Processing device and processing method for assembly hole at root of inner cavity side wall of composite material component

A technology of composite materials and processing devices, which is applied in metal processing equipment, grinding drive devices, and parts of grinding machine tools, etc., to achieve the effects of flexible adjustment, elimination of axial and radial gaps, and reduction of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

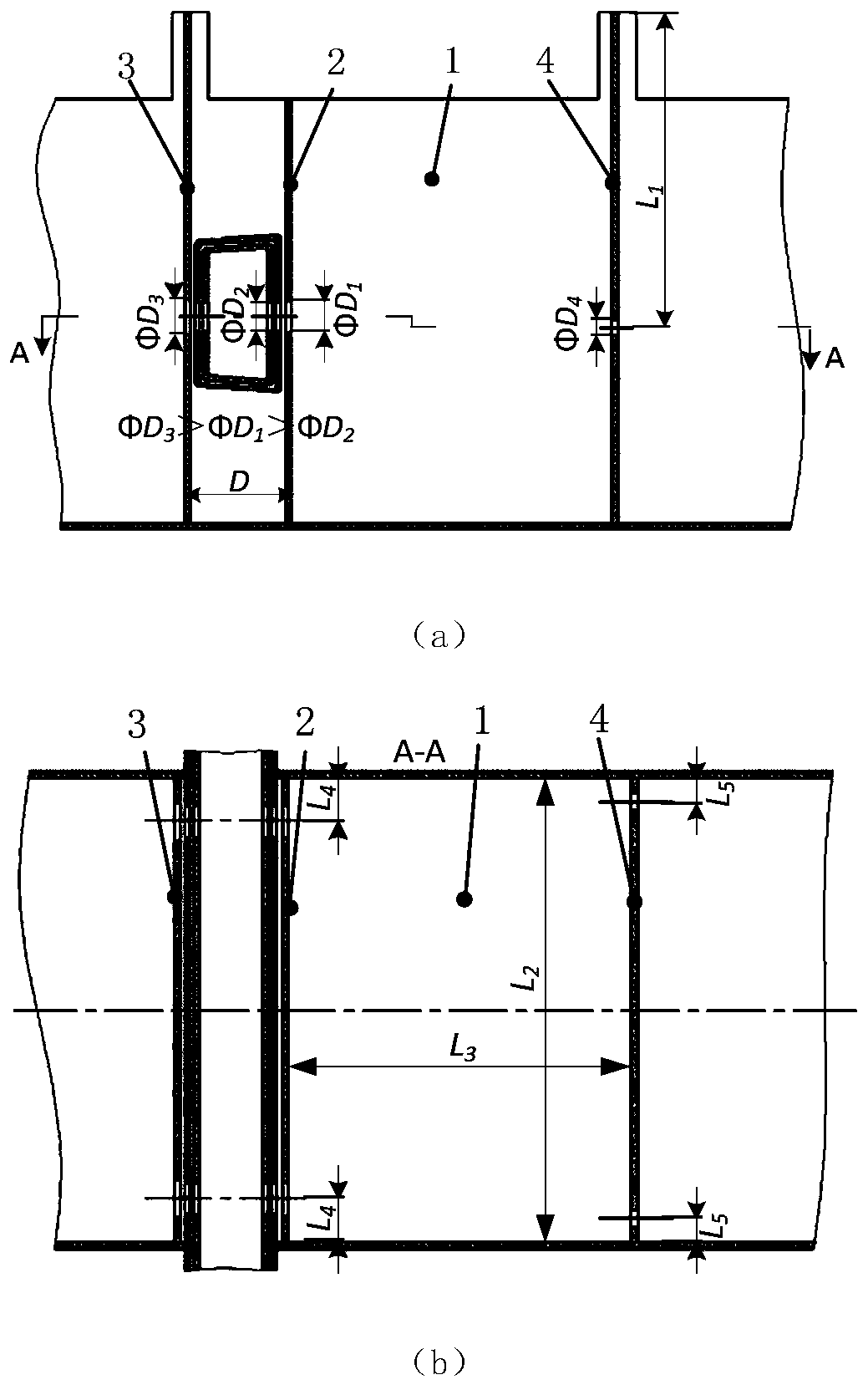

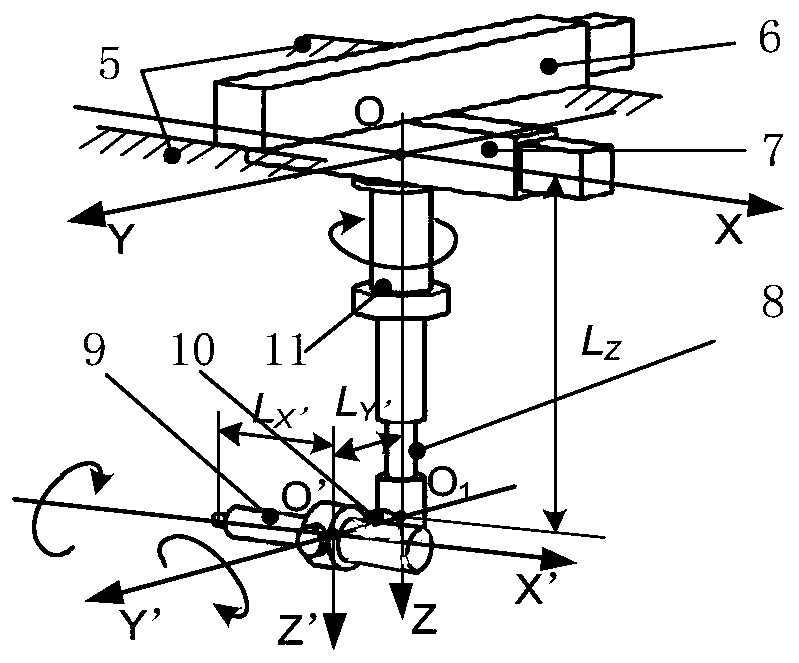

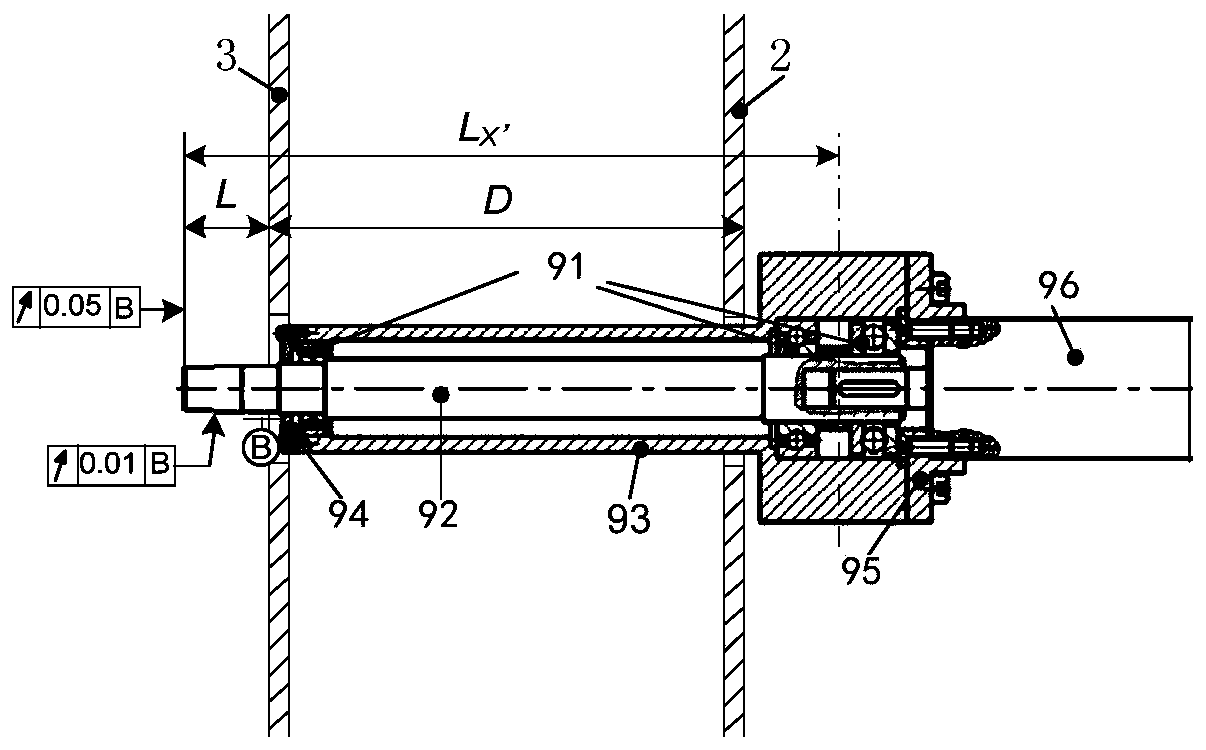

[0055] Such as Figure 1-7 As shown, the processing device for the assembly hole at the root of the inner cavity side wall of the composite material part, the processing device is a six-degree-of-freedom cantilever processing device, including the X-direction linear motion part 7, the Y-direction linear motion part 6, and the Z-direction linear adjustment part 8. X' axis cantilever hole making unit 9, Y' axis rotation adjustment part 10 and Z axis rotation adjustment part 11;

[0056] The Y-direction linear motion part 6 is fixed on the UAV assembly truss 5, the X-direction linear motion part 7 is connected to the slider of the Y-direction linear motion part 6, and the Z-axis rotation adjustment part 11 is connected to the X-direction linear motion part 11. On the slider of component 7, the Z-direction linear adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com