Manufacturing technology for axisymmetric nozzle of conventional hypersonic wind tunnel

An axisymmetric nozzle and hypersonic technology, which is applied in the field of conventional hypersonic wind tunnel axisymmetric nozzle manufacturing process, can solve the problems of processing difficulty, delay in wind tunnel test ability, and unqualified nozzle velocity field indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The purpose of the present invention is to finally achieve good results in the production and processing of the axisymmetric profile nozzle in a hypersonic wind tunnel through a good process route and control strategy, to realize that the nozzle has good velocity field quality performance, and to reduce the manufacturing risk in the processing process Repeated with the processing process.

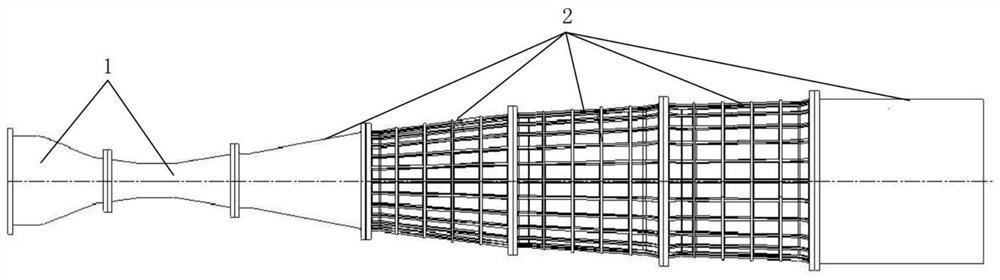

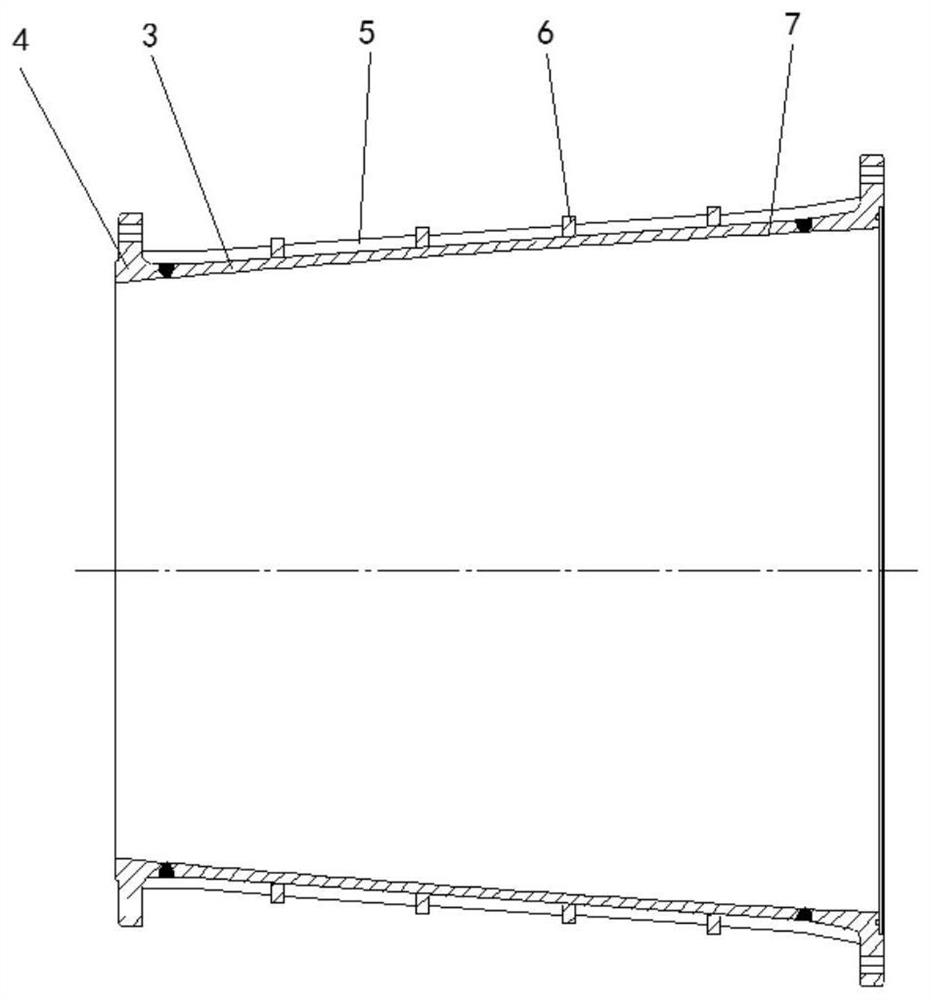

[0061] Conventional hypersonic wind tunnel axisymmetric surface nozzles are generally divided into throat section and diffusion section in terms of structure. The throat section can be divided into multiple sections according to its length and processing difficulty, generally made of forgings; It can be divided into multiple sections according to its length and processing difficulty, and it is determined whether to use forging or steel plate rolling according to the minimum diameter of each diffusion section. Generally speaking, when the minimum diameter is greater than Ф500mm, the r...

Embodiment 2

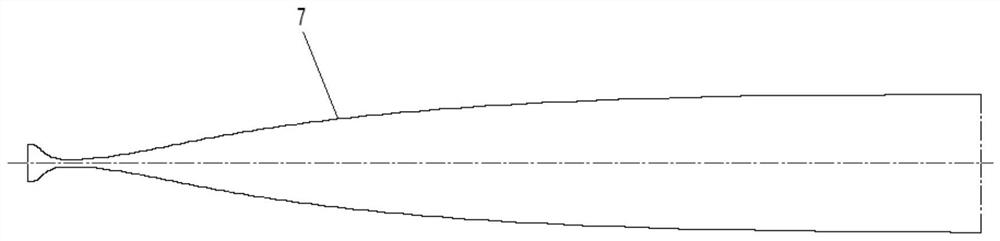

[0092] Such as Figure 9 , 10 As shown, a nozzle with a diameter of 2 meters at the outlet of a hypersonic wind tunnel has a total length of 12635 mm and is divided into 7 sections for processing. According to the manufacturing process of the present invention, a good manufacturing effect has been obtained, and the processing deviation of the inner surface is better than ± 0.03mm, and the coaxiality accuracy reaches Ф0.4mm. After the wind tunnel flow field calibration and debugging inspection, the maximum Mach number deviation is less than 1%, which meets the relevant requirements of the national military standard.

Embodiment 3

[0094] Such as Figure 11 , 12 As shown, a nozzle with a diameter of 1 meter at the exit of a hypersonic wind tunnel has a total length of 5615mm and is divided into 4 stages of processing. According to the manufacturing process route and measures of the present invention, a good manufacturing effect has been obtained, and the processing deviation of the inner surface is uniform. It is better than ±0.03mm, and the coaxiality accuracy reaches Ф0.2mm. After the wind tunnel flow field calibration and debugging inspection, the maximum Mach number deviation is less than 1%, which meets the relevant requirements of the national military standard.

[0095] To sum up, adopting the measures of this invention to eliminate various residual stresses generated in the manufacturing process effectively eliminates the continuous deformation of the nozzle and the change of the velocity field caused by the existence of residual stress in the later use of the nozzle. The problem of non-repetiti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com