Moment motor structure

A torque motor and motor shaft technology, applied in the field of torque motors, can solve problems such as difficulties, achieve the effect of solving design and assembly problems, ensuring coaxiality, and ensuring axial positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A specific embodiment of a torque motor structure of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is only used to illustrate the present invention and is not intended to limit the scope of the present invention. Those skilled in the art are familiar with various equivalent forms of the present invention All modifications fall within the scope defined by the appended claims of this application.

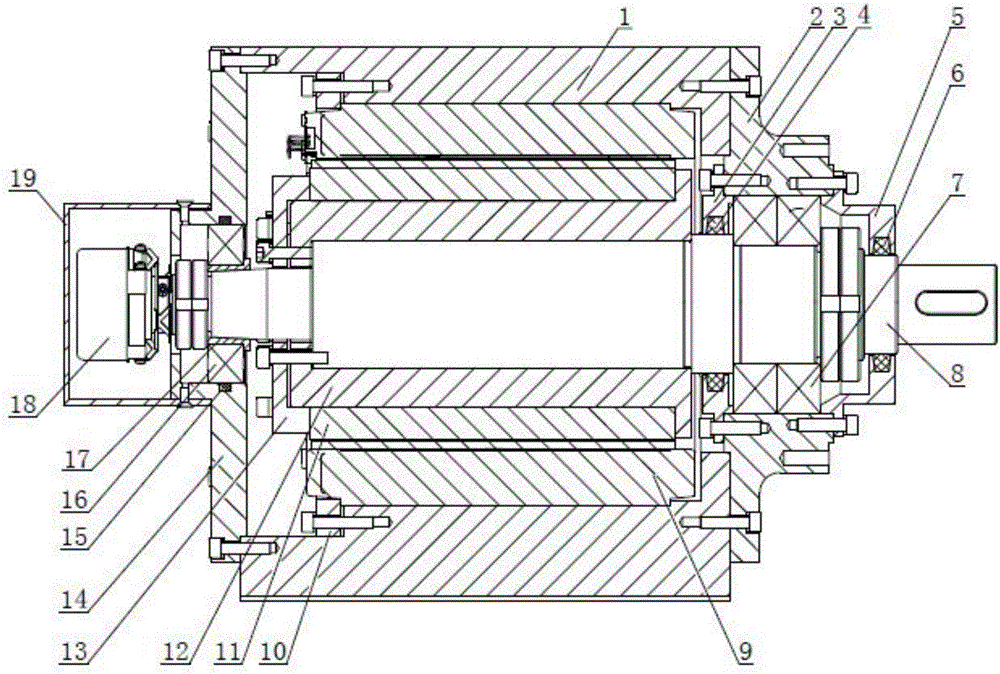

[0014] Such as figure 1 , a torque motor structure, including an aluminum outer casing 1, a bearing chamber is installed on the front end of the outer casing 1, and the bearing chamber includes a bearing seat 2, a bearing inner end cover 3, an inner felt sealing ring 4, a bearing outer end cover 5 and an outer The felt sealing ring 6 and the grouped angular contact ball bearings 7 are installed back to back in the bearing chamber. The grouped angular contact ball bearings 7 have been adjusted for the size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com