Ink color-separation device used for printing and using method thereof

An ink and color separation technology, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of printing color separation devices, such as publicity, randomness, waste of ink human resources, etc., to facilitate management and maintenance, and overcome The effect of movable partitions and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

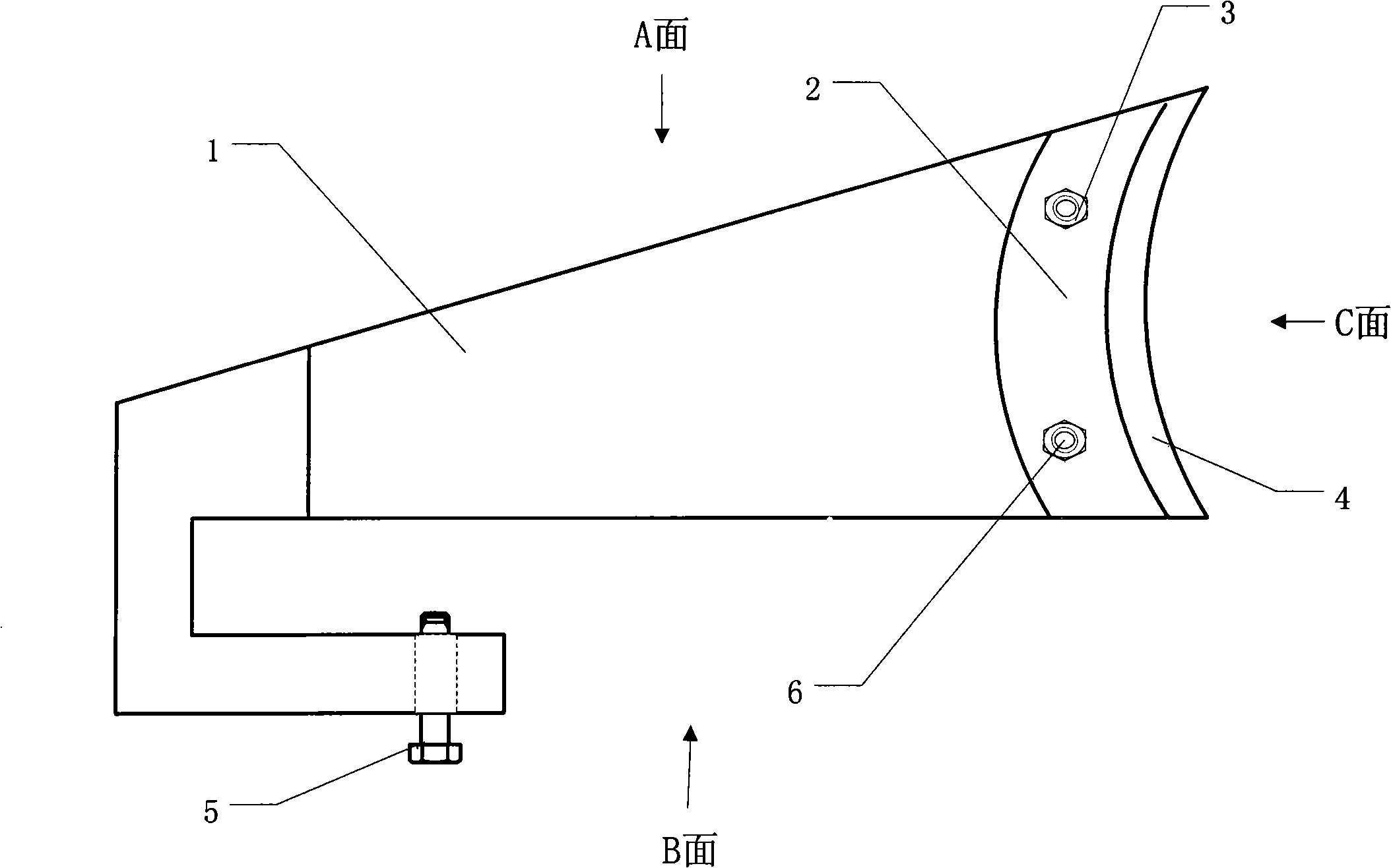

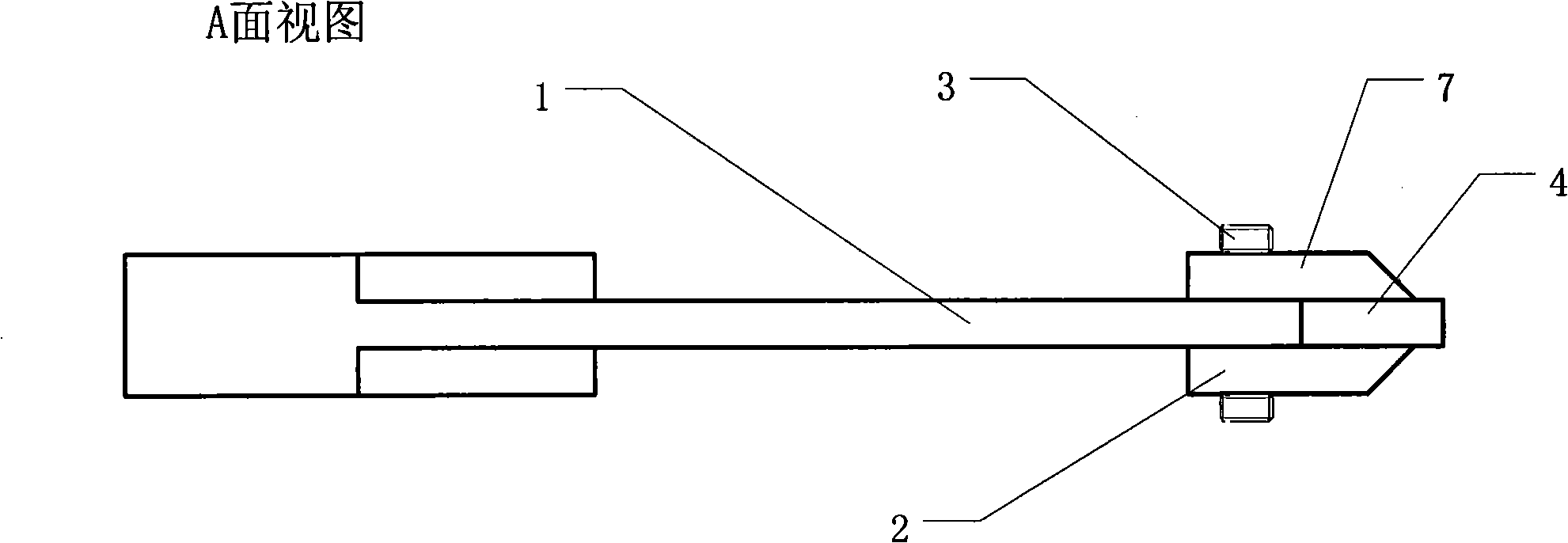

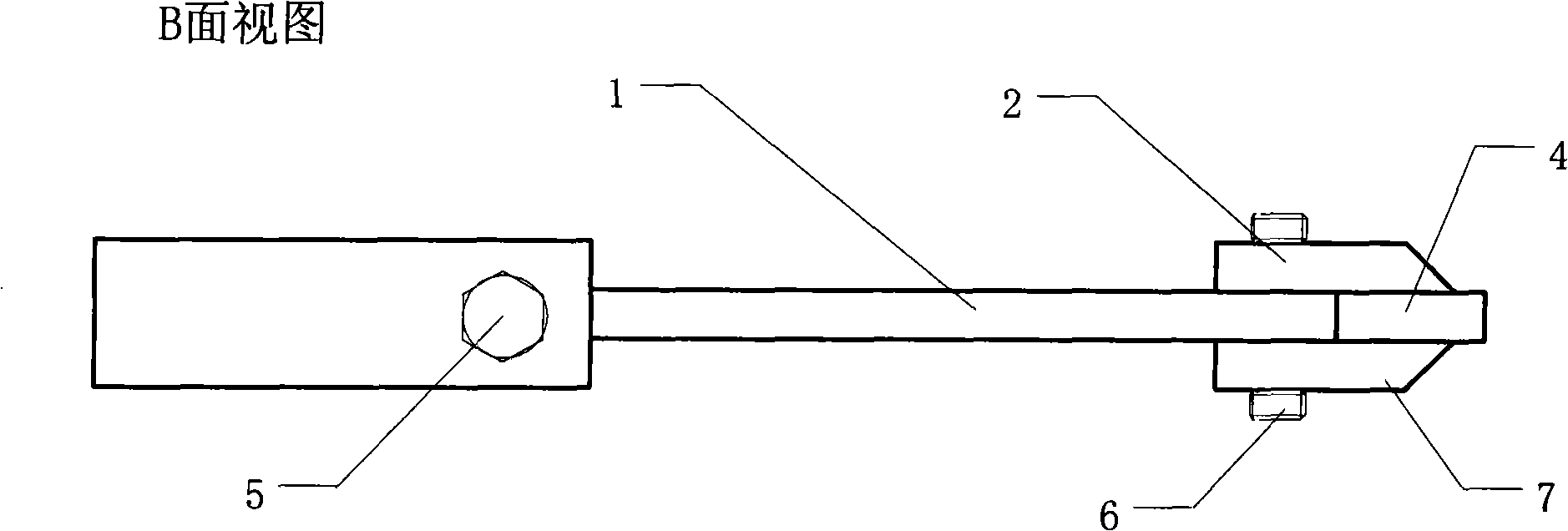

[0017] Below in conjunction with accompanying drawing, the present invention will be further described.

[0018] as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 And attached Figure 5 As shown, an ink color separation device for printing includes a clip type ink separation plate (1), a curved protective plate (4), a fixed connection mechanism (2, 7), and an installation positioning mechanism (5) , wherein, the arc-shaped protective plate (4) is connected with the clip-type ink separation plate (1) through the fixed connection mechanism (2, 7), and the installation and positioning mechanism (5) is used to place the The clip type ink separation plate (1) is arranged at a suitable position on the ink tank bottom plate (9).

[0019] In the ink color separation device used in the above printing, the clip type ink separation plate (1) is an ink separation plate with a rectangular bayonet opening on one side that is compatible with the ink tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com