Back air filling device of tire

An inflatable device and tire technology, applied in tires, transportation and packaging, vehicle maintenance, etc., can solve the problems of tire shaping accuracy, poor coaxiality, and easy deformation of tires, and achieve simple structure, low cost, and coaxiality. High precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

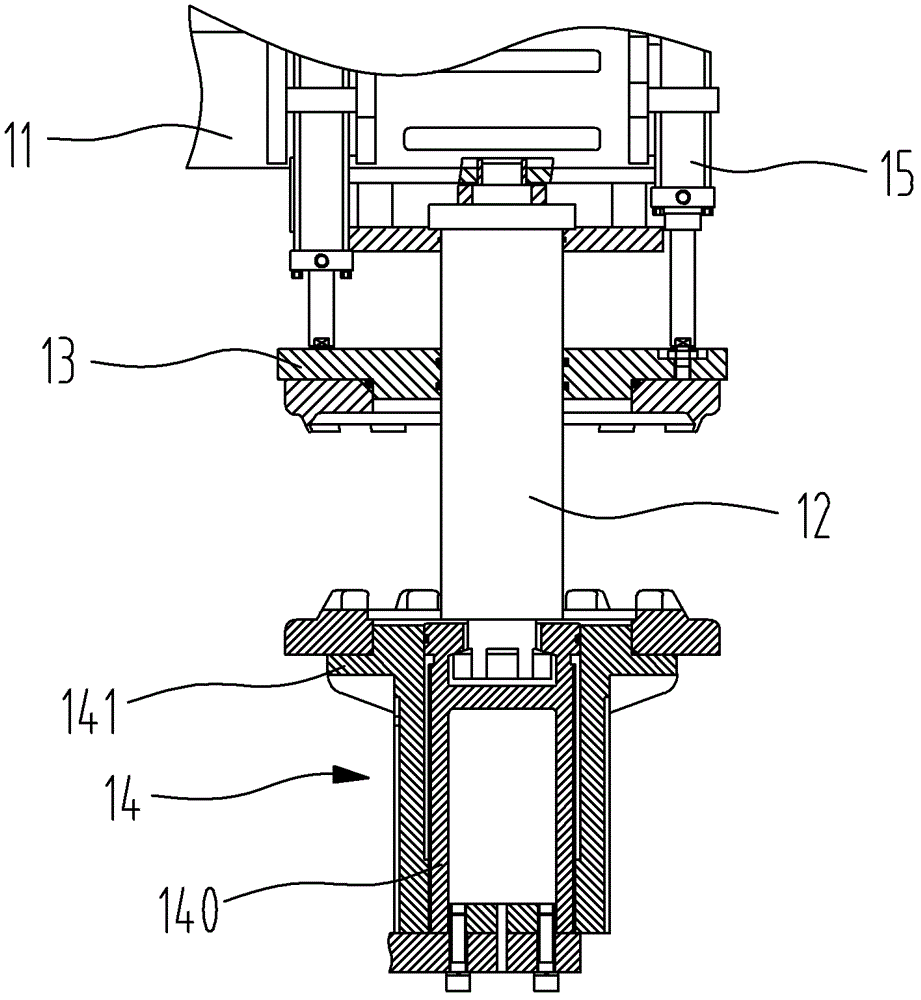

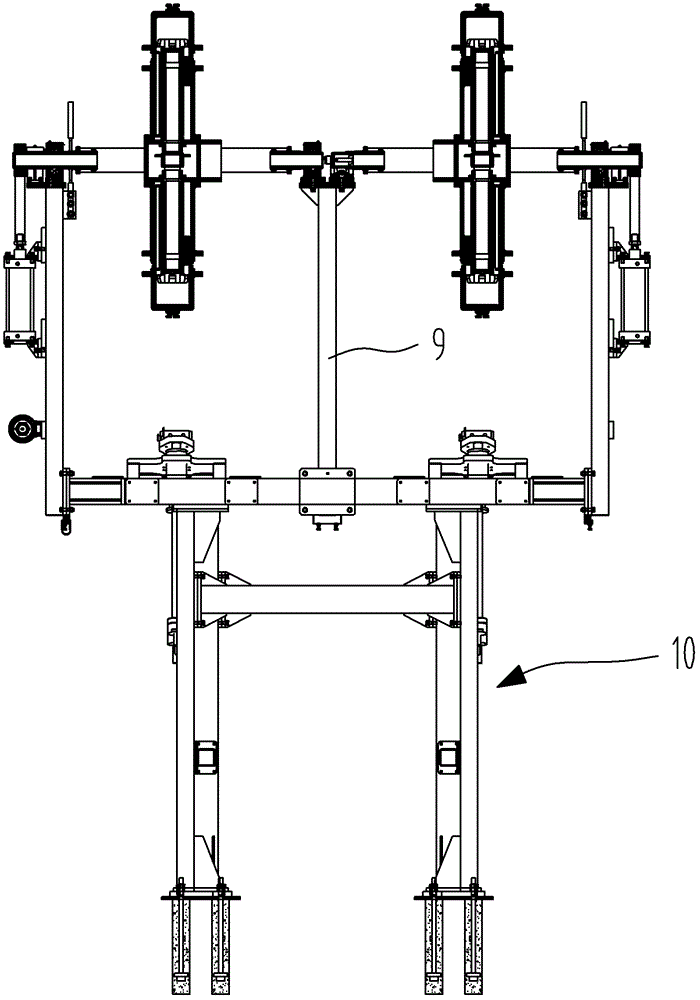

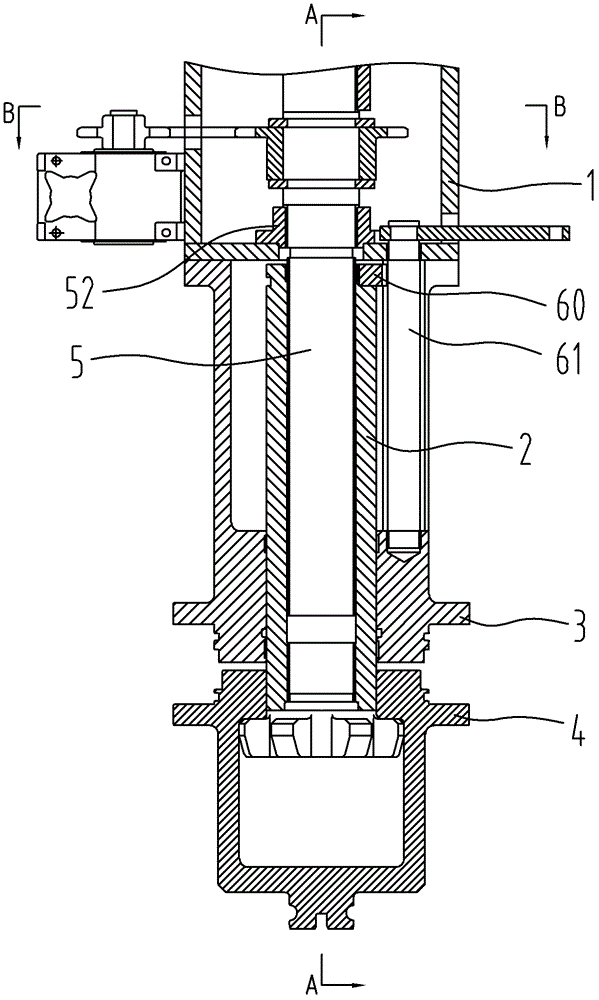

[0055] Embodiment one: see figure 2 with image 3 As shown, a tire rear inflation device includes a support beam 1, a locking rod 2, a center rod 5, a column 9, four stations and two lifting devices 10, the center rod 5 is supported on the support beam 1, and the upper The tray 3 and the lower tray 4 are coaxially arranged, and each station includes an upper tray 3, a lower tray 4 and a locking bar 2, the upper tray 3 and the upper chuck together constitute an upper chuck assembly, and the lower tray 4 and the lower tray The lower chucks form the lower chuck assembly together, and the tire is clamped between the upper and lower chucks when finalizing the shape.

[0056] The left and right sides of the column 9 are respectively provided with two stations, and the two stations located on the same side of the column 9 are respectively arranged on the upper and lower sides of the support beam 1 and share the support beam 1 .

[0057] The left and right sides of the column 9 are...

Embodiment 2

[0083] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 14 As shown, the drive mechanism 7 is a chain transmission, including a motor 73, a chain 74, a driving sprocket 75 and a driven sprocket 76 engaged with the chain 74, the motor 73 is fixed on the support beam 1, and the driving The sprocket 75 is fixed on the output shaft of the motor 73, and the driven sprocket 76 is fixed on the positioning end 51 of the central rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com