Machine element for a shaft-to-hub connection and production method for a shaft-to-hub connection

A technology for mechanical components and connecting devices, applied in the direction of connections, mechanical equipment, couplings, etc., can solve the problems of damage to mechanical components, high clamping force, and limitation of coaxiality accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

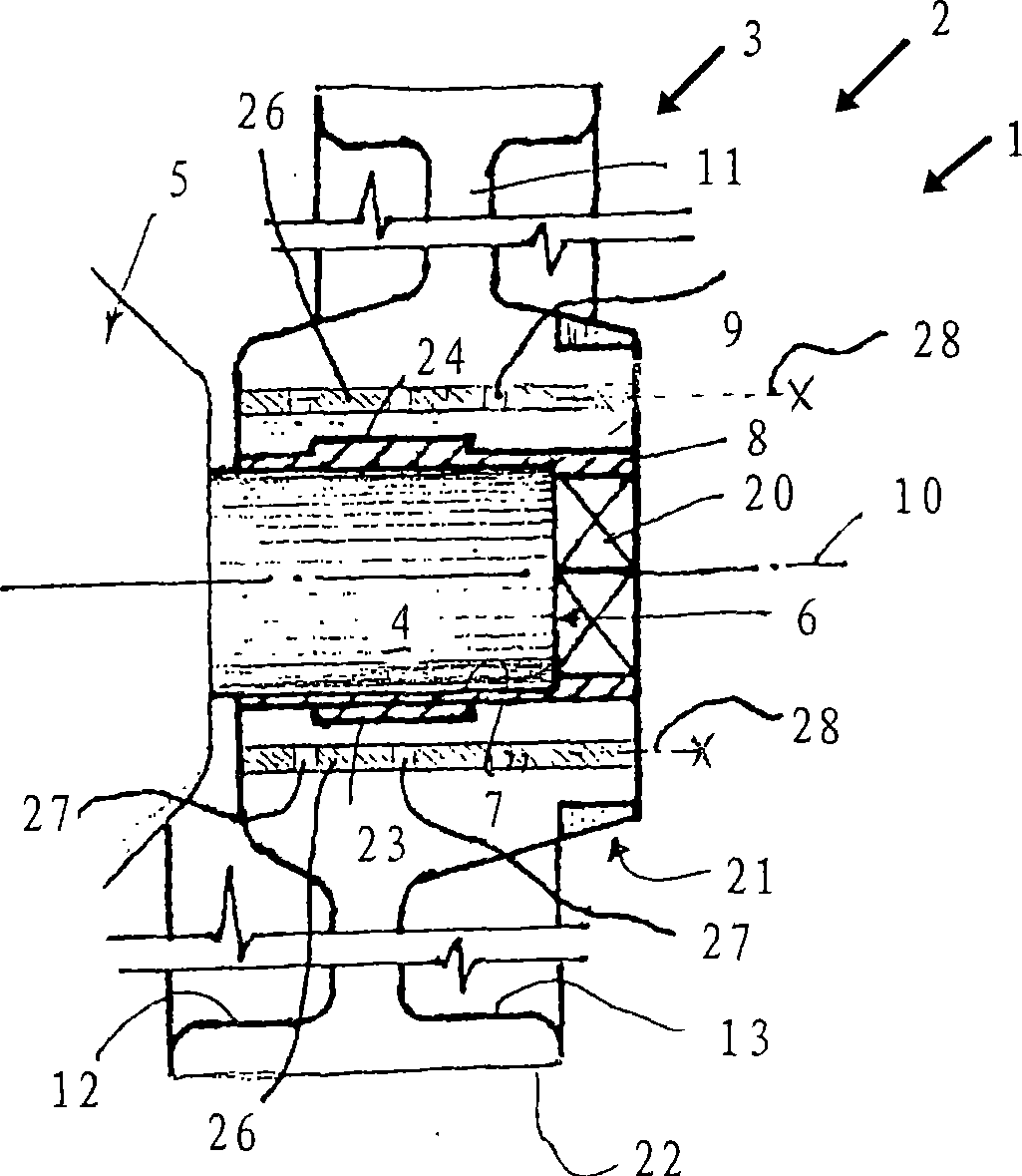

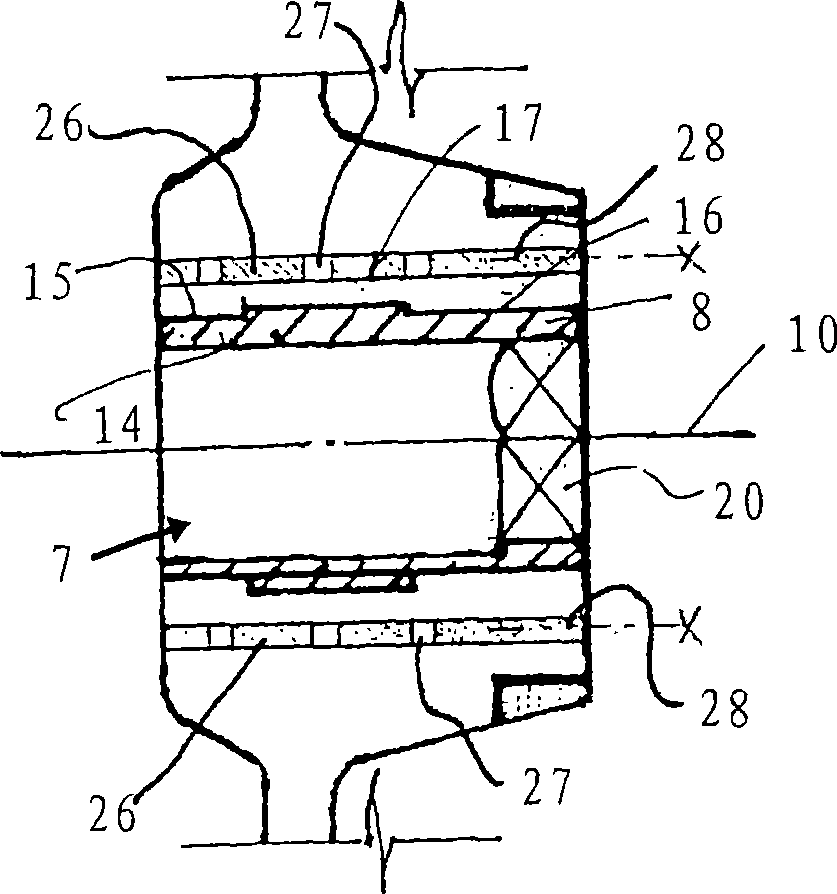

[0032] figure 1 A shaft-hub-connection 1 between a machine element 2 in the form of a pulley 3 and a shaft 4 or shaft end is shown. The shaft 4 is used to drive a vehicle assembly 5 , not further shown. However, the shaft-hub connection can also be used to connect other machine elements and shafts at other points.

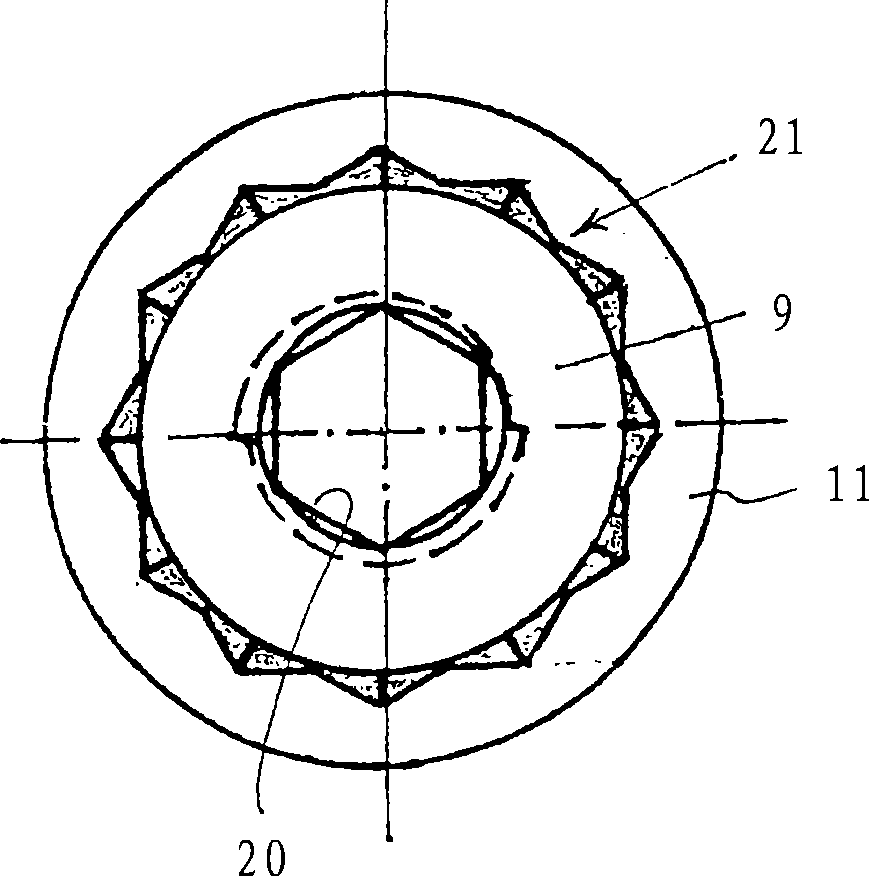

[0033] The shaft end 4 is substantially cylindrical. It has a preferably substantially flat end face 6 which is seated in the opening of a bore 7 in the form of a clamping element 8 which is arranged in a hub 9 of the belt pulley 3 . The clamping element 8 and thus the bore 7 are oriented concentrically to the axis of rotation 10 , which coincides with the axis of rotation of the shaft 4 .

[0034] The belt pulley 3 has a support sleeve 26 by means of which the forces and clamping forces occurring in the belt pulley 3 can be absorbed, so that the belt pulley 3 can withstand significantly greater forces from the clamping than without the support sleeve 26. compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com