Cable pulling assembly and method for preventing cable stretching

A technology for pulling components and cables, applied in the installation of cables, equipment for connecting/terminating cables, electrical components, etc., can solve the problems of displacement, easy stretching of cables, etc. hidden dangers, the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

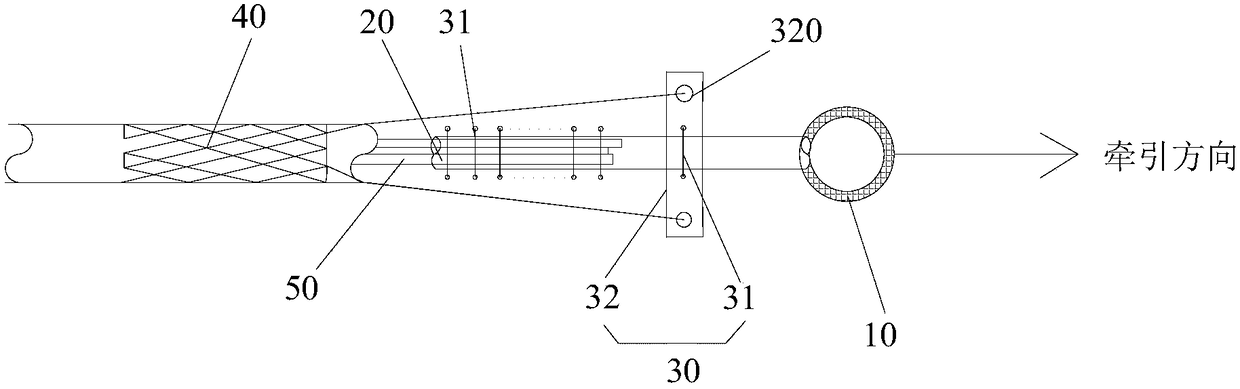

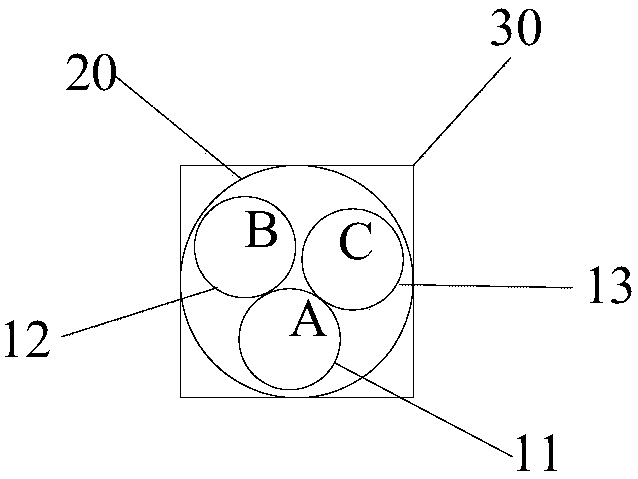

[0025] like figure 1 and figure 2 As shown, according to a specific embodiment of the invention, a cable is provided, and the cable pulling assembly includes a pulling part 10 and a tube body part 20 . One end of the tube body part 20 is connected to the traction part 10, and the other end of the tube body part 20 is arranged on the wire part 50 to prevent the wire part 50 from being stretched during laying.

[0026] In this embodiment, since the tube body portion 20 is provided on the wire portion 50, the tube body portion 20 and the wire portion 50 are simultaneously subjected to the traction force during the traction process of the wire portion 50. Since the tube body portion 20 is added,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com