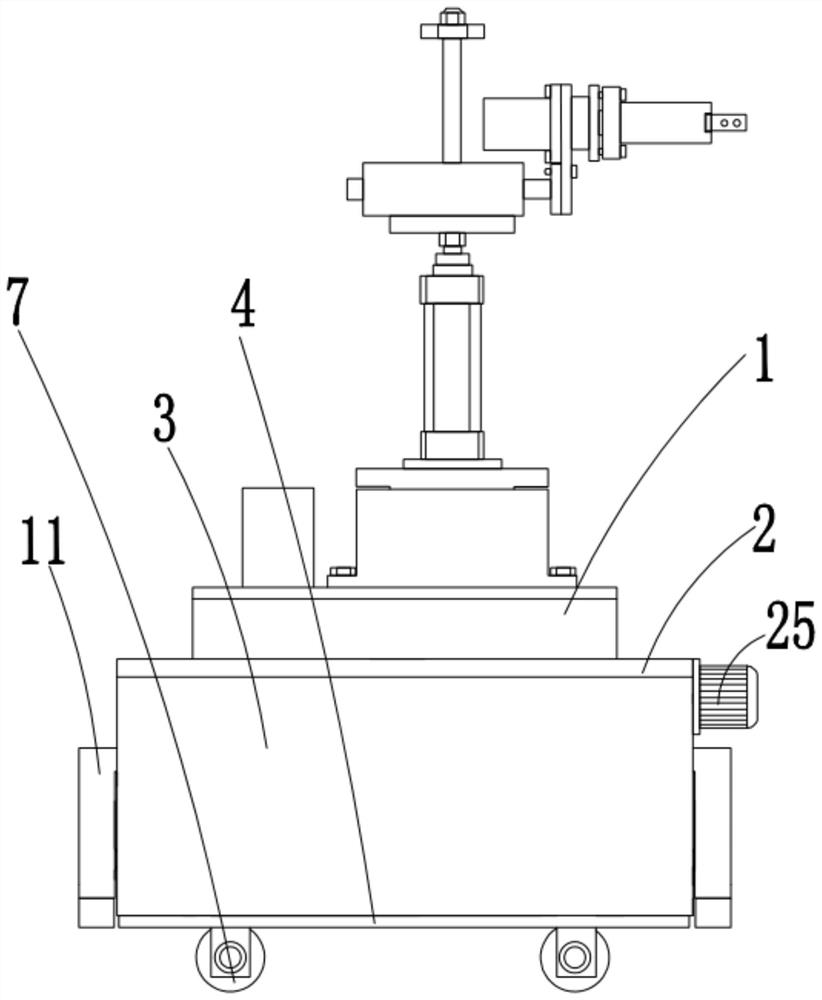

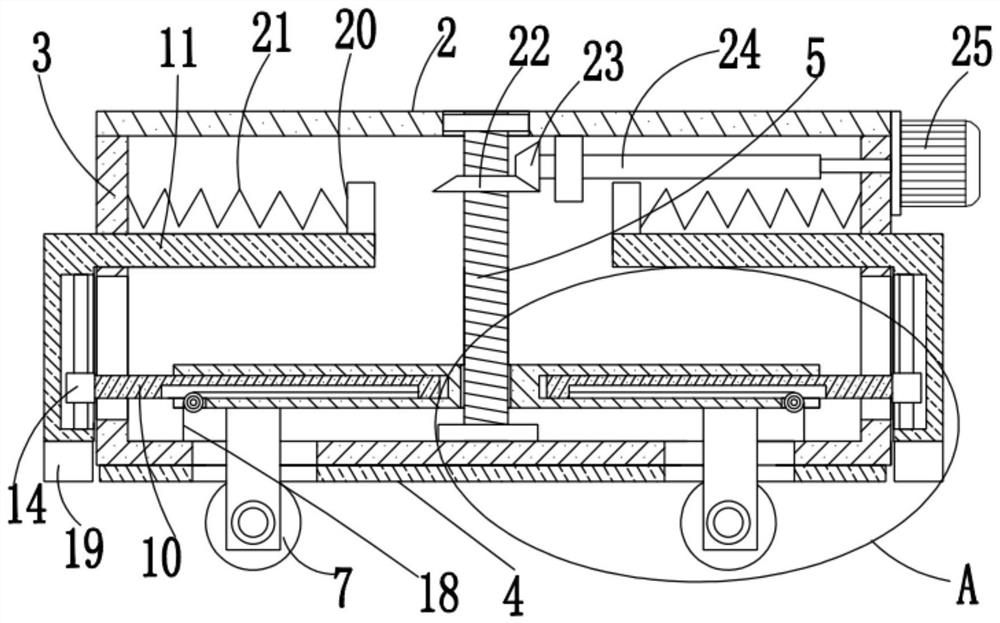

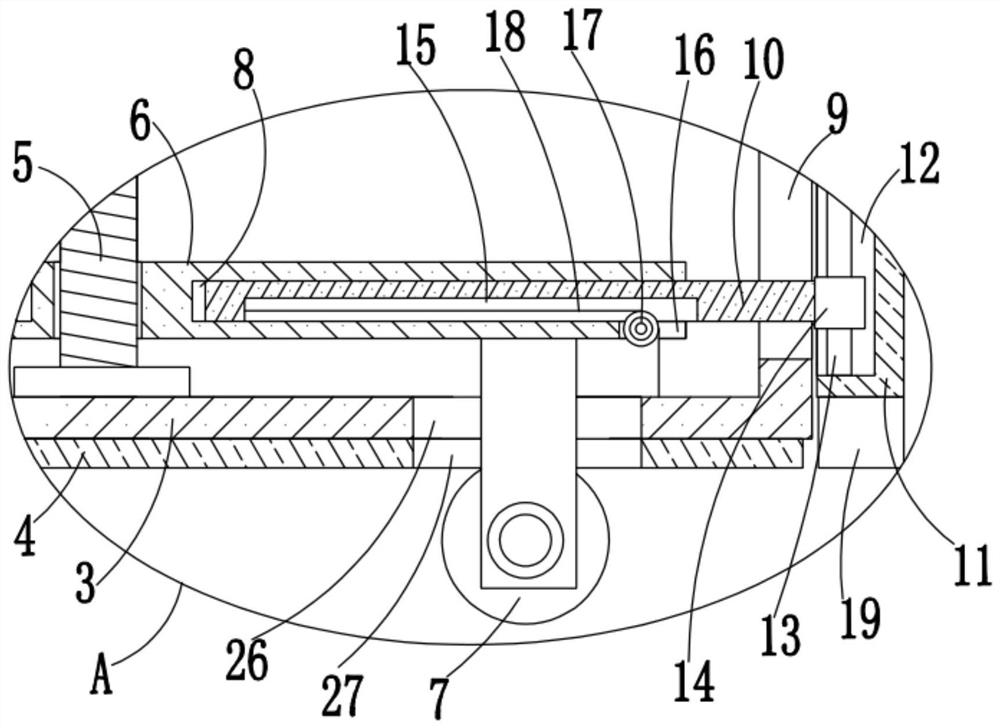

[0028] refer to Figure 1-5 , This embodiment proposes an industrial robot for gear processing, including an industrial robot main body 1, the bottom of the industrial robot main body 1 is provided with a roller synchronous storage mechanism and a horizontal expansion and stabilization mechanism matched with the roller synchronous storage mechanism, The roller synchronous storage mechanism includes a bottom plate 2 that is fixedly connected to the bottom of the main body 1 of the industrial robot, and the bottom of the bottom plate 2 is fixedly connected to a rectangular box 3 with an opening at the top. The bottom inner wall of 3 and the bottom of the bottom plate 2 are rotatably installed with the same screw 5, and the screw 5 is threadedly sleeved with a lifting plate 6. The bottom of the lifting plate 6 is rectangular and is rotated and installed with four walking wheels 7, and the The bottom extends to the bottom of the anti-skid rubber pad 4, the screw 5 is fixedly sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com