Counter bore once drilling device and assembly method

A countersunk and countersunk head technology, which is applied in the direction of drilling/drilling equipment, drill repairing, drilling tool accessories, etc., can solve the problems of machining accuracy, low efficiency, increased production cost, and poor cutting chip removal, etc., to achieve production High efficiency, smooth chip removal and wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

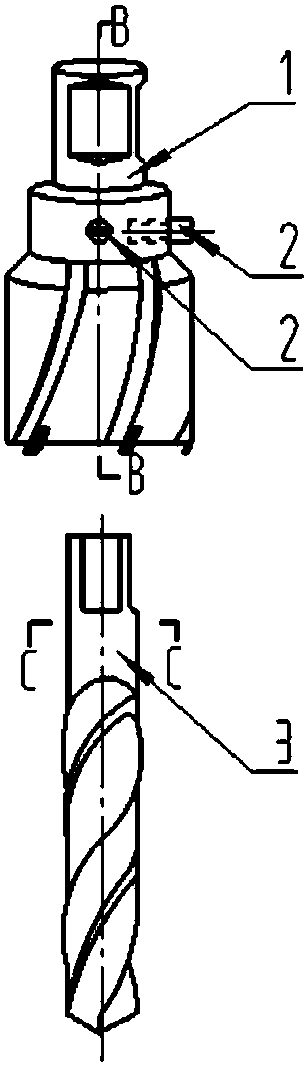

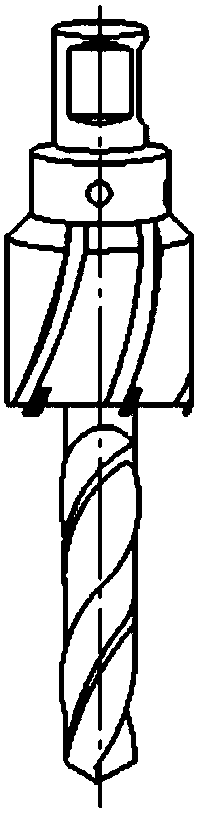

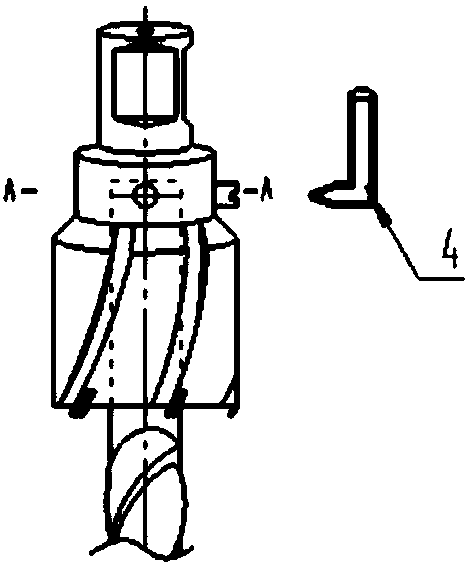

[0026] As shown in the accompanying drawing, the one-time drilling and forming device for countersunk holes includes countersunk drill bushing 1, inner slotted locking screw 2, side groove straight shank drill bit 3, and side groove straight shank drill bit 3 is connected to countersink drill bushing 1 Inside, the clamping end of the side groove straight shank drill bit 3 is a cylindrical structure surrounded by two mutually perpendicular planes 3.1 and an arc surface 3.2. 1.1 The radius of curvature is the same as that of the curved surface 3.2. The connecting hole 1.1 is provided with a radial locking hole 1.2 on the side wall of the bottom of the hole that matches the two vertical planes 3.1 of the side groove straight shank drill bit. The locking hole 1.2 is used to connect the side groove straight shank drill bit 3 to the countersunk d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com