Rear silencer assembly welding fixture of automobile exhaust system

A technology of automobile exhaust system and welding fixture, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unusable processing products, substandard accuracy, low efficiency, etc. demand, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only a part of the embodiments of the present invention, not all of them.

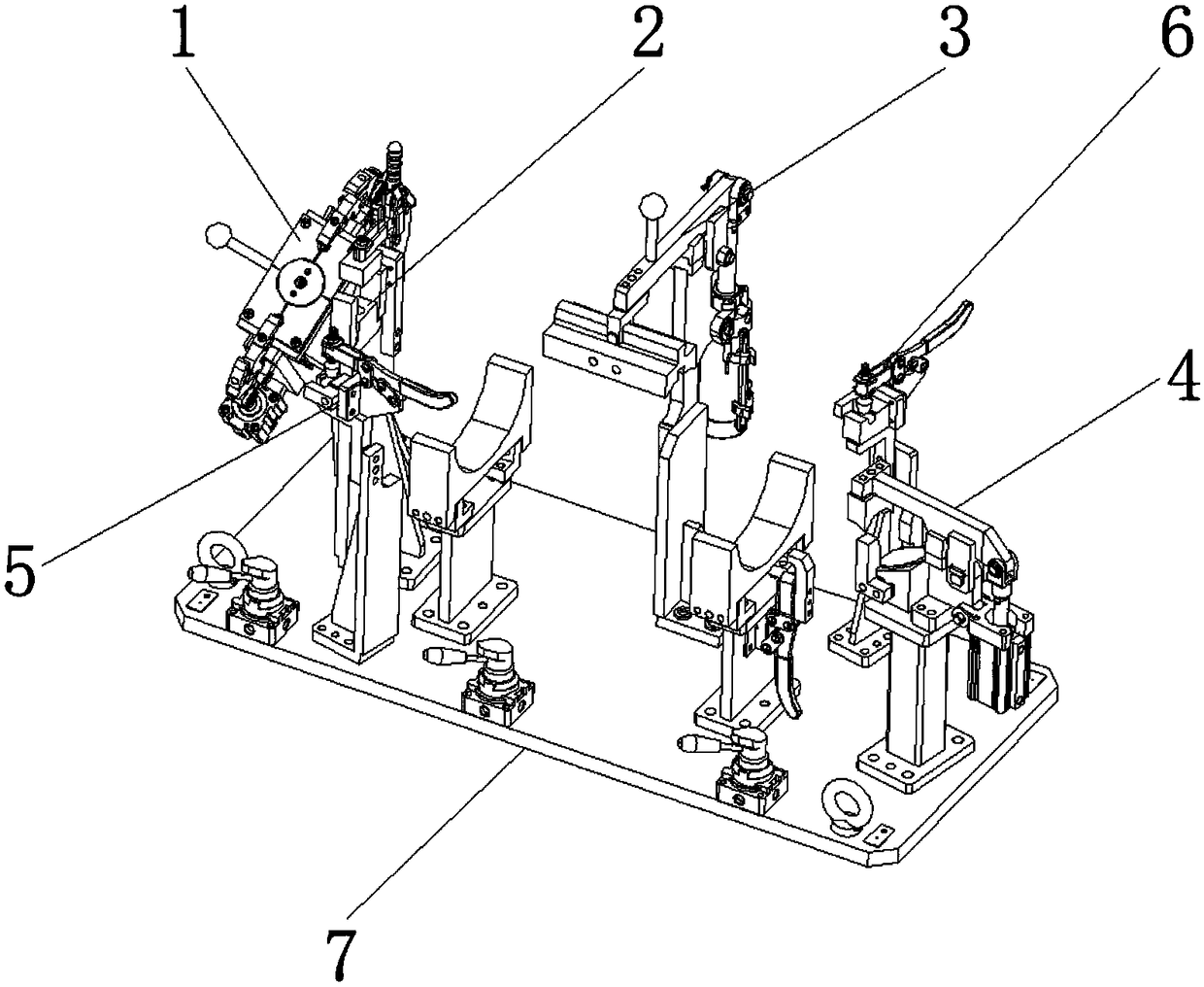

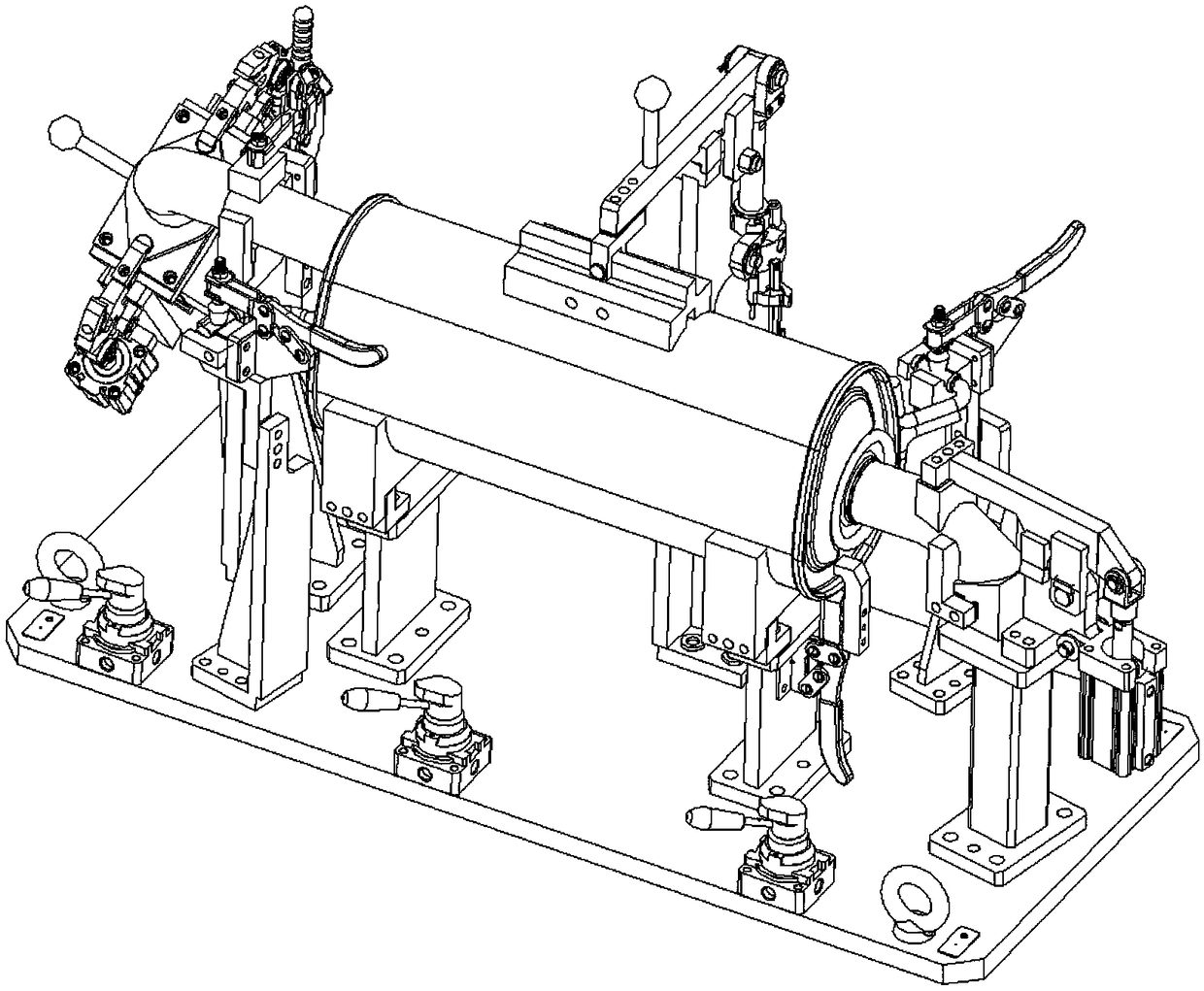

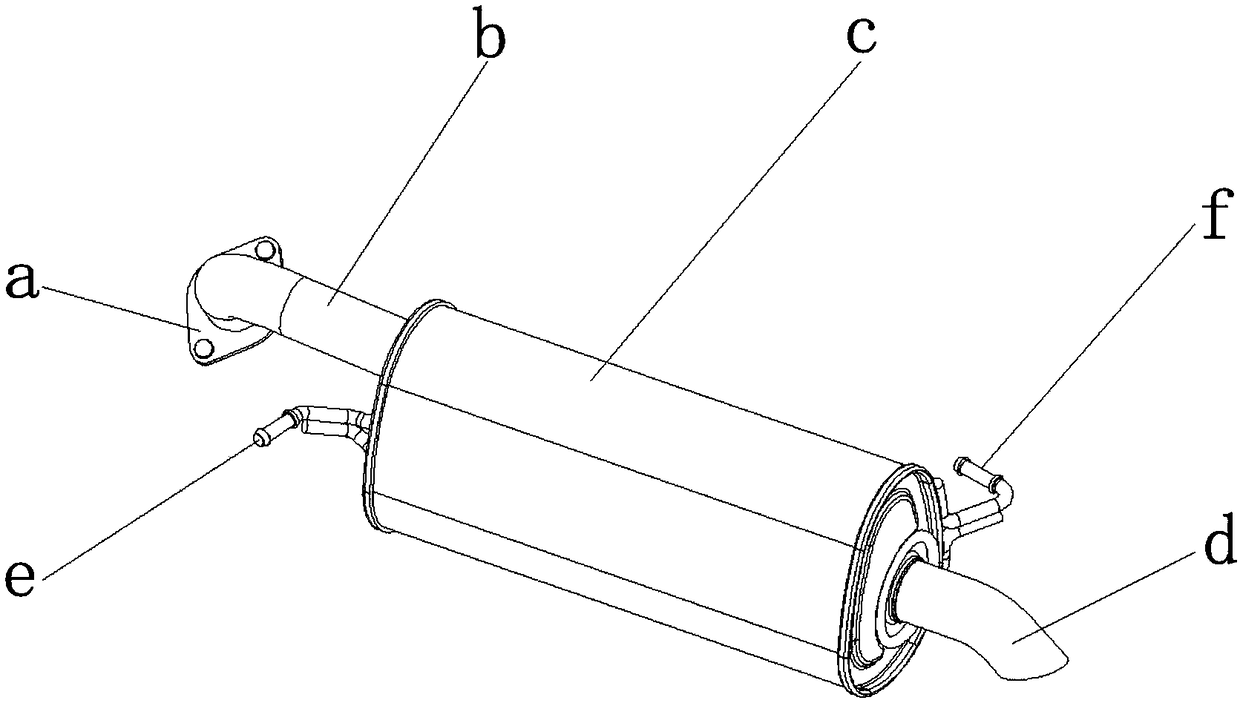

[0028] refer to Figure 1-9 , a welding jig for a rear exhaust assembly of an automobile exhaust system, comprising a flange positioning device 1 for accurately positioning and effectively fixing a flange a, an intake pipe positioning device 2 for accurately positioning and effectively fixing an intake pipe b, The muffler positioning device 3 for accurately positioning and effectively fixing the muffler c, the exhaust pipe positioning device 4 for accurately positioning and effectively fixing the exhaust pipe d, the first first rear muffler hook e for accurately positioning and effectively fixing The hook positioning device 5 and the second hook positioning device 6 for accurately positioning and ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com