Cloth cutting device for garment processing

A cutting device and cloth technology, which is applied in the field of clothing processing, can solve the problems of non-compliance with energy-saving and emission-reduction guidelines, easy displacement of cloth, and reduced cutting accuracy, so as to achieve fast and flexible cloth cutting, reduce wrinkles, and improve precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further illustrated by the following examples.

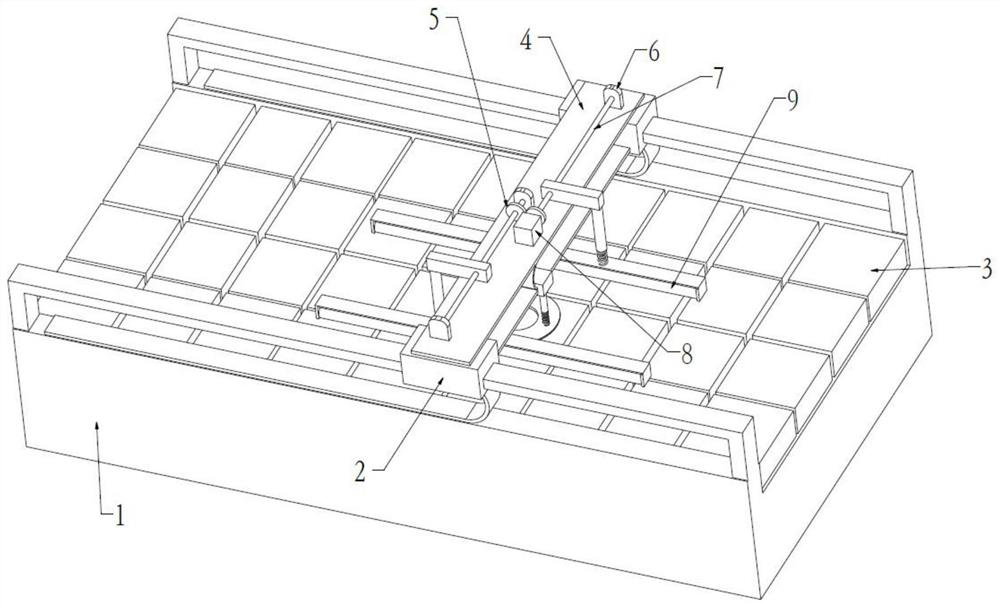

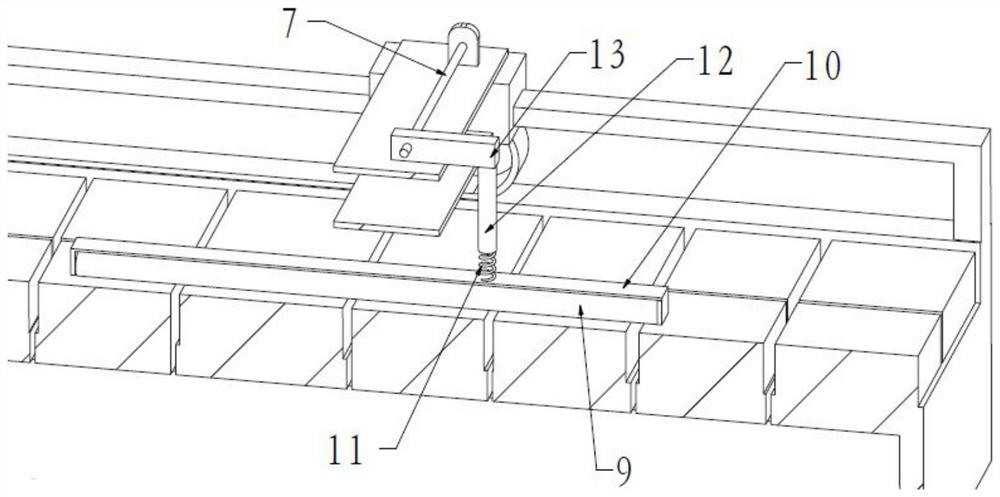

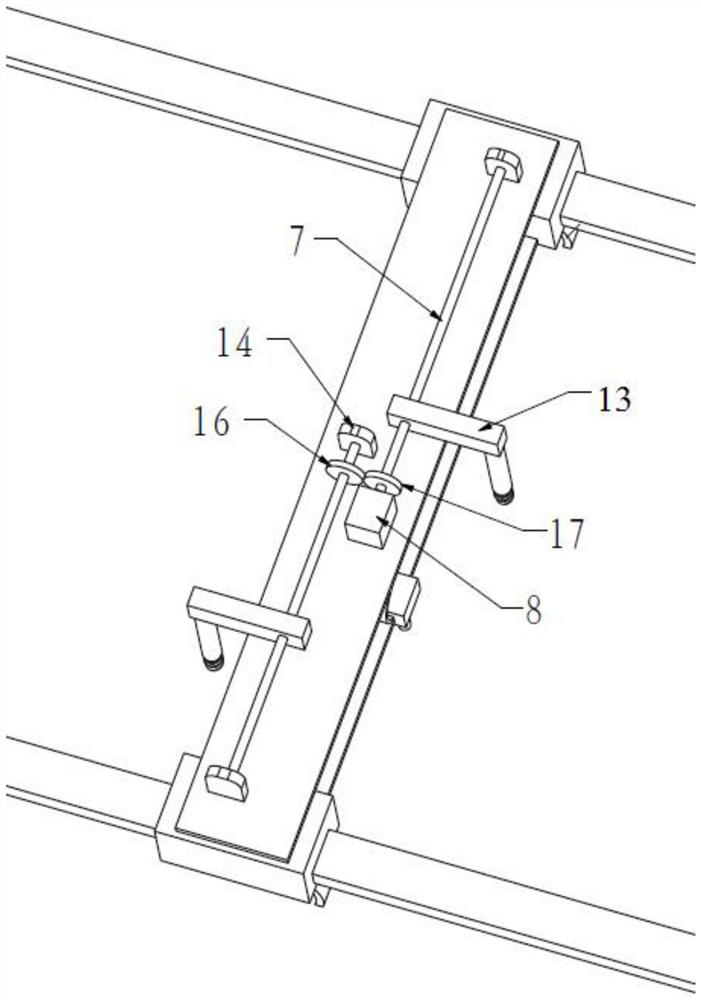

[0027] A cloth cutting device for garment processing, comprising a workbench 1, on which bristle bricks 3 are laid in an array, the workbench 1 is provided with a vacuuming through hole 25, and the vacuuming through hole 25 is connected with a vacuum branch pipe 26 , the vacuum branch pipe 26 is connected to the vacuum tube 22, and the vacuum tube 22 is connected to the vacuum pump; a telescopic cutter 20 is movable above the workbench 1, and the telescopic cutter 20 is driven by a linear motor assembly to move, and the outer ring of the telescopic cutter 20 A pressing member 18 that moves synchronously is provided, and a pressing roller 9 is movable on both sides of the telescopic cutter 20, and the pressing roller 9 is driven to be displaced by a screw drive assembly.

[0028] preferred, please refer to figure 1 , 2 , 4, the linear motor assembly includes a first linear motor 2 and a second li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com