Concrete pavement overall vibrating device and method

A technology of concrete pavement and vibrating device, which is applied to roads, roads, road repair and other directions, can solve the problems of difficulty in controlling the overall flatness of concrete pavement, and achieve the effects of saving manpower, ensuring construction quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

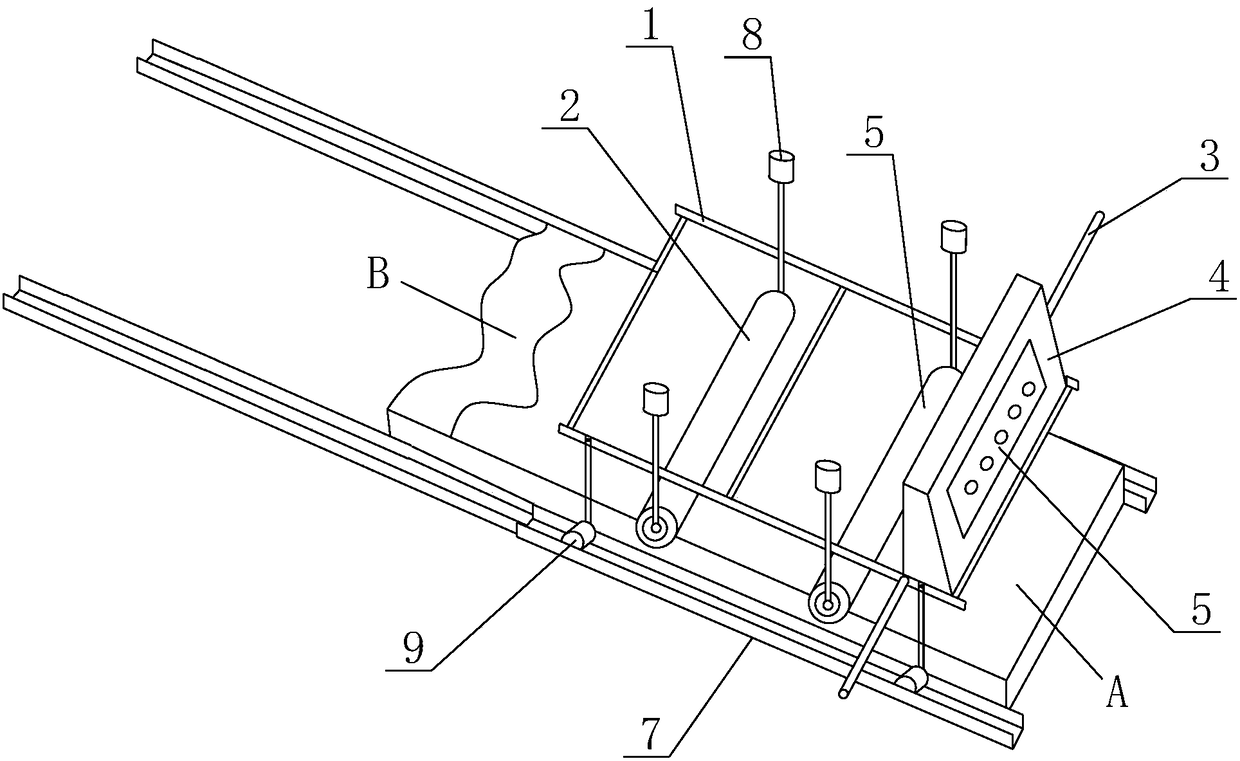

[0022] Such as figure 1 As shown, a concrete pavement integral vibrating device according to the present invention includes a frame body 1, a walking wheel 9, a leveling drum 2, a vibrating drum 6, an operating handrail 3 and a walking track 7; The walking wheel 9, the leveling roller 2 and the vibrating roller 6 are arranged at the bottom of the frame body 1 in a height-adjustable manner, and the axes of the leveling roller 2 and the vibrating roller 6 are all parallel to the rotation axis of the walking wheel 9; A vibrating motor is arranged inside the drum 6 ; the traveling track 7 is set correspondingly to the traveling wheels 9 , and the two sides of the frame body 1 are provided with operating handrails 3 for manually pushing the frame body 1 to move along the traveling track 7 .

[0023] Both the leveling drum 2 and the vibrating drum 6 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com