Method for detecting planeness of PCB based on network projection

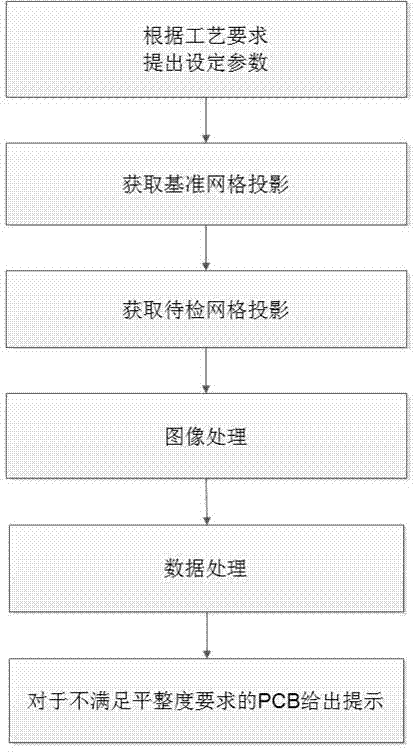

A technology of PCB board and grid projection, which is applied to measuring devices, instruments, and optical devices, etc., can solve the problems of low sensitivity, virtual welding, and high subjectivity of artificial visual detection, so as to overcome low sensitivity and high subjectivity. , Simple and accurate detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

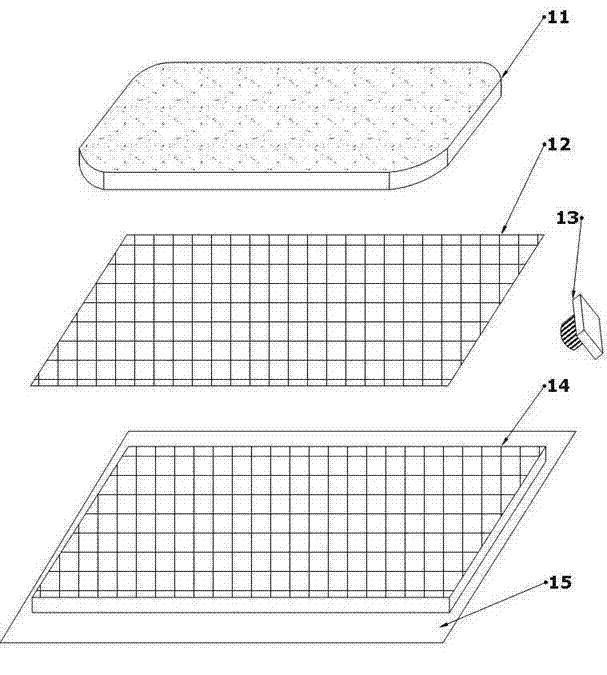

[0023] figure 1 A schematic structural view of the detection device of a preferred embodiment of the present invention is shown, including: PCB board 14 is placed on a horizontal workbench 15, a light source 11 and a baffle 12 are arranged vertically above the PCB 14, and the light source 11 is placed on the side of the baffle 12 Vertically above; the camera 13 is set at an angle of 60 degrees between the side and the horizontal workbench 15; the light source 11 projects the standard grid shadow on the baffle 12 on the PCB 14 through the baffle 12, and the camera 13 faces the The grid projection on the PCB board 14 is photographed.

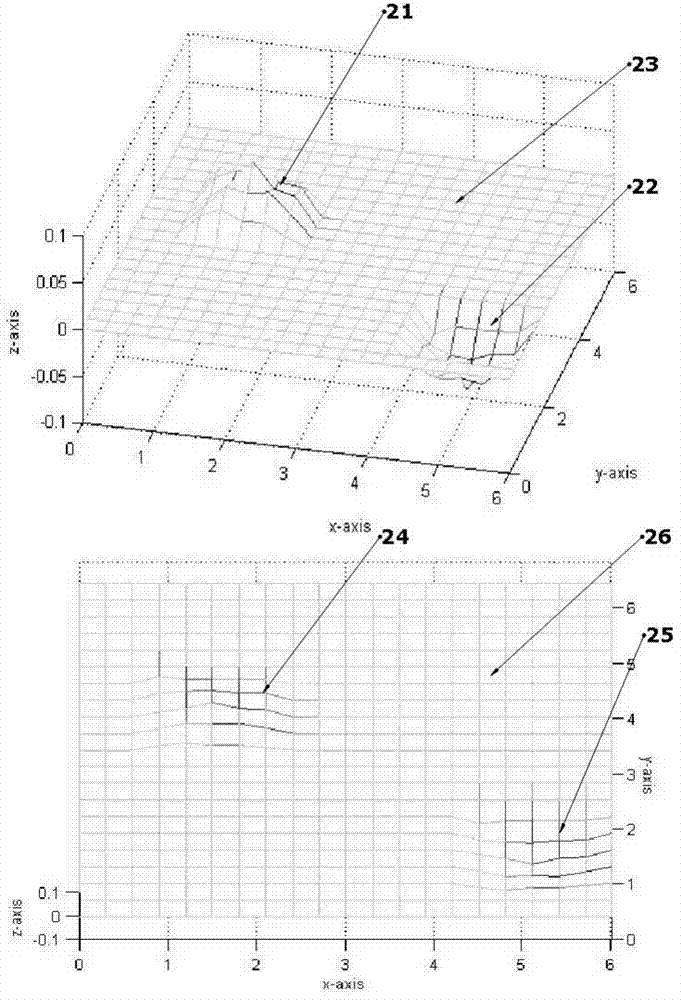

[0024] figure 2 It shows a schematic diagram of the detection principle of the preferred embodiment of the present invention, and the PCB grid shadow projection picture taken by the camera at 60 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com