Preparation method and application of polyester resin applied to thermo-sensitive base material powder coating

A powder coating, polyester resin technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of inability to provide a smooth coating film, high melt viscosity of polyester resin, inability to fully flow, etc., and achieve the appearance of the coating. And the effect of good chemical resistance, good adhesion, good hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

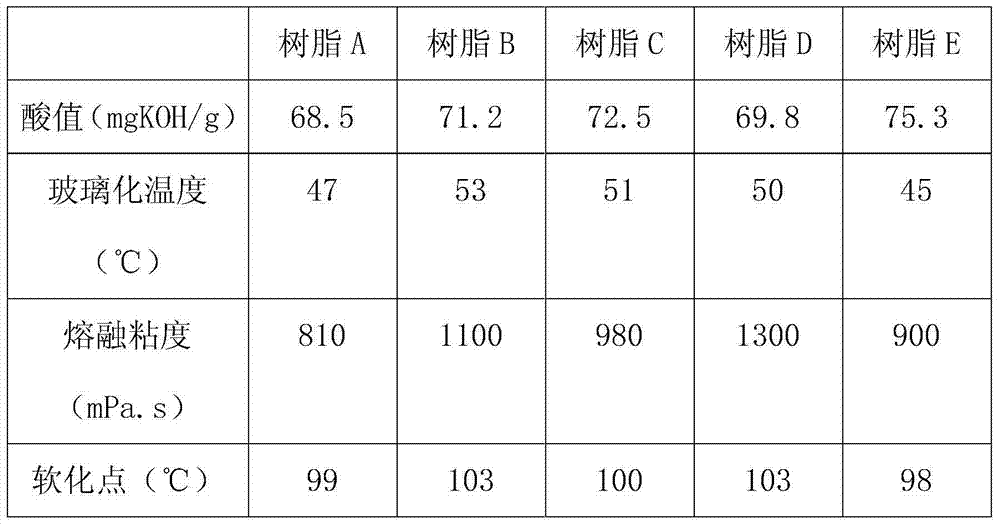

Examples

Embodiment 1

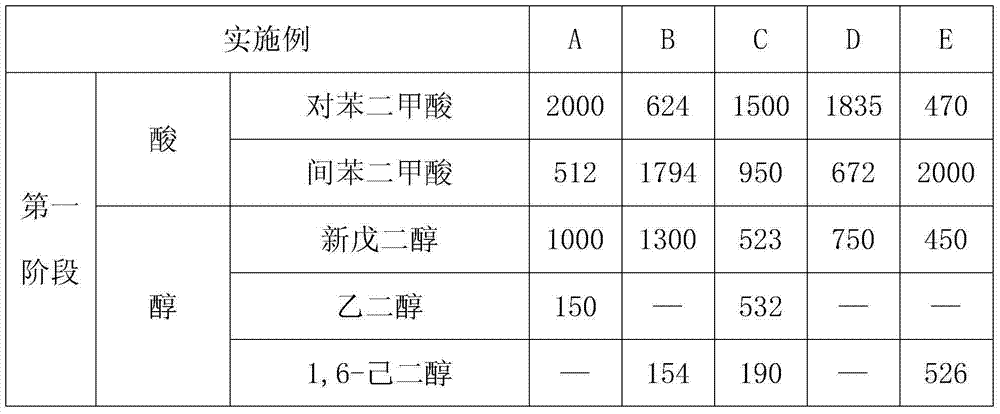

[0023] Preparation of polyester resin:

[0024] The first stage: Put the formula amount of alcohol into the reaction kettle, heat to 110°C, wait until the alcohol is completely melted, stir at a speed of 130r / min, then put in the formula amount of acid and esterification catalyst, heat up to 170°C, at 5°C Raise the temperature to 245°C at a heating rate of / 30min, maintain the reaction until the reactant is clear, and take a sample to test the acid value of the sample;

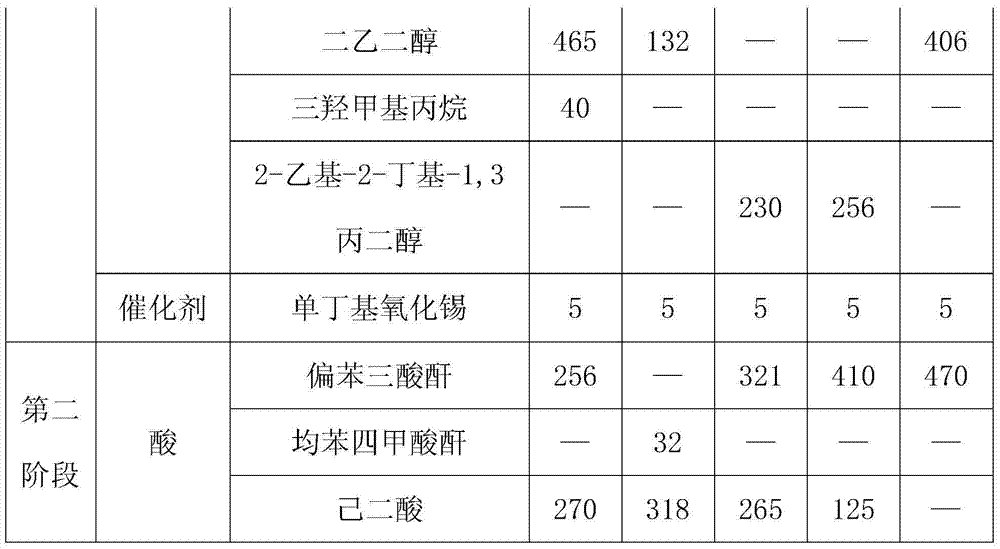

[0025] The second stage: Add acid, maintain the temperature at 210°C until the reactants are clear, take samples to measure the acid value;

[0026] The third stage: under the condition of 200°C, vacuumize at -0.095MPa for 1.5h until the reaction is complete, take samples to measure the acid value and viscosity.

Embodiment 2

[0028] Preparation of polyester resin:

[0029] The first stage: Put the formula amount of alcohol into the reaction kettle, heat to 115°C, wait for the alcohol to completely melt, stir at a speed of 135r / min, then put the formula amount of acid and esterification catalyst, heat up to 172°C, Raise the temperature to 246°C at a heating rate of / 30min, maintain the reaction until the reactant is clear, and take a sample to test the acid value of the sample;

[0030] The second stage: Add acid, maintain the temperature at 212°C, until the reactants are clear, take samples to measure the acid value;

[0031] The third stage: under the condition of 202°C, vacuumize at -0.095MPa for 1.6h until the reaction is complete, take samples to measure the acid value and viscosity.

Embodiment 3

[0033] Preparation of polyester resin:

[0034] The first stage: Put the formula amount of alcohol into the reaction kettle, heat to 120°C, wait for the alcohol to completely melt, stir at a speed of 140r / min, then put the formula amount of acid and esterification catalyst, heat up to 175°C, Raise the temperature to 247°C at a heating rate of / 30min, maintain the reaction until the reactant is clear, and take a sample to test the acid value of the sample;

[0035] The second stage: Add acid, maintain the temperature at 215°C until the reactants are clear, take samples to measure the acid value;

[0036] The third stage: under the condition of 204°C, vacuumize at -0.096MPa for 1.8h until the reaction is complete, take samples to measure the acid value and viscosity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com