Reciprocating pump facilitating maintenance of motor shaft auxiliary supporting sliding bearing and sealing structure

A technology for sliding bearings and auxiliary supports, applied in the direction of shafts and bearings, engine seals, bearing components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] The embodiments of the present invention are not limited to the following examples, and various changes made without departing from the gist of the present invention fall within the protection scope of the present invention.

[0028] The implementation of the present invention takes a reciprocating pump above 2200hp as an example. Since the motor shaft auxiliary support sliding bearing and the sealing structure are symmetrical on both sides, only one side is used as an example for illustration.

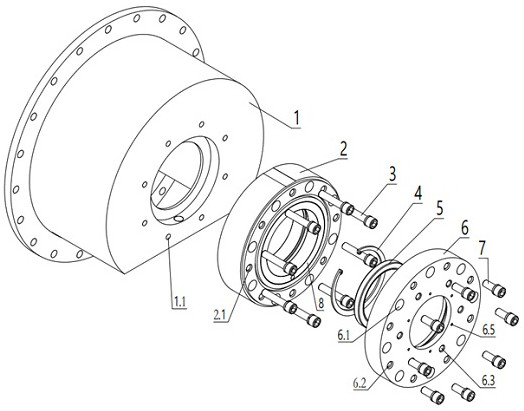

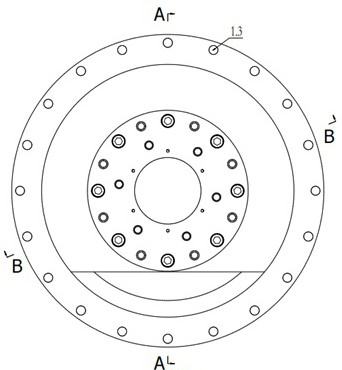

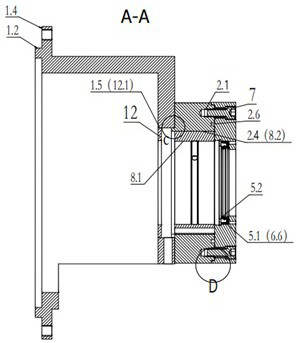

[0029] see Figure 1 to Figure 11 , a reciprocating pump in this embodiment facilitates maintenance of the motor shaft auxiliary support sliding bearing and sealing structure, including the motor shaft auxiliary support seat 1, the sliding bearing seat 2, the M12 screw washer group 3, the elastic retaining ring 4 for the hole, and the inner fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com