Test piece fixture for Helmholtz coil testing

A technology of Helmholtz coils and fixing fixtures, which is applied to the parts of electrical measuring instruments, measuring devices, and measuring electrical variables, etc., can solve the problem that it is difficult to ensure that the cuboid stage is placed horizontally, it is difficult to modify its size, and the measured To solve problems such as unstable components, achieve the effects of reasonable design, reduced scratches, and precise position fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

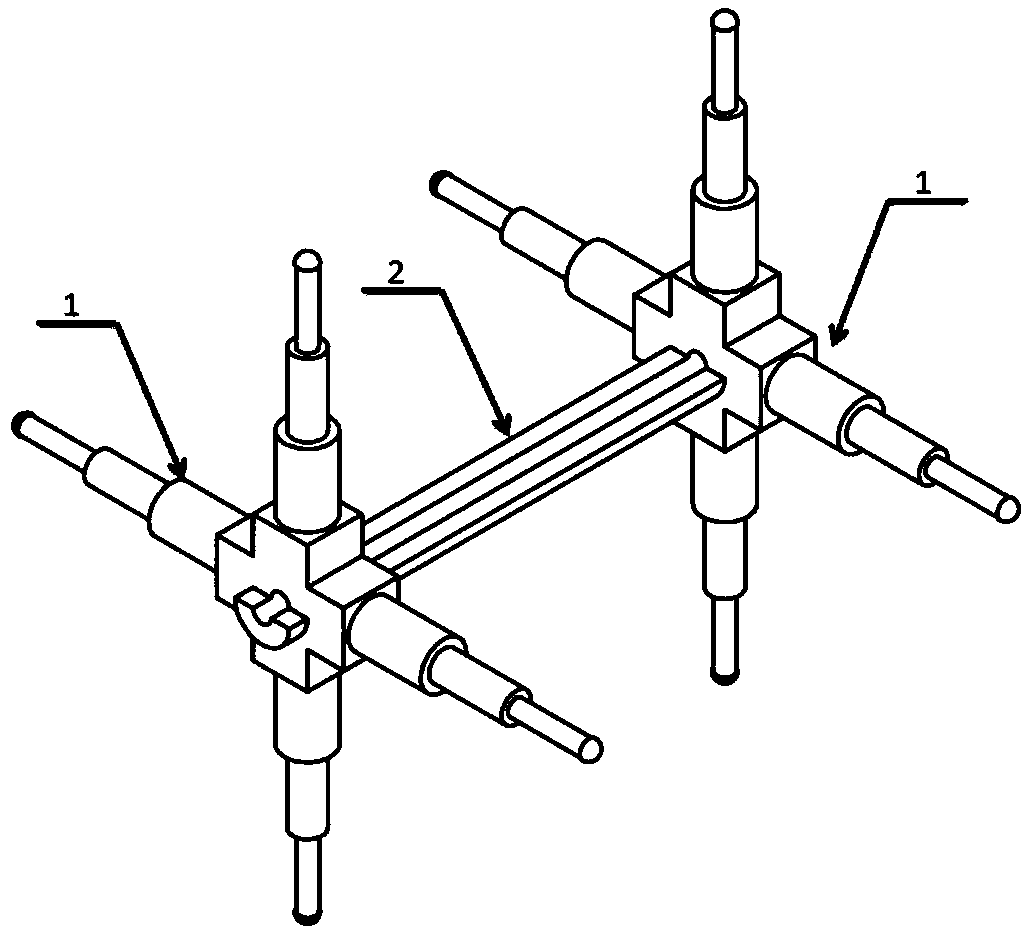

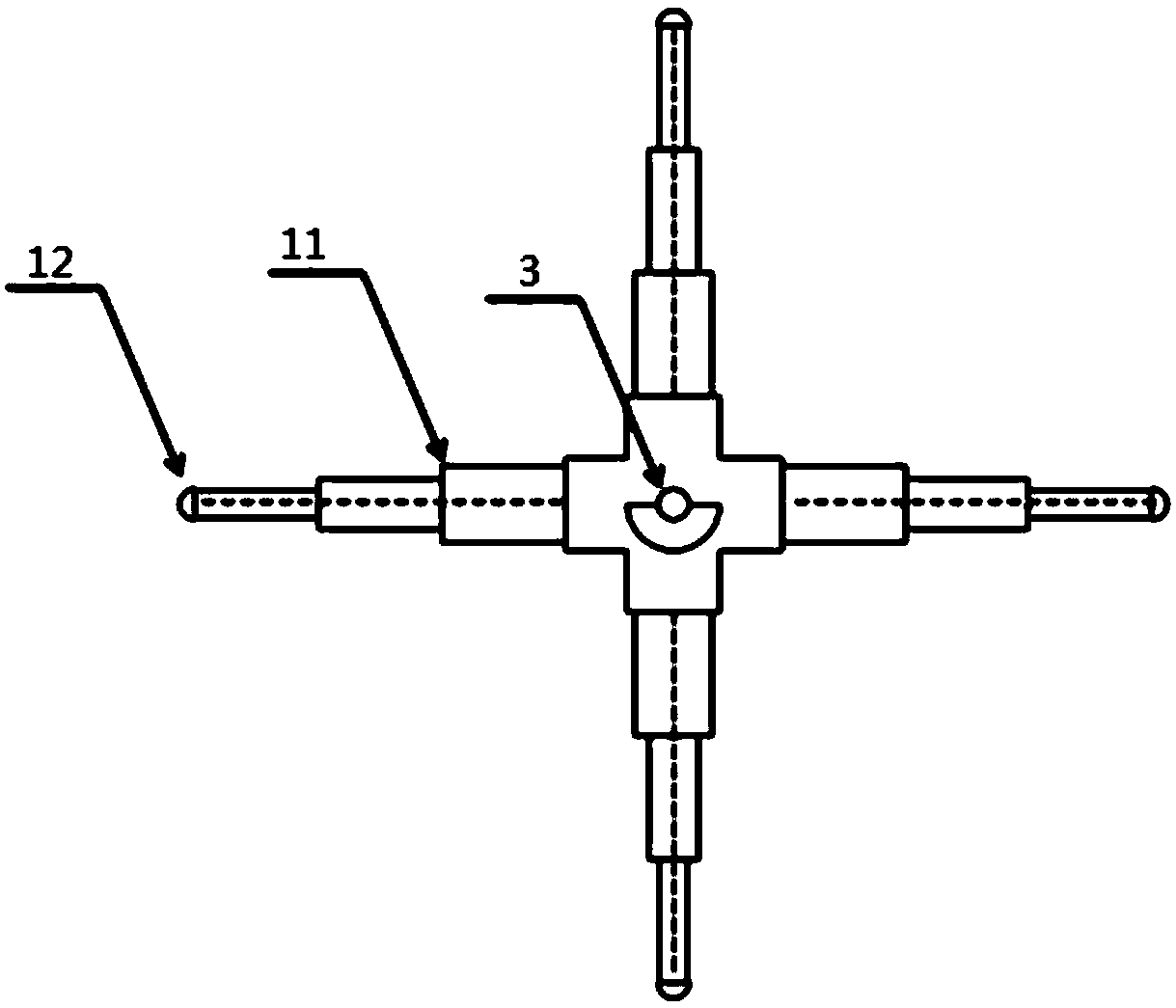

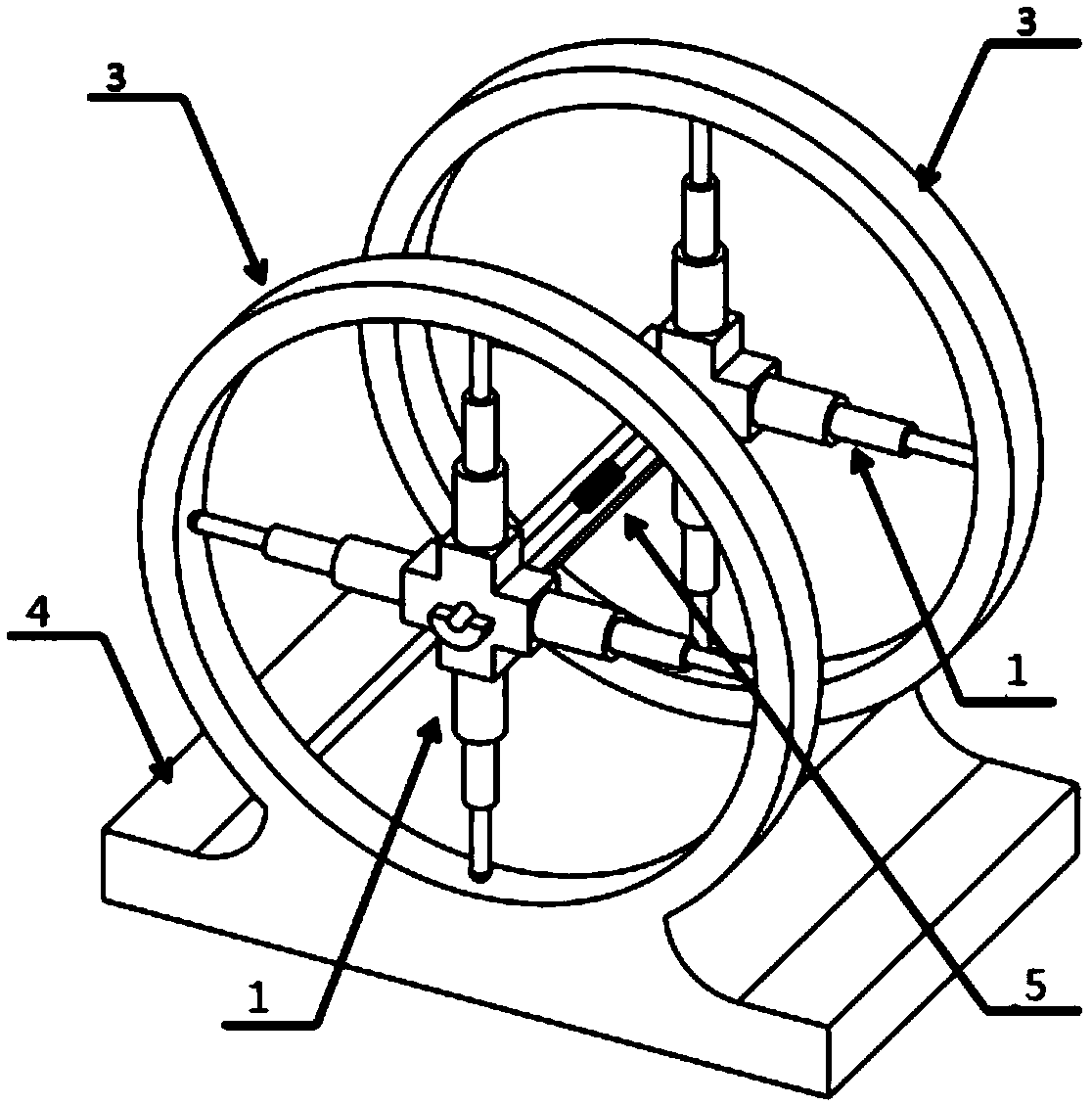

[0027] see figure 1 , the Helmholtz coil test fixture of this embodiment is composed of a slotted central shaft rod 2 and two cross-shaped connecting rods 1 . The lengths of the four poles of the two cross-shaped connecting rods 1 are equal, and the two connecting rods 1 are respectively fixed in the two coils of the Helmholtz coil, so as to ensure that the central axis rod 2 is located in the two coils of the Helmholtz coil. on the axis of each coil, and the axis of the central axis coincides with the axis of the coil. Therefore, it can be ensured that the center of the central shaft 2 is located in the area with the best uniform magnetic field of the Helmholtz coil, and the test piece used in the experiment is placed in the slot of the central shaft 2, that is, the test piece is completed. Permanent job.

[0028] The cross-shaped connecting rod 1 used in the fixture of this embodiment determines the center of a single Helmholtz coil through four equal-length struts, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com