Automatic welding equipment for fillet weld of sheets

An automatic welding and fillet welding technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low production efficiency, inability to meet requirements, and difficult processing, and achieve high welding efficiency, reasonable structural design, The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

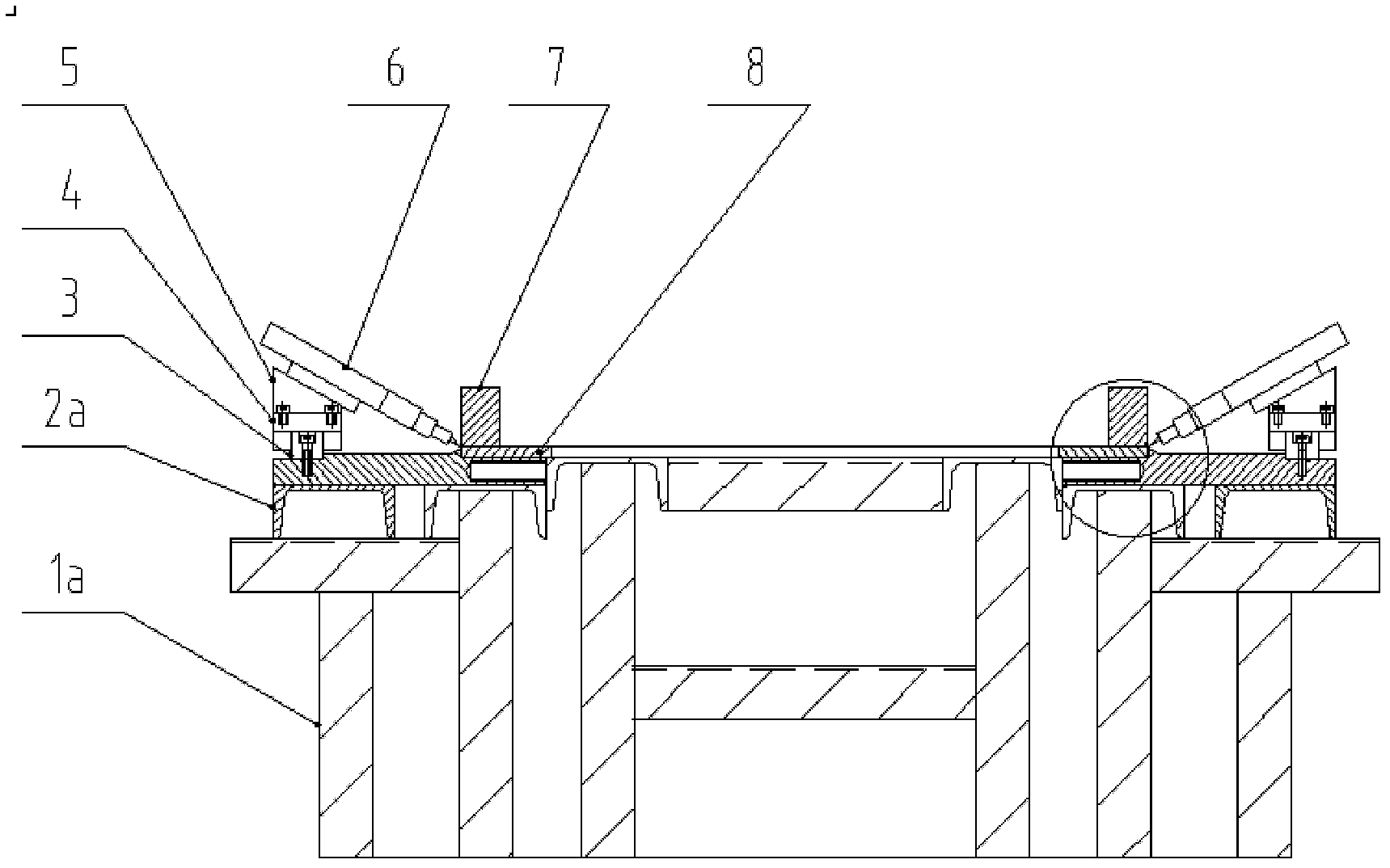

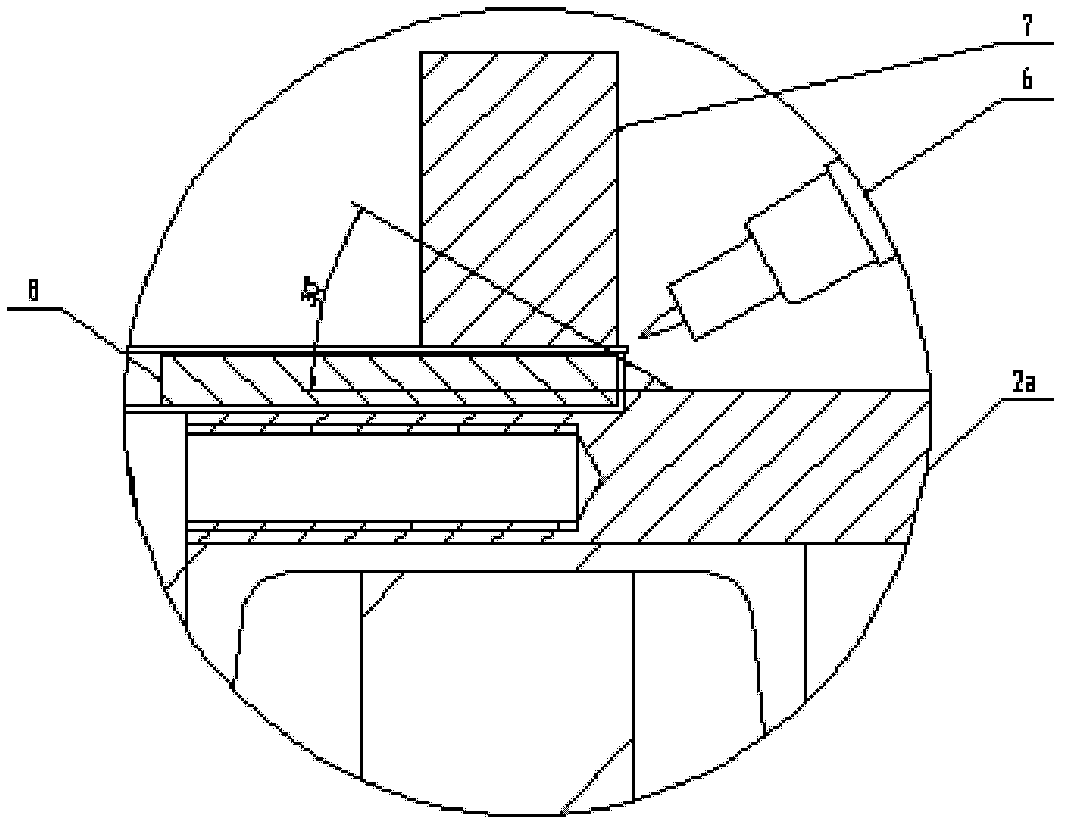

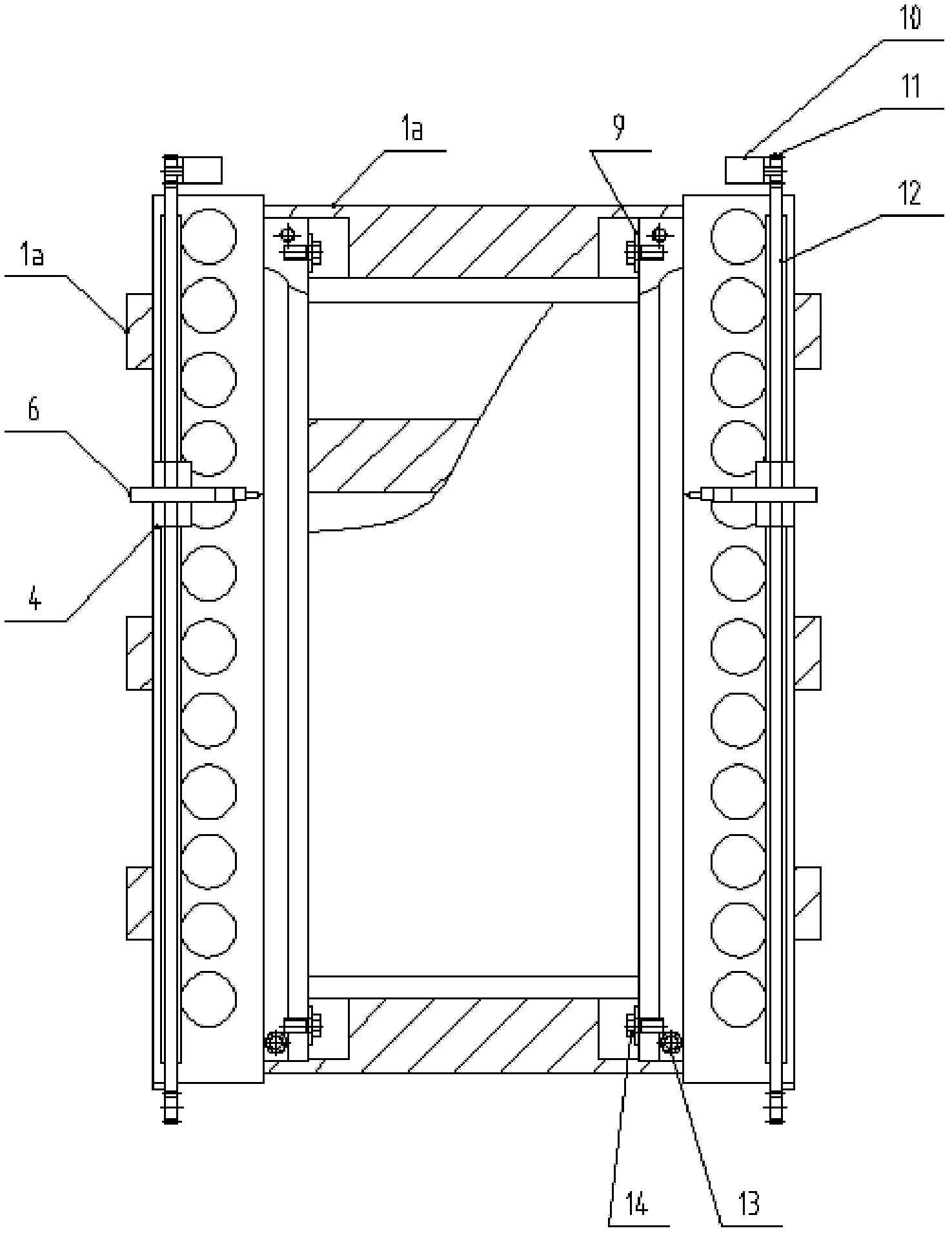

[0013] An automatic welding equipment for thin plate fillet welds, see figure 1 , figure 2 : Used for parallel welding operations where the welding seam is located at the 90° angle between the folded edge of the thin plate and the edge of the thin plate. It includes two structures, characterized in that the equipment structure of the long side of the welding angle is that the bottom plate 2a is fixed on the horizontal surface of the bracket 1a. The two ends of the bottom plate 2a are respectively fixed with the motor 10 and the two gears 11. The bottom plate 2a is equipped with a slide rail 3 and a sliding block 4, and the sliding block 4 is connected with an adjusting mechanism 5. The adjusting mechanism 5 is installed on the inclined plane of the welding gun 6 and the weldment assembly. The weldment has a 30° contact line; the weldment sheet is placed between the bottom plate 2a and the lining plate 8, and then a thin plate 2 is placed on the lining plate 8, and finally the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com