Production process of PTFE aramid fiber composite high-temperature-resistant needled filter bag

A production process, PTFE technology, applied in the production process of PTFE aramid fiber composite high temperature resistant needle punched filter bags, can solve the problems of baking, uneven heating, unfavorable control, etc., to reduce displacement, improve uniformity, avoid The effect of direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

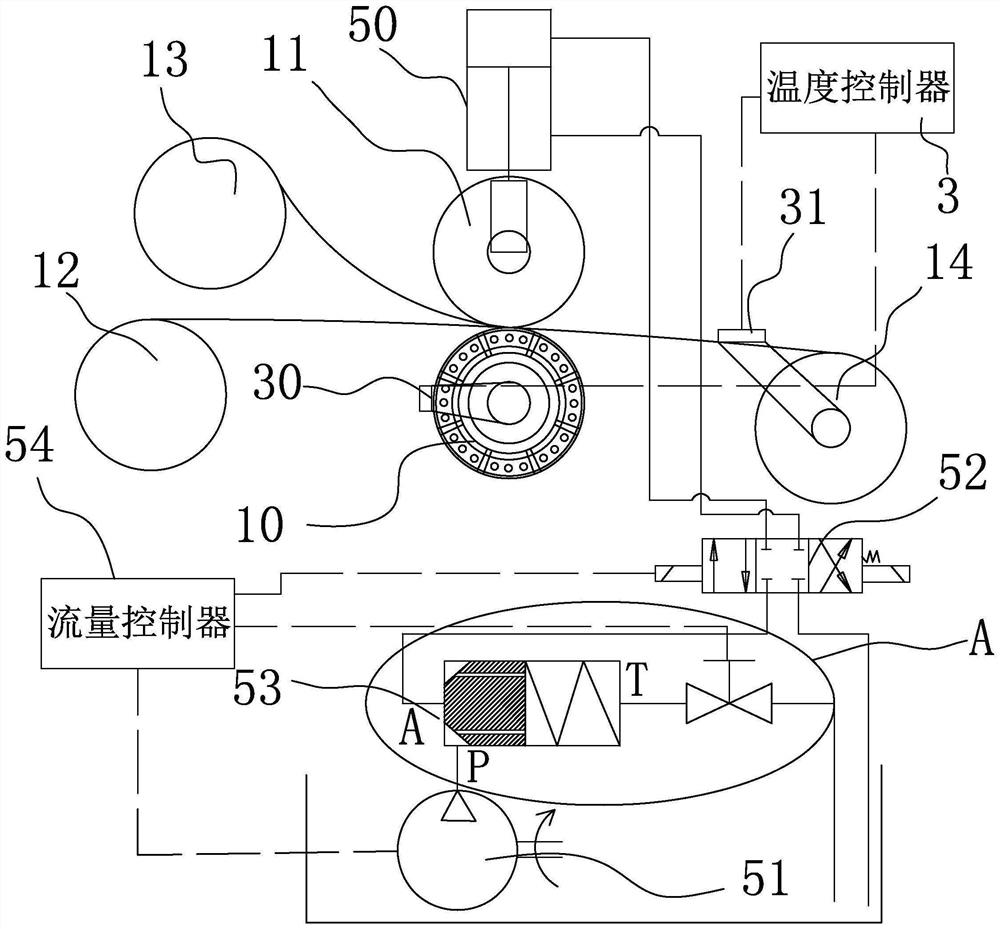

[0044] A production process for a PTFE-aramid fiber composite high-temperature-resistant acupuncture filter bag, comprising the following steps: S1, fiber proportioning, and mixing: selecting PTFE short fibers and aramid fibers, and the mixing ratio between the PTFE short fibers and the aramid fibers is: 50:50, mix PTFE short fiber and aramid fiber uniformly, and select PTFE filament base cloth as reinforcement base cloth;

[0045] S2. Opening: The mixed PTFE staple fibers and aramid fibers are fed to the needle opener through the conveying flat curtain, and the needle beater rotates at 200r / min for free opening;

[0046] S3. Carding and laying: the speed of the carding machine is 30m / min. The PTFE short fibers and aramid fiber webs made by the carding machine are laid on the surface of the reinforced base fabric according to the production process. The laying speed is 4m / min. The web feeding mechanism feeds the laid fiber web into the needling area;

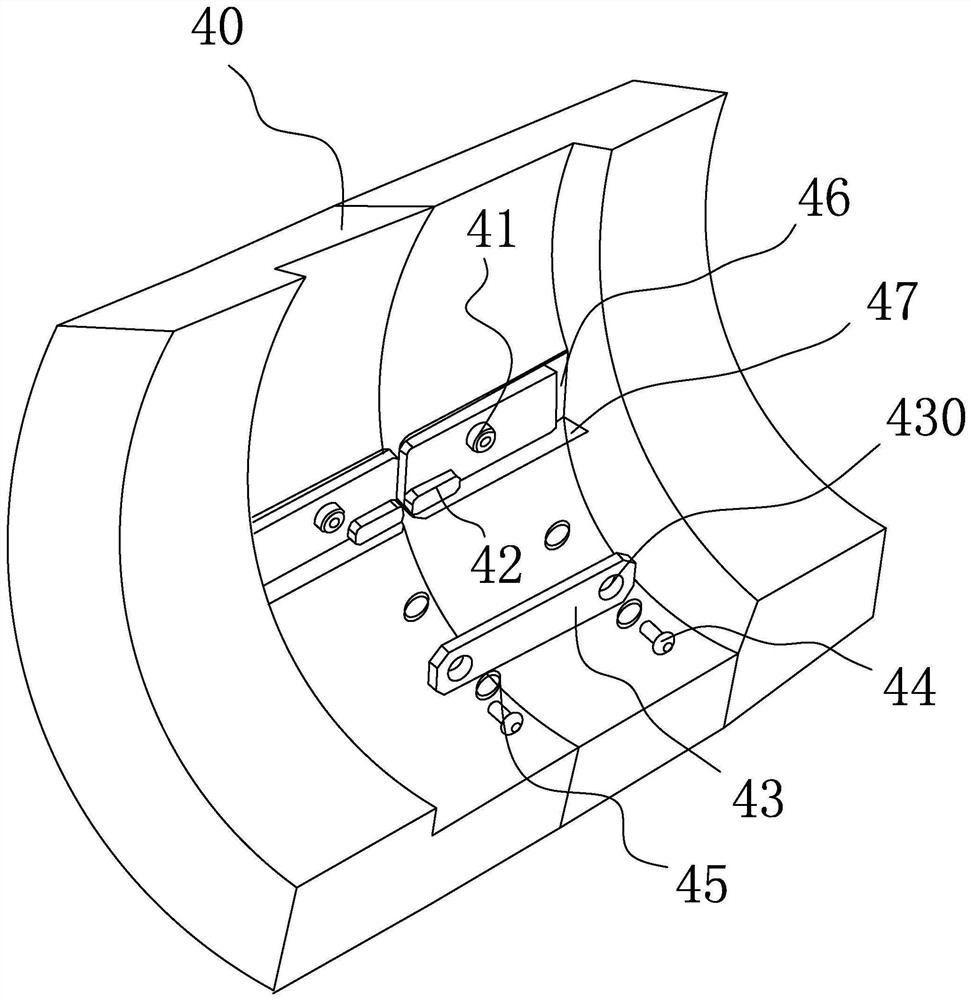

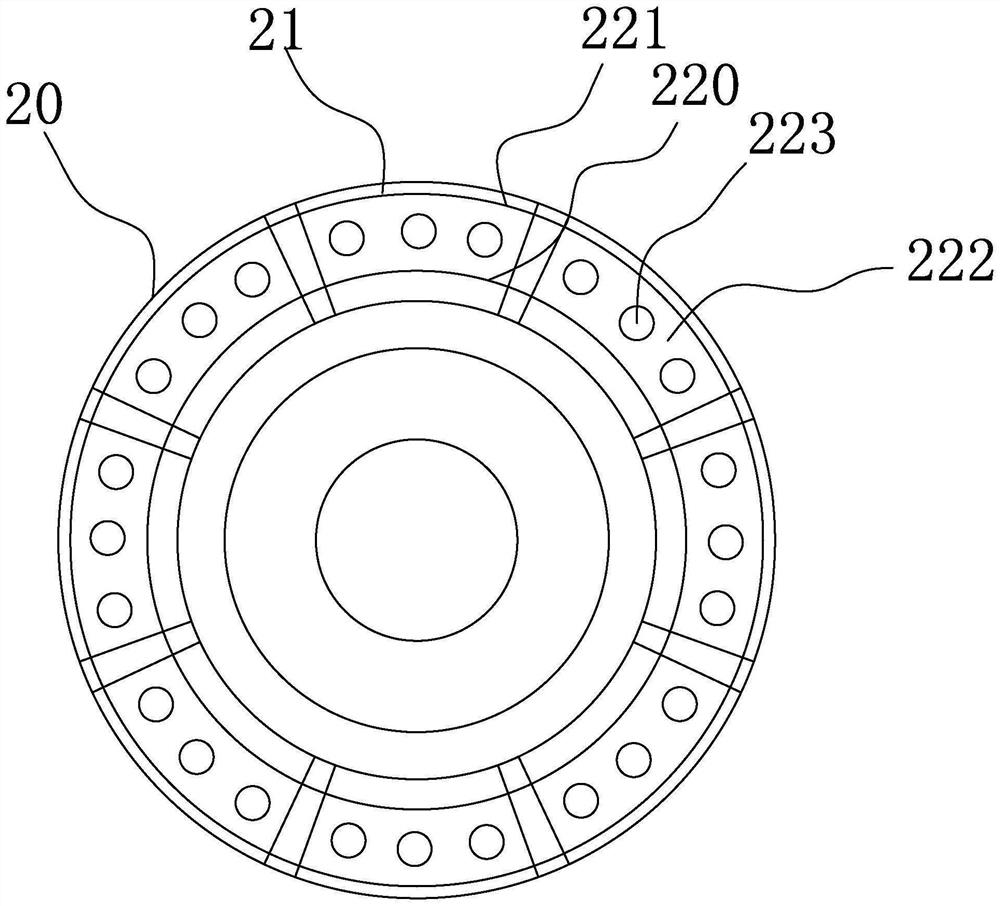

[0047] S4. Needling: Th...

Embodiment 2

[0071] The structure of this embodiment and the embodiment are basically the same, the only difference is that the flow regulator 53 in this embodiment includes two parts, the first part is the control valve 530, the second part is the on-off valve 531, the control valve 530 It includes a valve body 60 and a valve core 61 arranged in the valve body 60. The valve core 61 divides the inner cavity of the valve body 60 into an output cavity 601 and a return cavity 602. The valve core 61 includes a table-shaped portion 603 located in the output cavity 601 and Located on the plane portion 604 of the return chamber 602, the inclined surface area of the table portion 603 is smaller than that of the plane portion 604, the valve core 61 is provided with several through holes 605 connecting the output chamber 601 and the return chamber 602, and the valve body 60 is provided with a buffer spring 606 , one end of the buffer spring 606 is in conflict with the valve core 61 , and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com