Permanent magnet synchronous motor rotor component and manufacturing method thereof

A permanent magnet synchronous motor and rotor technology, applied in the direction of electric components, magnetic circuit rotating parts, electrical components, etc., can solve the problems of difficult installation and disassembly, affect the performance and energy consumption of the motor, and the temperature rise of the rotor, and achieve disassembly Easy maintenance, high pass rate, no effect of eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

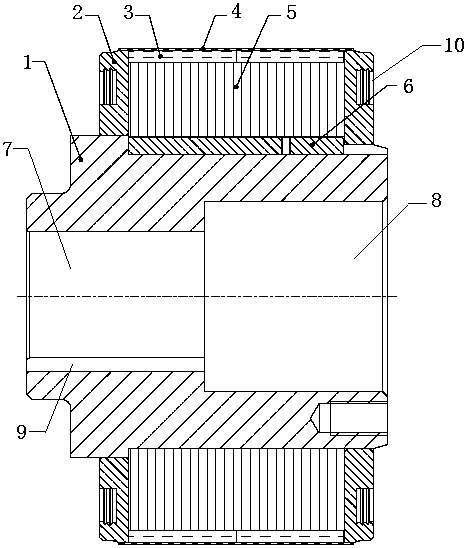

[0029] The following is based on Figure 1 to Figure 4 The specific embodiment of the present invention is further described:

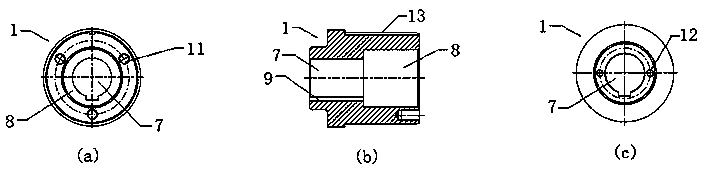

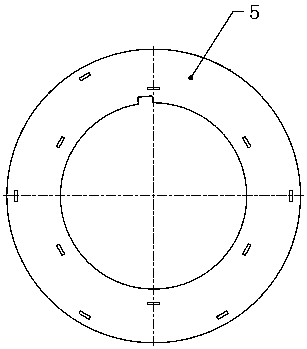

[0030] see figure 1 , a permanent magnet synchronous motor rotor assembly, including a rotating shaft 1, a balance ring 2, a magnetic steel 3, a carbon fiber sleeve 4, and a rotor core 5 (see image 3 ) and peace key 6, see figure 2 , figure 2 (a) is the right view of shaft 1, figure 2 (b) is the front cross-sectional view of the shaft 1, figure 2 (c) is the left view of the rotating shaft 1, the outer surface of the rotating shaft 1 is provided with a first U-shaped groove 13, the flat key 6 is arranged in the first U-shaped groove 13, and the rotor core 5 Sleeved on the outer surface of the rotating shaft 1 and the rotor iron core 5 is in interference connection with the rotating shaft 1, the balance ring 2 is sleeved on the end of the rotating shaft 1 and the balance ring 2 is respectively connected to the rotating shaft 1 and the rotor ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com