Workpiece fixture

A technology for fixing devices and workpieces, which is used in positioning devices, metal processing machinery parts, metal processing equipment, etc., and can solve the problems of inclined machining surface angle, fixture pressure deviation, different concentric angles, etc., and achieve reliable position setting. The effect of fixing and fixing, minimizing centrifugal force deviation, and reducing displacement phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Next, specific structures and effects of the present invention will be described based on the embodiments shown in the drawings.

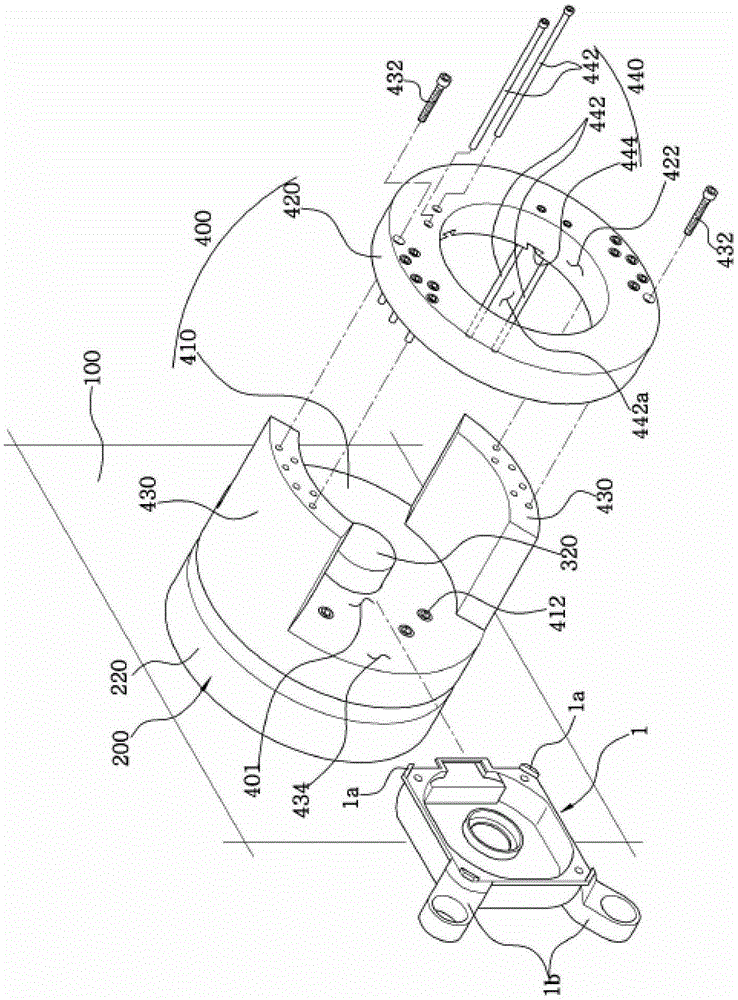

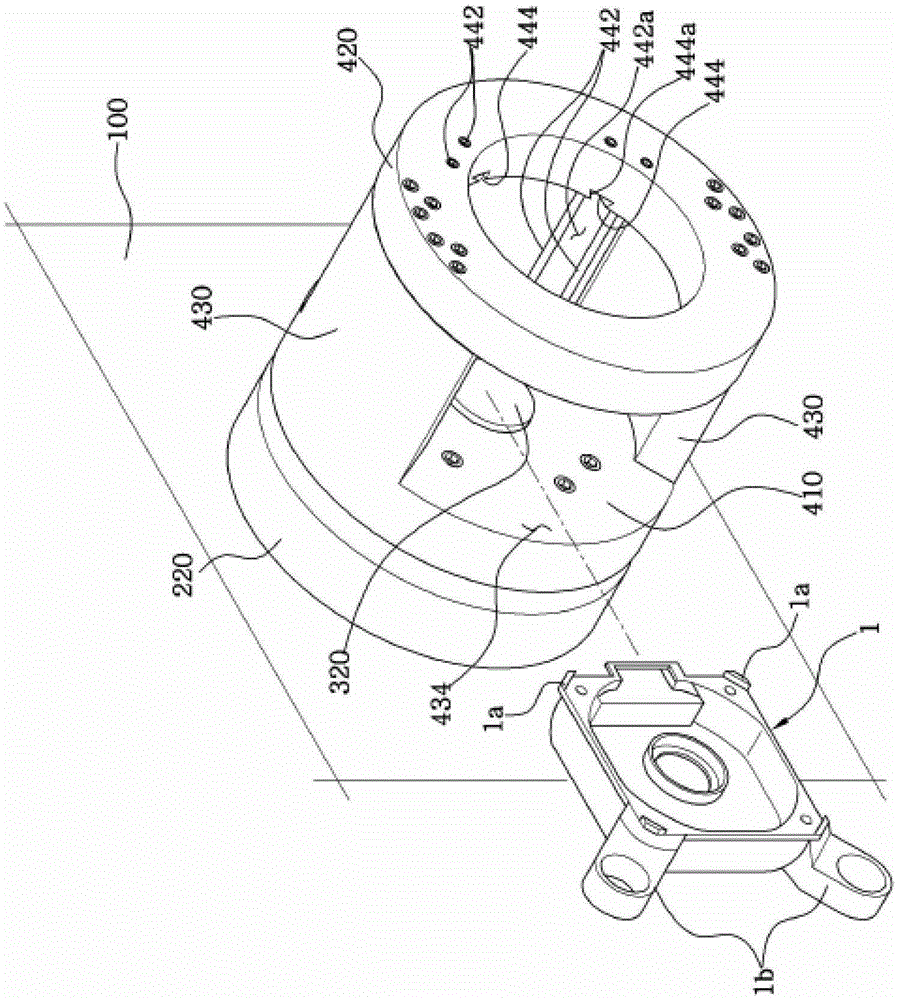

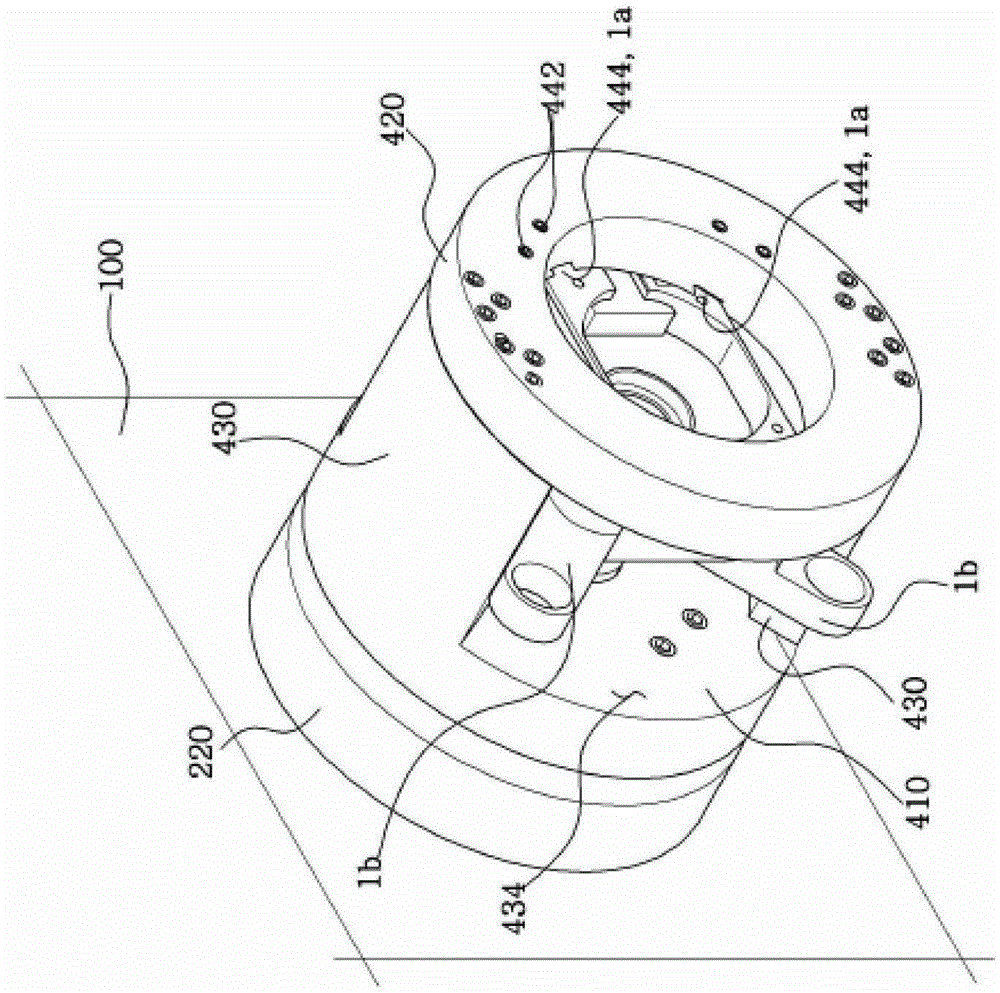

[0036] Such as Figure 1 to Figure 4 As shown, the workpiece fixing device of the present invention generally includes a main body 100 , a rotation driving part 200 , a pressing part 300 and a position setting part 400 .

[0037] Firstly, the main body 100 functions as a shell and a skeleton of the workpiece fixing device, and is configured with a structure suitable for lathe equipment or milling equipment according to the type of processing.

[0038] Therefore, in the drawings of this embodiment, the structure of the main body 100 is not detailed but shown in a simple schematic diagram.

[0039] Such a main body 100 is provided with a rotation drive unit 200 .

[0040] The rotation drive unit 200 includes a rotation motor 210 and a rotation shaft 220 , and rotates a position setting unit 400 described later to rotate the workpiece 1 set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com