Super-long and large horizontal embedded part reverse construction method

A technology of reverse construction and embedded parts, which is applied in construction and infrastructure engineering, etc., can solve the problems of large construction errors and difficult modification, and achieve the effect of improving the guarantee rate and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

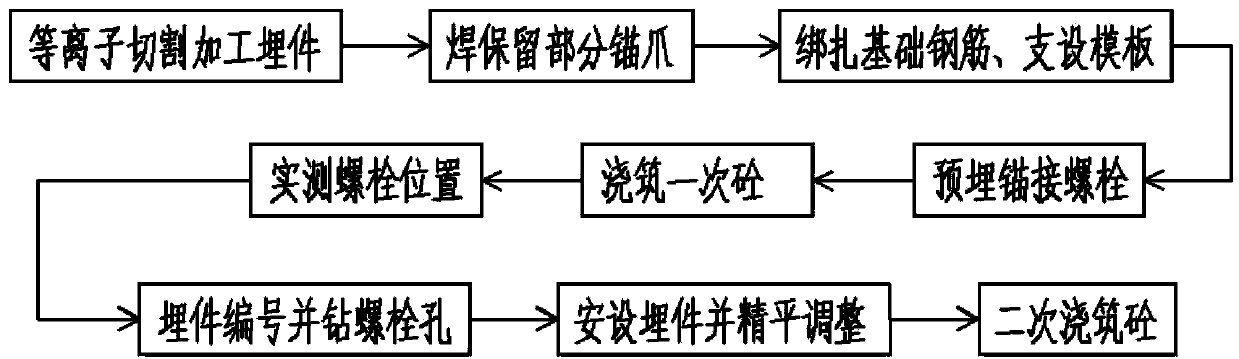

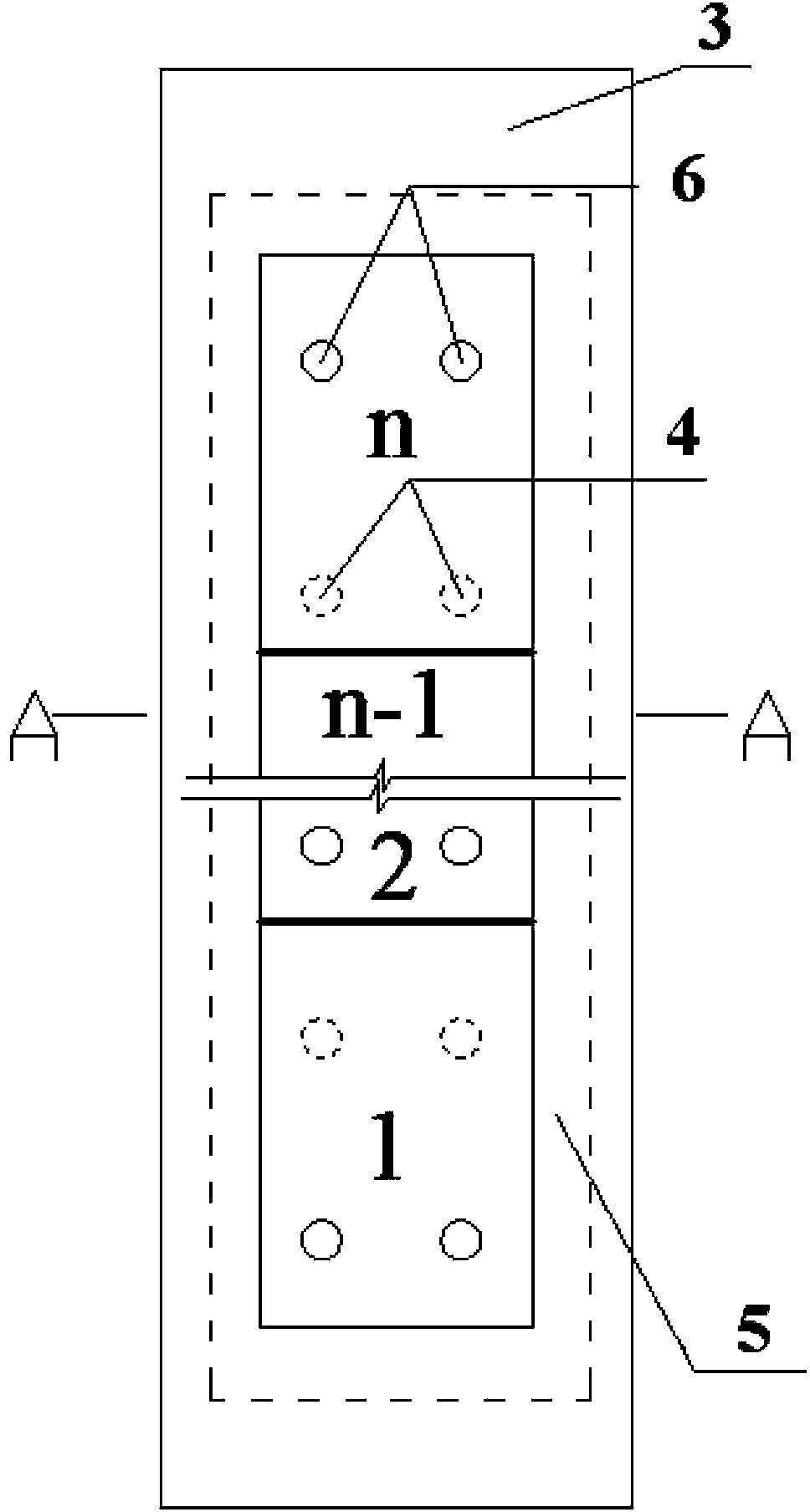

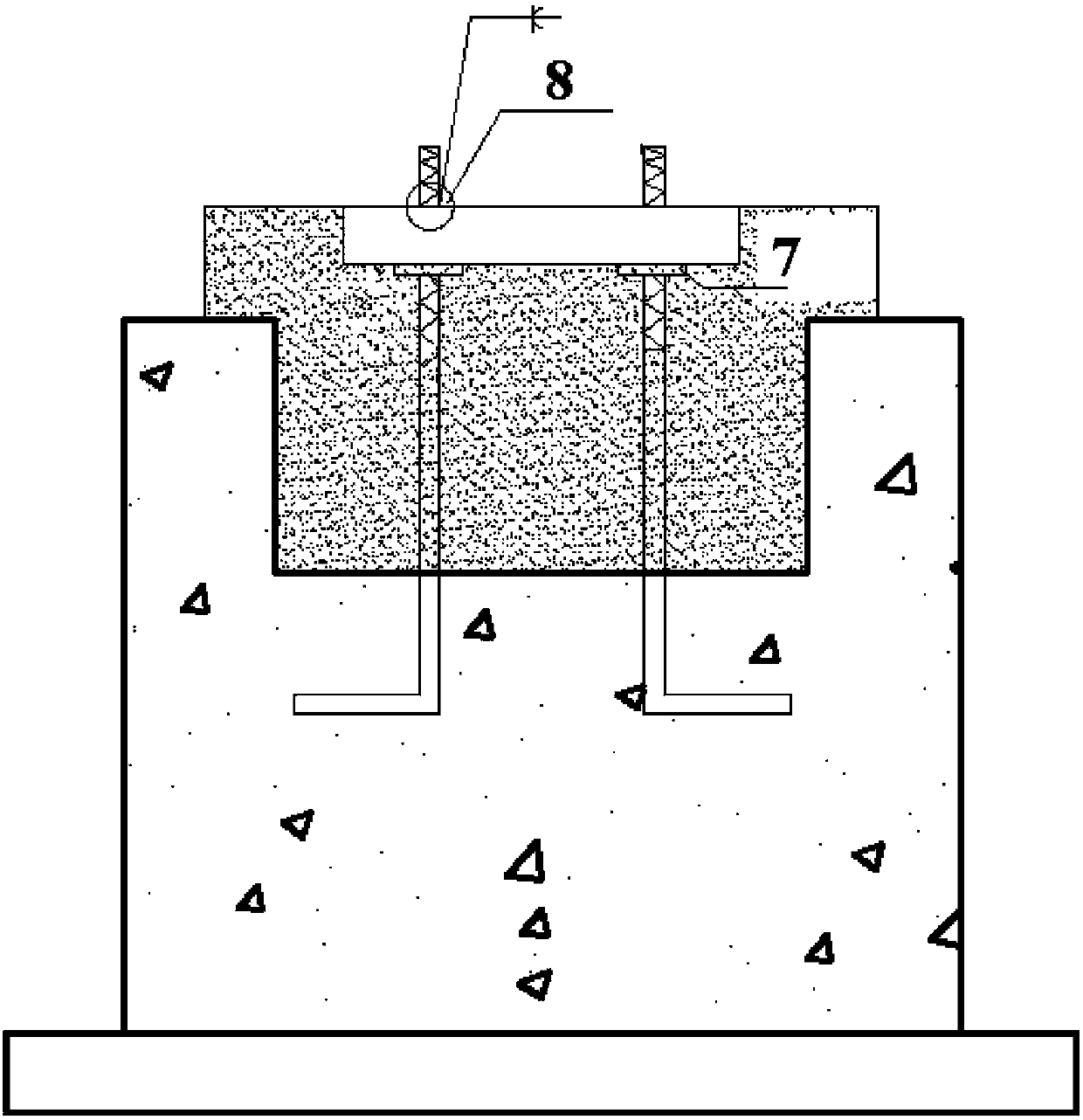

[0020] Such as figure 1 As shown, the reverse method steps of super long and large horizontal embedded parts of the present invention are as follows: 1. Before construction, the steel plate is cut and processed into the required size of embedded parts by plasma welding. Do not use gas cutting welding to avoid excessive thermal deformation, and then weld 1 / 2 to 2 / 3 of the anchor fluke on the embedded part according to the drawing. To avoid thermal processing, it is advisable to use single-head threaded bolts of the same thickness, specification and length for the reserved part of the anchor fluke to replace them with a spacing of about 500mm;

[0021] 2. Then tie up the equipment foundation reinforcement, support the equipment foundation template, measure and set out the wires, and pre-embed the anchor bolts according to the pre-replaced positions (to ensure that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com