Shock-absorbing boring cutter capable of machining slender stepped hole

A technology of stepped holes and boring tools, applied in metal processing equipment, tools for lathes, manufacturing tools, etc., can solve problems such as affecting the quality of hole processing, prone to corrugation on the surface, and vibration of tool shanks, to avoid machining size and Influence of roughness, improvement of coaxiality accuracy, effect of guaranteeing machining dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be explained below with reference to the drawings.

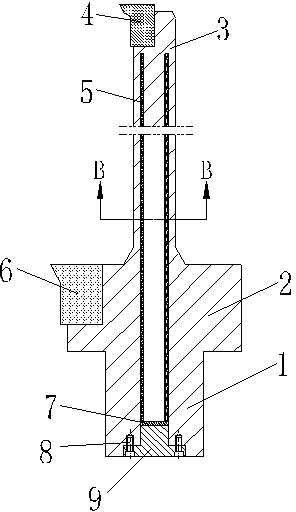

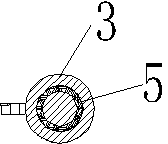

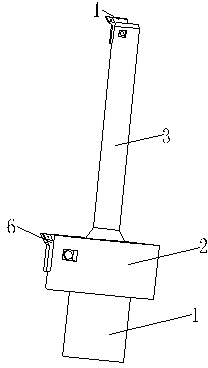

[0015] As attached Figure 1-3 A shock-absorbing boring tool capable of processing slender stepped holes according to the present invention shown includes a clamping part 1, a large boring tool bar 2, a small boring tool bar 3, a small boring tool 4, and a shock-absorbing material 5. Large boring tool 6, sealing ring 7, connecting screw 8, rear cover 9; the rear end of the large boring tool bar 2 is provided with a clamping part 1 for clamping on the machine tool, and a small boring Tool bar 3; the small boring tool 4 is installed on the front end of the small boring tool bar 3, the small boring tool 4 is detachable; the large boring tool 6 is installed on the large boring tool bar 2, the large boring tool 6 is detachable; an annular groove is opened in the cutter bar for filling soft shock-absorbing materials 5 such as polyurethane; the sealing ring 7 is installed at the rear end of the shock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com