Coating equipment applied to high-performance electricity-resistant coating of metal product

A technology for coating equipment and metal products, applied in the direction of spraying devices, etc., can solve the problems of no fixing of metal products, positional deviation of coated metal products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

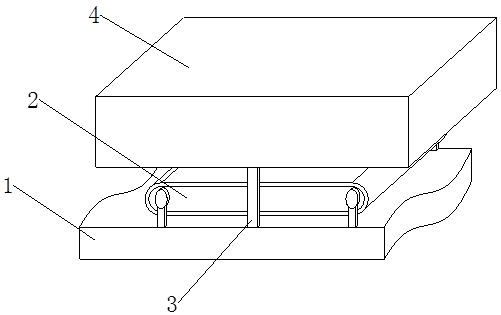

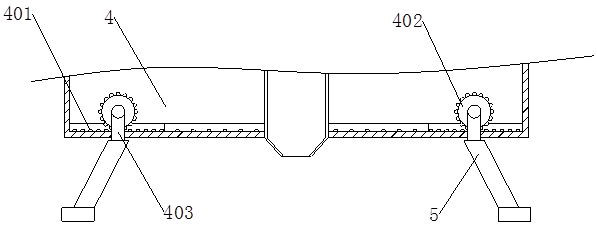

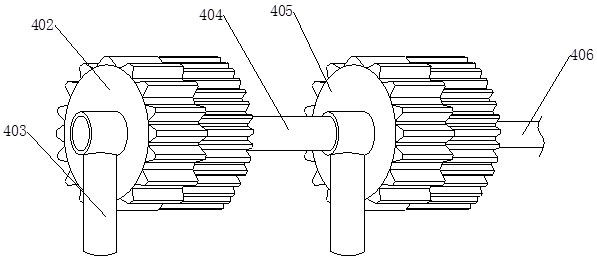

[0026] A high-performance resistive coating coating equipment applied to metal products, including a base 1, a conveyor belt 2 and a support column 3, the conveyor belt 2 is arranged above the base 1, and the base 1 is fixed on the front and rear sides of the conveyor belt 2 Connected to the support column 3, the end of the support column 3 away from the base 1 is provided with a fixed frame 4 that can be limited, and the inner bottom of the fixed frame 4 is provided with four slide rails 401, and the inside of the fixed frame 4 is located at the bottom of the slide rail 1 401. The side near the center is provided with slide rail three 409, slide rail one 401 and slide rail three 409 are staggered and connected front and back, the bottom ends of slide rail one 401 and slide rail three 409 are provided with tooth holes, and the inside of the fixed frame 4 is fixed A slide rail 2 408 is connected, and two slide blocks 407 are embedded inside the slide rail 2 408. The side of the ...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is that every two slide rails 401 are on the same plane and straight line.

[0034] Wherein: when the driven gear 402 and the driving gear 405 are moving along the slide rail one 401, the moving positions of the driven gear 402 and the driving gear 405 are the same, driving the fixed plate 5 to move, so that the fixed plate 5 is moving more convenient time.

[0035] The difference between the present embodiment and the first embodiment is that the surface of the moving plate 503 away from the moving rod 502 is uneven and is provided with a rubber layer.

[0036] Wherein: when the moving plate 503 is in contact with the metal product, increase the frictional force between the moving plate 503 and the metal product, so that when the metal product is fixed, it is more stable and reduces the displacement of the metal product during processing Phenomenon.

[0037] The difference between this embodiment and Embodiment 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com