Thermally or electrically conductive paste smearing device and smearing method

A technology of conductive paste and thermal paste, which is applied to devices and coatings that apply liquid to the surface, can solve problems such as burnout of power amplifiers, inability to quantitatively adjust the flatness, uniformity and thickness of the paste, and poor conduction. Achieving adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

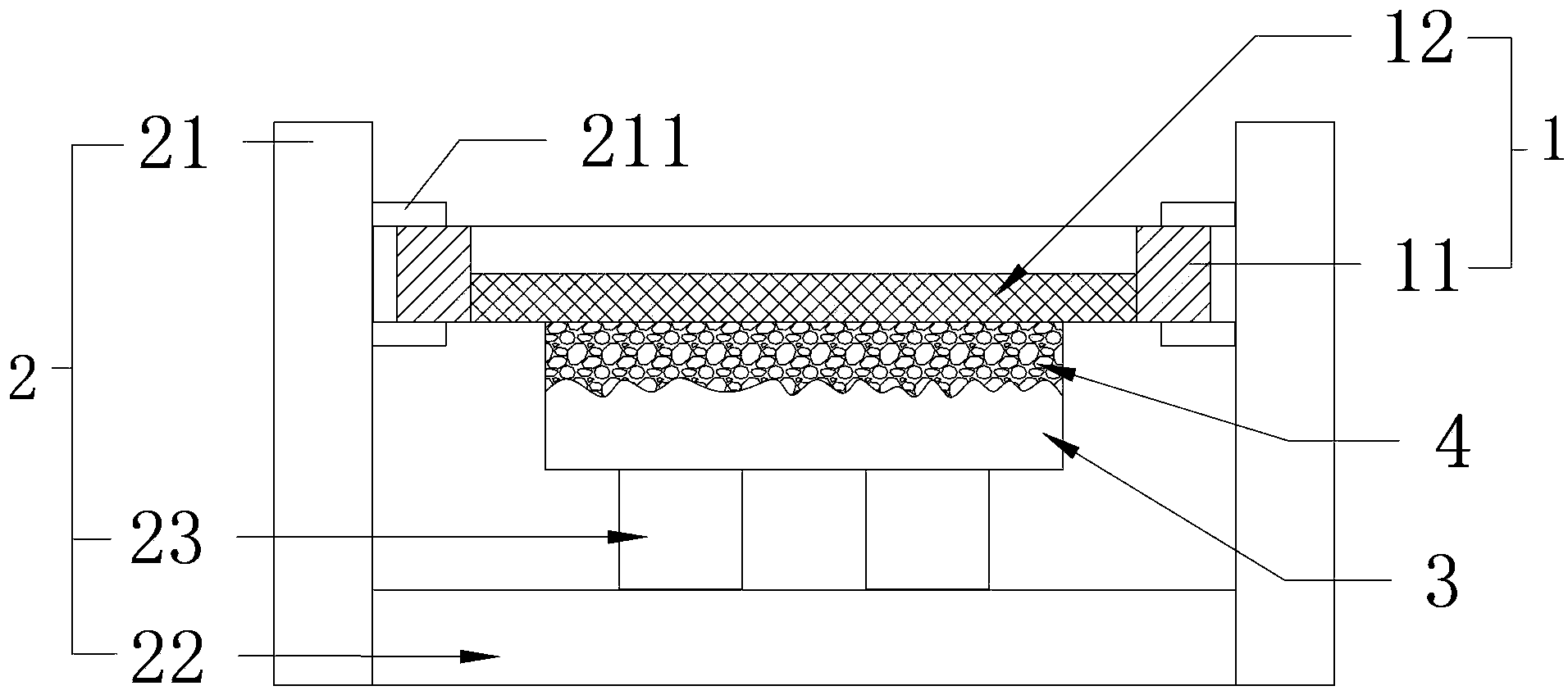

[0025] Please refer to figure 1 , the device for applying thermally conductive paste or conductive paste provided by the present invention includes a control surface device 1 and a positioning device 2 .

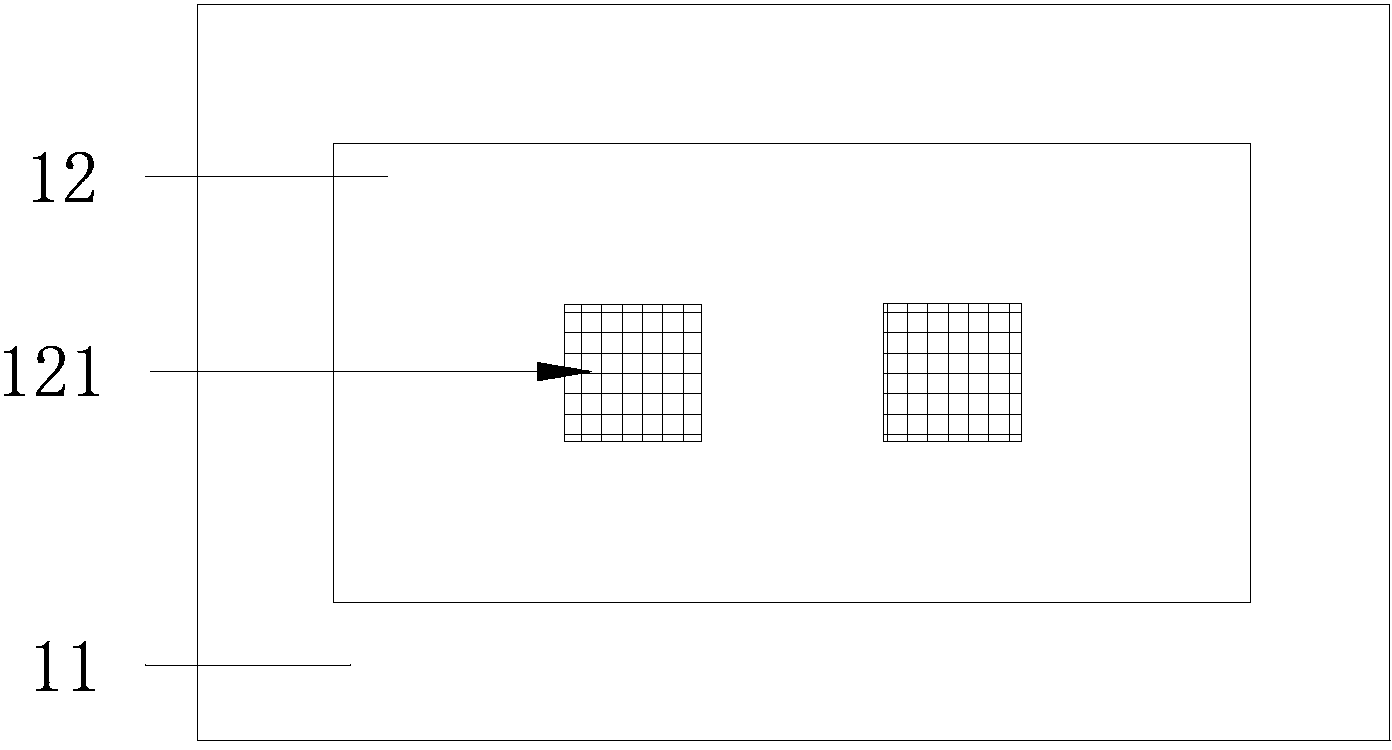

[0026] The control surface device 1 includes a mesh surface 12 and a screen frame 11; the mesh surface 12 is made of vertically and horizontally interwoven polyester filaments, which is the main area for paste application; the mesh frame 11 surrounds the mesh surface 12 Four weeks, for fixing and leveling the mesh surface 12.

[0027] The positioning device 2 includes a positioning frame 21 for fixing the control surface device 1, a positioning plate 22 positioned at the bottom of the positioning frame 21, and a positioning plate 22 arranged on the positioning plate 22 for fixing the object 3 to be plastered. Block 23. The contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com