A method for preparing a large-size molybdenum-niobium planar target

A flat target, large-scale technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems of coarse and uneven grains, difficult to meet quality, excessive oxygen content, etc., to achieve production High efficiency, improved powder purity, and high milling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

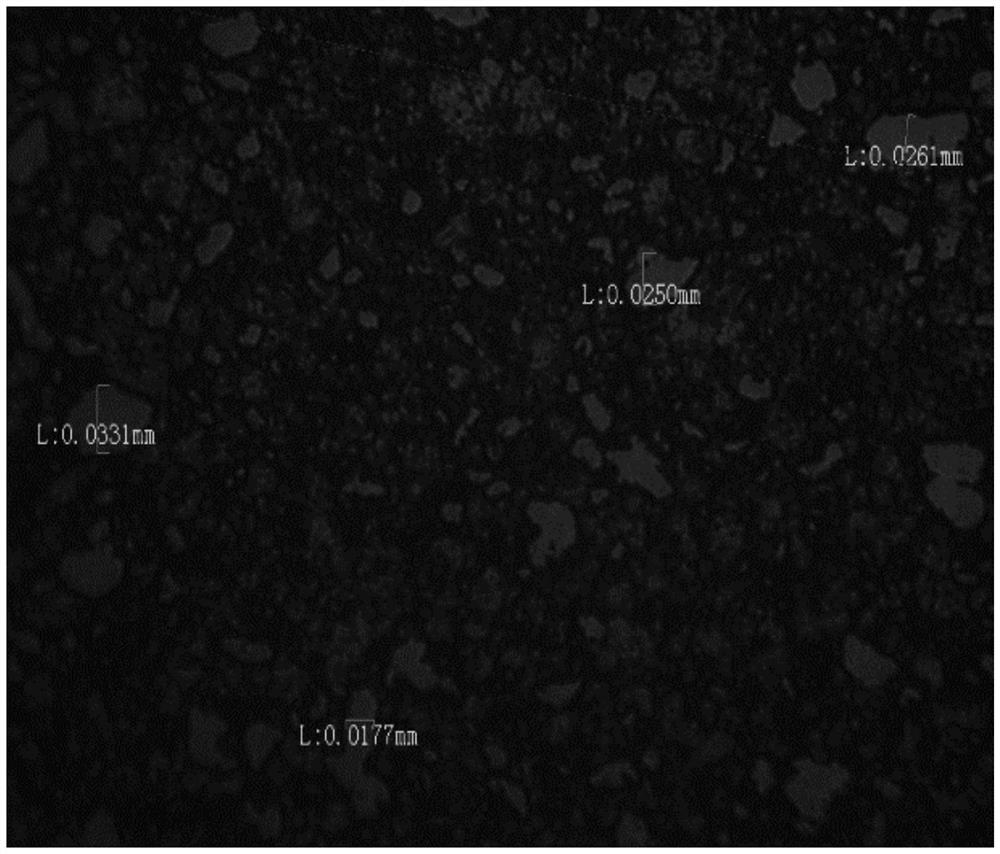

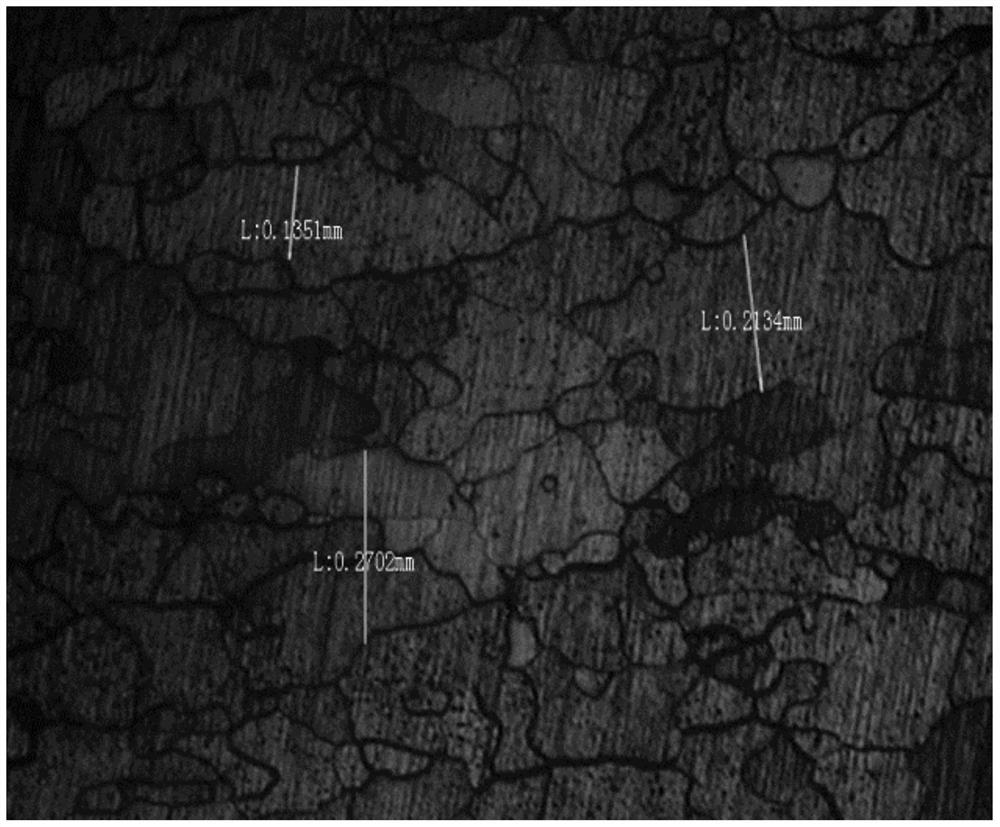

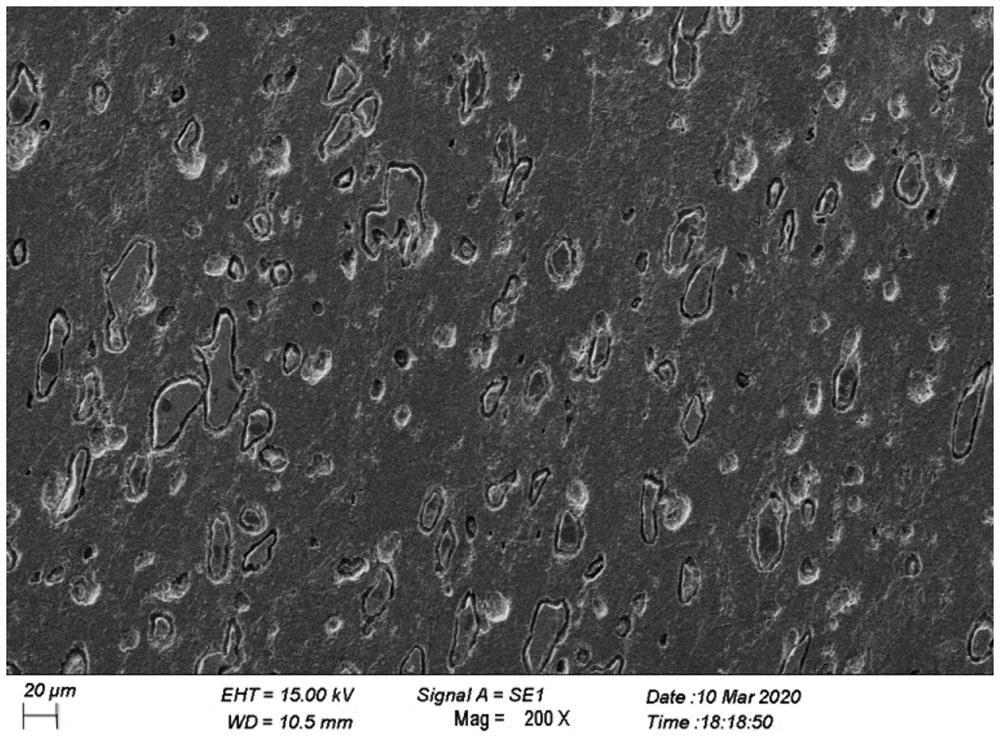

[0045] A method for preparing a large-size molybdenum-niobium planar target, Figure 1 to Figure 6 As shown, including 1) powder granulation step, 2) hot isostatic pressing step and 3) hot deformation step, large-sized molybdenum-niobium targets are obtained, and large-size molybdenum-niobium targets refer to lengths ranging from 1000mm to 4000mm molybdenum-niobium target.

[0046] Since molybdenum-niobium alloy belongs to replacement solid solution, because of its high melting point and high temperature brittleness, it is difficult to be prepared by smelting, casting or pressure processing. At present, most of them are prepared by powder metallurgy. Although sintering can quickly achieve densification, the sintering porosity is high and the density is low. The density is about 95% of the theoretical value, and it is difficult to meet the theoretical density requirement of more than 99%. Molybdenum and niobium sintered in a hydrogen atmosphere are easy to absorb hydrogen, resu...

specific Embodiment approach 1

[0071] 1.1) In the mixing step, high-purity molybdenum powder with a purity of ≥99.95%, an oxygen content of ≤1500ppm, and a particle size of 4 to 8 microns and a high-purity niobium powder with a purity of ≥99.9% and a particle size of 10 to 80 microns are used, according to the niobium content of 12at The % ratio is placed in a V-shaped mixer, and under the condition of vacuuming and filling with argon for 30 minutes, the high-purity molybdenum powder and high-purity niobium powder are fully mixed for 6 hours to obtain molybdenum-niobium mixed powder.

[0072] 1.2) In the compaction step, the molybdenum-niobium mixed powder is pressed into a compact by a four-column press. The 800T four-column press is selected. The size of the compact is 150*mm150mm*40mm, and the theoretical value of the density of the compact reaches 48%.

[0073] 1.3) Hydrogen pre-sintering step, put the block into a hydrogen atmosphere heating furnace for 3 hours and set the temperature in the heating fur...

specific Embodiment approach 2

[0080] 1.1) In the mixing step, high-purity molybdenum powder with a purity of ≥99.95%, an oxygen content of ≤1500ppm, and a particle size of 4 to 8 microns and a high-purity niobium powder with a purity of ≥99.9% and a particle size of 10 to 80 microns are used, and the niobium content is 5 at The % ratio is placed in a V-shaped mixer, and under the condition of vacuuming and filling with argon for 30 minutes, the high-purity molybdenum powder and high-purity niobium powder are fully mixed for 5 hours to obtain molybdenum-niobium mixed powder.

[0081] 1.2) In the compacting step, the molybdenum-niobium mixed powder is pressed into a compact by a four-column press. A 600T four-column press is selected. The size of the compact is 150*150*30mm, and the theoretical value of the density of the compact reaches 40%.

[0082] 1.3) Hydrogen pre-sintering step, put the block into a hydrogen atmosphere heating furnace for 2 hours, set the temperature in the heating furnace at 950°C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com