Vacuum pump with integrated cam shaft

A camshaft and integrated technology, applied in the direction of rotary piston pumps, pumps, pump components, etc., can solve the problems of cumbersome assembly, affecting the accuracy of coaxiality, and affecting the service life of blades, etc., and achieve a simple overall structure and high coaxiality. High precision and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

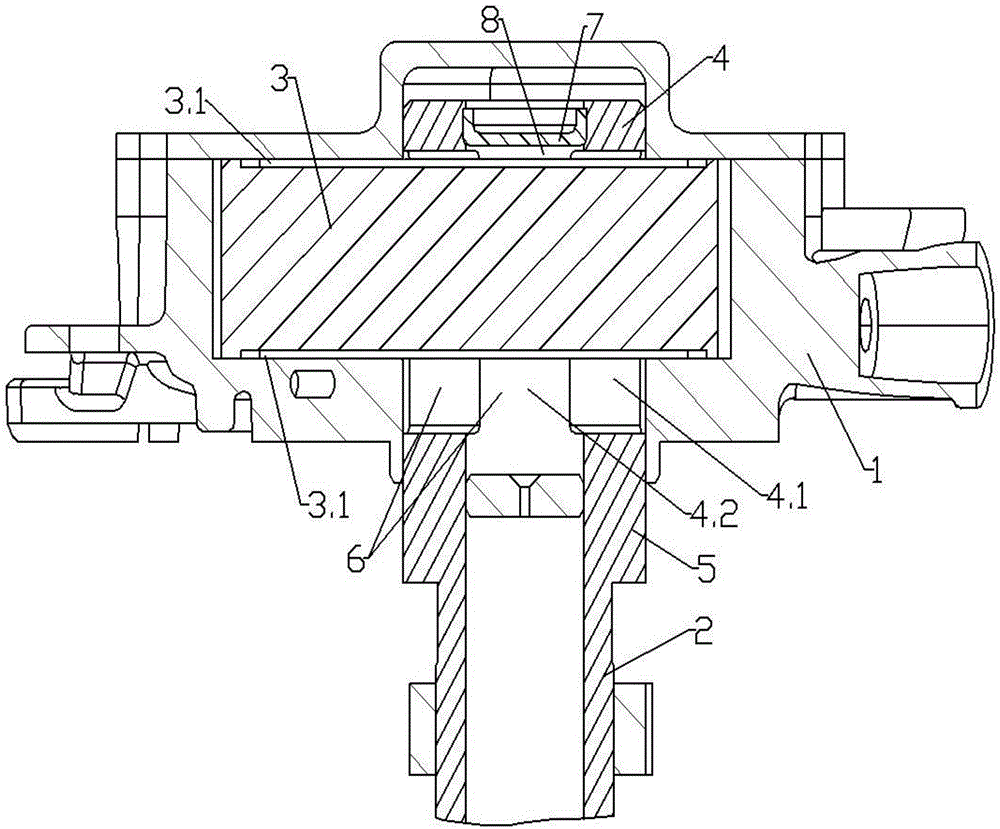

[0014] As shown in the figure, the camshaft integrated vacuum pump of the present invention includes a pump body 1 , a camshaft 2 , vanes 3 , and a rotor 4 installed in the inner chamber of the pump body 1 .

[0015] Different from the prior art, the lower end of the rotor 4 is formed with a connecting section 5 and the rotor 4 is integrated with the camshaft 2 through the connecting section 5 . After the integrated structure, it becomes a part, which saves the assembly process of each part, and at the same time, the coaxiality can also be effectively guaranteed.

[0016] The rotor 4 is provided with a radial installation hole 4.1, the shape and size of the installation hole 4.1 match the shape and size of the blade. In this embodiment, because the blade is rectangular, the installation hole 4.1 is also rectangular. The vane 3 is installed in the installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com