Polycrystalline diamond drilling and reaming integrated cutter and machining method

A polycrystalline diamond and cutting tool technology, which is applied in metal processing equipment, cutting tools for lathes, manufacturing tools, etc., can solve the problem that the precision affects the service life of carbon fiber composite materials, affects the working performance of carbon fiber composite materials, and the coaxiality of holes is affected Limit installation accuracy and other issues to achieve the effect of low cost, improved life, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

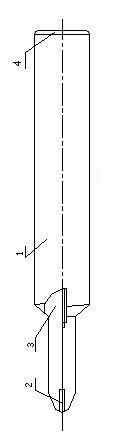

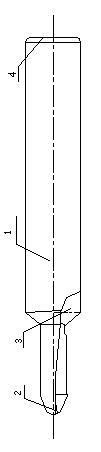

[0026] A kind of polycrystalline diamond drilling and spot-sinking integrated cutter, its composition comprises: cutter base 1, described cutter base 1 has drilling end 2, spot-sinking end 3 and clamping end 4 in turn, forms stepped straight groove structure, described The drilling end 2 is welded with a group of polycrystalline diamond PCD drilling end compound blades 5, and the spot facing end 3 is welded with a group of polycrystalline diamond PCD spot facing end compound blades 6.

Embodiment 2

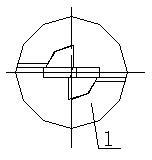

[0028] The polycrystalline diamond drilling and countersinking integrated tool described in Example 1, the drilling end 2 of the tool substrate is welded with a front polycrystalline diamond PCD composite blade 7 and a reverse polycrystalline diamond PCD composite blade 8, and the front polycrystalline diamond PCD composite blade 8 is welded. The diamond PCD composite blade 7 and the reverse polycrystalline diamond PCD composite blade 8 all have cutting edges, and the drilled end has a drill tip, and the drill tip is an apex cutting edge 9, a drill tip cutting edge 10 and a burr in sequence cutting edge11.

Embodiment 3

[0030] A method for processing a polycrystalline diamond drill and countersink integrated tool. The structure of this product is a stepped straight groove structure. The chips of the carbon fiber composite material are in the form of powder. The hole end is welded with a polycrystalline diamond PCD composite blade. The cutting edge is the first polycrystalline diamond PCD composite blade and the second polycrystalline diamond PCD composite blade is a PCD composite blade with two sides aligned. The cutting edge is made of a large top Angle cutting edge, drill tip cutting edge and burr cutting edge are composed of three parts. The large apex angle cutting edge makes the apex angle 2Φ larger to ensure that the drill tip has sufficient strength. Cut off more fiber filaments, the cutting edge of the burr cutting edge can cut off the burr at the exit hole of the carbon fiber composite material; the PCD composite blade is welded at the tool step to be the spot facing end, and the coni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com